Instructions for Use: Spray Gun

80-10-01, 80-10-70-05, 80-10-70-38, 80-10-72-05, 80-00-17, 80-00-44, 80-10-14, 80-10-

15, 80-01-05, 80-01-06, 80-01-08, 80-01-38, 80-10-12, 80-10-40, 80-10-41, 80-10-42, 80-

10-43, 80-10-44, 80-00-013, 80-10-70, 80-10-72, 80-20-20, 14RVT

For use when the highest level of cleanliness is necessary. The cleaning process is quick,

efficient and inexpensive, because the Spray Gun uses either water or pressurized air.

Range of Applications for Product

Ideal for the cleaning of cannulas, endoscopes, glassware, pipettes, syringes, catheters,

curettes, cystoscopes and a variety of other instruments, articles used in surgery, clinics,

laboratories and doctors offices.

Key specifications of product

The Spray Gun features a new type of internal flow control mechanism. It permits the

smooth and simple adjustment of the water or air flow across the entire range of the

trigger movement.

Use with the “universal” slip-tip, or the optional quick connect set of tips for

specialized functions.

Shipping Conditions & Requirements

Instructions for Using Product

For the cleaning of surgical instruments, endoscopes and other equipment.

Connection requirements

oWater connection:

Plumbing threaded tap or valve –3/8”, ½” or ¾” (standard gun kit includes ¾”

female connection).

oAir connection:

If operated with compressed air, the tubing must be connected to the air

supply by a suitable connector (Cannot be supplied by Healthmark).

When connecting the gun to water or air below the counter, it is recommended that a

rosette to be installed. It will minimize potential friction damage to the hose. A 1-3/8”

diameter hole will need to be drilled in the counter or sink top to accommodate the

rosette.

When the hose of the spray gun is installed to the water line, a separate shut off valve

needs to be installed to the spigot. (The spray gun is not a controller.)

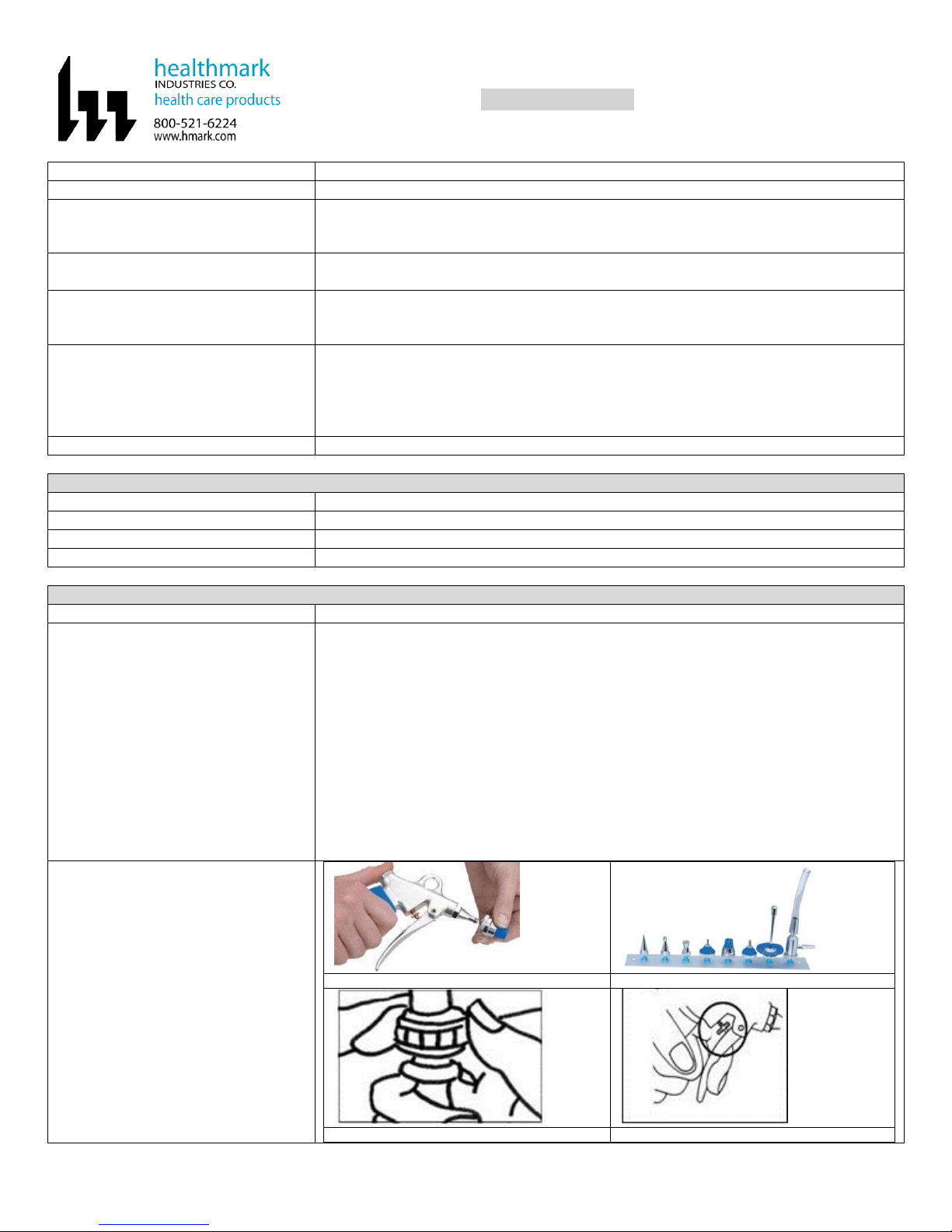

Diagrams (drawings, pictures):

Figure 1: Quick Connect Tips

Figure 2: Specialized Tips

Figure 3: Threaded nut for controlling maximum flow

Figure 4: Flow rate controlled by trigger handle