3.2Principle of operation

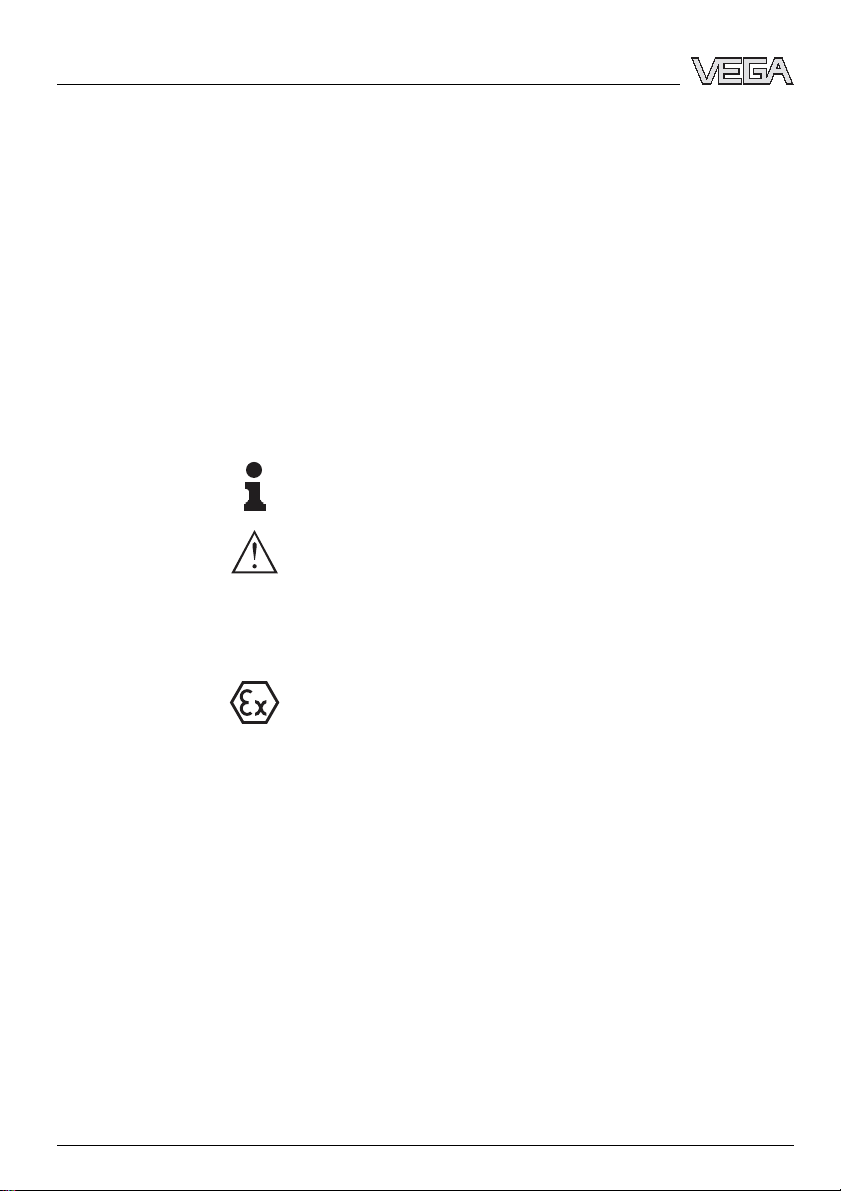

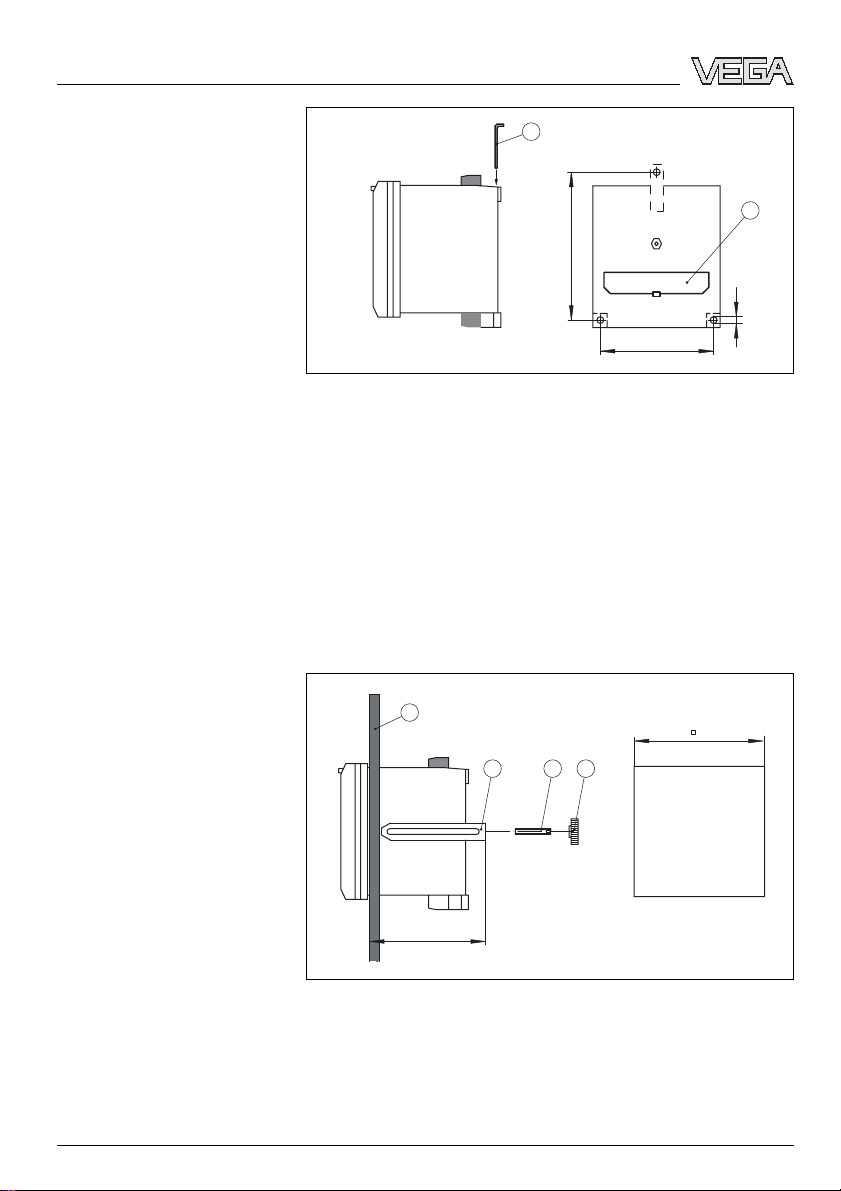

VEGAMET 381 Ex is a universal single signal conditioning

instrument with integrated level switches and display for

continuously measuring sensors.At the same time,it can

serve as power supply unit for connected sensors.VEGAMET

381 Ex is designed for connection of an individual 4…20 mA

sensor.The instrument is suitable for carrier rail,panel and

surface mounting.

The VEGAMET 381 Ex signal conditioning instrument can

power connected sensors and process their measured

signals.The requested parameter is displayed and outputted

in addition to the integrated current output for further

processing.Hence the measured signal can be transferred to

a remote indication or a superordinate control system.Two

level relays for control of pumps or other actors are also

integrated.

Wide-range power supply unit with 20 …253 VAC/DC for

world-wide use.

You can find detailed information on the power supply in the

"Technical data"in the "Supplement".

3.3Operation

The adjustment of VEGAMET 381 Ex is carried out via the

integrated keys and a 16-step function switch.

3.4Storage and transport

Your instrument was protected by packaging during transport.

Its capacity to handle normal loads during transport is assured

by a test according to DIN EN 24180.

The packaging of standard instruments consists of environ-

ment-friendly,recyclable cardboard.For special versions,PE

foam or PE foil is also used.Dispose of the packaging material

via specialised recycling companies.

lStorage and transport temperature see "Supplement -

Technical data -Ambient conditions"

lRelative humidity 20 …85 %

Area of application

Physical principle

Power supply

Packaging

Storage and transport tem-

perature

8VEGAMET 381 Ex-4…20 mAsignal conditioning instrument

Product description

30418-EN-060925