Healthy Climate HEPA Bypass Air Filtration Systems HEPA-20 User manual

INDOOR AIR QUALITY

KIT AND ACCESSORIES

504887-01

10/2021

Supersedes 3/2021

HEALTHY CLIMATE®

HEPA BYPASS AIR FILTRATION

SYSTEM

INSTALLATION INSTRUCTIONS AND HOMEOWNER GUIDE FOR HEALTHY CLIMATE®

MODELS HEPA-20, HEPA-40 and HEPA-60

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, personal injury

or loss of life.

Installation and service must be performed by a licensed

professional HVAC installer (or equivalent) or a service

agency.

Rules for Safe Installation and Operation

Please read instructions before installing and using the

HEPA Bypass Air Filtration System (HEPA system). This

will help you obtain the full benet of the HEPA system you

have selected. It will also help you to avoid needless ser-

vice costs.

1. Read this manual carefully. Failure to follow these rules

and instructions could cause a malfunction of air filter

or unsatisfactory service and could void your warranty.

2. Follow a regular service and maintenance schedule

to ensure ecient operation.

3. For safety and optimized performance of your HEPA

system, all installation and maintenance must be

performed by a Healthy Climate®dealer. The installer

should be made aware of your indoor air quality

situation and be familiar with your heating, ventilation

and air conditioning equipment.

4. Remove HEPA cartridge packing materials before initial

start-up of this product.

a. Remove safety screws from HEPA lter access

panel.

b. Unlatch the four retaining clips and lift o HEPA lter

access panel.

c. Remove and discard the cardboard packing material

between the HEPA cartridge and the lter access

panel.

d. Ensure HEPA cartridge is installed and locked into

place (brace the unit, press HEPA cartridge down

and turn it clockwise to lock it into place.)

e. Replace the HEPA lter access panel and latch it

with the four retaining clips.

f. Re-install safety screws into HEPA lter access

panel.

5. High particulate distribution may occur during initial

start-up of this product after installation or after

scheduled lter changes. Individuals who are highly

sensitive to airborne particulates should not be in the

building and allow 24 hours of operation for removal of

particulates from occupied spaces before re-entry.

Shipping and Packing List

Package 1 of 1 contains:

1 - HEPA System

1 - Complete Filter Set (Packed inside Unit)

1 - Warranty Certicate

1 - Installation Instructions (this manual)

HEPA System Models

HEPA-20 (X4912) is designed to lter air up to a rate of

180 cfm

HEPA-40 (X4913) is designed to lter air up to a rate of

320 cfm

HEPA-60 (X4914) is designed to lter air up to a rate of

660 cfm

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, personal injury

or loss of life.

Installation and service must be performed by a licensed

professional HVAC installer (or equivalent) or a service

agency.

WARNING

Electric Shock Hazard. Can cause injury or death. Unit

must be rounded in accordance with national and local

codes.

Line voltage is present at all components when unit is

not in operation. Disconnect all remote electric power

supplies before opening access panel. Unit may have

multiple power sources.

WARNING

Risk of Carbon Monoxide Poisoning.

Can cause injury or death.

Do not operate equipment without access panel in place.

Operation of this equipment without all access panels in

place may cause gas fumes from the heating system to

be drawn into occupied spaces.

2

Introduction

Congratulations! You will quickly realize that you have pur-

chased a very eective air cleaning system. It incorporates

state of the art HEPA (High Eciency Particulate Air) tech-

nology.

Your HEPA system comes with a limited warranty. With

proper attention to its care and maintenance, you will re-

ceive optimum performance.

If your indoor air has abnormally high concentrations of par-

ticulates, the life span of the lter media may be shortened.

Excessive particulates in the air will reduce the expected

life of the HEPA lter. Under normal conditions the HEPA

lter will last from two to ve years.

The optional activated carbon canister has a nite limit as to

the amount of odor or other gaseous volatile organic com-

pounds (VOCs) that it can adsorb. The higher the concen-

trations, the shorter the expected life. Higher humidity may

shorten the life of the carbon canister. Under normal condi-

tions, the carbon canister will last up to 6 months.

Initially, the HEPA lter’s particulate removal eciency im-

proves with use. However, the air ow through the HEPA

lter media will decrease, as dust builds up on the lter,

thus lowering its ability to circulate and clean as much air

as when it was new. If the air ow through your unit is no-

ticeably reduced, you can inspect the carbon pre-lter and

HEPA lter to see if they should be replaced. Replacement

of the carbon pre-lter every 12 months will help extend the

life of the HEPA lter.

Please contact your local Healthy Climate dealer regarding

replacement of lters, warranty information or if you have

any questions or concerns about the performance of your

HEPA system.

NOTE: This ltration system is an ADDITIONAL

lter, and does NOT replace the existing air

handler/furnace system lter.

To signicantly increase the quality of air in your home,

bringing in FRESH AIR is strongly recommended. Filtering

outdoor air with a HEPA/Carbon lter will remove many of

the containments and irritants from outdoor air.

The HEPA Air Filtration System when used with the LVCS

or HRV/ERV and Dehumidiers will lter ultra-ne particu-

lates, chemicals, odors and other toxins out of the new air

entering the home. Bringing in fresh air that is clean and

ltered will increase the quality of the air in the home. Slight

positive pressurization of the home will prevent unwanted

containments from walls and attics sneaking in! Ask your

Healthy Climate Dealer about installing a system that will

introduce fresh air. “Service and Application Note IAQ-06-

2”.

General Information

Media Filters

Media lters strain particulates from the air. The lter media

needs to have tiny holes to allow air to pass through, but not

particulates. Filter types vary for all sorts of purposes. The

most eective and proven lter media is HEPA. HEPA lter

media is 99.97% ecient at capturing particles which are

0.3 micron in size or larger.

Inner Charcoal Filter/Carbon Canister

Carbon media is used to capture chemicals and odors,

also referred to as VOCs. Chemicals and odors cannot be

captured with media type lters. Activated carbon attracts

chemicals and odors and holds them. If air passes through

the carbon lter before particulates are removed, the sur-

face of the carbon quickly gets covered with particulates,

rendering it ineective at capturing chemicals and odors. If

particulates are removed from the air with a HEPA lter, vir-

tually the entire surface area of the carbon can be used to

capture chemicals and odors. This increases the eciency

and lter life of the inner charcoal lter.

Separate HEPA and Carbon Filters

HEPA and carbon lters have dierent life spans. It is im-

portant for a ltration system to keep the lter components

independent from each other, so that the lter that is dirty/

saturated can be changed. This is more economical than

a system where you need to throw out two or three lters

when only one needs changing.

The HEPA System’s 3 Stage Filtration Process

The 3 stage ltration process is used to create a very eec-

tive ltration system. Each lter is independent and can be

changed individually.

• Stage 1: Carbon pre-lter - The inexpensive carbon

pre-lter removes larger particulates from the air, thus

prolonging the life of the HEPA lter.

• Stage 2: HEPA - The HEPA lter removes 99.97% of

particulates 0.3 micron and larger. The cleaned air then

passes through the third stage lter.

• Stage 3: Inner Charcoal Filter - The inner charcoal lter

is 1/2 an inch thick to give it plenty of surface area for

removing chemicals and odors from the air.

OPTIONAL UPGRADE: The stage 3 Inner Carbon Filter

may be replaced by an optional heavy duty granulated co-

conut shell carbon canister. The VOC Canister oers in-

creased capacity removal of chemicals and odors. Filled

with granulated coconut shell carbon, the surface area

available for adsorption of gas and chemical pollution is

approximately 60 to 70 million square feet. The lter up-

grade captures many containments in the air and holds

them safely in the carbon. The increased capacity of this

lter also extends the performance life. The VOC Canister

also captures low level ozone from outside air and uses the

ozone to turn the lter into an active system which actually

destroys VOCs rather than just holding them.

Product Application Guidelines

Notes:

• Industry experience indicates that one (1) air change

per hour generally provides adequate air cleaning. Ac-

tual results will depend on multiple factors such as out-

door particulate levels, inltration rate, indoor activities

etc.

• The chart is based on an inltration rate of 0.3 air chang-

es per hour, which is typical for residential construction.

Higher inltration typically brings in more particulates

and thus increases the air changes per hour needed for

3

HEPA bypass ltration. Other particulate sources in the

house will require higher air changes per hour.

• The chart is based on continuous operation of the HEPA

system. If the HEPA system is cycled, the capacity of

the lter needs to be increased. For example, if the

HEPA system is “ON” only half the time, then the capac-

ity of the unit needs be doubled or additional units need

to be installed.

• The more air changes per hour provided, the more ef-

fective a HEPA system will be. People with sensitivities

may desire a higher number of air changes per hour for

cleaner air.

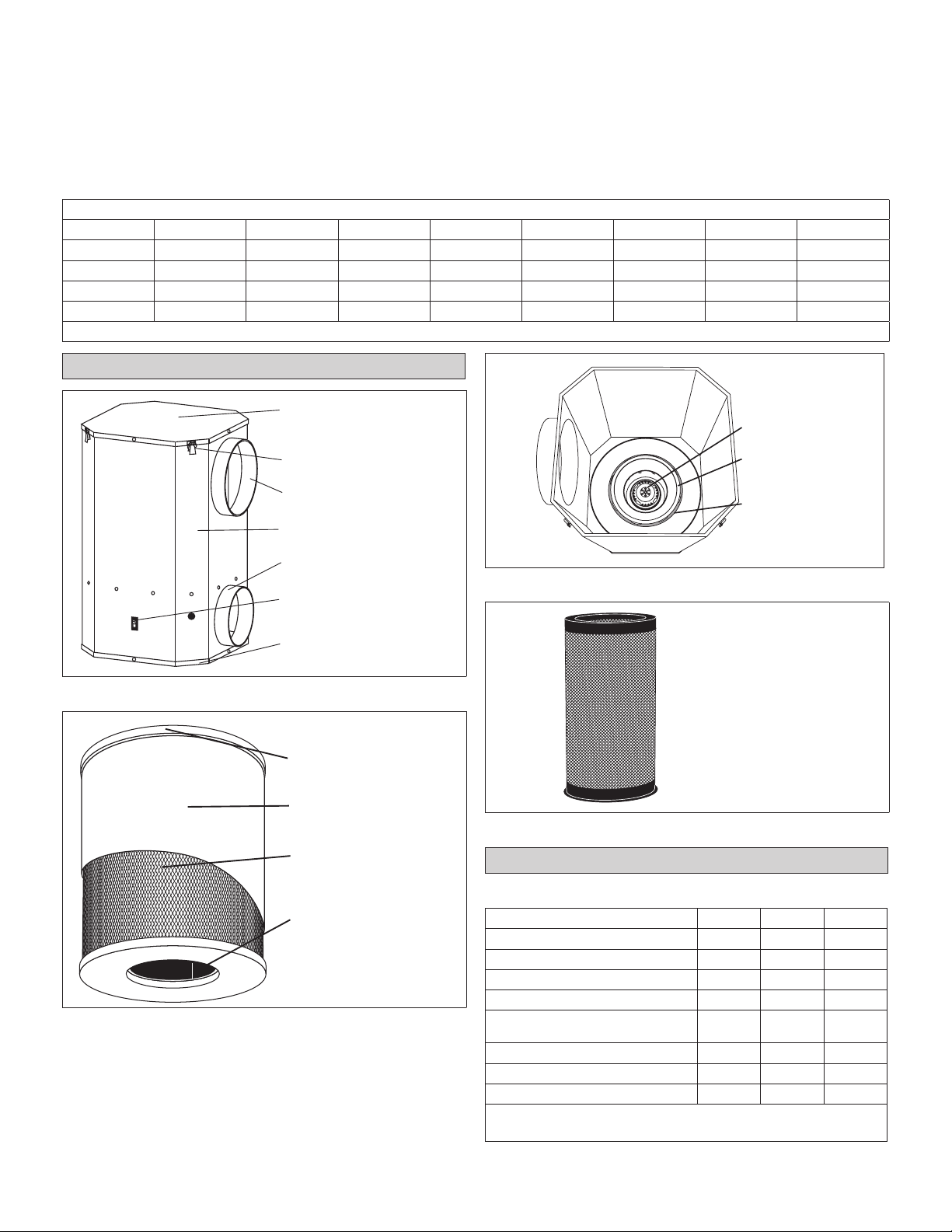

Table 1. Size of House versus Air Changes Per Hour

Size of House*

Model 1,000 ft2 1,200 ft2 1,500 ft2 1,800 ft2 2,000 ft2 2,500 ft2 3,000 ft2 3,500 ft2

Unit (8,000 ft3) (9,600 ft3) (12,00 ft3) (14,400 ft3) (16,000 ft3) (20,000 ft3) (24,000 ft3) (28,000 ft3)

HEPA-20 1.35 1.13 0.9 -- -- -- -- --

HEPA-40 2.4 2.0 1.6 1.3 1.2 1.0 -- --

HEPA-60 5.0 4.1 3.3 2.8 2.5 2.0 1.7 1.4

*Chart based on homes with 8 ft. ceilings.

Parts Identication

Filter Section Access

Panel

Retaining Clips (4)

Inlet Collar

Cabinet

Outlet Collar

On/Off Switch

Motor Section

Access Panel

Figure 1. Cabinet Parts

HEPA Filter

(STAGE 2)

Carbon Pre-Filter

(STAGE 1)

HEPA Filter Mesh

(Protects HEPA

Filter)

Inner Charcoal Filter

(STAGE 3)

Figure 2. HEPA Cartridge Parts

Motor/Impeller

Filter Adapter

(threaded)

‘O’ Ring

Figure 3. Inside Cabinet (Filter Section)

RECOMMENDED for

greater capacity removal

of chemicals and odors.

Located inside the HEPA

filter cartrige to provide

the third and final stage of

filtration.

Replace inner charcoal

filter when using the

optional carbon canister.

Figure 4. Optional Coconut Shell Carbon Canister

Specications

Table 2. Specications

HEPA-20 HEPA-40 HEPA-60

Nom. Air Flow @ 120VAC @ 0.0” E.S.P. 180 cfm 320 cfm 660 cfm

Weight (max - unpackaged) 30 lbs. 44 lbs. 49 lbs.

Supply Voltage 120 VAC 120 VAC 120 VAC

Nom. Measured Power Consumption 125 Watts 125 Watts 225 Watts

Motor Current Draw 1.0 amps,

60hz

1.0 amps,

60hz

1.8 amps,

60hz

Air Inlet Collar (max) 8”-round 10”-round 10”-round

Air Outlet Collar (max) 6”-round 8”-round 8”-round

Operating Temp. Range - Return air (ºF) 30 to 95 30 to 95 30 to 95

HEPA lter eciency = 99.97% @ 0.3 micron particles

Ambient temperature range: -40ºF to 130ºF

4

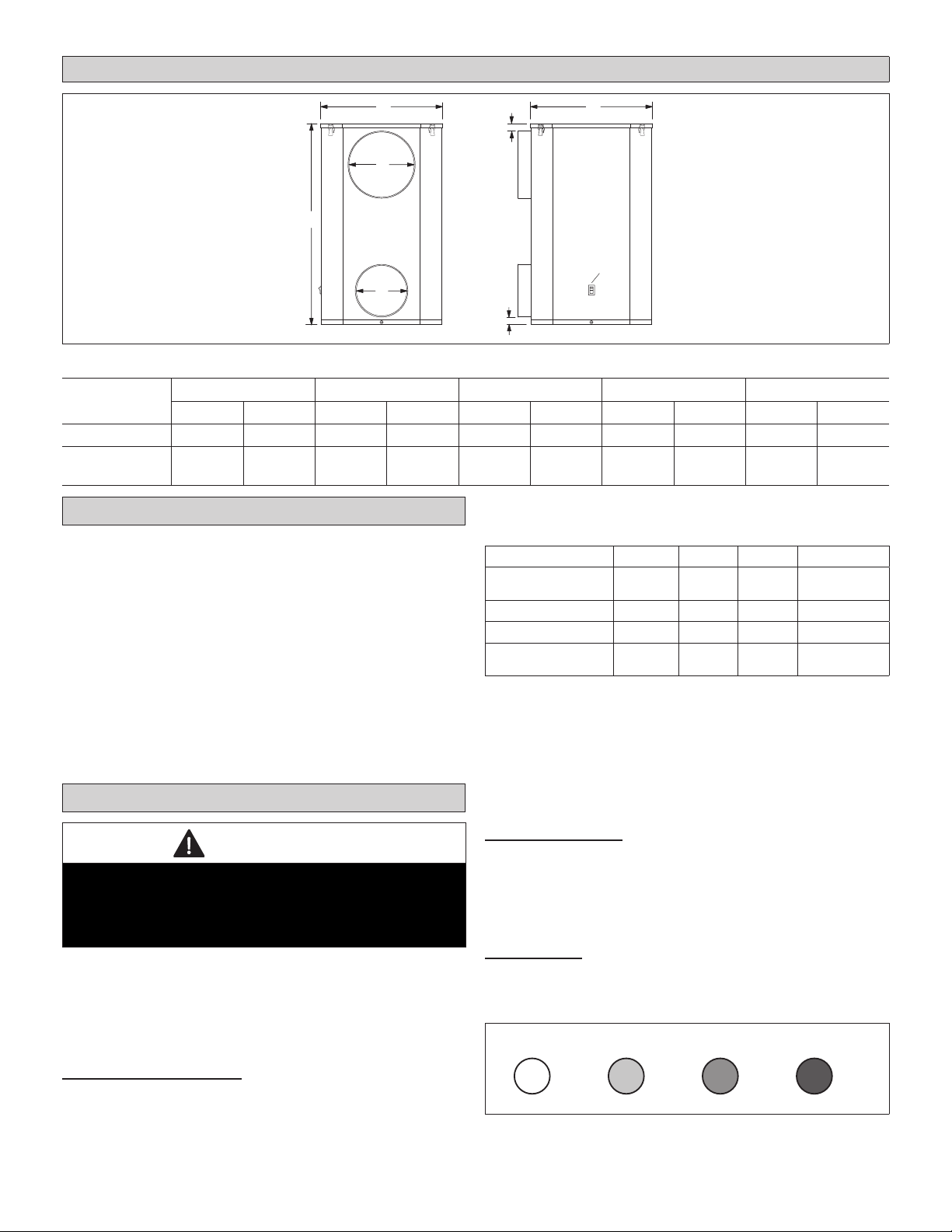

Unit Dimensions

A

B

C

D

Air Inlet

Air Outlet

1 (25)

A

E

Power

Switch

Figure 5. Unit Dimensions

Model No. A B C D E

in. mm in. mm in. mm in. mm in. mm

HEPA-20 14 356 17-7/8 454 8 203 6 152 1 25

HEPA-40

HEPA-60 16-1/8 410 28 711 10 254 8 203 1-3/4 44

Operation

1. Make sure that the unit is plugged into a grounded outlet

(120 Volt, 60 Hz).

2. For optimum performance, the HEPA system should

operate when the indoor air handler/furnace blower is

on. An optional air handler/furnace blower interlock

kit can be ordered for ‘cycled’ operation. (see

Replacement Parts)

3. Turn the unit on by pressing the on/o switch to the ‘1’

position. The switch should light up when the unit is

on.

4. To turn the unit o, press the on/o switch to the ‘0’

position. The switch light should turn o when the unit

is o.

Maintenance

CAUTION

Risk of Sharp Edges Hazard.

Equipment sharp edges can cause injuries.

Avoid grasping equipment edges without protective

gloves.

Proper care and maintenance of your HEPA system will en-

sure years of service. The unit must be turned o during

service/maintenance or when lters are being changed.

It is recommended that gloves and a ltered breathing mask

be worn during lter replacement.

Filter Change Schedule

NOTE: Failure to properly maintain your HEPA system will

decrease the eciency and air ow.

For enhanced odor control, the Coconut Shell Carbon Can-

ister provides up to one year of odor capture.

Table 3. Filter Replacement Schedule

Replacement Part HEPA-20 HEPA-40 HEPA-60 Replacement

HEPA Filter Cartridge

w/O-Ring 92X17 92X10 92X10 2 to 5 years

Carbon Pre-Filter X4137 X4138 X4138 12 months

Inner Charcoal Filter X2678 92X09 92X09 3 months

Carbon Canister

(Optional) 94X98 98X75 98X75 1 year

NOTE: Filter life is based on average air content. Some

lters may need to be changed more often due

to higher amounts of dust, humidity, or chemicals

found in your ambient air. Additionally, people who

are more sensitive to these air borne contaminates

may desire more frequent lter changes.

Filter Changing Guidelines

Carbon Pre-Filter:

Dust and other large particles will collect on the carbon

pre-lter over time. The color of the lter will change as

particulates build up on the carbon pre-lter. Change the

carbon pre-lter when you can see the particulate build up

start to clog up the carbon pre-lter.

HEPA Filter:

As the HEPA lter captures particulates, it will darken over

time. Replace the HEPA lter when it darkens to the level

seen in example D.

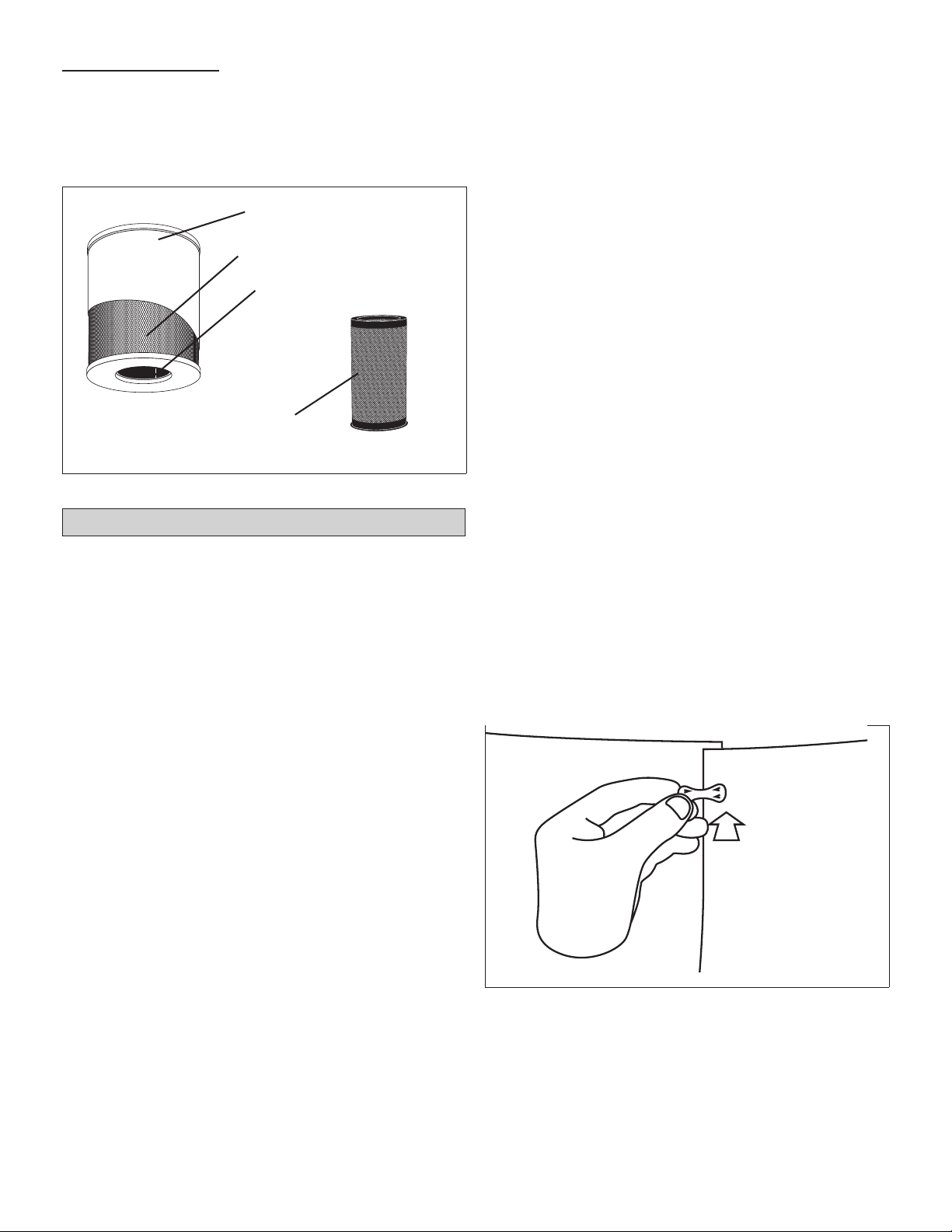

A. New B. Used C. Used D. Replace

Figure 6. HEPA Filter Color

5

Inner Charcoal Filter

The inner charcoal lter will rarely look used. This lter cap-

tures odors and gases, yet the lter’s appearance will not

change. When this lter has reached it’s maximum absor-

bency of odors and gases, it will no longer work. Replace

this lter when it no longer seems to capture odors, at least

every 3 months, whichever occurs rst.

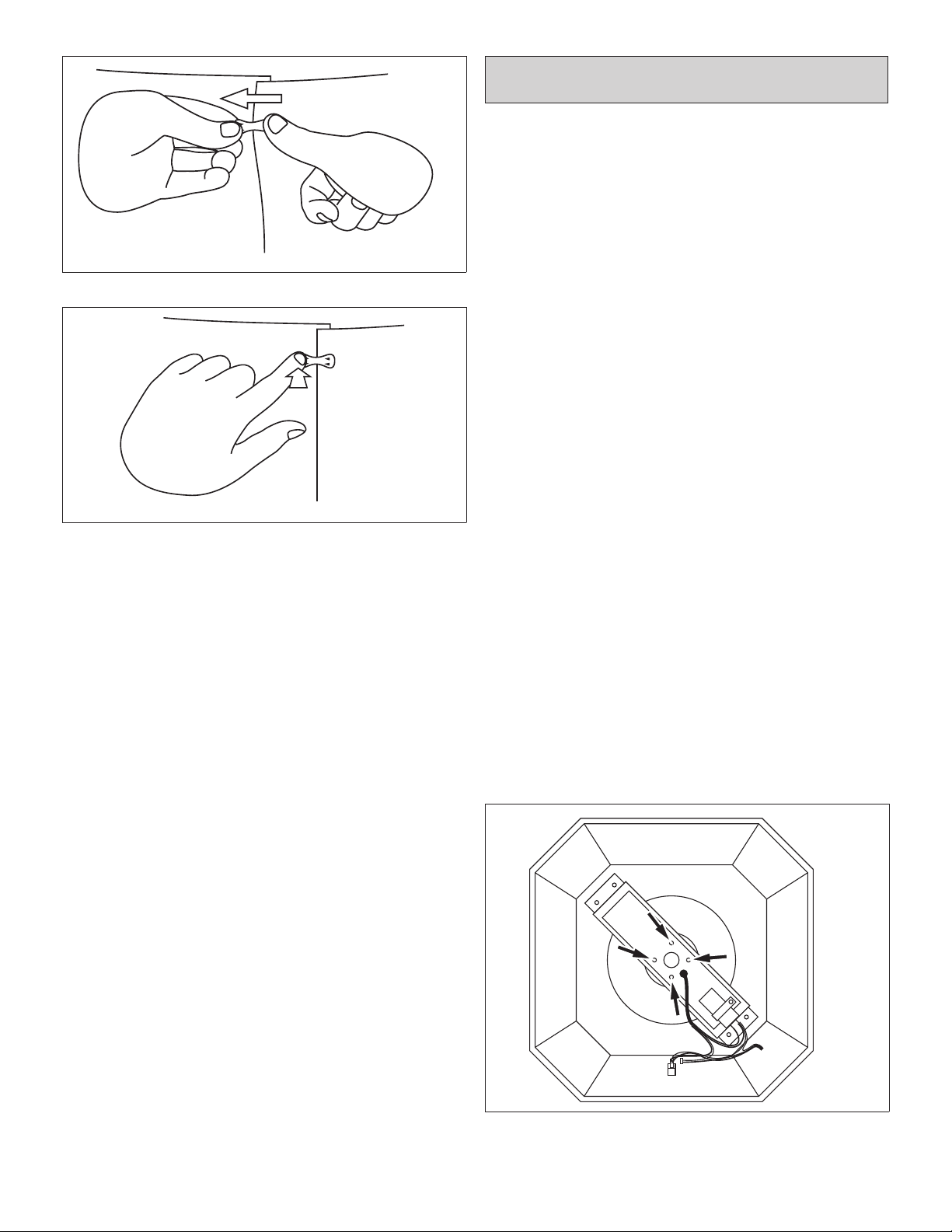

Carbon Pre-Filter

HEPA Filter

Inner Charcoal Filter

Optional Coconut Shell

Carbon Canister

replaces Inner Charcoal Filter

Figure 7. Inner Charcoal Filter

Dealer Filter Change Instructions

It is recommended that gloves and a ltered breathing

mask be worn during lter replacement to avoid breathing

particulates (dust, mold, pollen, etc.) captured on the lter

that become airborne during the lter(s) change out.

The old lters should be wrapped and sealed in plastic bags

immediately upon removal from the unit to avoid distribut-

ing particles throughout the house during the process of

disposal.

1. Accessing the filters

a. Remove safety screws from HEPA lter access

panel.

b. Unlatch the four retaining clips and lift o HEPA

lter access panel.

c. Bracing the unit so it does not move, turn the

HEPA cartridge counter-clockwise and lift out.

2. Carbon Pre-Filter Replacement

a. Locate the clips holding the carbon pre-lter in place.

Remove them and pull the carbon pre-lter o.

NOTE: The carbon pre-lter may contain contaminants,

remove it slowly to avoid releasing particles back

into the air.

b. Remove plastic shrink wrap from the new carbon

pre-lter.

c. Wrap the new carbon pre-lter around the HEPA

lter, making sure that the ends overlap.

d. Hook one end of the clip onto the overlapping

section of carbon pre-lter as shown in gure 13.

e. Press down on the hooked section while you pull it

across, stretching the carbon pre-lter tighter as

shown in gure 14.

f. Push down on the other end of the clip once the

carbon pre-lter is stretched tight to lock the clip

into place as shown in gure 15. Release clip, it

should hold tight on both ends of the carbon pre-

lter keeping it together.

g. Repeat steps d through f with the other clips,

spacing them evenly on the carbon pre-lter to

give it even support.

3. Inner Charcoal Filter Replacement

a. Look inside the HEPA cartridge to locate the two

ends of the inner charcoal lter.

b. Pull one end of the old inner charcoal lter in and

bend it into a loose roll so it can be removed.

c. Remove the inner charcoal lter from the HEPA

cartridge.

d. Remove plastic shrink wrap from the new inner

charcoal lter.

e. Unroll the inner charcoal lter and roll it up in the

opposite direction (this makes the lter follow a

more contoured prole against the inner HEPA

lter surfaces and helps keep it in place), place

the rolled inner charcoal lter inside the HEPA

cartridge and gently unroll it until the ends ‘butt’

together and the lter is snug against the HEPA

lter mesh.

4. HEPA Filter Replacement

a. If replacing the HEPA lter with a new lter, discard

old HEPA lter and use new when replacing the

HEPA lter into the unit.

b. With each HEPA replacement lter, a new ‘o’ ring

is provided. The old one is removed by pinching it

between two ngers and pulling it o the collar on

the blower deck.

c. Discard old ‘o’ ring.

d. Place the new ‘o’ ring onto the collar and slide it

down to the base of the blower deck.

Figure 8. Step 1

6

Figure 9. Step 2

Figure 10. Step 3

5. Optional Coconut Shell Carbon Canister

a. Remove old carbon canister (if installed) by pulling it

out from the inside of the HEPA lter.

b. If replacing an inner charcoal lter with the carbon

canister, remove inner charcoal lter by following

the steps a. to c. in section 3.

c. Remove the plastic shrink wrap from the new carbon

canister.

d. Slide the carbon canister into the HEPA cartridge,

smaller, tapered end rst. The carbon canister

should slide all the way in until the metal edges at

the base meet the HEPA lter.

e. Support the carbon canister with your ngers

so it does not slide out when replacing the HEPA

cartridge assembly into the unit.

6. Installing the HEPA Filter Cartridge

a. With the lters changed or inspected, all 3 lters

are ready to be placed back into the unit. Place

the HEPA cartridge gently into the unit (if a carbon

canister is being used, take care not to let it slide out

as it is heavy and could damage the unit)

b. When the HEPA cartridge is in place, brace the unit,

press down and turn it clockwise to lock it into place.

c. Replace the HEPA lter access panel and latch it

with the four retaining clips.

d. Re-install safety screws into HEPA lter access

panel.

e. Plug the unit back into a power outlet and turn it on.

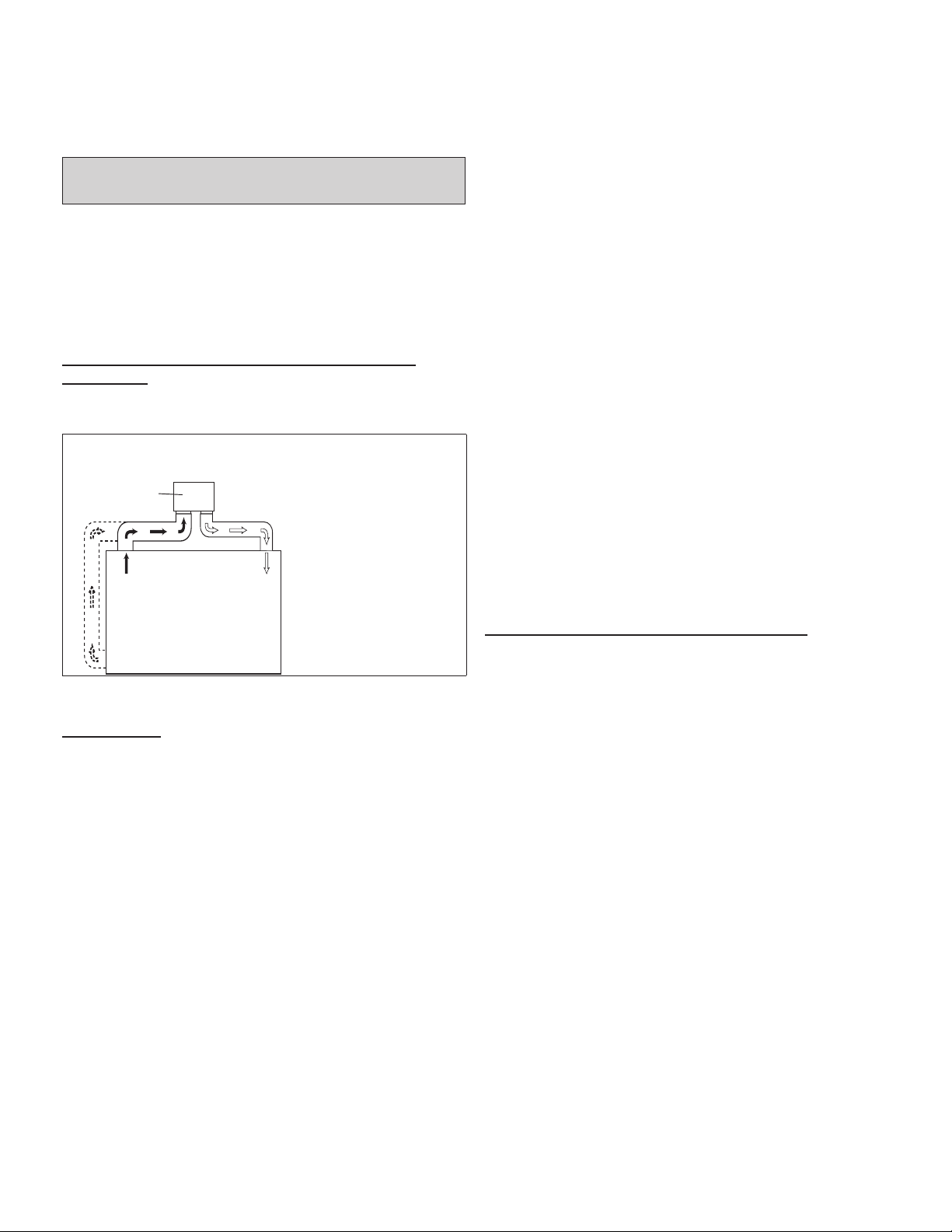

Dealer Motor Assembly Replacement

Instructions

1. Accessing the motor assembly

a. Turn the unit o and unplug it from any electrical

source before opening the cabinet.

b. To remove the motor section access panel, remove

the four screws on the panel, and lift o panel.

2. Removing the old motor assembly

a. Disconnect all four motor wires from switch, ground

post and capacitor.

b. Disconnect the two white wires from the capacitor.

c. Separate the motor from the motor mount by

removing the four screws found in gure 16.

d. Slide the motor out from under the motor mount

to remove it from the unit.

3. Installing the new motor assembly

a. Slide the new motor into the motor mount making

sure that the wires go through the smaller hole

oset from the center of the bracket.

b. Secure the new motor to the motor mount with the

four screws removed in step 2c.

c. Connect the wires as follows:

»Blue wire from motor to the on/o switch.

»Yellow/green wire from motor to the ground post.

»Brown wire from the motor to a capacitor post.

»Black wire from the motor to the other capacitor

post.

» White wire from the on/o switch to the capacitor

via the black wire piggyback post.

»White wire from the power cord to the capacitor

via the other white wire’s piggyback post.

4. Closing the unit

a. Replace the motor section access panel and

secure it with the eight screws removed in step 1b.

b. Plug the unit into it’s electrical source and turn it on.

Figure 11. Closing the Unit

7

Dealer Installation Instructions

Forced Air Handler/Furnace Systems

The HEPA system should be installed as a bypass system,

with part of the return ducted into the HEPA system.

The ltered air is then rerouted back into the return air, and

continues through the system to be heated/cooled.

Typical Return to Return Application (Upow)

For homes with up-ow forced air handler/furnace systems.

(Air handler/furnace is shown in a typical basement.

Distance

between A and

B should be 8’

to 16’ for best

Air Handler /

Furnance

Air Handler /

Furnace Filter

HEPA

System

A

B

Figure 12. Typical Return to Return Application

(Uplfow)

Typical Return to Return Application

For homes with horizontal forced air handler/furnace

systems. (Air handler/furnace is shown in an typical attic.

Air Handler/

Furnace

Air Handler/

Furnace Filter

HEPA System

A

B

Distance between A and B should

be 8’ to 16’ for best results.

Figure 13. Typical Return to Return Application

(Horizontal)

NOTE: This ltration system is an ADDITIONAL lter, and

does NOT replace the existing air handler/furnace

system lter.

Preparation

Here are some things to consider as you decide where to

install the HEPA system.

1. Location:

»Make sure there is room to open the HEPA lter ac-

cess panel for lter changes/inspections.

»Keep the HEPA system in a location where you can

still access the air handler/furnace lter.

»Keep the HEPA system away from possible water

damage.

»Vibration pads will reduce vibration for installations

where the unit is placed on the oor.

»Install HEPA System on oor or suspended platform.

If the unit is suspended, screws must not penetrate

through the cabinet. Make sure that you have the

proper chains/straps/joists and equipment to keep

unit secure.

2. Inlet (Marked as ‘Air In’ on unit):

»Inlet ducts should be installed upstream of any hu-

midiers and be installed on the main return.

»Inlet duct should be installed at least 8 ft. away from

the outlet duct on the main return.

»Use a 45 degree takeo to draw air from the main

return.

3. Outlet (Marked as ‘Clean Air Out’ on unit):

»Outlet duct should be installed as close to the air

handler/furnace inlet as possible but not directly into

the return air elbow of the main return.

»To reduce static pressure, install outlet with a 45

degree takeo directly up-line from the return air el-

bow.

»If the unit is being installed independently of any oth-

er system, room diusers are recommended to help

distribute airow evenly in the occupied space.

4. Ducting

»If HEPA system is installed where inlet and outlet

collars face down, metal elbows must be connected

to both inlet and outlet collars.

»Each connection must be sealed with aluminum

tape or mastic, including all take os.

»Installed duct runs should be as straight as possi-

ble (if the duct runs are too long, reduced CFM may

result).

»If duct is exposed to unconditioned air, externally in-

sulated ex duct is highly recommended.

»Externally insulated ex duct can also be used for

noise reduction purposes

»For best indoor air quality, do not use duct-board or

berglass inside of ducts.

5. Electricity

The unit must be plugged into a grounded 120V, 60Hz out-

let.

Required Materials for Installation of Unit:

1. For Model: HEPA-20

»8” diameter ex or rigid duct (as required)

»6” diameter ex or rigid duct (as required)

»8” diameter 45 degree takeo

»6” diameter 45 degree takeo

»Aluminum tape or mastic

»Miscellaneous hanging materials - eld provided

2. For Models: HEPA-40 and HEPA-60

»10” diameter ex or rigid duct (as required)

»8” diameter ex or rigid duct (as required)

»10” diameter 45 degree takeo

»8” diameter 45 degree takeo

8

»Aluminum tape or mastic

»Miscellaneous hanging materials - eld provided

NOTE: Be sure to review ‘Rules for Safe Installation and

Operation’ on page 1 of this document before

start-up of this unit.

Forced Air Handler/Furnace System with an HRV/ERV

Forced air handler/furnace system with an HRV/ERV This

application provides ltration of all Outdoor Air (OA) that is

brought into the home through the HRV/ERV, thus reducing

the introduction of dust, pollen and mold from the outdoor

air. For systems that have HRV/ERV units installed, we

recommend ducting the ‘fresh air’ outlet from the HRV/ERV

into the HEPA system. If the HRV/ERV CFM (cubic feet

per minute) rating is lower than that of the HEPA system,

an additional return needs to be installed into the HEPA

system.

The output air from the HEPA system then needs to be

installed into the main return of the air handler/furnace

system.

Example of Return to Return Installation with HRV/

ERV

For homes with a forced air handler/furnace system and an

HRV/ERV system.

Additional Return

Air Handler / Furnace

Air Handler / Furnace Filter

HEPA System

HRV /

ERV

Figure 14. Typical Return to Return Application

(HRV/ERV)

NOTE: This ltration system is an ADDITIONAL lter, and

does NOT replace the existing air handler/furnace

system lter.

Preparation

Here are some things to consider as you decide where to

install the HEPA system with an HRV/ERV.

1. Location:

»Make sure there is room to open the HEPA lter ac-

cess panel for lter changes/inspections.

»Keep the HEPA system in a location where you can

still access the air handler/furnace lter.

»Keep the HEPA system away from possible water

damage

»Vibration pads will reduce vibration for installations

where the unit is placed on the oor.

»Install HEPA System on oor or suspended platform.

If the unit is suspended, screws must not penetrate

through the cabinet. Make sure that you have the

proper chains/straps/joists and equipment to keep

unit secure.

2. Inlet (Marked as ‘Air In’ on unit):

»Most HRV/ERV systems will not move as much air

as the HEPA system. For these systems, install an

additional return from another treated air source into

the HEPA system.

»If using an additional return duct, it should be in-

stalled upstream of any humidiers. The fresh air

outlet of the HRV/ERV should be “Y” connected to

the additional return duct then connected to the inlet

of the HEPA system.

»The additional return duct (if any) should be installed

at least 8 ft. away from the outlet duct on the main

return.

»Duct both the HRV/ERV and the additional return

into the inlet of the HEPA system.

3. Outlet (Marked as ‘Clean Air Out’ on unit):

»Outlet duct should be installed as close to the air

handler/furnace inlet as possible but not directly into

the return air elbow of the main return.

»To reduce static pressure, install outlet with a 45 de-

gree takeo directly up-line from the return air elbow

of air handler/furnace.

4. Ducting

»If HEPA system is installed where inlet and outlet

collars face down, metal elbows must be connected

to both inlet and outlet collars.

»Each connection must be sealed with aluminum

tape or mastic, including all take os.

»Installed duct runs should be as straight as possi-

ble (if the duct runs are too long, reduced CFM may

result).

»If duct is exposed to unconditioned air, externally in-

sulated ex duct is highly recommended.

»Externally insulated ex duct can also be used for

noise reduction purposes

»For best indoor air quality, do not use duct-board or

berglass inside of ducts.

5. Electricity

The unit must be plugged into a grounded 120V, 60Hz out-

let.

Required Materials for Installation of Unit:

1. For Model: HEPA-20

»8” diameter ex or rigid duct (as required)

»6” diameter ex or rigid duct (as required)

»6” diameter 45 degree takeo

»Aluminum tape or mastic

»Miscellaneous hanging materials - eld provided

2. For Models: HEPA-40 and HEPA-60

»10” diameter ex or rigid duct (as required)

»8” diameter ex or rigid duct (as required)

9

»10” diameter 45 degree takeo

»8” diameter 45 degree takeo

»Aluminum tape or mastic

»Miscellaneous hanging materials - eld provided

Dealer Installation Instruction - Independent

Operation

The HEPA systems can be used independently of any other

equipment! The inlet and outlet of the ltration system can

be ducted into the same room to create a cleaner environ-

ment almost anywhere. The inlet or outlet can also be duct-

ed elsewhere. The inlet and outlet should be installed on

opposite sides of the room; however, this varies according

to your specic needs.

Example of Single Room Stand Alone System

Installation

For single rooms where increased ltration is desired such

as a dedicated ‘smoking room’.

HEPA System

A

B

Air should be drawn from

location B if space is

available, otherwise, use

location A.

Figure 15. Typical Single Room Stand Alone System

Preparations

Here are some things to consider as you decide where to

install the HEPA system independently of other systems.

1. Location:

»Make sure there is room to open the HEPA lter ac-

cess panel for lter changes/inspections.

»Keep the HEPA system away from possible water

damage.

»Vibration pads will reduce vibration for installations

where the unit is placed on the oor.

»Install HEPA System on oor or suspended platform.

If the unit is suspended, screws must not penetrate

through the cabinet. Make sure that you have the

proper chains/straps/joists and equipment to keep

unit secure.

2. Inlet (Marked as ‘Air In’ on unit):

»Inlet ducts should be installed near the oor for opti-

mum airow (see gure 11). If space does not allow,

then the inlet can be installed in the ceiling.

»Inlet duct should be installed at least 8 ft. away from

the outlet duct on the main return.

»Inlet duct should be installed at opposite end of the

room from the outlet duct(s) if in the same room.

»Diusers are recommended to help distribute airow

evenly.

3. Outlet (Marked as ‘Clean Air Out’ on unit):

»Outlet(s) should be installed in the ceiling away from

any other air inlet(s)

»Room diusers are recommended to help distribute

airow evenly in the occupied space.

4. Ducting

»If HEPA system is installed where inlet and outlet

collars face down, metal elbows must be connected

to both inlet and outlet collars.

»Each connection must be sealed with aluminum

tape or mastic, including all vent connections.

»Installed duct runs should be as straight as possi-

ble (if the duct runs are too long, reduced CFM may

result).

»If duct is exposed to unconditioned air, insulated ex

duct is highly recommended.

»Externally insulated ex duct can also be used for

noise reduction purposes

»For best indoor air quality, do not use ductboard or

berglass inside of ducts.

5. Electricity

The unit must be plugged into a grounded 120V, 60Hz. out-

let.

Required Materials for Installation of Unit:

1. For Model: HEPA-20

»8” diameter ex or rigid duct (as required)

»6” diameter ex or rigid duct (as required)

»8” diameter vent

»6” diameter vent

»Aluminum tape or mastic

»Miscellaneous hanging materials - eld provided

2. For Models: HEPA-40 and HEPA-60

»10” diameter ex or rigid duct (as required)

»8” diameter ex or rigid duct (as required)

»10” diameter vent

»8” diameter vent

»Aluminum tape or mastic

»Miscellaneous hanging materials - eld provided

NOTE: Be sure to review ‘Rules for Safe Installation and

Operation’ on page 1 of this document before

start-up of this unit.

NOTE: For details on the best way to combine HEPA ltra-

tion with other air quality products see Service and

Application Note Corp0602L1 (IAQ-06-2).

10

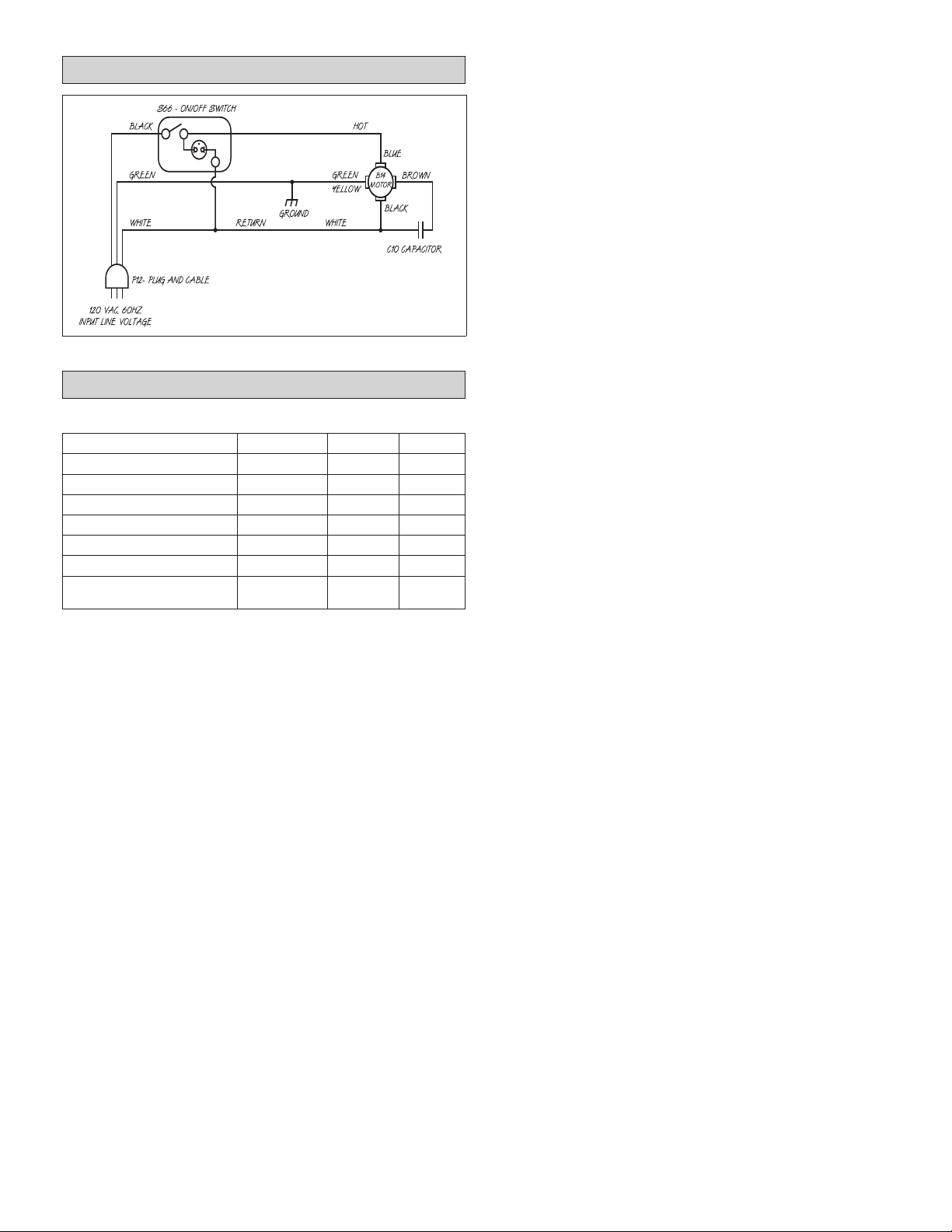

Electrical Diagram

Figure 16. Electrical Diagram

Replacement Parts

Table 4. Replacement Parts

Replacement Part HEPA-20 HEPA-40 HEPA-60

Complete Assembly X4912 X4913 X4914

Motor Assembly X2669 X2669 X2671

HEPA Filter Cartridge w/O-Ring 92X17 92X10 92X10

Carbon Pre-Filter X4137 X4138 X4138

Inner Charcoal Filter X2678 92X09 92X09

Carbon Canister 94X98 98X75 98X75

Optional Blower Interlock (24V

relay) X2680 X2680 X2680

Use this unit only in the manner intended by the manufacturer.

If you have questions, contact Healthy Climate.

Contact your local Healthy Climate dealer to order

replacement parts.

For the Healthy Climate dealer near you, dial 1-800-9

LENNOX or visit us at www.lennox.com

This manual suits for next models

5

Table of contents

Other Healthy Climate Air Cleaner manuals