HCFA HCA2 Series User manual

HCFA Corporation Limited

1

HARDWARE MANUAL

HCA2 SERIES PROGRAMMABLE CONTROLLERS

Foreword.......................................................................................................................................... 2

1. Introduction.................................................................................................................................5

1.1 Model Name....................................................................................................................... 6

1.2 Rules of Expansion........................................................................................................... 6

1.3 Back up Data...................................................................................................................... 7

1.3.1 EEPROM backup................................................................................................... 7

1.3.2 Capacitor backup................................................................................................... 7

1.3.3 Initialize Latched (Keep) Devices................................................................................ 7

2. Terminal layouts.........................................................................................................................8

3. Installation Notes.......................................................................................................................9

3.1 Product Outline.................................................................................................................. 9

3.2 HCA2RUN/STOP Control...............................................................................................10

3.3 General Specifications.................................................................................................... 11

3.4 PLC Mounting Arrangements........................................................................................ 12

3.5 DIN Rail Mounting........................................................................................................... 13

3.6 Direct Mounting................................................................................................................ 14

3.7 Wiring.................................................................................................................................14

3.7.1 Termination at Screw Terminals.........................................................................14

3.7.2 Removal and installation of quick-release terminal block............................. 15

3.8 Installing Optional Units..................................................................................................16

3.8.1 Expansion Boards................................................................................................ 16

4. Power Supply........................................................................................................................... 17

4.1 Wiring Techniques........................................................................................................... 17

4.2 Wiring Cautions................................................................................................................17

4.3 Power Supply................................................................................................................... 17

4.4 Power Requirements...................................................................................................... 18

4.5 Example Wiring................................................................................................................ 19

4.5.1 AC Power supply.................................................................................................. 19

4.5.2 24V DC Power supply......................................................................................... 19

4.5.3 12V DC Power Supply.........................................................................................20

4.6 Service Power supply..................................................................................................... 21

4.7 Earthing / Grounding....................................................................................................... 21

5. Inputs.......................................................................................................................................... 21

5.1 24V DC input Specifications.......................................................................................... 21

5.1.1 Typical Wiring........................................................................................................22

5.1.2 Input Circuit Connection......................................................................................22

HCFA Corporation Limited

2

5.1.3 Diodes and Inputs Connected in Series...........................................................22

5.1.4 Resistors and Inputs Connected in Parallel.................................................... 23

5.2 AC110V Input Extension Block......................................................................................23

6. Outputs.......................................................................................................................................24

6.1 Output Specifications...................................................................................................... 24

6.2 Relay Output Example....................................................................................................24

6.2.1 Product life of relay contacts.............................................................................. 24

6.2.2 Output circuit configuration.................................................................................25

6.3 Transistor Output Example............................................................................................ 27

6.3.1 Transistor Output Writing Diagram (Source Type)......................................... 27

6.3.2 Japanese Model Transistor Output (Sink Type)..............................................27

6.3.3 Response Times...................................................................................................28

6.3.4 External wiring precaution.................................................................................. 28

7. Diagnostics............................................................................................................................... 29

7.1 Preliminary Checks......................................................................................................... 29

7.2 ERROR LED ON (CPU ERROR)................................................................................. 29

7.3 Common Errors................................................................................................................29

7.4 Maintenance..................................................................................................................... 30

7.5 Operation and Error Flags............................................................................................. 30

7.6 PLC Status Registers...................................................................................................30

7.7 Error Registers................................................................................................................. 31

7.8 Error Codes...................................................................................................................... 31

7.9 Instruction List.................................................................................................................. 32

7.10 Device List...................................................................................................................... 33

HCFA Corporation Limited

3

Foreword

•This manual contains text, diagrams and explanations which will guide the reader in the

correct installation and operation of the HCA2 Series Programmable Controllers. It should

be read and understood before attempting to install or use the unit.

•If in doubt at any stage of the installation of an HCA2Series Programmable Controller

always consult a professional electrical engineer who is qualified and trained to the local

and national standards which apply to the installation site.

•If in doubt about the operation or use of HCA2Series Programmable Controller please

consult the nearest HCFA Electric distributor.

•This manual is subject to change without notice.

HCA2 SERIES PROGRAMMING CAUTION

Thank you for buying The HCFA HCA2 series controller.

Please note the following.

Notes: Block Move instruction

Applicable PLC: HCA2 Ver 1.00-2.10

Applicable instructions: BMOV, BMOVP(FNC15)

If the file register parameter setting and the registers D8000-D8225 are used as the

destination devices for the BMOV (BMOVP) instruction, program steps or file register data

may be lost or damaged. All other data registers can be used safely for BMOV(BMOVP)

instruction destination registers.

Program example

Guidelines for the safety of the user and protection of the HCA2.

This manual provides information for the installation and use of the HCA2. The manual

has been written to be used by trained and competent personnel. The definition of such a

person or persons is as follows;

a) Any engineer who is responsible for the planning, design and construction of automatic

equipment using the product associated with this manual should be of a competent nature,

(trained and qualified to the local and national standards required to fulfill that role). These

engineers should be fully aware of all aspects of safety with regards to automated

equipment.

b) Any commissioning or service engineer must be of a competent nature, trained and

qualified to the local and national standards required to fulfill that job. These engineers

should also be trained in the use and maintenance of the completed product. This

includes being completely familiar with all associated documentation for the said product.

All maintenance should be carried out in accordance with established safety practices.

c) All operators of the completed equipment (see Note) should be trained to use that

HCFA Corporation Limited

4

product in a safe manner in compliance to established safety practices. The operators

should also be familiar with documentation which is associated with the operation of the

completed equipment.

Note :The term ‘completed equipment’ refers to a third party constructed device which

contains or uses the product associated with this manual.

Note’s on the symbols used in this manual

At various times throughout this manual certain symbols will be used to highlight points of

information which are intended to ensure the users’ personal safety and protect the

integrity of the equipment. Whenever any of the following symbols are encountered, its

associated note must be read and understood. Each of the symbols used will now be

listed with a brief description of its meaning.

Hardware warnings

1) Indicates that the identified danger WILL cause physical and property damage.

2) Indicates that the identified danger could POSSIBLY cause physical and property

damage.

3) Indicates a point of further interest or further explanation.

Software warning

1) Indicates special care must be taken when using this element of software.

2) Indicates a special point which the user of the associate software element

should be aware of.

3) Indicates a point of interest or further explanation.

•Under no circumstances will HCFA Electric be liable or responsible for any

consequential damage that may arise as a result of the installation or use of this

equipment.

•All examples and diagrams shown in this manual are intended only as an aid to

understanding the text, not to guarantee operation. HCFA Electric will accept no

responsibility for actual use of the product based on these illustrative examples.

•Please contact a HCFA Electric distributor for more information concerning applications

in life critical situations or high reliability.

Note Concerning the CE Marking

This document does not guarantee that a mechanical system including this product will

comply with the following standards. Compliance to EMC directive and LVD directive of

the entire mechanical system should be checked by the user / manufacturer.

HCFA Corporation Limited

5

For more details please contact the local HCFA Electric sales site.

Programmable logic controllers are open-type devices that must be installed and used

within conductive control boxes.

Please use the HCA2Series programmable logic controllers while installed in conductive

shielded control boxes.

Please secure the control box lid to the control box (for conduction).

Installation within a control box greatly affects the safety of the system and aids in

shielding noise from the programmable logic controller.

HCFA Corporation Limited

6

1. Introduction

This manual covers hardware installation instructions for the HCA2Series PLC.

Table 1.1: HCA2Main Modules

AC Power Supply DC Power Supply DC INPUT Relay output Transistor output

Points L(mm) W(mm) H(mm)

HCA2-8X6Y(14 points) 100.2 90 81

HCA2-14X10Y(24 points) 130.2 90 81

HCA2-24X16Y(40 points) 182.2 90 83

HCA2-36X24Y(60 points) 220.2 90 83

Figure 1.1 :Main unit outline

Table 1.2: Powered Extension Units

■Input

Expansion

■Output

Expansion

■Special Expansion

Block/Analog Unit

■Input &

output

Expansion

Block

■Positioning

Control Block

■Analogue

Block

TX2N-8EX

TX2N-16E

X

TX2N-8EYR

TX2N-8EYT

TX2N-16EY

R

TX2N-16EY

T

A/D

TX2N-2A

D

TX2N-4A

D

TX2N-8A

D

D/A

TX2N-2D

A

TX2N-4D

A

TX2N-8ER

TX2N-16E

R

TX2N-32E

R

TX2N-32E

T

TX2N-48E

R

TX2N-48E

T

TX2N-1PG

TX2N-4PG

TX2N-10PG

TX2N-1RM-SE

T

TX2N-10GM

TX2N-20GM

TX0N-3A

TX2N-4AD-4D

A

TX2N-4AD-2D

A

TX2N-4AD-TC

TX2N-4AD-PT

TX2N-2LC

TX2N-1HC

HCFA Corporation Limited

7

1.1 Model Name

Code Contents

1HC represents the Chinese Character Pinyin Initials ‘HeChuan’

2A2 represents series number of PLC. HC PLC Types: A1~A8

336X represents 36 input points; Input points of A2 series: 8X, 14X, 24X, 36X

424Y represents 24 output points; Output points of A2 series: 6Y、10Y、16Y、24Y

Corresponding to the combination of input & output:

A2: 14 points, 24 points, 40 points, 60 points

5R(T) represents output type of PLC R: relay output T: transistor output

6A(D) represents power supply type of PLC A: AC 85V~264V input D: DC

20.4V~26.4V input

Table : Configuration Notes

A HCA2 Series Main Unit

B HCA2 Expansion Boards for Analog

I/O

C HCA2 Expansion Boards without

Analog I/O

D Memory Cassette or Display Module

E Programming Software

F RS-232C/RS-422 Converter for PC

F’ USB/RS-422 Converter for PC

G Dedicated Programming Tools

1.2 Rules of Expansion

The maximum I/O for an HCA2system is 128 I/O points and 8 special function blocks.

The HCA2 Series can be expanded as follows when used independently.

- 2 special function blocks

- 1 special function block and up to 16 I/O points

- Up to 32 I/O points

An AC powered HCA2 can be expanded by 8 special function blocks when used in

conjunction with an HCA5 extension unit (2+6).

•If a DC powered main unit is used with a power supply of less than 24VDC -15% (20.4V

DC or less), then it cannot be fully expanded by using special function blocks or powered

extension units.

It can accommodate a maximum of an additional 32 I/O points.

HCFA Corporation Limited

8

•If an HCA2 expansion board is being used, it does not alter the rules of expansion

outlined above, as it utilizes special M coils for its operation and therefore does not

contribute to the maximum 128 I/O point count. Only one special function board can be

used at any time.

See section 3.8 for more details.

1.3 Back up Data

1.3.1 EEPROM backup

Data includes the Program, Comment, File Registers (D1000 ~ D7999), and parameter

data.

This will be stored as long as the EEPROM is not damaged. HCFA Electric has

guaranteed a life cycle time of 10,000 writes to the EEPROM memory. Users may

experience operational writes to the EEPROM in excess of 10,000; however, due to

temperature effects a quantitative estimation cannot be given.

When saving the device status in the EEPROM, the electric power of the PLC's built-in

capacitor is used.

If the PLC has been powered on for five minutes or more, the following device data will be

saved in the EEPROM at power down: S0 ~ S127, M384 ~ M511, C16 ~ C31, C235

~C255, and D128 ~ D255.

When the EEPROM keep device status cannot be correctly saved to the EEPROM by

shortage of electric charge, at the next power-on the status of the device will be that which

saved to the EEPROM at the last save.

1.3.2 Capacitor backup

The capacitor backed memory includes M512 ~ M1535, S128 ~ S999, T246 ~ T255, C32

~ C199, C220 ~ C234, D256 ~ D7999 and the RTC.

The capacitor backed memory will retain data for a maximum of 10 days (Ambient

temperature: 25 °C), and requires 30 minutes to recharge upon power up.

Note: The HCA2 does not have battery backup, if a system requires backup of more than

10 days (Ambient temperature: 25 °C), a peripheral backup power source must be

provided.

1.3.3 Initialize Latched (Keep) Devices

•When using non-latched devices

To use the latched devices as the non-latched devices, reset the latched devices by an

initial pulse (M8002) in program.

•When using capacitor latched (keep) devices

If the voltage of a capacitor drops, the capacitor keep device status may be stored

incorrectly. Therefore, when using the PLC after it has been powered off for more than 10

HCFA Corporation Limited

9

days (Ambient temperature: 25 °C), re-set up the required devices and the current time

after initializing capacitor latched (keep) devices before selecting RUN.

Initialization method

Latched (keep) devices can be initialized in the PLC memory by using peripheral

equipment, and the special auxiliary relay M8032, or executing the ZRST instruction. The

two major methods are described below.

•Latch memory all clear by special auxiliary relay (M8032)

When M8032 is turned ON, all latched (keep) devices (including reset coils of timers and

counters) are cleared. M8032 can be turned ON and OFF using the forced ON/OFF

operation from peripheral equipment or within the sequence program. Note that latched

devices cannot be turned ON while M8032 is ON. When turning ON M8032 within the

sequence program, note that latched devices are cleared during END processing after

M8032 is turned ON.

Program example: This program clears all latched devices.

•Reset of device by ZRST (zone reset) instruction

The ZRST instruction can clear multiple devices at once. (Because a limited device range

can be specified for the ZRST instruction, only part of the latched (keep) devices can be

cleared at a time.)

However, initialization method by the ZRST

instruction for capacitor backed timer and

counter devices

(T246 ~ T255, C32 ~ C199, C220 ~ C234)

does not reset the associated coil devices.

In order to initialize the associated coil

devices, execute the RST instruction for

the coil devices being used in the user

program as shown in the example program

on the left.

2. Terminal layouts

The following selection of terminal layouts are taken from the HCA2product range.

Note: All layouts are schematic only and are intended to aid the creation of wiring

diagrams.

HCFA Corporation Limited

10

3. Installation Notes

The installation of HCA2products has been designed to be safe and easy. When the

products associated with this manual are used as a system or individually, they must be

installed in a suitable enclosure. The enclosure should be selected and installed in

accordance to the local and national standards.

3.1 Product Outline

Figure 3.1:Features of the HCA2 PLC

HCFA Corporation Limited

11

①Status indicator POWER LED: power-up state

RUN LED: running lights

ERROR LED: When program error, indicating lamp twinkles

When CPU error, indicating lamp lights

②Input indicator: HCA2 is octal.

③Output indicator: HCA2 is octal.

④RS422&485 communication port: Operating according to arrow direction

⑤RS422 communication port: Operating according to arrow direction

⑥RUN/STOP switch

⑦Terminal cover

⑧The right expansion cover

⑨The front cover, built-in battery interface

○

10 Two analog potentiometer opening

3.2 HCA2RUN/STOP Control

RUN or STOP of the HCA2can be controlled by:

①The RUN/STOP switch mounted next to the programming port.

②A standard input (X0 to X17) defined by the system parameters.

③Remotely from a personal computer or other programming peripheral

Note: The HCA2RUN/STOP switch works in parallel with the RUN-input terminal.

Please refer to the table below.

During remote operation the HCA2RUN/STOP status is determined by the most recently

operated control.

E.g. If the RUN/STOP switch is in RUN and a remote STOP is made from a personal

computer the RUN/STOP switch must be switched to STOP then back to RUN to switch

the MPU back to RUN mode

HCFA Corporation Limited

12

Figure 3.2:RUN input terminal

Table : RUN/STOP selection

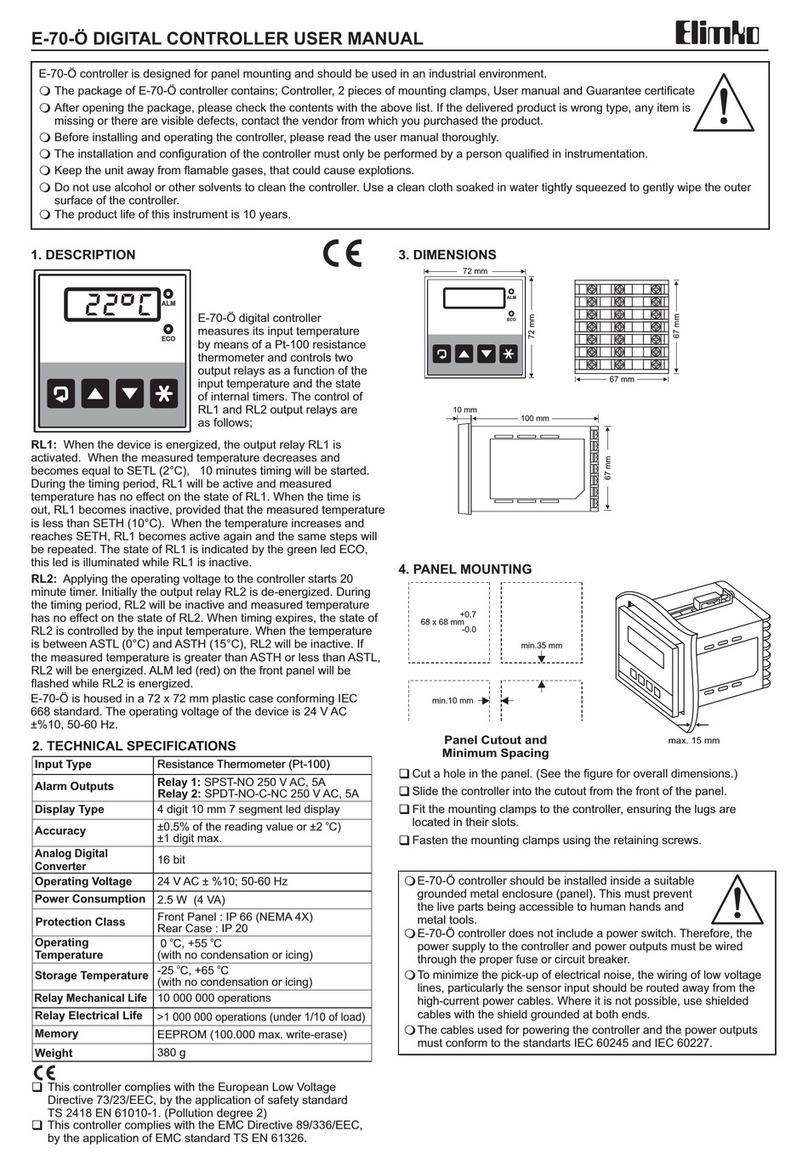

3.3 General Specifications

Item Description

Operating

Temperature

0 to 55 °C (32 to 131 °F)

Storage

Temperature

-20 to 70 °C (-4 to 158 °F)

Operating

Humidity

35 to 85% Relative Humidity, No condensation

storage Humidity 35 to 90% Relative Humidity, No condensation

Vibration

Resistance

- Direct Mounting

10 - 57 Hz: 0.075 mm Half Amplitude

57 - 150 Hz: 9.8 m/s 2Acceleration

Sweep Count for X, Y, Z: 10 times (80 min in each direction)

Vibration

Resistance

- DIN rail

Mounting

10 - 57 Hz: 0.035 mm Half Amplitude

57 -150 Hz: 4.9 m/s 2Acceleration

Sweep Count for X, Y, Z: 10 times (80 min in each direction

Shock Resistance 147m/s2

Acceleration, Action Time: 11 ms

3 times in each direction X, Y, and Z

Noise Immunity 1000 Vp-p, 1microsecond, 30 - 100 Hz, tested by noise simulator

Dielectric

Withstand

Voltage

AC PSU: 1500 V AC > 1 min., tested between each terminal with ground terminal*1

DC PSU: 500 V AC > 1 min., tested between each terminal with ground terminal*1

Insulation

Resistance

5 MΩ> at 500 V DC, tested between each terminal with ground terminal*1

Ground Grounding resistance 100 Ωor less

HCFA Corporation Limited

13

Working

atmosphere

Free from corrosive or flammable gas and excessive conductive dust

Working altitude <2000m*2

EC Directive EMC (EN61000-6-2, EN50081-2), LVD (EN61010-1)

*1 Perform dielectric withstand voltage and insulation resistance tests at the stated

voltage between each terminal and the main unit’s ground terminal.

*2 Do not use the PLC under pressure higher than the atmospheric pressure. Doing so

may damage the PLC.

3.4 PLC Mounting Arrangements

To prevent a rise in temperature, mount the units to walls. Never mount them to the floor

or ceiling of an enclosure.

Below (left) Single row arrangement

Caution

•Units should not be installed in areas subject to the following conditions: excessive or

conductive dust, corrosive gas (salt air, Cl2, H2S, SO2, NO2, etc.) or flammable gas,

moisture or rain, excessive heat, regular impact shocks or excessive vibration.

•Take special care not to allow debris to fall inside the unit during installation e.g. cut

HCFA Corporation Limited

14

wires, shavings etc. Once installation is complete remove the protective paper band, to

prevent overheating.

•Always ensure that mounted units and blocks are kept as far away as possible from

high-voltage cables, high-voltage equipment and power equipment.

•Do not lay signal cables near high voltage power cabling or cabinet housing along the

same trunking duct. Effects of noise or surge induction may occur. Keep signal cables of

more than 100 mm (3.94") away from these power cables.

•Install necessary power supply cut off precautions to the enclosure of the final system.

Attach a warning label (hazard symbol 417-IEC-5036) concerning electric shock to the

enclosure.

•Use the HCA2series PLC with consideration for electrical noise in an environment that

does not exceed conditions provided by EN50081-2 and EN61000-6-2.

•Cut off all phases from the power source before installation or performing wiring work to

avoid electric shock. Incorrect operation can lead to serious damage to the product.

•Cut off all phases from the power source before installing/removing extension or

communication cables to modules to avoid electric shock, incorrect operation or serious

damage to the product.

•Replace the terminal cover provided, after installation or wiring work is completed, and

before supplying power and operating the unit to avoid electric shock.

•After reading the manual's safety instructions, initiate the operation for making program

changes while the PLC is in RUN mode, forcing ON/OFF and switching RUN/STOP.

•The power supply of the extension units/blocks and the special function units/blocks

should be started at the same time or earlier than the HCA2Series main unit.

•DO NOT use the “●” terminal in PLC.

•When using an incorrect power source or performing incorrect operation, serious

damage will occur regardless of the level of the voltage and frequency.

•When performing incorrect wiring or operation, serious damage will occur.

•The “L” and “N” terminals are not reversible.

If the “L” and “N” terminals are reversed, the units/blocks may be seriously damaged.

•The “24V” and “0V” terminals are not reversible.

If the “24V” and “0V” terminals are reversed, the units/blocks may be seriously damaged.

•During transportation avoid any impact as the PLC is a precision instrument.

It is necessary to check the operation of PLC after transportation, in case of any impact

damage.

•When storing the PLC, conform to the environmental conditions specified by the

general specification.

3.5 DIN Rail Mounting

Units can be snap mounted to 35mm (1.37") DIN rail (DIN 46277). To release, pull the

spring loaded clips away from the rail and slide the unit up and off.

HCFA Corporation Limited

15

3.6 Direct Mounting

Table :Hole positions

UNIT mm

±0.2

inches

±0.01

A = W-8mm (0.32")

HCA2-18X6Y

☆2-∅

(→)

82 3.23

HCA2-14X10Y

☆

82 3.23

HCA2-24X16Y

☆

122 4.81

HCA2-36X24Y

☆

167 6.58

∅= 4.5mm (0.17")

•Make sure to turn OFF the power before installing this product.

3.7 Wiring

3.7.1 Termination at Screw Terminals

Terminal screws should be tightened to between 0.5 to 0.8 N‚m. Terminal screws must be

secured to prevent a loose connection thus avoiding a malfunction.

The terminal screws for the HCA2, HCA5 Series PLCs are M3.0. When installing 1 or 2

crimp terminals to a terminal, see explanation Figure 3.5 and 3.8.

However, 3 crimp terminals or more should not be installed to a single terminal.

1) Handle the crimp terminal of the following size when 1 wire is used per terminal. Refer

to

Figure 3.5 for installation instructions

Figure 3.3:Crimp Terminal for M3.5 Screws

Figure 3.4:Crimp Terminal for M3 Screws

HCFA Corporation Limited

16

Figure 3.5:Installing 1 wire Per a Terminal

2) Handle the crimp terminal of the following size when 2 wires are used per terminal.

Refer to

Figure 3.8 for installation instructions.

Figure 3.6:Crimp Terminal for M3.5 Screws

Figure 3.7:Crimp Terminal for M3 Screws

Figure 3.8:Installing 2 Wires Per a Terminal

Caution: Make sure to turn OFF the power before starting any wiring work.

3.7.2 Removal and installation of quick-release terminal block

•Removal : Loosen the left and right screws evenly.

•Installation : Tighten the left and right screws evenly.

Tightening torque 0.4 to 0.5 N•m

Make sure that the center of the terminal block is not lifted

HCFA Corporation Limited

17

3.8 Installing Optional Units

3.8.1 Expansion Boards

The following is a generic explanation of how to install an expansion board on to the

HCA2PLC.

For greater detail, specifications and wiring examples for each optional unit, please see

the relevant product manuals.

MODEL USE WITH TX1N-EEPROM-8L USE WITH TX1N-BAT

TX1N-EEPROM-8L X X

TX1N-232-BD Possible for program upload and

download

while the PLC is in the STOP mode

Standard life of TX1N-BAT: 2

years

(at ambient temperature of

25 °C (77 °F))

For details on installation and

maintenance, etc., refer to the

TX1N-BAT USER'S MANUAL

TX1N-422-BD

TX1N-485-BD

TX1N-4EX2EYT-BD

TX1N-2AD-BD

TX1N-1DA-BD

TX1N-BAT X X

Always make sure the power is turned off, before installing a special function board. Only

one board can be used at any one time, do not try to stack multiple boards.

A) Special function or optional equipment board.

B) Optional equipment connector port.

C) M3 screw to secure board.

D) Top cover for board.

E) M3 screw to secure top cover.

Note: Do not remove this screw.

•Remove base unit top cover.

•Plug board A) into connector B).

•Fix board to base unit using screws C).

HCFA Corporation Limited

18

•Attach top cover for board D) removing section D)’ to expose connector etc. (if

applicable)

•Secure top cover with M3 screw E)

4. Power Supply

4.1 Wiring Techniques

Wiring for HCA2products has been designed to be safe and easy. If the user is concerned

about the correct installation of these products or associated products, please contact a

professional electrician who is trained to the local and national standards applicable to the

installation site.

4.2 Wiring Cautions

•Do not run input signals in the same multicore cable as output signals or allow

them to share the same wire.

•Do not lay I/O signal cables next to power cables or allow them to share the same

trunking duct. Low voltage cables should be reliably separated or insulated with regard to

high voltage cabling.

•Where I/O signal lines are used over an extended distance consideration for voltage

drop and noise interference should be made.

4.3 Power Supply

•When wiring an AC supply, the “Live” cable should be connected to the “L”

terminal and the

“Neutral” cable should be connected to the “N” terminal. Do NOT connect the “Live” wire

to the “N” terminal, otherwise, the user may receive a dangerous shock upon power up.

•When wiring a DC supply the “Live” cable should be connected to the “+” terminal and

the

“Neutral” cable should be connected to the “-” terminal. Do NOT connect the “Live” wire

to the “-” terminal, otherwise, the user may receive a dangerous shock upon power up.

•When using a DC power supply type, it is the power source for an input extension block

between "24V" and "0V" terminals.

Never supply an external power supply to these terminals.

HCFA Corporation Limited

19

Moreover, do not connect any equipment except an extension block to these terminals.

•Never connect the "0V" and the "-" terminals of a DC power supply type main unit.

4.4 Power Requirements

*1 Includes the input current(5 or 7mA per point).

*1 Includes the input current (5 or 7mA per point).

Table 4.1 :AC Power Supply Units

HCA2-8X6Y HCA2-14X10Y HCA-24X16Y HCA2-36X24Y

Power supply 100 - 240V AC +10%, -15%, 50-60Hz

Max. allowable

momentary

power failure

period

10ms; if less than 10ms, the PLC will continue operation.

If 10ms or more, the PLC will shut down

Fuse (size) rating 250V 1A 250V 3.15A (3A)

In-rush current 100V AC - Max. 30A for 5ms

200V AC - Max. 50A for 5ms

Power

consumption

29W *1 30W *1 32W*1 35W *1

24V DC Service

Supply

400 mA

*1 Includes the input current(5 or 7mA per point.

Table 4.2 :DC Power Supply Units

HCA2-8X6Y HCA2-14X10Y HCA-24X16Y HCA2-36X24Y

Power supply 12 - 24V DC +20%, -15% (10.2 - 28.8V DC)

Max. allowable

momentary

power failure

period

5 ms; If less than 5 ms, the PLC will continue operation.

If 5 ms or more, the PLC will shut down

Fuse (size) rating 125 V 3.15A

In-rush current 24V DC - Max. 25A for 1ms

12V DC - Max. 22A for 0.3ms

Power

consumption*1

13W 15W 18W 20W

*1 Includes the input current (5 or 7mA per point).

HCFA Corporation Limited

20

4.5 Example Wiring

4.5.1 AC Power supply

*1 It is recommended to use the same power source to power the main unit, powered

extension units and special function blocks/units. If two sources are required, follow the

below guidelines:

- Supply power to the powered extension units and special function blocks/units before or

at the same time the main unit is powered.

- The power supplies may be cut the same time after ensuring system safety.

4.5.2 24V DC Power supply

*1 It is recommended to use the same power source to power the main unit, powered

extension units and special function blocks/units. If two sources are required, follow the

Table of contents

Other HCFA Controllers manuals