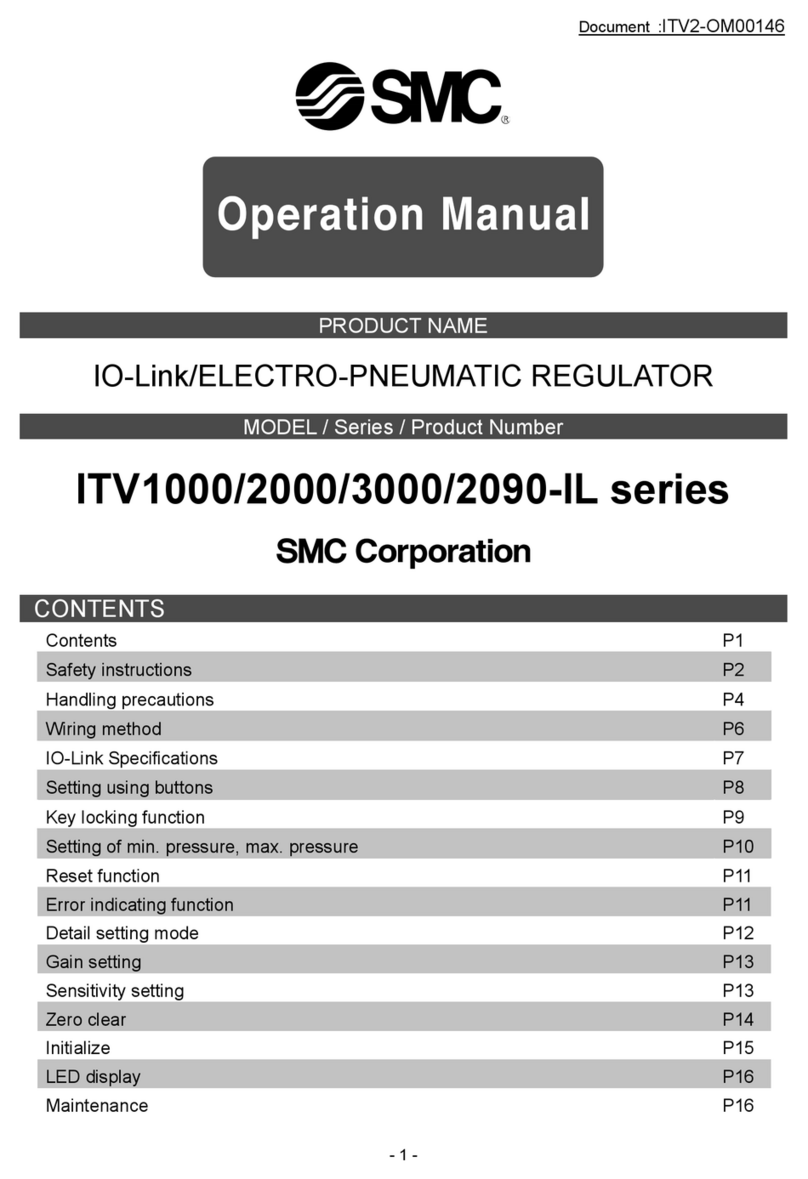

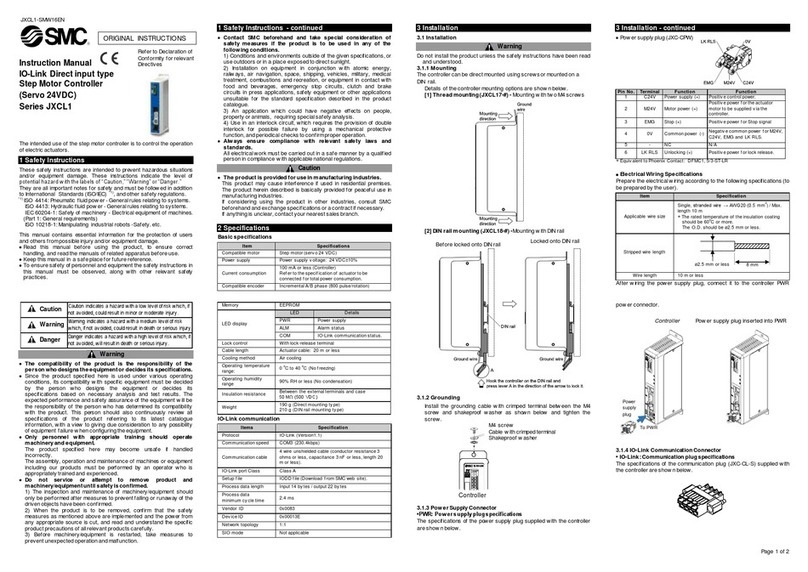

2 Specifications

Installation and Maintenance Manual

ITV10*0-X305, ITV20*0-X305 ,ITV30*0 X305,

(CC-Link) Electro-Pneumatic Regulator

EMC Directive 89/336/EEC

EN61000-6-2:2001: Electromagnetic Compatibility (EMC) - Immunity

EN55011 +A1:1998 Electromagnetic Compatibility (EMC) - Emission

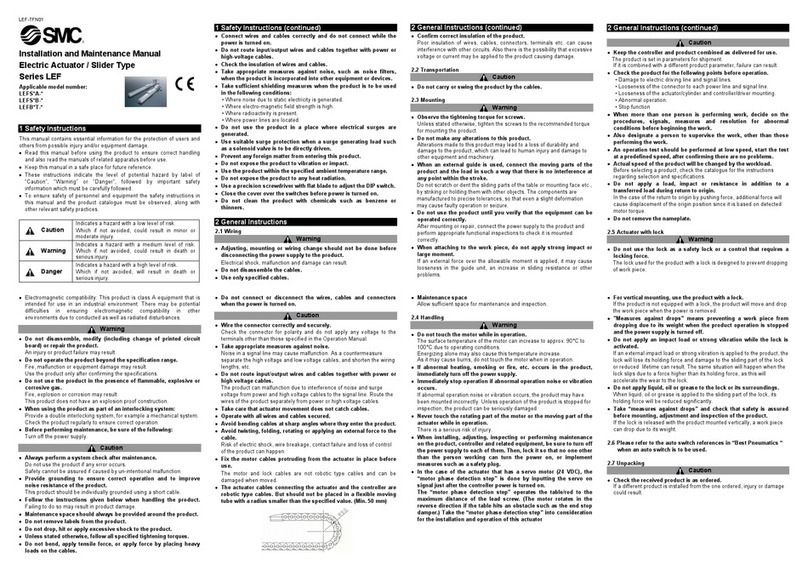

1 Safety Instructions

This manual contains essential information for the protection of users

and others from possible injury and/or equipment damage.

Read this manual before using the product, to ensure correct

handling, and read the manuals of related apparatus before use.

Keep this manual in a safe place for future reference.

These instructions indicate the level of potential hazard by label of

"DANGER", "WARNING" or "CAUTION", followed by important safety

information which must be carefully followed.

To ensure safety ISO4414: Pneumatic Fluid power and JIS B 8370:

Pneumatic System principles must be observed, along with other

relevant safety practices.

ITV2-TFL05GB

WARNING

The compatibility of pneumatic equipment is the responsibility of the

person who designs the pneumatic system or decides its specifications.

Since the products specified here are used in various operating

conditions, their compatibility for the specific pneumatic system must be

based on specifications or after analysis and/or tests to meet your spe-

cific requirements.

Only trained personnel should operate pneumatically operated machin-

ery and equipment.

Compressed air can be dangerous if an operator is unfamiliar with it.

Assembly, handling or repair of pneumatic systems should be

performed by trained and experienced operators.

Do not service machinery / equipment or attempt to remove

component until safety is confirmed.

1) Inspection and maintenance of machinery / equipment should only

be performed after confirmation of safe locked-out control positions.

2) When equipment is to be removed, confirm the safety process as

mentioned above. Switch off air and electrical supplies and exhaust

all residual compressed air in the system.

3) Before machinery / equipment is re-started, ensure all safety

measures to prevent sudden movement of cylinders etc. (Bleed air

into the system gradually to create back-pressure, i.e.

incorporate a soft-start valve.)

Contact SMC if the product is to be used in any of the following condi-

tions.

1) Conditions and environments beyond the given specifications, or if

product is used outdoors.

2) Installation on equipment in conjunction with atomic energy, railway,

air navigation, vehicles, medical equipment, food and beverage,

recreation equipment, emergency stop circuits, press applications, or

safety equipment.

3) An application which has the possibility of having negative effects on

people, property, or animals requiring special safety analysis.

CAUTION

Ensure that the air supply system is filtered to 5 micron.

3 Operation Principal

When the input signal increase, the supply solenoid valve turns on and the

exhaust solenoid valve turns off. Supply pressure is passed to the pilot

valve through the supply solenoid valve. The pilot valve will open the main

valve allowing partial supply pressure to pass to the out port.

The pressure sensor will provide output pressure feedback to the control

circuit . The control circuit will balance the input signal and output pressure

to ensure that the output pressure remains proportional to the input signal.

5

4

3

2

1

4 Block Diagram

Fig 5

5 Wiring

CAUTION

Connect the cable to the connector on the main unit as shown in the

following diagram. Take precautions as incorrect wiring will damage the unit.

Use a DC power supply capable of supplying the necessary power require-

ments with minimal ripple.

When 3m straight cable connection is specified, this refers to the power sup-

ply cable, the communications cable should be ordered separately.

Fig 6

5.1 Communications Protocol

6 LED Display

7 Address Dip Switch

CAUTION

1. The setting of an address switch requires the removal of 4 screws in the

front panel of the unit (Fig 6). Take care that the panel hinges to

90 degrees maximum.

2. After setting an address, always close and fix the panel securely.

Tighten the screws to torque of 0.6 - 1.0 Nm.

8 Installation

CAUTION

1. This product is pre-set at the factory and must not be dismantled by the

user. Contact your local SMC office for advice.

2. Ensure, when installing this product, that is kept clear of power lines to

avoid noise interference.

3. Ensure that load surge protection is fitted when inductive loads are pres-

ent (i.e. solenoid, relay etc.).

4. Ensure precautions are in place if the product is used in a 'free flow out-

put ' condition. All will continue to flow continuously.

5. Do not use a lubricator on the input side of this product.

If lubrication is necessary, place the lubricator on the 'output' side.

6. Ensure all air is exhausted form the product before maintenance.

7. Length of connector cable shall be 10m or less.

9 Contacts

SMC Corporation www.smcworld.com (Global) www.smceu.com

Specifications are subject to change without prior notice from the manufacturer.

The descriptions of products in this document may be used by other companies.

© SMC Corporation All Rights Reserved.

Item Specification Note

Field bus CC-Link Ver 1.1

Station type Remote device -

Device type Analogue I/O Code 04H

Occupied station number 1 Station Fixed

Transmission speed 10M/5M/2.5M/

625k/156k bps Due to the dip switch

Node address 1 to 64 Due to the dip switch

Transmission method RS-485 -

Item Pin assign Wire colour (note1)

1. 24[V] Brown

2. F.G. White

3. 0[V] Blue

4. N.C. Black

Connector for Communication Please install the bus adaptor (attached).

Fig 7

Note1) Wire colour when the option cable is used

Connector for

Power supply

CC-Link IN

CC-Link OUT

Item Type Pin assign

1. SLD

2. DB

3. DG

4. DA

1. SLD

2. DB

3. DG

4. DA

5. N.C.

Item Turning ON Turning OFF Blinking (0.4s cycle)

Power Power ON Power OFF -

L RUN Normal Abnormal -

L ERR Communication error Normal The switch setting has changed from

Switch setting error the setting whenreset is released.

POWER LED

L RUN LED

LED display

L ERR LED

Communication

Line

Power Supply Line

Address Switch

AUSTRIA (43) 2262-62 280

BELGIUM (32) 3-355 1464

CZECH REP. (420) 5-414 24611

DENMARK (45) 70 25 29 00

FINLAND (358) 207-513 513

FRANCE (33) 1-64 76 1000

GERMANY (49) 6103 4020

GREECE (30) 1- 342 6076

HUNGARY (36) 1-371 1343

IRELAND (353) 1-403 9000

ITALY (39) 02-92711

NETHERLANDS (31) 20-531 8888

NORWAY (47) 67 12 90 20

POLAND (48) 22-548 50 85

PORTUGAL (351) 2 610 89 22

SPAIN (34) 945-18 4100

SWEDEN (46) 8-603 0700

SWITZERLAND (41) 52-396 3131

TURKEY (90) 212 221 1512

UNITED KINGDOM (44) 1908-56 3888

Fig 9

ITV20*0-X305

Bus Adaptor

Fig 4

Model ITV*010-X305 ITV*030-X305 ITV*050-X305

Max. Supply Pressure 0.2MPa 1.0MPa

Setting Pressure Range 0.005~0.1MPa 0.005~0.5MPa 0.005~0.9MPa

Supply Voltage 24VDC±10%

Current Consumption Max. 140mA

Input Signal Indicates input signal by 12bit (0~4095)

Output signal Retransmits output pressure by 12 bit (0~4095)

Linearity ±1%F.S. or less

Hysteresis 0.5%F.S. or less

Repeatability ±0.5%F.S. or less

Sensitivity 0.2%F.S. or less

Temperature Characteristics ±0.12%F.S. or less / C

Protection Structure Main unit: Equivalent to IP65

Ambient and Fluid Temperature 0~50 C (without condensation)

Symbol

Fig 2

DANGER In extreme conditions, there is a possibility of

serious injury or loss of life.

WARNING If instructions are not followed there is a

possibility of serious injury or loss of life.

CAUTION If instructions are not followed there is a

possibility of injury or equipment damage.

Fig 1

Table 1 the setting of node address

Node address\SW SW40 SW20 SW10 SW8 SW4 SW2 SW1

1 OFF OFF OFF OFF OFF OFF ON

2 OFF OFF OFF OFF OFF ON OFF

3 OFF OFF OFF OFF OFF ON ON

: : : :::::

64 ON ON OFF OFF ON OFF OFF

Table 2 the setting of transmission rate

Communication rate\SW BS4 BS2 BS1

0 (156kbps) OFF OFF OFF

1 (625kbps) OFF OFF ON

2 (2.5Mbps) OFF ON OFF

3 (5.0Mbps) OFF ON ON

4 (10Mbps) ON OFF OFF

Table 3 the setting of Hold/Clear when communication fails

Hold/Clear\SW Switch 1 Function

Hold OFF Hold output pressure

Clear ON Clear output pressure

Fig 3

Fig 10

X

Fig 8