HCT DRF2 User manual

021-DRF Rev B DRC User Manual 1

Copyright © Enovation Controls – 2018

DRF Valve Controller

DRF

Closed-loop and Open-loop

Proportional Valve Controller

Enovation Controls reserves the right to improve this product at any time and without notice. This manual may

contain mistakes and printing errors. The content is regularly checked and updated. Please check our website

or contact our customer support for latest version. Enovation Controls accepts NO liability for technical mistakes

or printing errors or their consequence.

021-DRF Rev B DRC User Manual 2

Copyright © Enovation Controls – 2018

DRF Valve Controller

Contents

Welcome.....................................................................................................................Error! Bookmark not defined.

Product Application Guidelines..................................................................................................................................3

DRF Controllers.........................................................................................................................................................4

Operating Specifications....................................................................................................................................4

Physical Description ..........................................................................................................................................5

User Interface....................................................................................................................................................5

Configuration.....................................................................................................................................................6

Parameter List...................................................................................................................................................9

PID Algorithm...................................................................................................................................................12

Setup Procedure..............................................................................................................................................12

Wiring ..............................................................................................................................................................17

Order Information.....................................................................................................................................................18

Application Examples ..............................................................................................................................................19

Open Loop Double Solenoid Control (DRF2-Vxx) ...........................................................................................19

Double/Single/Single Solenoid Control (DRF4-Vxx)........................................................................................20

Closed Loop Velocity Mode (DRF2-Vxx) .........................................................................................................21

Revision Record......................................................................................................................................................21

021-DRF Rev B DRC User Manual 3

Copyright © Enovation Controls – 2018

DRF Valve Controller

Cautions

Changing setup values or operating modes while a machine is running may cause unintended machine movement.

It could lead to possible injury or death. Any moving parts should be disabled prior to changing setup values or

operating modes. In every case, exercise caution and work should be completed only by qualified personnel.

Product Application Guidelines

ALWAYS do the following

•FULLY read this manual and accompanying data sheets BEFORE starting.

•Isolate this unit from all other equipment BEFORE any form of welding.

•Isolate the controller from ANY form of battery charging or battery boosting.

•Be aware of the electrical & mechanical connections, and the expected reactions of the equipment.

•Operate the units within the temperature range.

•Use the correct tools to do the job (i.e. P.C., software) etc.

•Separate High Voltage AC cables from Low Voltage DC signal and supply cables.

•Make sure power supply is CORRECT, ELECTRICALLY CLEAN, STABLE, and rated for the full load.

•Make sure the controller output voltage & current is compatible with the equipment.

•All unused wires / terminals should be terminated safely.

•Ensure ALL connectors have no unintended SHORT or OPEN circuits.

•Ensure ALL connectors are wired correctly, secure, locked in place and fully connected.

•Disconnect or connect wires to or from this unit only when the power supply is disconnected.

•Use adequate screening in areas of intense Radio Frequency fields.

•Ensure ALL work areas are clear of personnel before operating the controller.

•Follow and abide by local and country health & safety standards.

021-DRF Rev B DRC User Manual 4

Copyright © Enovation Controls – 2018

DRF Valve Controller

DRF Controllers

The DRF controller drives proportional solenoid valves in a closed loop system to follow a command signal. When

the feedback is greater than the command input, the coil receives full current; when the feedback is less than the

command input, the coil receives 0 current.

Once configured, the settings are permanently stored in the controller memory.

DRF Features

Easily configured using HCT Graphical User Interface (GUI) or HCT Hand Held Interface (HHI)

LED indication of power, output current and fault status

DIN-rail mount housing with removable terminal blocks

Multiple modes for open loop and closed-loop applications, programmable enable input

All input and output limits are independently adjustable

Adjustable output with short circuit protection, adjustable ramp up and ramp down rates

Fully adjustable PID control loop

Operating Specifications

Supply Voltage 9 to 32VDC

Supply Current Valve current + 50mA (Quiescent Max)

Output Current DRF-x06: 600mA MAX. per channel

DRF-x12: 1.2A MAX. per channel

DRF-x25: 2.5A MAX. per channel

Coil Resistance 2Ω MIN.

Reference Voltages +10V, -10V @ 20mA (DRF-Vxx versions only)

Dither Frequency 30, 50, 75, 100, 125, 150, 175, 200, 225, 250, 275, 300, 1000 Hz

Analog Input Range DRF-Vxx: -10V to 10V DRF-Axx: 0 to 20mA

Analog Input Impedance

DRF-Vxx:

38kΩ

DRF-Axx:

250Ω

Analog Input Resolution 10 bits

Operating Temperature Range -20º to 70º C; -40º to 85º C (storage)

Enclosure Polyamide

Dimensions Inch: 0.69 W x 4.50 H x 4.30 D; mm: 17.5 W x 114.5 H x 109.4 D

021-DRF Rev B DRC User Manual 5

Copyright © Enovation Controls – 2018

DRF Valve Controller

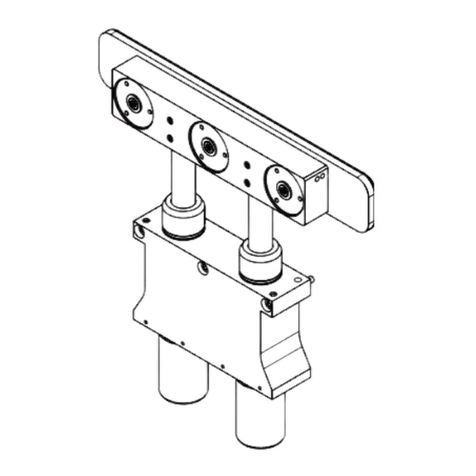

Physical Description

There are PWR LED and OUTx LEDs. For DRF-4, there are 5 LEDs. The PWR LED is

green when the applied voltage is within the operating range.

OUTx LEDs indicate current output for a given channel. The LEDs are yellow and the

brightness will vary with the output current.

In the case of a fault the LEDs will flash red with a flash code. See Fault Status for

details.

The DRF communicates with the Graphical User Interface through the USB port.

When connected to a PC, the DR controller is recognized as a USB device with or

without power supply. However, it must be powered when configuring the settings.

User Interface

The DRF has a number of internal settings.

Users can open the Graphical User Interface to view, make changes and save the settings in a data file which can

be uploaded to any DRF controller.

021-DRF Rev B DRC User Manual 6

Copyright © Enovation Controls – 2018

DRF Valve Controller

Configuration

The GUI has 4 buttons (ran from a PC): Lock, Unlock, Up, and Down. There are short-cut keys: ‘/’(lock), ‘*’(unlock),

‘+’(up), and ‘-‘(down).

Use the up and down arrows to navigate through the parameter list. The display will show the next parameter in the

list when pressed. The parameter name is on the first line and the value is on the second line. The list is in circular,

stepping down from the last parameter to the first and vice-versa.

There are three types of parameters: fixed; monitor; and variable. Fixed parameters show the module’s firmware

version, etc. Monitor parameters display output current and system voltage. Use variable parameters to configure

the controller, such as maximum output current, operating mode, etc. Some parameters combine variable and

monitor in one line. Use it to set a variable according to the current monitor value.

Press the unlock button to enter the edit mode. An asterisk (*) will appear at the beginning of the second line. Use

the up and down buttons to change the value. For parameters containing both variable and monitor, the monitor

data is in square brackets.

Press the lock button to save the parameters and end edit mode.

When the lock button is pressed, the changes take effect immediately. Change values only when the machine is

NOT running.

021-DRF Rev B DRC User Manual 7

Copyright © Enovation Controls – 2018

DRF Valve Controller

“Read settings from controller” displays a static table of values from non-volatile memory. The changes made to the

settings by selecting “lock” are not updated in the table unless “read settings from controller” is selected again.

To save the settings into a file for future use, click “read settings from controller” before clicking “save settings to

file”.

021-DRF Rev B DRC User Manual 8

Copyright © Enovation Controls – 2018

DRF Valve Controller

When uploading settings from a data file, the static table shows the settings from the data file, but they are not in

the controller yet.

Click “write settings to controller” before clicking “read settings from controller”. After this step, the static table will

display the DRF settings from the data file.

021-DRF Rev B DRC User Manual 9

Copyright © Enovation Controls – 2018

DRF Valve Controller

Parameter List

The following table outlines the DRF parameters as well as the limits and units of measure for each parameter.

Parameter Limits Units

DRFx-xxx Version #

C1 Mode See Mode Description Mode #

C1 Proportional gain 0.0 to 100 %

C1 Integral gain 0.0 to 100 %

C1 Derivative gain 0.0 to 100 %

C1 PID loop time 1 to 30 Cycles

C1 Deadband 0.0 to 2.0 V (mA)

Previous 5 parameters repeated for channel 3

2

C1 Min input -10 to +10.0; 4 to 20.0 V (mA)

C1 Max input -10 to +10.0; 4 to 20.0 V (mA)

C1 Min output 0 to 6001mA

C1 Max output 0 to 6001mA

C1 Ramp up 0.0 to 120.0 Seconds

C1 Ramp down 0.0 to 120.0 Seconds

Previous 6 parameters repeated for all channels2

Dither frequency 30 to 1000 Hz.

C1 Command input V (mA)

C1 Output current mA

Previous 2 parameters repeated for all channels2

Supply voltage Volts

Fault status Fault

10 to 1.2 A for –12A version, 0 to 2.5 A for –25A version

2Parameters starting with C1 are repeated for each channel and are displayed as C2 to C4

021-DRF Rev B DRC User Manual 10

Copyright © Enovation Controls – 2018

DRF Valve Controller

DRFx-xxx -The title parameter is fixed. It displays the model number and the firmware version.

Cx MODE -Four modes of operation.

Open Loop Modes -

Modes 1 and 2 are open loop modes for channel 1 & 3.

For modes 1 & 2, channels 2 & 4 use its own inputs.

For modes 3 & 4, channels 2 & 4 use the inputs from channel 1 & 3 for dual-coil applications.

E.g., to drive a two-coil directional proportional valve, set C1 mode 1 and C2 mode 3. Do not overlap the input

ranges.

Closed Loop Modes - Modes 3 and 4 use the velocity PID algorithm. Channel 1 or 3 input is the command input;

channel 2 or 4 input is the feedback. Only channel 1 or 3 has output current.

When the feedback is bigger than the command, the output reduces to 0A; when the feedback is smaller than

the command, the output current increases to maximum current until the feedback matches the command.

PROPORTIONAL GAIN –Sets the P term in a PID control loop. It is a multiplication of the error added to the

output. The higher the setting, the faster the response will be. Also, higher settings result in shorter ramp time,

but it can cause oscillation. It is variable type.

INTEGRAL GAIN – Sets the I term in a PID control loop. It is the sum of the error over time. It overcomes an offset

in the output or to correct for small deviations over time. A higher gain will result in more integral control but

can cause oscillation. It is variable type.

DERIVATIVE GAIN –Sets the D term in a PID control loop. It is the rate of change of error. The higher the

derivative gain, the quicker the system will respond to sudden changes. It is variable type.

PID LOOP TIME -Sets the PID loop closure time in number of dither cycles. The lower the number, the more

quickly the system responds to error. It is a variable type.

Mode Enable Channels comments

1 CUR NO ENBL 1,3 Open loop, use its own input

2 CUR USE ENBL X 1,3 Open loop, use its own input

3 VEL NO ENBL 1,3 Closed-loop, C1 & C3 are the command inputs

4 VEL USE ENBL X 1,3 Closed-loop, C1 and C3 are the command inputs

1 IN2 NO ENBL 2,4 Open loop, single-coil valve, use its own input;

Closed-loop, feedback

2 IN2 USE ENBL X 2,4 Open loop, single-coil valve, use its own input;

Closed-loop, feedback

3 IN1 NO ENBL 2,4 Open loop, dual-coil valve, use inputs from C1 & C3

4 IN1 USE ENBL X 2,4 Open loop, dual-coil valve, use inputs from C1 & C3

021-DRF Rev B DRC User Manual 11

Copyright © Enovation Controls – 2018

DRF Valve Controller

DEADBAND -Sets the error tolerance of the PID loop. The control will only respond to error greater than the

Deadband parameter. For a velocity loop the output will remain at a fixed level. For a position loop both

outputs will remain off. This parameter is a variable type.

Cx MIN INPUT -Sets the minimum command input. The input can be inverted. The value in the brackets is the

present command input.

Cx MAX INPUT - Sets the maximum command input. The input can be inverted. The value in the brackets is the

present command input.

Cx MIN OUTPUT - Sets the minimum output current (milliamps for -06A, amps for -12A,-25A). The value in the

brackets is the present output current.

Cx MAX OUTPUT - Sets the maximum output current (milliamps for -06A, amps for -12A,-25A). It cannot be

inverted. The value in the brackets is the present output current.

Cx RAMP UP/DOWN - Sets the time for Output current to ramp UP or Down through the full input range. These

parameters are variable.

DITHER FREQ. – Options: 30, 50, 75, 100, 125, 150, 175, 200, 225, 250, 275, 300, and 1000 Hz. Set the PWM or

dither frequency according to the valve specifications. This parameter is variable.

Cx COMMAND INPUT - Displays the present input. This parameter is a monitor type.

Cx OUTPUT CURRENT -Displays the present output current. This parameter is a monitor type.

SUPPLY VOLTAGE -Displays the module’s power supply voltage. It is helpful for troubleshooting. This parameter

is a monitor type.

FAULT STATUS -The STATUS LED will flash red 2 times for Coil Open and 3 times for Coil Short in both open-

loop modes and closed-loop modes.

In open loop mode, the LED will continue to flash until clearing faults by moving the command signal out of

active range or cycling the power.

In closed-loop mode, only power cycle can clear the faults.

021-DRF Rev B DRC User Manual 12

Copyright © Enovation Controls – 2018

DRF Valve Controller

PID Algorithm

The controller uses a digital, velocity PID algorithm as shown:

O(t) = O(t-1) + P*(e(t)-e(t-1)) + I*T*e(t) + D/T*(e(t) + e(t-2) – 2*e(t-1))

Where:

O = output

P = proportional gain term

I = integral gain term

D = derivative gain term

e(t) = error at time t

T = PID loop time

Setup Procedure

1. Select the operating frequency.

2. Set the Minimum and Maximum Outputs according to the valve specs.

3. Set the Dither Frequency according to the valve specs. Higher dither frequencies can improve frequency

response.

4. Start with Proportional only to achieve a stable system.

5. Add Integral.

6. Add Derivative to improve system response and/or stability.

021-DRF Rev B DRC User Manual 13

Copyright © Enovation Controls – 2018

DRF Valve Controller

DRF Closed-loop control:

Place channel 1 in Mode 3 or 4, channel 2 in

mode 1 or 2.

When the feedback (channel 2 input 5.5V) is

greater than the command (channel 1 input

3.8V), DRF outputs 0A to Channel 1.

Channel 2 does not have an output.

When the feedback (channel 2 input 5.5V) is

less than the command (channel 1 input

9.8V), DRF outputs 0.74A to Channel 1.

Channel 2 does not have an output.

021-DRF Rev B DRC User Manual 14

Copyright © Enovation Controls – 2018

DRF Valve Controller

When the feedback (channel 2 input 5.5V) is

greater than the command (channel 1 input

1.3V), DRF outputs 0A to Channel 1.

Channel 2 does not have an output.

When the feedback (channel 2 input 5.5V) is

less than the command (channel 1 input

7.2V), DRF outputs 0.74A to Channel 1.

Channel 2 does not have an output.

021-DRF Rev B DRC User Manual 15

Copyright © Enovation Controls – 2018

DRF Valve Controller

Open-loop dual coil Mode:

0.5V to 9.5V drives the channel 1 output, -0.5

to -9.5V drives the channel 2 output.

Channel 1 has an output of 0.56A because

the input is 5.5V.

Channel 1 has an

output of 0.22A because

the input is 2.4V.

021-DRF Rev B DRC User Manual 16

Copyright © Enovation Controls – 2018

DRF Valve Controller

Channel 2 has an output of 0.34A because

the input is -3.5V.

Channel 2 has an

output of 0.64A because

the input is -6.4V.

021-DRF Rev B DRC User Manual 17

Copyright © Enovation Controls – 2018

DRF Valve Controller

Wiring

Terminal functions are listed in the table below.

Terminal Function

J1-1 +V Supply

J1-2 Supply Common

J1-3 Enable Input

J2-1 Output Ch. 1

J2-2 Common

J2-3 Output Ch. 2

J3-1 Output Ch. 3

J3-2 Common

J3-3 Output Ch. 4

J4-1 -10V Reference

J4-2 Common

J4-3 +10V Reference

J5-1 Command Input Ch. 1

J5-2 Common

J5-3 Command Input Ch. 2

J6-1 Command Input Ch. 3

J6-2 Common

J6-3 Command Input Ch. 4

021-DRF Rev B DRC User Manual 18

Copyright © Enovation Controls – 2018

DRF Valve Controller

Order Information

The following is a break-down of the DRF part numbering system:

DRF4-V12 06 = 600mA max

12 = 1.2A max

25 = 2.5A max

V = -10 to +10V input

A = 0 to 20mA

# = Number of channels (2 or 4)

Required Communication Cables:

For the PC software SAM: PN: 108-00134

021-DRF Rev B DRC User Manual 19

Copyright © Enovation Controls – 2018

DRF Valve Controller

Application Examples

Open Loop Double Solenoid Control (DRF2-Vxx)

The DRF can drive a dual-coil valve with a

joystick or

potentiometer of 10kΩ.

If enable switch is not used, set channel 1 to be Mode 1,

channel 2 to be Mode 3.

If enable switch is used,

set channel 1 to be Mode 2,

channel 2 to be Mode 4.

The minimum and maximum input parameters for the two

channels should not be overlap.

Set the dither and output settings according to the valve

specifications.

Schematic

FUSE

+V Power Input

9 - 32VDC

+V = Enabled

PWR J1-1

DRF2

Electronic Valve

Controller

Enable J1-3

GND J1-2

-10V Ref. Out J4-1

+10VDC @ 20mA

0 to 10VDC

+10V Ref. Out J4-3

Ch. 1 I/P J5-1

Sig GND J4-2

J5-2

VDC I/P

mA I/P

Supply Voltage

4-12mA

Ch. 2 I/P J5-3

Prop. PWM (Sourcing)

Sig GND J2-2

Ch. 1 Out J2-1

Ch. 2 Out J2-3

Prop. PWM (Sourcing)

0 to -10VDC 12-20mA

Example Settings

Input / Output Diagram

-10V

(Ch. #2)

600mA

5mA

600mA

5mA

Center (0V)

Ch. #2

Current Ch. #1

Current

10V

(Ch. #1) Command

Input

-0.2V

(Ch. #2) 0.2V

(Ch. #1)

Parameter

Value

C1 Mode 2 CUR USE ENBL

C1 Min input 0.2 V

C1 Max input 10.0 V

C1 Min output 5 mA

C1 Max output 600 mA

C1 Ramp up 1 S

C1 Ramp down 1 S

C2 Mode 4 IN1 USE ENBL

C2 Min input -0.2 V

C2 Max input -10.0 V

C2 Min output 5 mA

C2 Max output 600 mA

C2 Ramp up 1 S

C2 Ramp down 1 S

Dither frequency 150 Hz.

021-DRF Rev B DRC User Manual 20

Copyright © Enovation Controls – 2018

DRF Valve Controller

Double/Single/Single Solenoid Control (DRF4-Vxx)

The DRF drives a dual-coil valve with joystick input J5-1 and 2

single-coil valves with joystick input J6-1 and J6-3.

Set the dither and output settings accordi

ng to the valve

specifications.

Schematic

FUSE

+V Power Input

9 - 32VDC

+V = Enabled

PWR J1-1

DRF4

Electronic Valve

Controller

Enable J1-3

GND J1-2

-10V Ref. Out J4-1

+10VDC @ 20mA

0-10VDC

+10V Ref. Out J4-3

Ch. 1 I/P J5-1

VDC I/P

mA I/P

Supply Voltage

4-12mA

Ch. 2 I/P J5-3

+10VDC @ 20mA

0-10VDC

Ch. 3 I/P J6-1

Sig GND J6-2

VDC I/P

mA I/P

Supply Voltage

4-20mA

Ch. 4 I/P J6-3

Prop. PWM (Sourcing)

Ch. 3 Out J3-1

Sig GND J3-2

Ch. 4 Out J3-3

Prop. PWM (Sourcing)

+10VDC @ 20mA

0-10VDC

VDC I/P

mA I/P

4-20mA

Supply Voltage

Sig GND J4-2

J5-2

Prop. PWM (Sourcing)

Ch. 2 Out J2-3

Prop. PWM (Sourcing)

Ch. 1 Out J2-1

Sig GND J2-2

0 to -10VDC 12-20mA

Example Settings

Parameter

Value

C1 Mode 2 CUR USE ENBL

C1 Min input 0.2 V

C1 Max input 10.0 V

C1 Min output 5 mA

C1 Max output 600 mA

C1 Ramp up 1 S

C1 Ramp down 1 S

C2 Mode 4 IN1 USE ENBL

C2 Min input -0.2 V

C2 Max input -10.0 V

C2 Min output 5 mA

C2 Max output 600 mA

C2 Ramp up 0 S (NOT USED)

C2 Ramp down 0 S (NOT USED)

C3 Mode 2 CUR USE ENBL

C3 Min input 0.2 V

C3 Max input 10.0 V

C3 Min output 5 mA

C3 Max output 600 mA

C3 Ramp up 1 S

C3 Ramp down 1 S

C4 Mode 2 IN4 USE ENBL

C4 Min input 0.2 V

C4 Max input 10.0 V

C4 Min output 5 mA

C4 Max output 600 mA

C4 Ramp up 1 S

C4 Ramp down 1 S

Dither frequency 150 Hz.

This manual suits for next models

1

Table of contents

Other HCT Controllers manuals