Sices DST4600A User manual

Filename: EAAM006212EN.docx

Rev. 12 Date: 30/05/2013

ID Document: EAAM0062

Product: DST4600A

ii User’s Manual

1General Information .....................................................................................................5

1.1 Definitions.............................................................................................................5

1.2 Symbols................................................................................................................5

1.3 Document validity .................................................................................................5

2Front Panel....................................................................................................................6

2.1 Operating and Functions Controls Area................................................................7

2.1.1 Operating area ...............................................................................................7

2.1.2 Functions Area...............................................................................................9

2.1.3 Operating Conditions and Measurements Area............................................11

2.1.4 Faults Area...................................................................................................12

3Start Initialization........................................................................................................14

4Faults...........................................................................................................................14

4.1 List of Fxx Codes................................................................................................15

4.2 Alarms ................................................................................................................16

4.2.1 Low oil pressure...........................................................................................16

4.2.1.1 From digital input..................................................................................16

4.2.1.2 From Analogue Input............................................................................16

4.2.2 High Cooling Water Temperature.................................................................16

4.2.2.1 From Digital Input.................................................................................16

4.2.2.2 From Analogue Input............................................................................16

4.2.3 Starting Battery Fault....................................................................................17

4.2.4 Minimum Fuel Level in the Tank...................................................................17

4.2.4.1 From Digital Input.................................................................................17

4.2.4.2 From Analogue Input............................................................................17

4.2.5 Maximum Fuel Level in the Tank..................................................................17

4.2.5.1 From Digital Input.................................................................................17

4.2.5.2 From Analogue Input............................................................................17

4.2.6 Auxiliary Alarm .............................................................................................18

4.2.7 KR close failure............................................................................................18

4.2.8 KG close failure............................................................................................18

4.2.9 Max power....................................................................................................18

4.3 Deactivations......................................................................................................19

4.3.1 Generator’s Voltage Under Minimum Threshold (“UNDERVOLTAGE”) .......19

4.3.2 Generator’s Frequency Under the Minimum Threshold

(“UNDERFREQUENCY”).........................................................................................19

4.4 Blocks.................................................................................................................19

4.4.1 Emergency STOP ........................................................................................19

4.4.2 Manual Stop in AUTO ..................................................................................20

4.4.3 Fuel END......................................................................................................20

4.4.3.1 Digital input...........................................................................................20

4.4.3.2 From Analogue Input............................................................................20

4.4.4 Low Oil Pressure..........................................................................................20

4.4.4.1 From Digital Input.................................................................................20

4.4.4.2 From Analogue Input............................................................................20

4.4.5 High Cooling Water Temperature.................................................................21

User’s Manual iii

4.4.5.1 From Digital Input.................................................................................21

4.4.5.2 From Analogue Input............................................................................21

4.4.6 Non-masked Auxiliary Block.........................................................................21

4.4.7 Masked Auxiliary Block.................................................................................21

4.4.8 Generator’s Voltage Over the Maximum Threshold (“OVERVOLTAGE”).....22

4.4.9 Generator’s Frequency Over the Maximum Threshold

(“OVERFREQUENCY”) ...........................................................................................22

4.4.10 Engine Over speed .................................................................................22

4.4.10.1 From Digital Input...............................................................................22

4.4.10.2 From Frequency.................................................................................22

4.4.11 Overload .................................................................................................23

4.4.11.1 From Digital Input (“OVERLOAD”)......................................................23

4.4.11.2 From Current (“OVERCURRENT”).....................................................23

4.4.12 Short circuit.............................................................................................23

4.4.13 Belt Break ...............................................................................................24

4.4.14 Operating Speed not reached.................................................................24

4.4.15 “OVERCRANK”.......................................................................................24

4.4.16 Hardware fault.........................................................................................24

4.4.17 Shutdown Failure....................................................................................25

4.4.18 Energy Inversion.....................................................................................25

4.4.19 Inhibition of the generator set Use..........................................................25

4.4.20 Engine not in thresholds when KG closed...............................................25

5Operating Sequence...................................................................................................26

5.1 Definitions...........................................................................................................26

5.1.1 Mains Voltages Status..................................................................................26

5.1.2 Generator’s Voltages Status.........................................................................27

5.1.3 Engine Status...............................................................................................28

5.1.3.1 Definition of Engine Running................................................................28

5.1.3.2 Definition of Dead Engine.....................................................................28

5.1.3.3 Starting Request...................................................................................29

5.1.3.4 Stop Requests......................................................................................29

5.2 Shutdown System...............................................................................................29

5.3 Sequence in “MAN” mode ..................................................................................30

5.3.1 Entering the MANUAL mode........................................................................30

5.3.2 Engine Starting.............................................................................................30

5.3.3 Engine Shutdown .........................................................................................30

5.3.4 Power Change-over .....................................................................................31

5.4 Sequence in “AUTO” mode ................................................................................31

5.4.1 Start Requests Wait .....................................................................................31

5.4.2 Engine Starting Attempts..............................................................................31

5.4.3 Generator Waiting ........................................................................................32

5.4.4 Delay before supply the power.....................................................................32

5.4.5 Switching users on the Generator................................................................32

5.4.6 No start requests wait...................................................................................33

5.4.7 Switching users to Mains..............................................................................33

5.4.8 Engine Cooling Cycle...................................................................................33

5.4.9 Engine Shutdown Cycle ...............................................................................33

5.5 Sequence in “TEST” mode .................................................................................33

6Power Measurement...................................................................................................34

6.1 Power Factor......................................................................................................34

iv User’s Manual

6.2 Active Power.......................................................................................................34

6.3 Reactive Power ..................................................................................................34

6.4 Apparent Power..................................................................................................35

6.5 Energy Meter......................................................................................................35

6.6 Connection caution.............................................................................................35

7Auxiliary Functions ....................................................................................................36

7.1 Automatic recovery from KR close failure...........................................................36

7.2 Automatic Periodical Test...................................................................................36

7.3 Fuel Pump..........................................................................................................37

7.4 Remote Test.......................................................................................................37

7.5 Remote Signals ..................................................................................................37

7.6 LOW POWER or MAX POWER signaling ..........................................................38

7.6.1 Low load status signal..................................................................................39

7.6.2 Maximum power...........................................................................................39

7.7 Real Time Clock option.......................................................................................40

7.7.1 How to display Time and Date of RTC.........................................................40

7.7.2 Setting time and date ...................................................................................41

7.7.3 Storing time/date into Data Record databases.............................................41

7.7.4 Automatic Periodical Test.............................................................................41

7.7.4.1 RTC based periodical test....................................................................41

7.7.4.2 Standard mode periodical test..............................................................41

7.7.5 Generator set Time Lock function ................................................................42

8Differences between DST4600A and DST4600A/P...................................................43

8.1.1 ALARM2 input for PARALLEL FAULT..........................................................43

8.1.2 KR management ..........................................................................................43

8.1.3 KG management in test operation................................................................43

8.1.4 “MAINS SIMULATION” delay time ...............................................................43

8.2 Differences with DST4600A/P for asynchronous engines ..................................43

8.2.1 Generator frequency and voltages ...............................................................43

8.2.2 Terminal 8 function.......................................................................................43

8.2.3 Terminal 10 function.....................................................................................44

8.2.4 “Engine not in threshold with KG closed” alarm............................................44

9References..................................................................................................................44

9.1 SMS Protocol for Boards DST4600A and REMOTE SIGNALS..........................44

9.2 DTS4600-PC Communication Protocol ..............................................................44

9.3 ModBus protocol implementation for SICES equipment.....................................44

9.4 Remote signal operating manual........................................................................44

User’s Manual 5

The board DST4600A, included into a special electric switchboard, is able to control the

automatic intervention of a generator set, to monitor it during the operation and to keep it in

the best possible conditions while inactive, in order to assure a quick and safe intervention in

the event of power failure. It works with both three- and single-phase systems.

Throughout this document the word “BLOCK” is used to indicate an alarm that makes

generation function impossible and causes the automatic generator shutdown with the

emergency procedure (without cooling cycle).

The word “DEACTIVATION” is used to indicate an alarm that makes generation function

impossible and causes the automatic generator shutdown with the normal procedure (with

cooling cycle).

The word “ALARM” is used to indicate a warning that requires an operator action but doesn’t

require the automatic generator shutdown.

Throughout this document the words “SOFTWARE” and “FIRMWARE are used as

synonymous if they are referred to the board firmware.

Software code is reported in short format on the board back panel. It is in the form xx.yy.uu,

where xx is the firmware short identified code, yy is the major version number and uu is the

minor version number.

The complete SW identification number for the standard DST4600A is EB0220008yyuu

reported in back panel as (for example) 8.00.22.

The complete SW identification number for the DST4600A/P is EB0220012yyuu reported in

back panel as (for example) 12.05.22.

The complete SW identification number for the DST4600A for asynchronous engines is

EB0220029yyuu reported in back panel as (for example) 29.07.39.

The minor version is consistent between the two types of software (uu field is kept aligned).

The major version for the DST4600A/P is increased by 5respect the standard version.

The major version for the DST4600A for asynchronous engines is increased by 7 respect the

standard version.

Thus the SWs 08.00.39, 12.05.39 and 29.07.39 share the same main features and functions.

In this document a vertical bar on the right margin or a gray background indicates that the

chapter or the paragraph has been amended with respect to the last document’s version.

This manual is valid starting from SW 00.38 release; for previous SW release, please check

manual version 09 or previous. Otherwise use this version very carefully checking document

version notes on page ii.

If the SW version number is greater than this, this manual maybe nevertheless consistent;

please in case check for new document release.

6User’s Manual

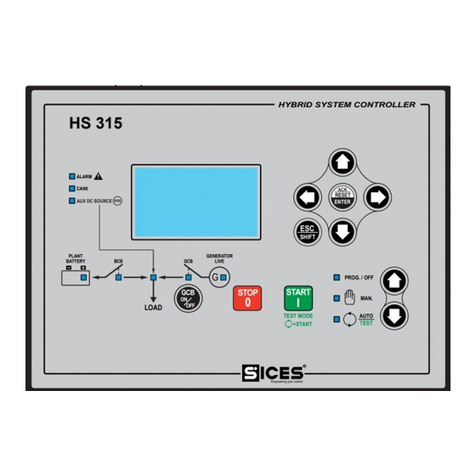

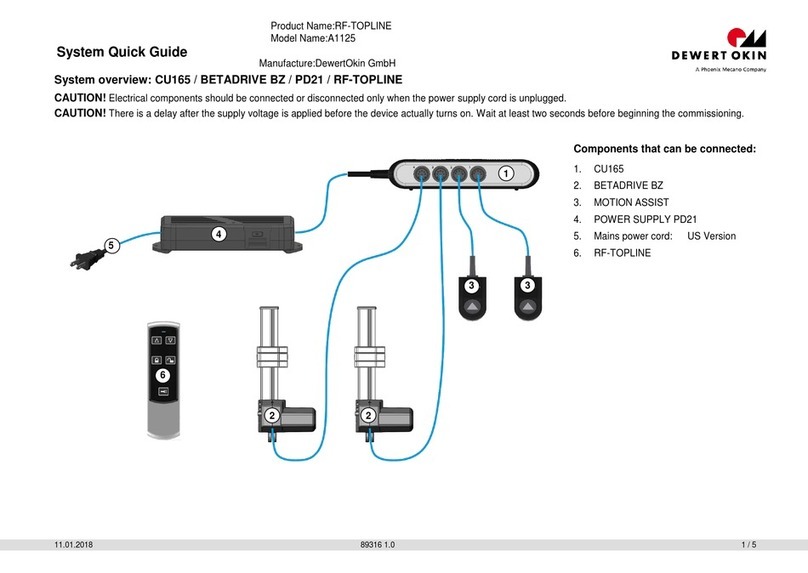

DST4600A and DST4600A/P front panels.

User’s Manual 7

The front part of the board is made by a polycarbonate panel, oil- and solvent-resistant with the

identifying symbols and inscriptions. There are two slightly different front panels. The

DST4600A front panel is the standard one. The DST4600A/P front panel is used mainly for

switchboard for parallel application; the boards with the DST4600A/P panel have different part

number.

“/P” version assigns a special meaning to the followings signals:

“ALARM 1” signal means “EXTERNAL SHUTDOWN”

“ALARM 2” signal means “AUX ALARM”

“MAINS VOLTAGE” signal means “MAINS VOLT./SIM. STATUS »

Substantially, the panel is divided into the three operational areas as described below.

This area can be functionally further divided in two different areas.

It corresponds to the right bottom part of the front panel. It groups all the available control units.

It includes:

A button (“START”) for the manual starting of the generator set engine. The manual start

can be executed only with the key selector on MAN. This button, alone or combined with

the others, can also take other meanings during some particular procedures not directly

related with the management of the generator set (programming, calibration, etc.).

A button (“STOP”) for the manual shutdown of the generator set engine. The manual

shutdown can be executed only with the key selector on MAN. By pressing this button

with the key selector in other working positions (AUTO or TEST) the engine shutdown

will be executed through the emergency procedure (see the faults management). This

button, alone or combined with the others, can also take other meanings during some

particular procedures not directly related with the management of the generator set

(programming, calibration, etc.).

A button (bearing the symbol of a siren, from now on called “MODE / ACK”) for the faults’

acknowledgement and the consequent muting of the audible alarm and to reset the

alarms, too. This button, alone or combined with other buttons, can also have other

meanings.

Two buttons (bearing the symbols of two arrows, from now on called “F1” and “F2”) used

to select what to show on the display “MULTIFUNCTION” (see par.2.1.2). These

buttons, alone or combined with other buttons, can also have other meanings.

A key selector allowing to select the board’s controlling mode of the generator set’s

operation: OFF/RESET - PROGRAMMING - MANUAL - AUTOMATIC –TEST. The key

can be extracted only in the positions OFF/RESET and AUTOMATIC. Here follows a

short description of the operating modes:

a) OFF/RESET: in this mode the board is on, but all the functions for the control and

the running of the generator set are disabled. It is used in all the cases in which

the intervention of the generator set is not required (i.e. in order to prevent

unnecessary automatic interventions during the closing periods of a factory etc.)

and above all as a safety position during the maintenance. Actually, when the

selector is on OFF/RESET, the control device is completely disabled and

therefore the generator set cannot intervene in the event of mains voltage failure.

The mains contactor is forced at work therefore the users are powered by the

mains (if it’s present). The monitoring of the mains status, of the engine and of

the generator are anyway enabled and the indicators belonging to the “functional

8User’s Manual

status and measurements” area mirror such conditions.

By switching the selector to “OFF/RESET” the following operations are executed:

1) Activation of the engine shutdown sequence

2) Forced control of mains power supply

3) Reset of any stored fault causing the generator set shutdown

When the board is in the “OFF/RESET” mode the direct current consumption is

reduced to a minimum since the displays show only a central dash, while all the

signals are off except the indicator “KR” (turned on, only for SW type 08) as well

as the indicators “ENGINE RUNNING”, “GENERATOR LIVE” and “MAINS LIVE”

showing respectively the engine, the generator and the mains status (normally

only the indicator “MAINS LIVE” is turned on).

b) PROG. (PROGRAMMING): in this mode the board behaves exactly as in the

“OFF/RESET” mode but with the opportunity to view and/or change the value of

the parameters configuring the operating sequences of the generator set

c) MAN. (MANUAL): in this mode the board is set to manage the manual running of

the generator set. In short:

1) The procedures for the manual starting and shutdown of the engine are

enabled, while those for the automatic starting and shutdown of the engine

are disabled (therefore the board will never automatically start the engine).

2) It is possible to manual operate the power changeover on the generator set

through an explicit command of the operator (if the generator is ready to

supply, of course). In MAN, the board will never execute such switching

automatically.

When the selector is switched on “MAN”, the engine keeps its status

(running/dead).

d) AUTO (AUTOMATIC): this is the normal operating mode of the board. In this

mode the engine is automatically started/stopped in case of mains failure or at

regular intervals to keep it efficient. In the same way, the power changeover is

automatically switched on mains or on the generator according to their status.

Warning: when the selector is on this mode any maintenance of the

generator set and/or on the electric switchboard is forbidden.

e) TEST: this mode allows starting the generator set keeping all the functions for the

management of the changeover as in the AUTOMATIC mode. By switching the

selector on TEST, a series of starting attempts will be executed (automatically,

the operator will not have to press “START”), independently from the mains

status. In the same way, by quitting the TEST mode (for the AUTOMATIC mode),

if the mains is present the engine will stop (with the usual cooling cycle).

Normally, in the TEST mode the users are switched on the mains. They can be

switched on the generator set (if it is ready to supply) only in the following two

cases:

1) Mains failure

2) Explicit command of the operator (in order to test the entire system, not only

the generator set).

For the SW version 12 (/P boards), KG is activated in the TEST mode if the

generator is ready to supply power. It can be deactivated by manual command.

User’s Manual 9

In this area is located a digital display (called display “MULTIFUNCTION”) showing the

measurements of various quantities that can be selected through the buttons “F1” and “F2”

and indicated to the operator through the corresponding indicators.

The available quantities are:

“DATA – HOURS COUNT / START COUNTER”: by selecting this function the display

“MULTIFUNCTION” normally shows the number of operating hours of the generator set

engine. The hours count doesn’t consider if the users are connected to the generator but

the condition of engine running only. By keeping pressed the button “MODE / ACK”, you

can view the number of starts of the engine (the number refers to the performed starts,

not to the start attempts). As soon as “MODE / ACK” is released the engine’s operating

hours can be viewed again. The corresponding indicator is turned on when the display

shows the engine’s operating hours, while it flashes when the number of starting attempts

is viewed. If the number of starts of the operating hours exceeds 999, the number is

divided by 10 and displayed with a decimal point on the right digit.

It is possible to program (through the parameter P50) a number of operating hours for the

engine after which maintenance has to be carried out. When the hour-counter reaches or

exceeds such parameter (NB: it is set by tens of hours) in order to signal the maintenance

request the number of operating hours will flash alternatively to the message “SER” (with

the selector on MAN, AUTO and TEST the function to view the operating hours is

automatically selected after 60 seconds without pressing any button). This condition stays

until the hour-counter is reset or until the value of the Parameter P50 is changed (by

increasing it or by forcing it to 0). Both the counters are reset with a common operation

(they cannot be reset separately):

By pressing the “F1” and “F2” select the “DATA – HOURS COUNT / START

COUNTER” function

Switch the key selector to OFF_RESET.

Press at the same time “MODE / ACK” and “STOP” for 5 seconds. After 5 seconds

the counters will be reset. The display does not indicate the reset in any way;

therefore the operator has to count the 5 seconds.

There is another hour counter. It cannot be cleared in any way. Its value is not shown on

the DST4600A front panel, but can be read by the serial port.

“GEN-SET FREQUENCY”: when this function is selected, the display

“MULTIFUNCTION” shows the frequency measured on the phase L1 (terminal 63) of the

generator (in Hz with a decimal).

“MAINS VOLTAGE (Vac) / (MAINS VOLT./SIM STATUS) / REACTIVE POWER (kvar)”:

when this function is selected, the display “MULTIFUNCTION” shows one of the phase-

to-phase voltages measured by the board, according with the status of the indicators

“L1/L2”, “L2/L3” and “L3/L1” located between the displays “A” and “V”:

- Indicator “L1/L2” turned on: phase R-S

- Indicator “L2/L3” turned on: phase S-T

- Indicator “L3/L1” turned on: phase T-R

If the board is programmed not to use the internal mains sensor, display shows “---“. If

the board is programmed to use the internal mains sensor and the input “MAINS

SIMULATION” (terminal 24) is enabled, the indicator “MAINS VOLTAGE (Vac) /

REACTIVE POWER (kvar)” flashes. If the board is supplied with the power measurement

option and if the displays “V” and “A” are showing the active power and the power factor

(POWER DISPLAY FUNCTION), the display “MULTIFUNCTION” shows the reactive

power (in this case, the measure could blink if at least one of the current measure circuits

of the board is saturated, that means that the current is higher than the TA nominal value).

“BATTERY VOLTAGE (V) / APPARENT POWER (kVA)”: when this function is selected,

the display “MULTIFUNCTION” indicates the voltage measured on the battery

(terminals 47-48 or 49-48) (in Volts with a decimal). If POWER DISPLAY FUNCTION is

active, the display indicates the apparent power (in this case, the measure could blink if

at least one of the current measure circuits of the board is saturated, that means that

the current is higher than the TA nominal value).

10 User’s Manual

“OIL PRESSURE (bar)”: when this function is selected, the display “MULTIFUNCTION”

shows the engine’s oil pressure measured on the analogue sensor (terminal 42) (in Bars

with a decimal). If the sensor isn’t configured (P47=0), the display will show three dashes

(“---“).

“TEMPERATURE (°C)”: when this function is selected, the display “MULTIFUNCTION”

shows the cooling water temperature measured on the analogue sensor (terminal 43) (in

°C). If the sensor isn’t configured (P46=0), the display shows three dashes (“---“).

“FUEL LEVEL (%)”: when this function is selected, the display “MULTIFUNCTION” shows

the fuel level in the tank measured on the analogue sensor (terminal 45) (percentage). If

the sensor isn’t configured (P48=0), the display will show three dashes (“---“).

Under particular conditions, during the operation the display “MULTIFUNCTION” can show

messages having no relation with the selected function. In this situation, all indicators related

to display “MULTIFUNCTION” are turned off. In detail, the messages are the following:

“STA” during a starting attempt, that is when the output “START” (terminal 20) is

activated.

“PRE” during the preheating phase preceding the starting attempt in diesel engines, that

is when the “PREHEAT OUTPUT” (“AUX OUTPUT 1”, terminal 15) is activated.

“SER” signals that the generator set requires field service maintenance.

“F01” in presence of the deactivation for generator’s voltage under the minimum threshold

(“UNDERVOLTAGE”).

“F02” in presence of the block for generator’s voltage over the maximum threshold

(“OVERVOLTAGE”).

“F03” in presence of the deactivation for generator’s frequency under the minimum

threshold (“UNDERFREQUENCY”).

“F04” in presence of the block for generator’s frequency over the maximum threshold

(“OVERFREQUENCY”).

“F05” in presence of block for belt break (“BELT BREAK”).

“F06” in presence of block for maximum current supplied by the generator

(“OVERCURRENT”).

“F07” in presence of block for “STOP” pressed in the AUTOMATIC or in the TEST mode.

“F08” in presence of block for operating condition not reached.

“F09” in presence of alarm for data error in the non-volatile memory

“ F10” in presence of alarm from “INPUT ‘B’” (terminal 13)

“F11” in presence of block for “ENERGY INVERSION”

“F12” in presence of block for “INHIBITION OF THE GENERATOR SET USE”

“F13” in presence of alarm “KR CLOSE FAILURE”

“F14” in presence of alarm “KG CLOSE FAILURE”

“F16” in presence of alarm “SHORT CIRCUIT”

“F21” in presence of block for “SHUTDOWN FAILURE”

“F40” if the “engine in threshold” signal is missing while KR is closed (for asynchronous

engine version only)

“F49” in presence of alarm for “MAX POWER”

“F50” in presence of block for “BOARD FAULT”

During the shutdown cycle the display “MULTIFUNCTION” alternates, every two seconds, the

message “STO” with the message it would display if the shutdown cycle was not in progress.

User’s Manual 11

In this area (right top of the front panel) is displayed the status of the generator set and of the

mains. The following signals are provided:

Indicators “KG” and “KR” (green): indicate the status of the contactors managing the

power changeover. The indicator “KR” is not present for SW type 12 (/P boards). If the

green indicator is turned on the corresponding external connected contactor is closed.

The external connected contactors can never be both closed, while they can be both open

during the switching. The default configuration shows the KG and KR command status,

not the actual status. However it is possible to configure the board to use two inputs to

monitor the status:

“INPUT A” (terminal 14) for KG status

“INPUT C” (EXTERNAL OVERSPEED default configuration) (terminal 12) for KR

status

Connect the proper terminal to ground when KG or KR is activated.

When this function is enabled the indicators “KG” and “KR” work in a different way:

OFF: the contactor is open

ON: the contactor is closed

Flashing at 50% duty cycle: the contactor is open but the command is on

Flashing at 90% ON: the contactor is closed but the command is off

Indicator “ENGINE RUNNING” (green): it indicates the status of the engine of the

generator set. It takes the following meanings:

Turned off: engine shut down

Flashing: engine cooling (this condition occurs only in the AUTOMATIC mode).

Turned on: engine running

Indicator “GENERATOR LIVE” (green): it indicates the status of the generator set. It takes

the following meanings:

Turned off: the generator doesn’t produce any voltage.

Flashing: The generator is living but some of the parameters (voltages on one or

more phases or frequency) are not within the programmed tolerance limits, therefore

the users cannot be switched on it.

Turned on: The generator is living and all its parameters are within the programmed

tolerance limits, therefore it is possible to switch the users on it.

“MAINS LIVE” indicator (green): It indicates the mains status. It takes the following

meanings:

Turned of: mains failure.

Flashing: the mains is present but the voltage on one or more phases is not within

the limits of the programmed tolerance thresholds, therefore if the users are currently

switched on the generator, they will have to stay on it.

Turned on: the mains is present and within the programmed tolerance limits,

therefore the users can be switched on it.

NB: the board has an input (“MAINS SIMULATION”, terminal 24) that can be used to

inhibit the automatic operation of the genset. If this digital input is activated, independently

from what has been acquired with the mains sensor, the engine is not automatically

started.

Furthermore, there are two digital displays (each of them having 3 digits) to show the electric

quantities measured on the generator. The left display (called display “V”) shows the

generator’s voltages (phase-to-phase for three-phase systems, phase-to-neutral for single-

12 User’s Manual

phase systems) Volts. The right one (called display “A”) shows the phase currents in

Amperes. The view format changes according to the set TA ratio (P17):

P17 < 10: the currents are displayed with two decimals

P17 >=10 and <100: the currents are displayed with one decimal

P17 >=100: the currents are displayed without any decimal. If the current measurement

exceeds 999 Ampere, it is displayed divided by 10 and the indicator “X10” (yellow),

located over the display “A” turns on.

If the current measured (in the board side of TA) is higher then 5 Amperes, the display “A”

blinks to indicate lower measure precision.

If the board is supplied with the power measurement option it is possible to view the power

factor (indicated by “POWER FACTOR (cos )”) on the display “V” and the active power

(indicated by “ACTIVE POWER (kW)”) on the display “A” (POWER DISPLAY FUNCTION).

Furthermore, it is possible to view the energy meter (kWh on the display “A” and MWh on the

display “V”). All these measures will blink if at least one of the current measurement circuits of

the board is saturated (see description at the previous paragraph).

Three yellow indicators (called “L1/L2”, “L2/L3” and “L3/L1”) located between the two displays

are also present. They indicate to which phase the measurements displayed in any moment

refer. On single-phase systems the voltage and the current of the only present phase are

always displayed, therefore the indicator “L1/L2” is always turned on, while the “L2/L3” and

“L3/L1” are always off. On three-phase systems, the three phases are periodically alternated

every 4 seconds on the displays and the indicators “ L1/L2”, “L2/L3” and “L3/L1” show the

current phase. However, it is possible to force the display of one phase only even on three-

phase systems by pressing at the same time the buttons “F1” and “F2” when the displays show

the quantities relating to the phase one intends to force: the phases scanning will be

interrupted and will start again when the two buttons “F1” and “F2” will be pressed at the same

time again.

This area (top left of the front panel) contains all the indicators for the generator set’s common

faults Here follows a short description of the indicators, for a more detailed description of all

the faults, see paragraph 6. At the fault acquisition, the corresponding indicator flashes, by

pressing the “MODE / ACK“ button it stops flashing to indicate that the operator acknowledge

it.

Indicator “TEMPERATURE” (red): it indicates the alarm or block status due to the high

cooling water temperature. The indicator flashes at a different speed to indicate an alarm

(more quickly) or a block (more slowly, as for all other blocks). It can be acquired from:

Digital input “WATER WARNING” (terminal 10)

Digital input “WATER. ALARM” (terminal 09)

Analogue input “TEMPERATURE” (terminal 43)

Indicator “LOW OIL PRESSURE” (red): it indicates the alarm or block status due to the

low oil pressure of the engine. The indicator flashes at a different speed to indicate an

alarm (more quickly) or a block (more slowly, as for all other blocks). It can be acquired

from:

Digital input “OIL WARNING” (terminal 08)

Digital input “OIL P. ALARM” (terminal 07)

Analogue input “OIL PRESSURE” (terminal 42)

Indicator “MAX LEVEL” (yellow): It indicates the alarm status due to the maximum fuel

level in the tank. It can be acquired from:

Digital input “HIGH LEVEL FUEL” (terminal 04)

Analogue input “FUEL LEVEL” (terminal 45)

User’s Manual 13

Indicator “ALARM1” (“EXTERNAL SHUTDOWN”) (red): it indicates the non-masked

general block status. It can be acquired from:

Digital input “ALARM 1” (terminal 01)

Indicator “OVERCRANK” (red): It indicates the block status due to a failure in the

automatic start of the engine. It is produced by the operating sequence in the AUTOMATIC

mode.

Indicator “DISCHARGED” (yellow) it indicates the alarm status due to the charge level of

the starting battery of the generator set. Such battery also powers the board DST4600A.

The alarm is produced if the battery voltage exceeds the tolerance limits:

11.8 … 15 V (for nominal voltage of 12 V battery)

23.2 … 30 V (for nominal voltage of 24 V battery)

Indicator “MIN LEVEL” (yellow): it indicates the alarm status due to the minimum fuel level

in the tank. It can be acquired from:

Digital input “LOW LEVEL FUEL” (terminal 05)

Analogue input “FUEL LEVEL” (terminal 45)

Indicator “ALARM2” (“AUX. ALARM”) (red): it indicates the masked generic block status.

It can be acquired from:

Digital input “ALARM 2” (terminal 02)

Indicator “OVERSPEED” (red): it indicates that the engine is running too fast and it could

damage the alternator or the engine itself. It can be acquired from:

Digital input “OVERSPEED” (“INPUT C” terminal 12)

Generator’s frequency exceeding the set threshold (parameter P21)

Indicator “OVERLOAD” (red): it indicates a system overload. It can only be acquired from:

Digital input “OVERLOAD” (terminal 11)

Indicator “NO FUEL” (red): it indicates the block due to the end of the fuel in the tank. It

can be acquired from:

Digital input “FUEL END” (terminal 06)

Analogue input “FUEL LEVEL” (terminal 45)

Indicator “EMERGENCY STOP” (red): it indicates the block that follows the pressing of

the emergency button. It can be acquired from:

Digital input “EMERGENCY STOP” (terminal 03). NB: the block is enabled when

the digital input is not activated.

14 User’s Manual

As soon as the board is powered it executes the following operations:

Lamp Test: during this phase it turns on all the indicators in the front panel and it shows

888 (with the decimal points turned on) on the three displays. This operation lasts two

seconds and allows the identification of any failure in the front panel that could involve

visual signaling of a fault.

It checks if it has to execute the CALIBRATION procedure. To request the execution of

such procedure press “MODE / ACK” while turning the board. In this phase all the

indicators on the front panel are turned off as well as the displays “V” and “A”, while the

display “MULTIFUNCTION” shows three question marks (this procedure can be made

only by trained operator using proper measurement systems).

Display the software level. The display “MULTIFUNCTION” shows the message “REL”

(release). The display “V” shows the main version; the display “A” shows the secondary

version. For instance, for a software level 1.23 the display “V” will indicate “1” and the

display “A” will indicate “23”. In this phase all the indicators on the front panel are turned

off. This phase lasts one second.

In the event of data errors in the non-volatile memory, the display “MULTIFUNCTION” shows,

in place of “REL” the message:

“INI” if the non-volatile memory doesn’t contain any data

“F09” if the non-volatile memory contains mistaken data

After the execution of the above-mentioned operations, the board starts executing the work

sequences, according to the position of the key selector.

During the operation of the generator set (but even when it is not running) some faults may

occur. The faults can be divided into three categories according to the way the affect the

generator set:

Alarms: faults that are not immediately dangerous for the generator set and for its load,

and that therefore allow the generator set to keep on working. They require an operator’s

intervention otherwise they could cause a more dangerous fault.

Deactivations: these faults are more dangerous for the load that needs to be switched

immediately on the mains (even if there’s a mains failure) but they aren’t immediately

dangerous for the generator set and/or for the operator: the generator set will have to be

stopped in any case but it can be stopped with the standard procedure (cooling cycle,

etc.).

Blocks: these faults can damage the generator set and sometimes the load, too. When

they are activated, the load is immediately switched on the mains (even if there’s a mains

failure) and the engine is stopped through the emergency procedure (without the cooling

cycle).

Any fault can be activated only if the key selector is on MAN, AUTO or TEST.

The alarms can always be activated. There may be more than one alarm at the same time.

The deactivation can be activated if in the moment the cause occurs no deactivation or block

is present, while one or more alarms can be present. There cannot be two deactivation at the

same time.

The blocks can be activated only if in the moment the cause occurs no other block is present,

while deactivation and/or alarms can be present. As a principle, there cannot be two blocks at

User’s Manual 15

the same time, but actually, the blocks “NO FUEL”, “EMERGENCY STOP” and “MANUAL

STOP IN AUTO” are an exception since they can be activated even in presence of other blocks

When a fault occurs, whatever be its category, the audible alarm is activated (“ALARM

OUTPUT”, terminal 16) as well as the corresponding visual signal. Such signal can be an

indicator on the front panel (fault area) or a message “FXX” on the display

“MULTIFUNCTION”. In the case of an indicator it flashes.

The audible alarm stays active for the time programmed through the parameter P54 than it

turns off automatically (if P54 is equal to 999 the siren does never turn off automatically, if P54

is equal to 0 the siren never turns on), while the visual signal keeps on flashing until the

operator doesn’t ”recognize” it.

The “recognition” involves the pressing of “MODE / ACK”. As a consequence, the signal stops

flashing and stays turned on and the audible alarm (if still active) is disabled.

Once the operator has recognized the alarms, they are automatically cancelled by DST4600A

when the corresponding cause ceases to exist. If the alarm is cancelled, the visual signal turns

off, too.

While the blocks and deactivation can be cancelled only by switching the key selector to

“OFF/RESET”.

Code

Description

F01

Generator’s voltage under the minimum threshold (block)

F02

Generator’s voltage over the maximum threshold (block)

F03

Generator’s frequency under the minimum threshold (block)

F04

Generator’s frequency over the maximum threshold (block)

F05

Belt break (block)

F06

Generator’s current over the maximum current (block)

F07

Stop button pressed in automatic (block)

F08

Operating speed not reached (block)

F09

Error in the non-volatile memory (warning)

F10

Alarm from “INPUT B” (terminal 13) (warning)

F11

Energy inversion (block)

F12

Inhibition of generator set use (block)

F13

KR close failure (warning)

F14

KG close failure (warning)

F16

Short-circuit

F21

Shutdown failure (block)

F40

Engine not in thresholds when KG closed (only for asynchronous engine

version)

F49

Max power (warning)

F50

Board failure (block)

16 User’s Manual

Disabling

Bit 2 of Parameter P39 = 0

Conditions to activate it

Engine running from the time set through the parameter P31

Digital input “OIL WARNING” (terminal 08) shorted to ground

Fuel solenoid activated.

Not existent in asynchronous engine version

Filter time

2 seconds

Visual signal

Quick flashing of the indicator “LOW OIL PRESSURE”

Disabling

Parameter P47 = 0 and/or parameter P25 = 0

Conditions to activate it

Engine running from the time set through the parameter P31

Pressure detected by the analogue input “OIL PRESSURE”

(terminal 42) lower or equal to the threshold set through the

parameter P25

Fuel solenoid activated.

Filter time

2 seconds

Visual signal

Quick flashing of the indicator “LOW OIL PRESSURE”

Disabling

Bit 0 of the Parameter P39 = 0

Conditions for its

activation

Fuel solenoid closed (output “FUEL SOLENOID”, terminal 22

enabled)

Digital input “TEMP. WARNING” (terminal 10) shorted to

ground

Filter time

2 seconds

Visual signal

Quick flashing of the indicator “TEMPERATURE”

Disabling

Parameter P46 = 0 and/or P26 parameter = max

Conditions for its

activation

Fuel solenoid closed (“FUEL SOLENOID” output, terminal 22

enabled)

Temperature detected from the analogue input

“TEMPERATURE” (terminal 43) over or equal to the threshold

set through the parameter P26

Filter time

2 seconds

Visual signal

Quick flashing of the indicator “TEMPERATURE ”

User’s Manual 17

Disabling

Bit 7 of the Parameter P49 = 0

Conditions for its

activation

Starting not in progress (output “START”, terminal 20 not

enabled)

Battery voltage under 11.8 (or 23.2) V or battery voltage over

15 (or 30) V

Filter time

40 seconds

Visual signal

Slow flashing of the indicator “DISCHARGED”

Disabling

Bit 6 of the Parameter P39 = 0

Conditions for its

activation

Digital input “LOW LEVEL FUEL” (terminal 05) shorted to

ground

Filter time

2 seconds

Visual signal

Slow flashing of the indicator “MIN LEVEL”

Disabling

Parameter P48 =0 and/or parameter P33 = 0

Conditions for its

activation

Level detected from the analogue input “FUEL LEVEL”

(terminal 45) under or equal to the threshold set through the

parameters P33

Filter time

2 seconds

Visual signal

Slow flashing of the indicator “MIN LEVEL”

Disabling

Bit 6 of the parameter P39 = 0

Conditions for its

activation

Digital input “HIGH LEVEL FUEL” (terminal 04) shorted to

ground

Filter time

2 seconds

Visual signal

Slow flashing of the indicator “MAX LEVEL”

Disabling

Parameter P48 =0 and/or parameter P27 = max

Conditions for its

activation

Level detected from the “FUEL LEVEL” analogue input

(terminal 45) over or equal to the threshold set through the

parameter P27

Filter time

2 seconds

Visual signal

Indicator “MAX LEVEL” slowly flashing

18 User’s Manual

Disabling

Bit 4 of the Parameter P49 = 0

Conditions for its

activation

Digital “INPUT B” (terminal 13) shorted to ground

Filter time

Time set through the parameter P40

Visual signal

Message “F10” on the display “MULTIFUNCTION”

Disabling

P75 = 0

Conditions for its

activation

AUTO o TEST mode. Bit 1 of parameter P61 = 1 (KR status

connected to INPUT C). KR command active.

Filter time

Time set through the parameter P75

Visual signal

Message “F13” on the display “MULTIFUNCTION”

Starting from revision 08.00.24 (not available for /P version and for asynchronous engine

version). Setting bit 5 of P61 at 1, it is activated a function that switch the load to Generator

set, keeping it running, in case of F13 alarm.

Starting from revision 08.00.38, this block may be masked if mains is not present by using bit

one of parameter P79.

Disabling

P75 = 0

Conditions for its

activation

AUTO o TEST mode. Bit 0 of parameter P61 = 1 (KG status

connected to INPUT A). KG command active.

Filter time

Time set through the parameter P75

Visual signal

Message “F14” on the display “MULTIFUNCTION”

Starting from revision 08.00.24.

Disabling

Board without power measure option, otherwise

Parameter P56 = 0

Parameter P58 = 0

Parameter P56 >= P58

Bit 7 of parameter P61 = 0

Conditions for its

activation

Active power higher than P58 threshold (see paragraph 7.6.2)

Filter time

Time set through the parameter P59

Visual signal

Message “F49” on the display “MULTIFUNCTION”

This warning is present only from software release EB02200080037.

User’s Manual 19

Disabling

Parameter P13 = 0

Conditions for its

activation

No deactivation

No block

Engine running

Generator already in the operating window from starting.

Shutdown cycle not in progress

Fuel solenoid activated

With selector on MAN, generator set contactor closed

Generator’s voltage under the threshold set through the

parameter P13 at least on one phase

Not existent in asynchronous engine version

Filter time

Time set through the parameter P24

Visual signal

Message “F01” on the display “MULTIFUNCTION”

Disabling

Parameter P11 = 0

Conditions for its

activation

No deactivation

No block

Engine running

Generator already in the window from starting.

Shutdown cycle not in progress

Fuel solenoid activated

With selector on MAN, generator set contactor closed

Generator’s frequency under the threshold set through the

parameter P11

Not existent in asynchronous engine version

Filter time

Time set through the parameter P23

Visual signal

Message “F03” on the display “MULTIFUNCTION”

Disabling

Cannot be disabled

Conditions for its

activation

“EMERGENCY STOP” input, terminal 03 open

Filter time

0.5 seconds

Visual signal

Indicator “EMERGENCY STOP” slowly flashing

20 User’s Manual

Disabling

Cannot be disabled

Conditions for its

activation

Key selector on AUTO or TEST

STOP button pressed o external STOP command

Filter time

0 seconds (immediate)

Visual signal

Message “F07” on the display “MULTIFUNCTION”

Disabling

Bit 5 of the Parameter P39 = 0

Conditions for its

activation

“FUEL END” digital input (terminal 06) shorted to ground

Filter time

20 seconds

Visual signal

Indicator “NO FUEL” slowly flashing

Disabling

Parameter P48 = 0 and/or parameter P28 = 0

Conditions for its

activation

Level detected from “FUEL LEVEL” (terminal 45) less or equal

than the threshold set by means parameter P28

Filter time

20 seconds

Visual signal

Indicator “NO FUEL” slowly flashing

Disabling

Bit 3 of the Parameter P39 = 0

Conditions for its

activation

No block

Engine running from the time set through the Parameter P31

Fuel solenoid activated

“OIL P. ALARM” digital input (terminal 07) shorted to ground

Filter time

2 seconds

Visual signal

Indicator “LOW OIL PRESSURE” slowly flashing

Disabling

Parameter P47 = 0 and/or parameter P34 = 0

Conditions for its

activation

No block

Engine running from the time set through the parameter P31

Fuel solenoid activated

Pressure detected from the “OIL PRESSURE” analogue input

(terminal 42) under or equal to the threshold set through the

parameter P34

Filter time

2 seconds

Visual signal

Indicator “LOW OIL PRESSURE” slowly flashing

Other Sices Controllers manuals