HDE GREENLEE TAG-200X User manual

8/21

52093091 REV 00 © 2021 Greenlee Tools, Inc.

TAG-200X & TAG-200XMR

Voltage Detectors

Read and understand all of the instructions and

safety information in this manual before operating

or servicing this tool.

KEEP THIS MANUAL

INSTRUCTION MANUAL

Record serial number here

_______________________

www. .com information@itm.com1.800.561.8187

TAG-200X & TAG-200XMR

52093091 REV 002© 2021 Greenlee Tools, Inc.

KEEP THIS MANUAL

Table of Contents

Cover Page..................................................................... 1

Safety Symbols Key ....................................................... 3

Tool Specic Safety Information..................................... 4

Greenlee Contact Information........................................ 4

Tool Description & Features ........................................... 5

Specications................................................................. 5

Tool Identication ........................................................... 6

Decals & Locations......................................................... 7

Training & Qualications................................................. 8

Pre-Operation Inspection & Set-up................................ 8

Tool Operation ................................................................ 9

Storage......................................................................... 10

Maintenance................................................................. 10

Service.......................................................................... 11

Disposal........................................................................ 11

TAG Underground Probes ............................................ 11

www. .com information@itm.com1.800.561.8187

TAG-200X & TAG-200XMR

352093091 REV 00 © 2021 Greenlee Tools, Inc.

This symbol means always wear

safety glasses with side shields or

goggles when handling or using this

equipment to reduce the risk of eye

injury.

This symbol means to always wear

gloves when using this equipment to

reduce the risk of injury.

This symbol means read the

instruction manual carefully before

using the equipment. The operator’s

manual contains important

information on the safe and proper

operation of the equipment.

This symbol indicates the risk of arc

ash.

This symbol indicates the risk of

electrical shock.

Safety Symbols Key

In this operator’s manual and on the product, safety

symbols and signal words are used to communicate

important safety information. This section is provided

to improve understanding of these signal words and

symbols.

indicates a hazardous situation which, if not avoided,

WILL result in death or serious injury.

indicates a hazardous situation which, if not avoided,

COULD result in death or serious injury.

indicates hazards or unsafe practices which, if not

avoided, MAY result in injury or property damage.

This is the safety alert symbol. It is

used to alert you to potential personal

injury hazards. Obey all safety

messages that follow this symbol to

avoid possible injury or death.

www. .com information@itm.com1.800.561.8187

TAG-200X & TAG-200XMR

52093091 REV 004© 2021 Greenlee Tools, Inc.

• Use the correct accessories for your application.

Use of the wrong or underrated accessories

increases the risk of injury and tool damage.

• Stay alert, watch what you are doing and use

common sense when using this tool. Do not

use tool while you are tired or under the inuence

of drugs, alcohol or medication. A moment of

inattention could result in serious injury or death.

• Do not allow another high voltage conductor,

or grounded point to contact the tool housing

during use. Keep the housing clear of all

conductors. Always maintain proper high voltage

work clearances.

• Do not use the detector at voltages outside

of its designed range. Testing outside of the

specied range will result in a false reading or

no reading at all and could lead to a hazardous

situation. Consult the product label for the specic

ranges for the unit supplied.

• Confirm proper operation before and after each

use to reduce the risk of injury due to false

readings. False readings could lead to a hazardous

situation and increases the risk of severe injury or

death.

• Do not overreach. Always keep proper footing and

balance, this enables better control of the tool in

unexpected situations.

• Keep tools clean and in good condition. A dirty

or damaged tool increases the risk of false readings

and increases the risk of electrical shock.

Tool Specific Safety Information

Safety is essential in the use and maintenance of

Greenlee tools and equipment. This instruction manual

and any markings on the tool provide information for

avoiding hazards and unsafe practices related to the

use of this tool. Observe all the safety information

provided in this manual.

Before operating this tool, read and understand:

• This operator’s manual

• The instructions for any other equipment or

material used with this tool

• Markings on the tool

• Required worksite safety procedures

Failure to follow all instructions and warnings may

result in serious injury or death.

• Only a person trained in working around and

on high voltage electric systems should use

this tool. The voltages these instruments operate

around are to be considered live and dangerous

and are lethal. Severe injury or death can occur if

improperly used.

• Always follow proper high voltage procedures,

including use of personal protective equipment,

when working near or around high voltage

equipment or conductors.

• Always use hot sticks when using this tool.

Follow rigorous hot stick work practices to reduce

the risk of injury or death from electric shock or arc

ash.

• Do not touch any part of the detector while it is

in contact with high voltage. The tool should be

considered as at the same voltage as the conductor

under test. Maintain proper high voltage work

clearances.

• Do not let familiarity gained from frequent use

of these tools allow you to become complacent

and ignore tool and work site safety principles.

A careless action can cause severe injury or death

within a fraction of a second.

• Use this tool for the manufacturer’s intended

purpose only. Use other than what is instructed in

this manual could result in a hazardous situation.

www. .com information@itm.com1.800.561.8187

TAG-200X & TAG-200XMR

552093091 REV 00 © 2021 Greenlee Tools, Inc.

Tool Description & Features

The TAG-200X and TAG-200XMR Voltage Detectors are designed to detect line voltage on distribution lines within a

range of operating voltages.

The TAG-200X Voltage Detector is a single range voltage detector with one range of operating

voltages set within the unit.

The TAG-200XMR Voltage Detector is a multi-range voltage detector that can be set for up to three

operating voltage levels.

Features

• Higher voltage levels can be set so the level is no more than three times (e.g. 4kV to 12 kV and 35kV) the

previous voltage setting.

• Specic voltages are chosen by the customer before delivery for the minimum and maximum ratings of the unit.

The on-product markings will show the specic voltage range settings of the unit.

• An audible alarm and red LEDs indicate voltage detection within range of the unit settings.

• The All-Check self-test feature provides a full test of the battery, the electronic circuitry and the audible and

visual alarm.

• A universal spline and shotgun connection for hot sticks is built into the polycarbonate housing.

Specifications

Dimensions.............................................................................10 in. x 2.5 in. x 3.7 in. (25.4 cm x 6.4 cm x 9.4 cm)

Weight ............................................................................................................................................0.86 lb (0.39 kg)

Buzzer Noise Level............................................................................................................................103 dB @ 2 ft.

ENVIRONMENTAL CONDITIONS

Operating Temperature................................................................................................5°F to 120°F (-15°C to 49°C)

Enclosure Material............................................................................................................. Polycarbonate UL94V-2

Printed Circuit Board.........................................................................................................................FR-4 UL94V-0

Environmental Conditions ................................................................................................. Indoor and Outdoor use

Humidity .................................................................................................................95% to 49°C (non-condensing)

ELECTRICAL SPECIFICATIONS

Minimum Voltage Setting ...............................................................................................4kV (2.4kV line-to-ground)

Maximum Voltage Setting .............................................................................................69kV (40kV line-to-ground)

Operating Frequency.................................................................................................................................. 50/60Hz

Check on product markings for the specific ranges of the unit.

BATTERY

Battery.................................................................one 9V Alkaline 1604A, IEC 6LR61 or Lithium 9V ANSI-1604LC

Battery Life (Alkaline)................................................................................................ 10 hrs. Continuous Operation

Battery Life (Lithium).................................................................................. .............. 16 hrs. Continuous Operation

Battery life with typical usage .................................................................................................................... 1 month

All specifications are nominal and may change as design improvements occur.

www. .com information@itm.com1.800.561.8187

TAG-200X & TAG-200XMR

52093091 REV 006© 2021 Greenlee Tools, Inc.

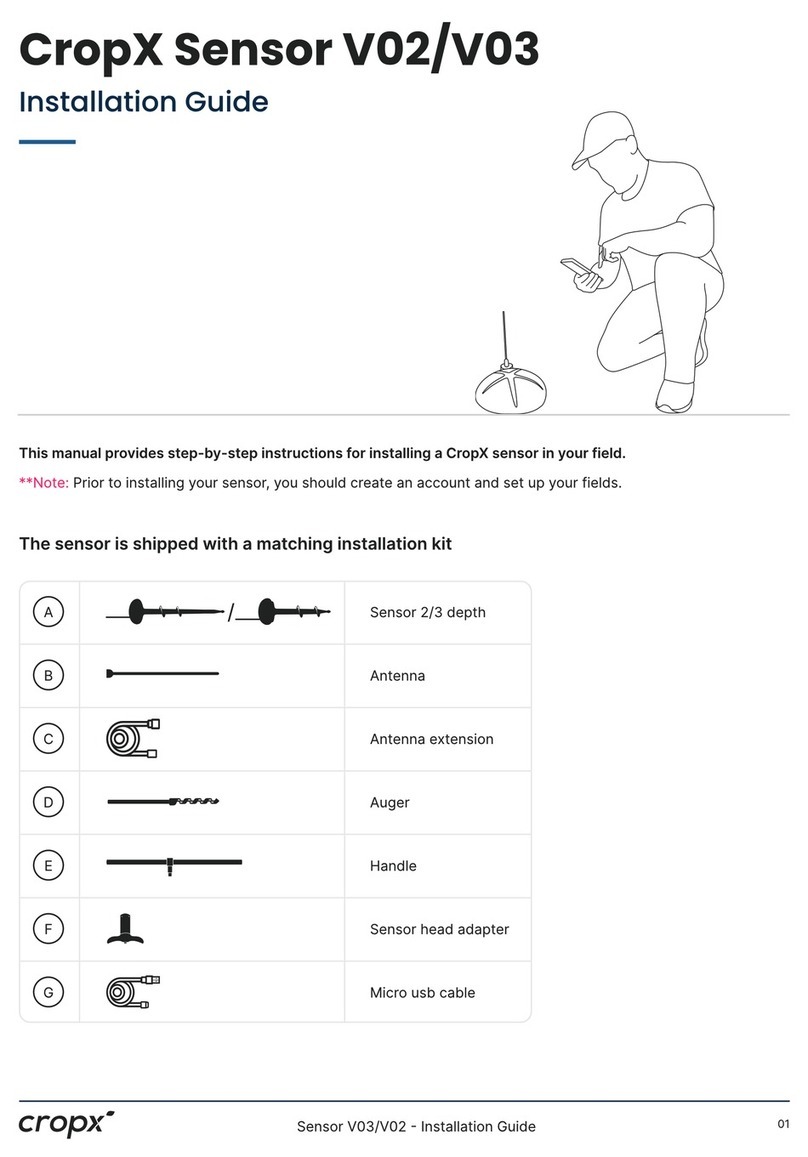

Tool Identification

1. Outer Housing

2. Carrier

3. Electronic Sub-Assembly

4. Probe Connection

5. Universal Spline (Hot Stick Attachment)

6. Battery Holder

7. Locking Pin

8. Buzzer

9. Test Button

10. ON / Good Battery LED (Green)

11. Voltage Indicator LEDs (Red)

12. 9V Battery (Alkaline/Lithium)

7

3

6

2

A

11

5

4

B

9

11

8C

10

1

12

www. .com information@itm.com1.800.561.8187

TAG-200X & TAG-200XMR

752093091 REV 00 © 2021 Greenlee Tools, Inc.

Frequency:

Part Number:

Serial Number:

Twist to Open

Climate Category: N

Outdoor Type

Group: 3

Production Date:

Calibration Date:

50/60Hz

07/20 520XXXXX REV 0

MULTI-RANGE

SINGLE-RANGE

4kV

12kV

35kV

12kV-35kV

To reduce the risk of severe injury or death from electric shock or arc flash

· Read instructions

· Users must be properly trained for work on high voltage systems

· Always use a hot stick

· Keep housing clear of conductors

· Do not touch detector when near high voltage

Greenlee Tools, Inc.

Southaven, MS U.S.A.

www.Greenlee.com

9V alkaline or lithium batteries only

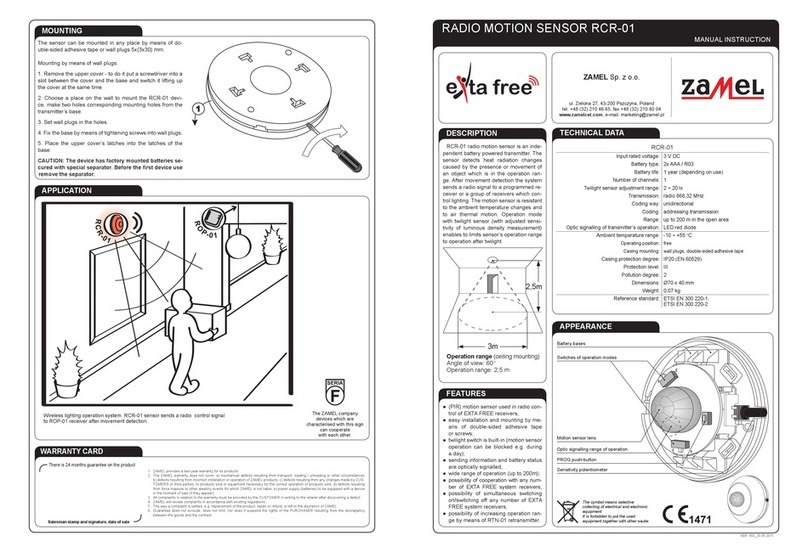

Decals & Locations

A. Safety and Product Information Decal

B. Detector Threshold Decals

C. User Panel Overlay

A.

C.

B.

www. .com information@itm.com1.800.561.8187

TAG-200X & TAG-200XMR

52093091 REV 008© 2021 Greenlee Tools, Inc.

Training & Qualifications

This product is designed for use by professionals

trained for working on and around high voltage electrical

equipment. If you are not trained in the work methods

required for safe operation, do not use this product.

It is recommended at least a second trained and

qualied person is present at appropriate distance to

respond if needed.

Follow all training and proper jobsite safety precautions

outlined by your industry, government and employer.

Make certain all other safety considerations have been

identied, implemented and are in place prior to using

this equipment.

Pre-Operation Inspection & Set-up

• Always use hot sticks when using this tool.

Follow rigorous hot stick work practices to reduce

the risk of injury or death from electric shock or arc

ash.

• Use the correct accessories for your application.

Use of the wrong or underrated accessories

increases the risk of injury and tool damage.

• Always follow proper high voltage procedures,

including use of personal protective equipment,

when working near or around high voltage

equipment or conductors.

• Confirm proper operation before and after each

use to reduce the risk of injury due to false

readings. False readings could lead to a hazardous

situation and increases the risk of severe injury or

death.

Check for damage and any other condition that may

affect the tool’s operation. Do not use this product if it

is damaged or not working as expected. Remove from

service and arrange for repair or replacement before

use. Many accidents are caused by poorly maintained

tools. A dirty or damaged detector increases the risk of

false readings.

1. Check that the detector and probes are clean and

dry before using.

2. Check housing and probes for damage such as

cracks, distortion in the case or probe and burns.

3. Identify the correct probe for the application and

make sure it is screwed rmly in place at the end of

the detector. Do not over-tighten. The probe will be

more difcult to remove.

CATALOG # VISUAL DESCRIPTION

TAG-42029X OVERHEAD Y PROBE

SMALL, TAG

TAG-41811X

OH STRAIGHT

SHORT PROBE,

TAG

TAG-200X Overhead Probes

For underground distribution (UG) and metal-enclosed

switchgear, use underground probes. Insert the probe

directly into the bushing, keep probe clear of all

surrounding surfaces. (See Page 11 - TAG Underground

Probes Table)

4. After assembly, test the TAG Voltage Detector by

using the Self-Test function.

Do not perform the All-Check Self-Test if the TAG

Detector is in contact with a voltage source.

Self-Test

i. Hold detector securely, looking at the User

Panel.

ii. Push and hold the TEST button. The red LEDs

will ash and the buzzer will sound.

iii. After releasing the TEST Button, a successful

test will show the green LED remaining ON

while the red LEDs and buzzer turing OFF.

The green LED will stay ON for approximately

three (3) minutes following the most recent

activity and will turn Off if the device remains

idle.

If holding the test button does not cause the

red and green LEDs to light and the buzzer

to sound, check the battery and change if

necessary. Repeat the Self-Test.

If the unit still doesn’t show the actions

described above, remove the unit from service

and send it for repair. Do not use the detector if

it does not pass the Self-Test.

5. After conrming completion of the self-test,

continue to hold the detector using the spline or

hot stick to test the fully assembled TAG Voltage

Detector on a known voltage source, such as the

PT-DET Proof Tester Voltage Detector Tester, before

using the detector on an unknown voltage source.

For overhead applications use the Y probe:

www. .com information@itm.com1.800.561.8187

TAG-200X & TAG-200XMR

952093091 REV 00 © 2021 Greenlee Tools, Inc.

Tool Operation

• Do not touch any part of the tool while it is in

contact with high voltage. The tool should be

considered as at the same voltage as the conductor

under test.

• Do not allow another high voltage conductor,

or grounded point to contact the tool housing

during use. Keep the housing clear of all

conductors. Always maintain proper high voltage

work clearances.

• Do not use the detector on voltages outside

of its designed range. Testing outside of the

specied range will result in a false reading or

no reading at all and could lead to a hazardous

situation. Consult the product label for the specic

ranges for the unit supplied.

• Do not overreach. Always keep proper footing and

balance, this enables better control of the tool in

unexpected situations.

• OPPOSITE PHASE INTERFERENCE: This

condition may occur if you are testing a

grounded and de-energized conductor which

is close to a live, ungrounded conductor. When

applying the TAG Detector, attempt to approach

the conductor you want to test from outside

this possible eld. If you are within the eld of

the energized conductor, the TAG Detector may

indicate that the de-energized line is energized

due to induced current.

Choose where on the conductor the detector will be

used avoiding the previously mentioned situations.

2. Place the TAG Detector in direct metal-to-metal

contact with the conductor being tested for voltage.

The TAG Voltage Detector should be positioned

as close to a 90° orientation (perpendicular) to the

conductor as possible.

• If the conductor is energized within the range of

the detector, there will be both an audible sound

and the red lights will turn On.

• If the conductor is not energized no red lights will

show, the green LED from the Self-Test may still

be on if it is within 3 minutes from the Self-Test.

• The TAG will not give an alarm due to induced

voltage on de-energized conductors, unless the

induced voltage level exceeds the threshold

voltage of the detector.

3. Repeat the Self-Test. If the unit doesn’t pass the

Self-Test after testing the line, remove the unit from

service and send it for repair. Do not assume the

test results from that TAG Voltage Detector are

correct. Retest the conductor with a different TAG

Voltage Detector.

1. Inspect job site and conrm you have the right

tools for the job. Avoid these situations where false

readings may occur.

• 90° CORNER CONFIGURATIONS: Conductor

congurations, busbar and other electrical

apparatus all apply. Reposition the TAG

Detector to at least 3 feet (1 m) on both sides

of the 90° corner conguration and attempt to

retest.

• SAME PHASE INTERFERENCE: When two

conductors of the same phase are close to

each another, the eld generated could shield

the TAG Detector, causing it not to operate.

Reposition the TAG Detector to areas outside of

this eld.

6. Securely attach the detector to the appropriate hot

stick, if it is not already attached, using the built-in

universal spline. Company, government and industry

hot stick safety procedures must be followed at all

times.

If any issues are found, do not use this tool until xed.

www. .com information@itm.com1.800.561.8187

TAG-200X & TAG-200XMR

52093091 REV 0010 © 2021 Greenlee Tools, Inc.

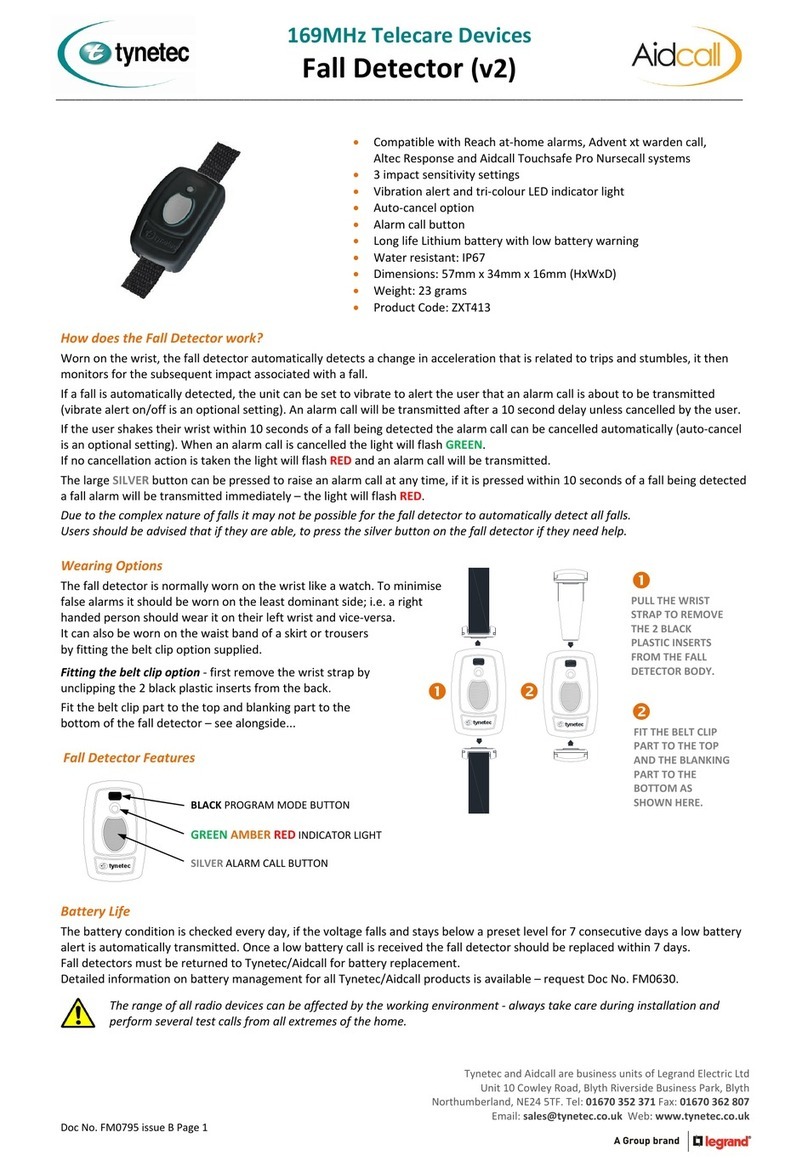

Batteries should be changed on a regular schedule,

and it is recommended the battery be changed every 6

months.

1. Pull out and rotate the locking pin

90 degrees to lock it in the “out”

position. (Fig. 2)

2. Withdraw the electronic sub-

assembly by pulling down on the

carrier.

3. Remove the existing battery and

replace it with a fresh 9V battery.

When inserting battery into

housing, make certain that the

polarity is correct. (Fig. 3) Figure 2

4. Push the electronic sub-assembly back into

the outer housing. Turn the locking pin until it

snaps back into a “closed” position to secure the

assembly.

Cleaning

Use a silicone impregnated cloth to clean housing prior

to use in order to maintain the surface.

Changing the Battery

Maintenance

• Do not perform any maintenance other than

as described in this manual. Personal injury or

damage to the tool may result.

• Do not modify this tool. Modifying the tool in any

manner may result in personal injury and damage to

the tool.

• Do not attempt to open the tool except to change

the battery. It contains no user-serviceable parts

• Do not touch the testing surface to reduce the

risk of electric shock.

• Do not use this tester except as directed to

reduce the risk of injury.

• Do not apply to energized circuits or equipment.

This tester could cause a short and cause injury.

• Do not operate this tester if housing is cracked

or without the battery cover to reduce the risk

of injury.

• Do not attempt to open the tool except to change

the battery. It contains no user-serviceable parts.

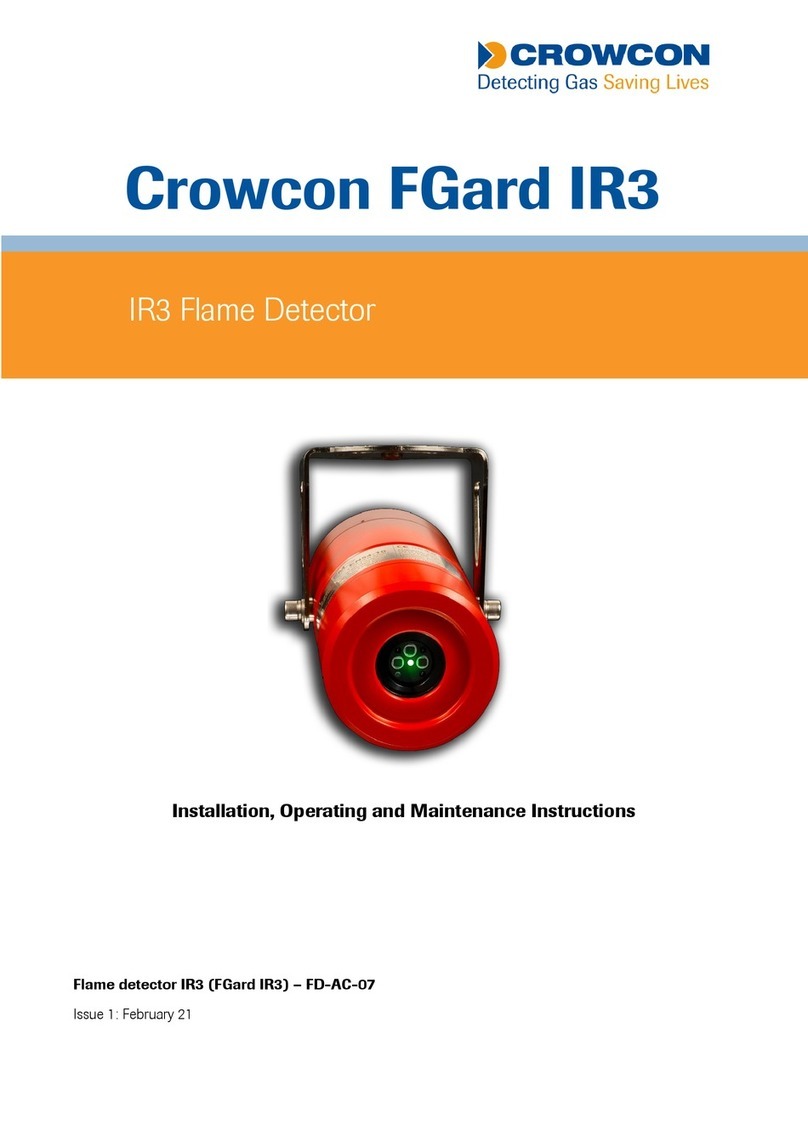

PT-DET Proof Tester

The PT-DET Proof Tester Voltage Detector Tester (Fig.

1) generates a high voltage AC for testing theTAG-200X

and TAG-200XMR Voltage Detectors only, up to and

including 69kV.

1. Hold the Tester in one hand and the TAG Detector in

the other hand by the spline or hot stick.

2. While touching the TAG Detector probe to the metal

end plate on the Tester, press and hold the TEST

button on the Tester. A properly operating TAG

Detector will signal the presence of voltage with

both a beeper and ashing lights.

If the Tester or Detector lights do not light, replace

the battery with a 9V lithium or alkaline type battery

of the unresponsive unit and try again.

Figure 1

Storage

It is recommended to store the TAG-200X and

its accessories in the carrying case provided. If a

prolonged period of storage is anticipated (six or more

months), remove the battery. Replace with a new battery

prior to using the TAG-200X again after a long time in

storage.

Figure 3

www. .com information@itm.com1.800.561.8187

TAG-200X & TAG-200XMR

1152093091 REV 00 © 2021 Greenlee Tools, Inc.

Every twelve months the TAG Voltage Detector should

be sent for inspection, cleaning, and function evaluation.

If needed, the unit will be recalibrated. This should be

done at a factory trained repair facility, the HDE factory,

or other qualied location.

If any repairs are required before recommended service,

contact Greenlee’s Customer Service.

• Tool service must be performed only by qualified

repair personnel. Service or maintenance

performed by unqualied personnel could result in a

risk of injury.

• When servicing a tool, use only identical

replacement parts. Use of unauthorized parts or

failure to follow maintenance instructions may create

a risk of electric shock or injury.

Service

Disposal

Parts of these tools contain valuable materials and

can be recycled. There are companies that specialize

in recycling that may be found locally. Dispose of

the components in compliance with all applicable

regulations. Contact your local waste management

authority for more information.

For EU Countries: Do not dispose of

electrical equipment with household

waste! According to the European

Guideline 2012/19/EU for Waste Electrical

and Electronic Equipment and its

implementation into national legislation,

electrical equipment that is no longer

usable must be collected separately and

disposed of in an environmentally correct

manner.

TAG Underground Probes

P/N CATALOG # DESCRIPTION

IEP-UD/C

PROBE FOR 15KV AND 25kV

LOADBREAK BUSHINGS.

IEP-EA/C

PROBE FOR 15KV AND 25KV

LOADBREAK ELBOWS

IEP-EA/C-35

PROBE FOR LARGE INTERFACE

35KV LOADBREAK ELBOWS.

IEP-TAG-EXT

EXTENSION PROBE FOR DIRECT

CONTACT WITH BARE LIVEFRONT

SWITCHGEAR

ASP-15/25 with

IEP-UDP

PROBE FOR 15KV AND 25KV

LOADBREAK BUSHINGS.

REQUIRES IEP-UDP ADDAPTER

TO USE.

www. .com information@itm.com1.800.561.8187

This manual suits for next models

16

Table of contents

Other HDE Security Sensor manuals

Popular Security Sensor manuals by other brands

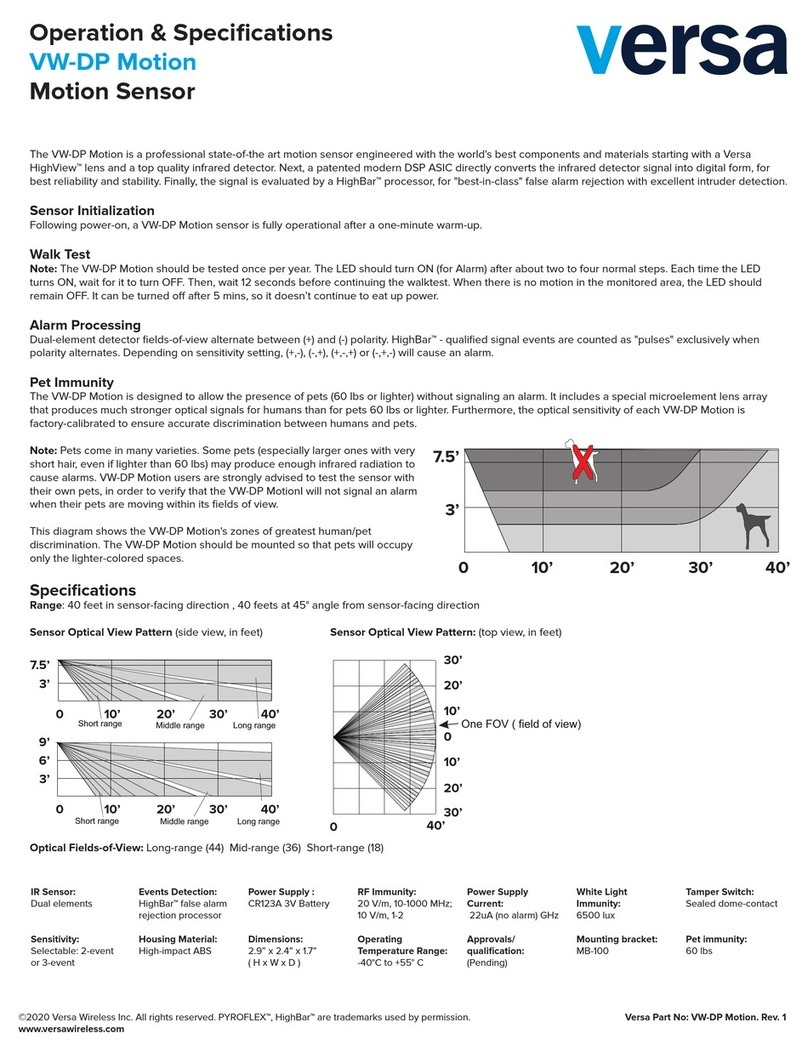

versa

versa VW-DP Motion Operation & Specifications

PCB Piezotronics

PCB Piezotronics HT352B01 Installation and operating manual

REI

REI ORION HX quick start guide

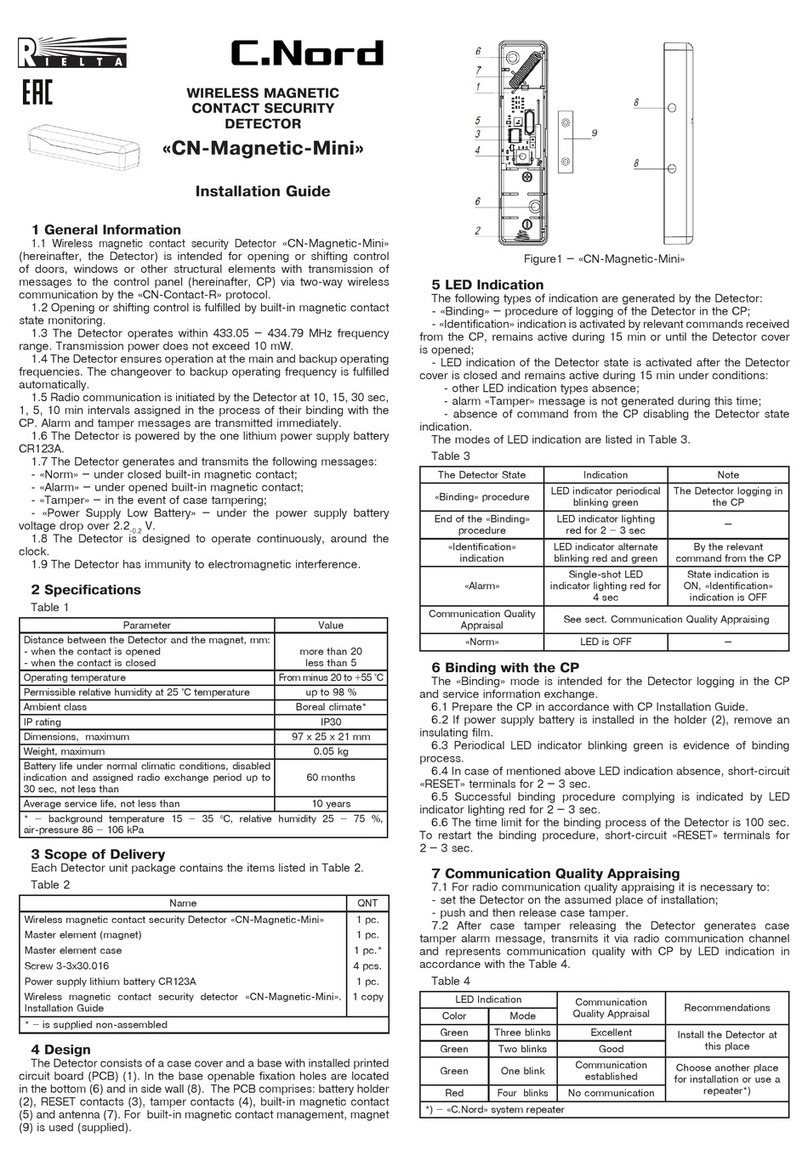

C.Nord

C.Nord CN-Magnetic-Mini installation guide

no-flame

no-flame 83197 instruction manual

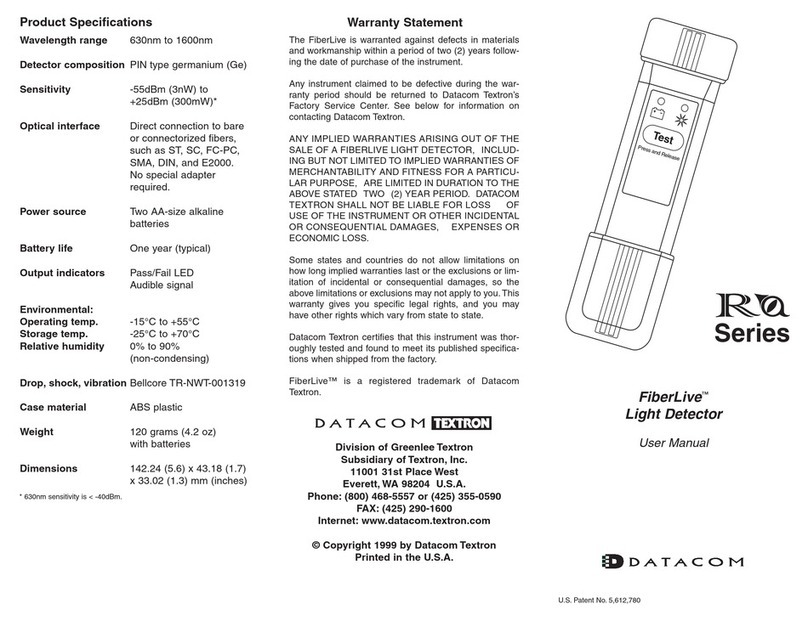

DATACOM TEXTRON

DATACOM TEXTRON FiberLive R Series user manual