Healthmark 64-20810-00 User manual

Instructions for Use: Stainless-Steel Spray Gun

Brand Name of Product

Stainless-Steel Spray Gun

Generic Name of Product

Spray Gun

Product Code Number(s)

64-20810-00

Purpose of Product

For cleaning an item with water or air.

Range of Applications for Product

N/A

Key Specifications of Product

Stainless-steel construction.

Variable flow control.

Easily swap tips for different applications.

316 / 316L Stainless steel.

Technical data:

oMedium: Oil-free compressed air/cold de-ionized water

oMax pressure: 0.5 MPa (5 bar or 72.5 psi).

Shipping & Storage

Shipping Conditions &

Requirements

N/A

Storage Conditions

N/A

Packaging Contents

N/A

Shelf Life

N/A

Instructions for Using Product

Description of Use(s)

For rinsing of items; particularly, the internal channels.

Preparation for Use

A trained specialist must install the cleaning gun unit in accordance with the guidelines

applicable depending on the intended use.

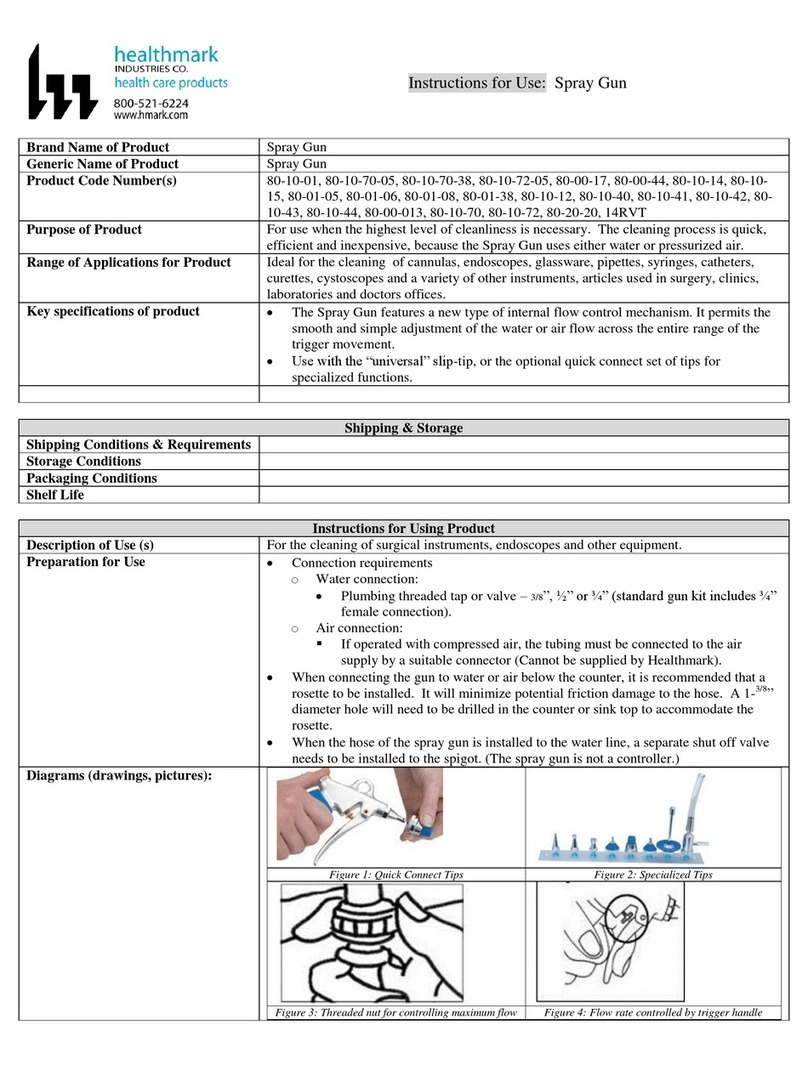

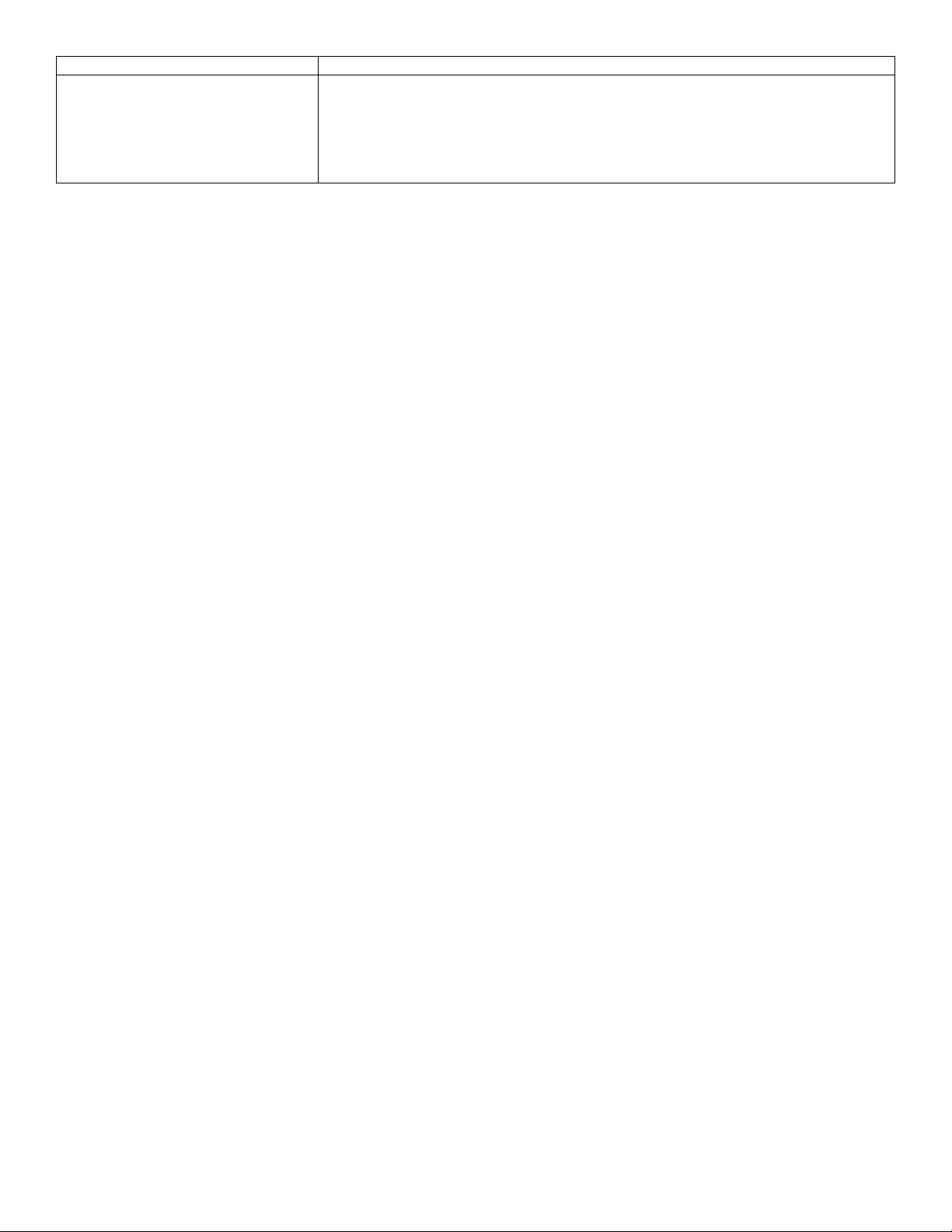

Diagrams (drawings, pictures)

Spray Gun

Coupling Protection Cap

Nozzle

Nozzle Cap

Gun handle for

quick-lock

coupling – DN7.2

Piston

Body of Gun

Piston Spring

End Cap

Document

Version

2

Hose End Cap

Steps for Use of Product

1. Prior to operation, the user must make sure attachments are correctly

seated on the safety conell by firmly pushing them onto the Spray Gun rinse tip.

a. ⚠Caution: Do not point the spray gun at parts/orifices of the body

because the compressed water or air jet may be harmful.

b. Depending on the field of application, suitable safety measures/PPE

(e.g., protective goggles, protective mask, etc.) must be taken to protect

the user from splashes of contaminated water.

2. If required, the maximum water or air pressure value can be set by using the

small threaded nut located behind the trigger handle.

3. Flow is controlled by pulling the trigger up to the maximum set point fixed by

the threaded nut.

Interpretation of Results

N/A

Contraindications of Test Results

N/A

Documentation

N/A

Special Warnings and Cautions

The enclosed silicone oil is not sterile.

Oils containing white oil or paraffin oil will damage the O-rings.

If tubing other than that supplied by Healthmark is used, the facility should

independently verify the safe and effective performance of that tubing. In such a

case, the facility assumes the liability for operation of the Spray Gun.

Warranty claims will only be honored for components purchased from

Healthmark.

The Spray Gun is not a medical product and should not be used as part of

medical treatments.

⚠Caution: Do not point the spray gun at parts/orifices of the body because the

compressed water or air jet may be harmful. Wear proper PPE according to

facility and industry guidelines.

Disposal

N/A

Reprocessing Instructions

Point of Use

N/A

Preparation for Decontamination

(After instrument parts are completely cleaned and dried) check the parts for possible

defects.

Perform sterilization in a single, transparent sterilization package.

Disassembly Instructions

N/A

Cleaning – Manual

N/A

Cleaning – Automated

1. Pre-cleaning: Cleaning agents for Spray Gun parts should be neutral detergent.

Clean the parts in the cleaning solution with a soft brush and by fully immersing

them into the liquid to remove all visible contamination.

2. Ultrasonic cleaning: This is imperative!

a. Cleaning agents for instruments: Depending on the level of

contamination 1–3%.

b. Duration of ultrasonic cleaning: 15 minutes.

c. Water temperature: room temperature, but not exceeding 40 ℃.

d. The ultrasonic device must be suitable for the cleaning of medical

instruments and should have a frequency of 35–40 kHz.

e. The cleaning duration is to be extended when devices with a higher

frequency are used.

f. All instrument parts must be fully immersed in the cleaning solution

and all hollow spaces must be filled.

g. Ultrasonic baskets may not be overloaded as this could lead to

acoustical shadows and the cleaning effect could not be guaranteed!

3. Rinsing: Remove all chemical residues with water which is free from pathogenic

germs.

4. Drying: Dry all parts with a lint-free cloth and medical compressed air. Check

the cleaning effect.

Disinfection

N/A

Drying

Dry all parts with a lint-free cloth and medical compressed air. Check cleaning and

drying.

Document

Version

2

Maintenance, Inspection, and

Testing

Assembly of Spray Gun

1. Lubricate the front end of the piston and the small piston O-ring with pure

silicone oil prior to the assembly.

a. Use only minimal lubrication.

b. If you insert the dry piston, the piston seal will be damaged.

2. Insert the piston into the Spray Gun body.

3. Position the piston spring onto the piston and screw the end cap to the gun body.

4. Screw the nozzle cap to the front of the gun body, and screw the desired nozzle

into the nozzle cap.

5. Screw the gun handle into the gun body as far as it will go.

6. (If it is difficult to insert it into or remove it from stainless-steel coupling), oil

the plug nipple of the handle DN7.2 with pure silicone oil.

Disassembling the cleaning gun:

1. Disassemble the endcap from the body of the gun by turning it

counterclockwise.

2. Remove the piston spring.

3. Pull trigger back and pull the piston out backwards.

4. Loosen nozzles from nozzle cap by turning them counterclockwise.

5. Disassemble the nozzle cap from the body of the gun by turning it

counterclockwise.

6. Disassemble the handle from the body of the gun by turning it counterclockwise.

7. Disassemble the shower nozzle sieve from the shower nozzle body by turning it

counterclockwise.

Reassembly of the cleaning gun to the gun coupling:

1. Introduce the gun handle with coupling plug DN7.2 straight into the gun

coupling and press it in until it audibly engages into position.

2. Open the pressure supply line.

3. Check the whole system for leakage.

Dismounting the cleaning gun from the gun coupling:

1. If you want to dismount the cleaning gun from the coupling, again, for

reprocessing, you must interrupt the pressure supply.

2. Relieve the pressure in the hose by activating the gun trigger.

3. (After pressure is relieved), press the gun handle into the coupling and

simultaneously pull the sliding ring and top of coupling down toward the hose,

and pull the gun out of the coupling.

4. Put the sterile coupling protection cap over the gun coupling.

5. The hose must be stored in such a way that it does not come into contact with

liquids and cannot be contaminated.

6. Clean and sterilize the coupling protection cap the same way as the cleaning

gun parts.

Maintenance

It is recommended to decalcify the Spray Gun approximately every four (4)

weeks.

a. Disassemble the Spray Gun and place its inner parts in an approved

decalcifying agent.

b. This is beneficial for the service life and reliability of the Spray Gun.

If it is difficult to remove the cg piston from the gun body or insert it into the

gun body, then you must replace the small O-ring for the cg piston.

Replacement parts and instructions for repair are available from Healthmark.

Reassembly Instructions

N/A

Packaging

N/A

Sterilization

N/A

Storage

N/A

Additional Information

Caution: Oils containing white oil or paraffin oil will damage the O-rings.

Related Healthmark Products

N/A

Other Product Support Documents

N/A

Document

Version

2

Reference Documents

ProSys™ Brochure, ProSys™ Price List

Customer Service Contact

Healthmark Industries Company, Inc.

18600 Malyn

Fraser, MI 48026

1-586-774-7600

hmark.com

2023-01-03 msmith

Document

Version

2

Other Healthmark Paint Sprayer manuals