Contents

Original operation manual AIRCOMBI 3

AirCombi_BAoDB_en_1701 • rs

Contents

1 Foreword....................................................................................................7

2 Safety .........................................................................................................8

2.1 Explanation of symbols............................................................................8

2.2 Safety notes...........................................................................................10

2.2.1 Operating pressure ......................................................................10

2.2.2 Risks caused by the spray jet ......................................................10

2.2.3 Hazard from electrostatic charging .............................................. 11

2.2.4 Hazards from hot or cold surfaces............................................... 11

2.2.5 Explosion protection ....................................................................12

2.2.6 Health risks ..................................................................................13

2.3 Safety signs ...........................................................................................13

2.4 Safety features ......................................................................................14

2.4.1 Safety valve .................................................................................14

2.4.2 Compressed air shut-off valve .....................................................15

2.4.3 Ground cable ...............................................................................15

2.5 Operating and maintenance personnel .................................................16

2.5.1 Machine owner's duties ...............................................................16

2.5.2 Personnel qualication.................................................................16

2.5.3 Authorized operating personnel ...................................................16

2.5.4 Personal Protective Equipment ...................................................16

2.6 Notes on warranty .................................................................................17

2.6.1 Conversions and alterations ........................................................17

2.6.2 Spare parts ..................................................................................17

2.6.3 Accessories..................................................................................18

2.7 Emergency procedures .........................................................................18

2.7.1 Stop the machine and release the pressure................................18

2.7.2 Leakages .....................................................................................18

2.7.3 Injuries .........................................................................................18

3 Machine Description...............................................................................19

3.1 Intended use..........................................................................................19

3.2 Erroneous use .......................................................................................20

3.3 Machine design .....................................................................................20

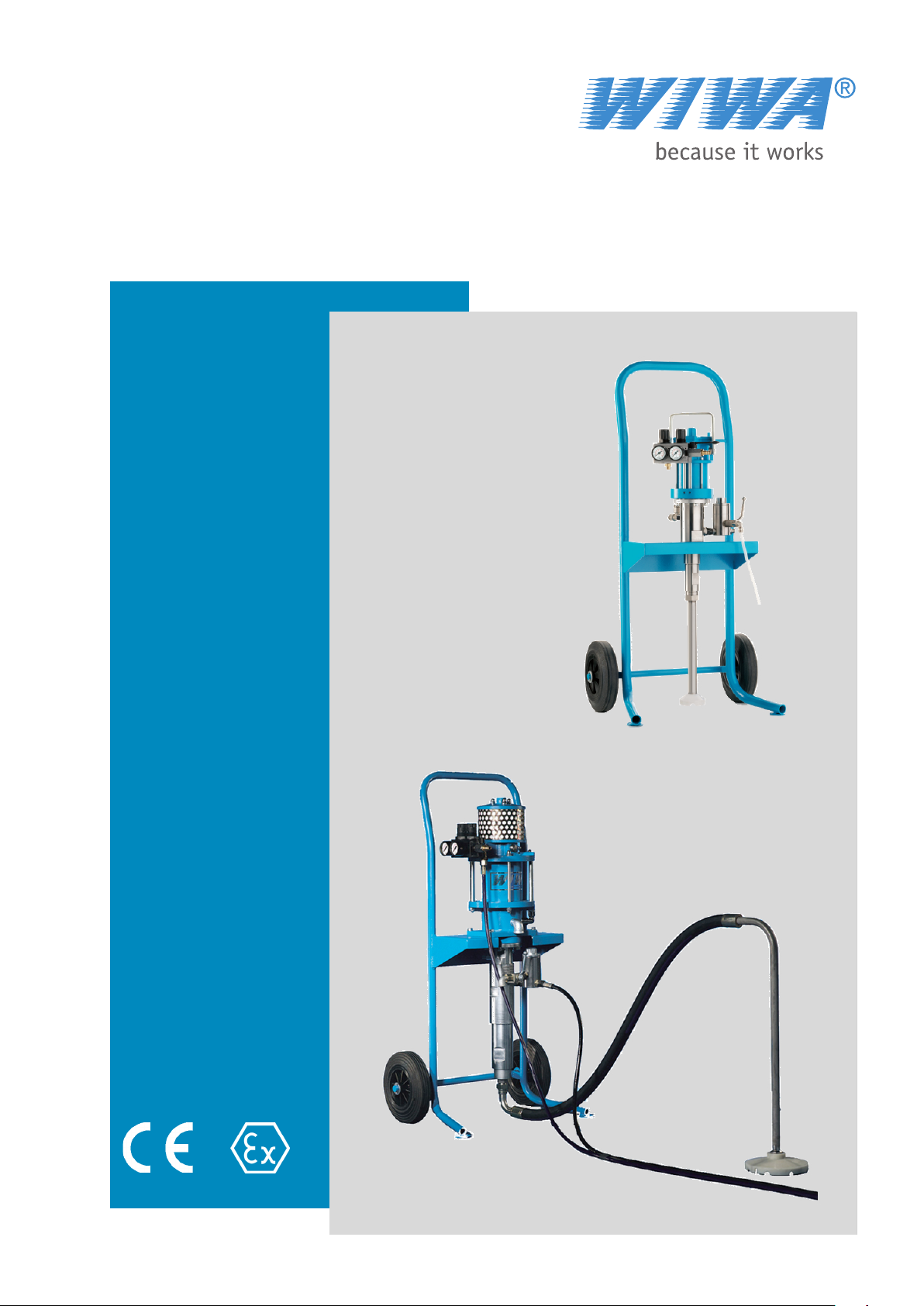

3.3.1 PROFIT series .............................................................................21

3.3.2 PHOENIX series ..........................................................................22

3.4 Dual air regulator ...................................................................................23

3.5 Maintenance unit ...................................................................................24

3.6 Optional expansion parts and accessories............................................25

3.6.1 AirCombi spray gun .....................................................................25

3.6.2 Material uid heater .....................................................................25

3.6.3 Agitator.........................................................................................25