HealthyAire HA-SCP-G3-W User manual

Source Capture

Air Purification System

HA-SCP-G3

Owner’s Manual

Table of Contents

HealthyAir® HA-IFM-1111 Filter

1

Important Safety Instructions

2

Technical Specifications

3

Packaging Reference

4

Packing Notice

5

Component Reference

6

Assembly Instructions

7-11

Operation Guidelines

12-13

Filter Replacement

14-16

Maintenance

17

Basic Service and Troubleshooting

18-22

Electrical Wiring Schematic

23

1-Yeart Limited Warranty

24

Product Registration Form

25

Distributed by

Aerovex Systems, Inc.

800-288-2023

www.aerovexsystems.com

1

HealthyAir®Model HA-SCP-G3

Source Capture Air Purification System

with

HealthyAir®HA-IFM-1111 Filter

at

www.aerovexsystems.com

2

WARNING

Unplug the power cord before servicing or replacing filters. Failure

to do so could result in serious personal injury and death.

I. Important Safety Instructions

Read the Owner's Manual and Important Safety Instructions carefully. Failure to

follow these instructions could cause a malfunction of the filter or unsatisfactory

performance. Follow a regular service and maintenance schedule for efficient

operation.

To reduce the risk of electric shock, fires, and/or injury:

•Do not use the air purifier in wet or damp locations

•Do not use outdoors

•Do not use at ambient temperature of above 95°F/35°C

•Do not use fabrics or other material to cover the inlet and outlet of the unit

•Do not allow children to operate or play with the unit

For safety reasons and to prevent electric shock, unplug the power cord from the

electric outlet socket under the following conditions:

•When not in use for a long period of time

•When cleaning, servicing the machine or during replacement of filters

•When moving the air purifier

To prevent electric shock, do not dismantle, repair or modify this product.

Maintenance and cleaning instructions should be followed exactly as directed in

this manual. In case of malfunction, please contact an authorized distributor or

Healthy Air Inc. for service instructions.

To reduce the risk of electric shock, the equipment has a grounding type plug that

has a third (grounding) pin. This plug will only fit into a grounding type power

outlet. If the plug does not fit into the outlet, contact qualified personnel to install

the proper outlet. Do not alter the plug in any way.

To reduce the risk of electric shock, do not pull the cord to remove the plug from

its outlets. Protect the cord against heat, oil and sharp objects. Do not run any

appliance over the cord. Do not pull or carry by the cord, use cord as a handle,

close a door on the cord, or pull cord around sharp edges or corners.

3

II. Technical Specifications

Model Number

HA-SCP-G3-W/B/G

Rated Voltage

120V/60HZ

Power Consumption

200W

Weight

37 lbs. (17 kg)

Base Dimensions

14x12x24 in. (350×310×615 mm)

Flex Hose Length

45 in. (114.3 cm)

Air Flow Rate

240 cfm (400 m3/h)

Noise Level

56 dB

4

III. Packaging Reference

The Source Capture Air Purification System is shipped in two (2) cartons, as

follows:

Carton 1: (1) Source Capture Air Purification Unit w/ (1) Integrated Filter

Module, (4) Wheel Casters, (1) Acoustic Mat, (1) Remote

Control, (1) Power Cord, (1) Screwdriver, (1) Manual

Carton 2: (1/2) Flex Hose + Hood, (1/2) Hose Clamp, (1/2) Grill + LED Cable

+ LED Bulb (Optional)

5

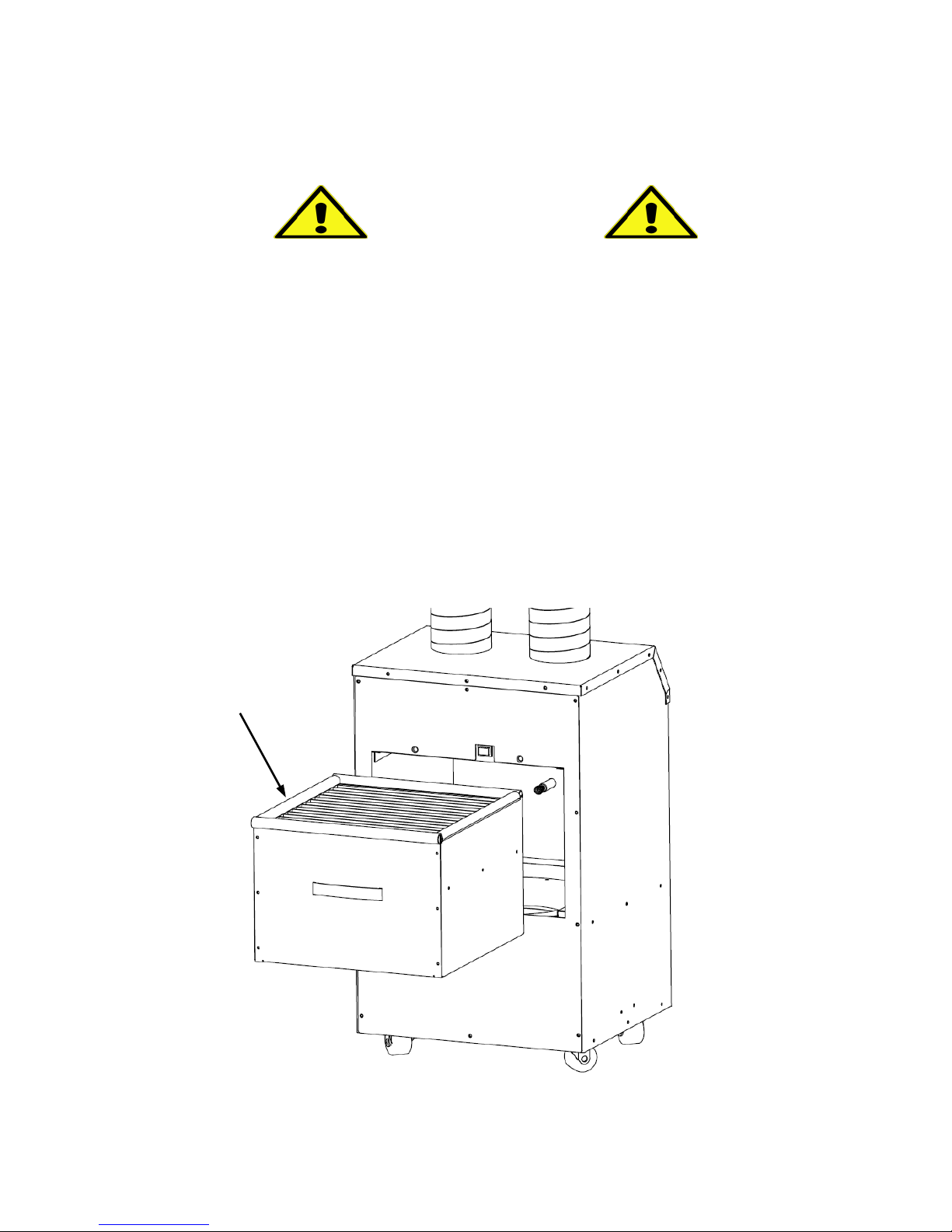

IV. Packaging Notice

NOTICE

Before operating the machine, do the following:

1. Open the Access Door (Refer to Section 8.2)

2. Remove the Integrated Filter Module (HA-IFM-1111)

3. Remove the plastic wrapping from the filter!

4. Re-install the Integrated Filter Module

5. Replace and secure the Access Door

Remove plastic wrapping

from Integrated Filter

Module prior to use!

6

V. Component Reference

1. Outer Frame

2. Acoustic Mat

3. Blower/Motor

4. Metal Screen

5. Caster Wheels

6. Bottom Plate

7. Motor Mount Plate

8. Baffle Plate

9. Air Inlet Guide

10. Integrated Filter Module

11. Activated Carbon Filter

12.eHEPA®Filter

13. eGrid

14.Silicon Seal

15. Pre-Filter

16. HV PCB

17.Switch

18. Capacitor

19. PCB

20. Flex Hose

21.LED

22. Hood

23. G4 Bulb Mount (Option)

24. LED Grill (Option)

25.LED Cable Plug (Option)

26.LED Cable Socket

27. Inlet Tube

28. Control Panel Display

29. Control Panel

30. Plastic Screw

31.HV Contact Spring

32. Power Cord

33. Remote Control

7

VI.Assembly Instructions

6.1 Install Caster Wheels

The following procedure is for Standard Application of the unit, whereby purified

air is vented through the Base Plate and recirculated within the facility.

For Outside Vent Applications, in which purified air is vented out of the facility,

skip Section 6.1 and refer to the wheel installation instructions in Section 6.4.

6.1.1 Place the unit on its side on a flat surface, as shown in Fig. 1.

6.1.2 Locate the four (4) Caster Wheels and the Screwdriver that are

provided in Carton 1.

6.1.3 Unscrew and remove the screws that are pre-mounted onto the Base

Plate, on the bottom of the unit. There are four (4) screws per wheel,

for a total of sixteen (16) screws.

6.1.4 Align the holes of the Caster Wheel Mount with the holes on the Base

Plate, and use four (4) screws to securely mount each Caster Wheel to

the Base Plate one by one.

Fig. (1) –Caster Wheel Installation

Base Plate

(16) Screws for

mounting wheels

8

VI.Assembly Instructions

6.2 Install LED Lighting (Optional)

Note that, the LED Lighting system is an optional feature. To add this feature,

visit www.aerovexsytems.com and

If LED Lighting was not purchased, skip section and proceed to Section 6.3.

6.2.1 Mount the LED Light Bulb on the Grill, by inserting the lip of the bulb

into the 4-piece cylinder located in the center of the Grill.

6.2.2 Connect the LED Cable to the LED Light Bulb, by sliding the two (2)

prongs of the bulb into the G4 Bulb Mount.

6.2.3 Pass the 52” LED Cable through the Hood and entire length of the Flex

Hose, such that the LED Cable Plug passes through the bottom of the

Flex Hose.

6.2.4 Connect the Grill to the Hood by snapping the Grill onto the rim of the

Hood, as shown in Fig. 2.

6.2.5 Connect the LED Cable Plug to the LED Cable Socket of the LED

Cable that is fixed to the edge of the Inlet Port.

Fig. (2) –LED Lighting Installation

Grill

LED

Bulb

LED Cable w/

Bulb Mount

LED Cable

Plug

LED Cable

Socket

9

VI.Assembly Instructions

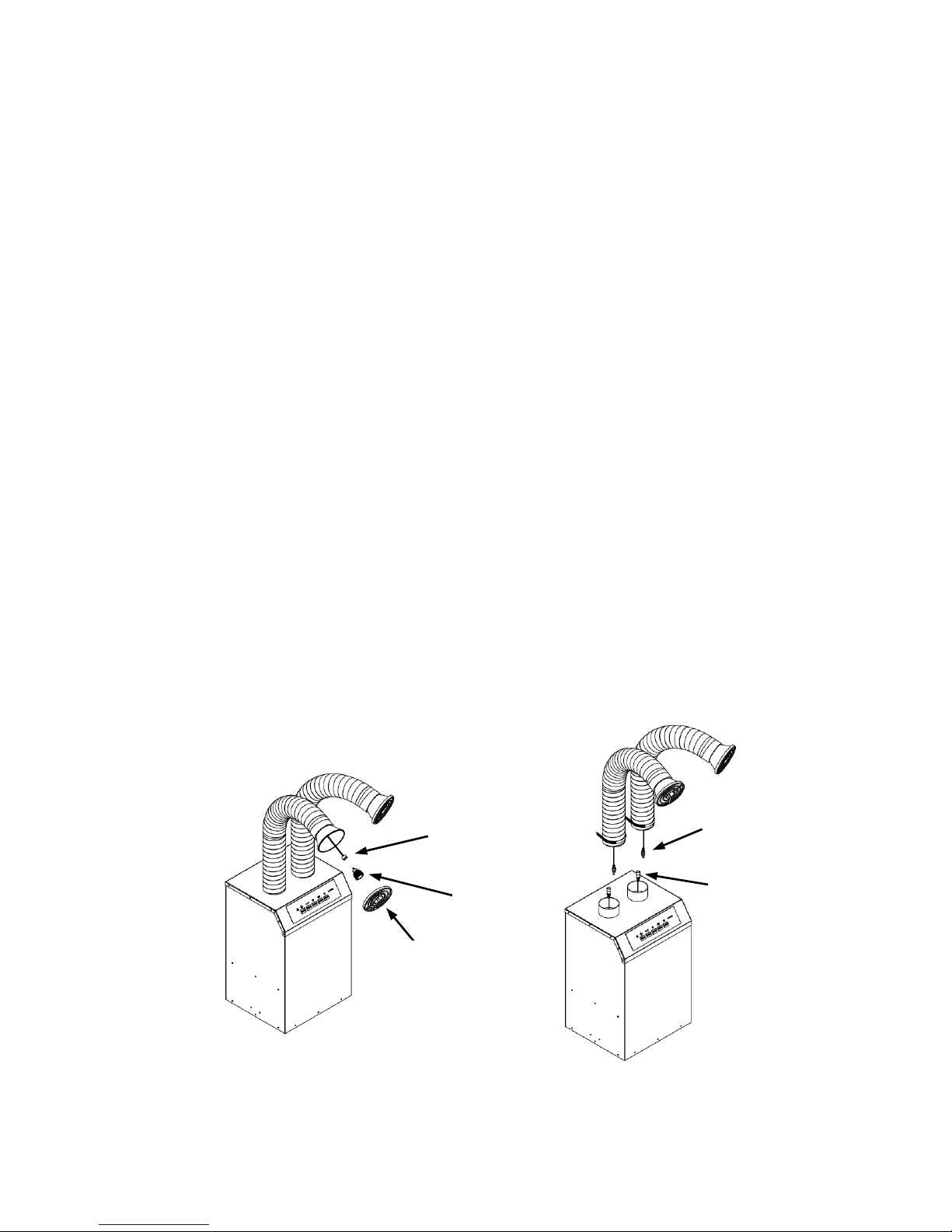

6.3 Install Flex Hose

The Flex Hose is constructed of interlocking bands that enable its length and

shape to be adjusted. Note that, the Flex Hose will unravel if it is lengthened or

bent past its tolerance point. The diameter of the Flex Hose can be also

adjusted by 10% by rotating sections of the hose counterclockwise.

6.3.1 Install the Flex Hose on the unit by sliding the end of the Flex Hose over

the Inlet Port, as shown in Fig. 3.

If the diameter of the Flex Hose needs to be increased, rotate the end

of the hose counterclockwise.

6.3.2 Hold the end of the Flex Hose and rotate it clockwise, to reduce its

diameter, to fit it to the diameter of the Inlet Port.

6.3.3 Position the Hose Clamp at the base of the Flex Hose, and screw the

hex nut to tighten the Hose Clamp and secure the Flex Hose on the

Inlet Port. Ensure that the connection is tight to optimize performance.

Fig. (3) –Flex Hose Installation

Hood

Inlet Port

Grill w/

LED Light

(Optional)

Flex Hose

Hose

Clamp

10

VI.Assembly Instructions

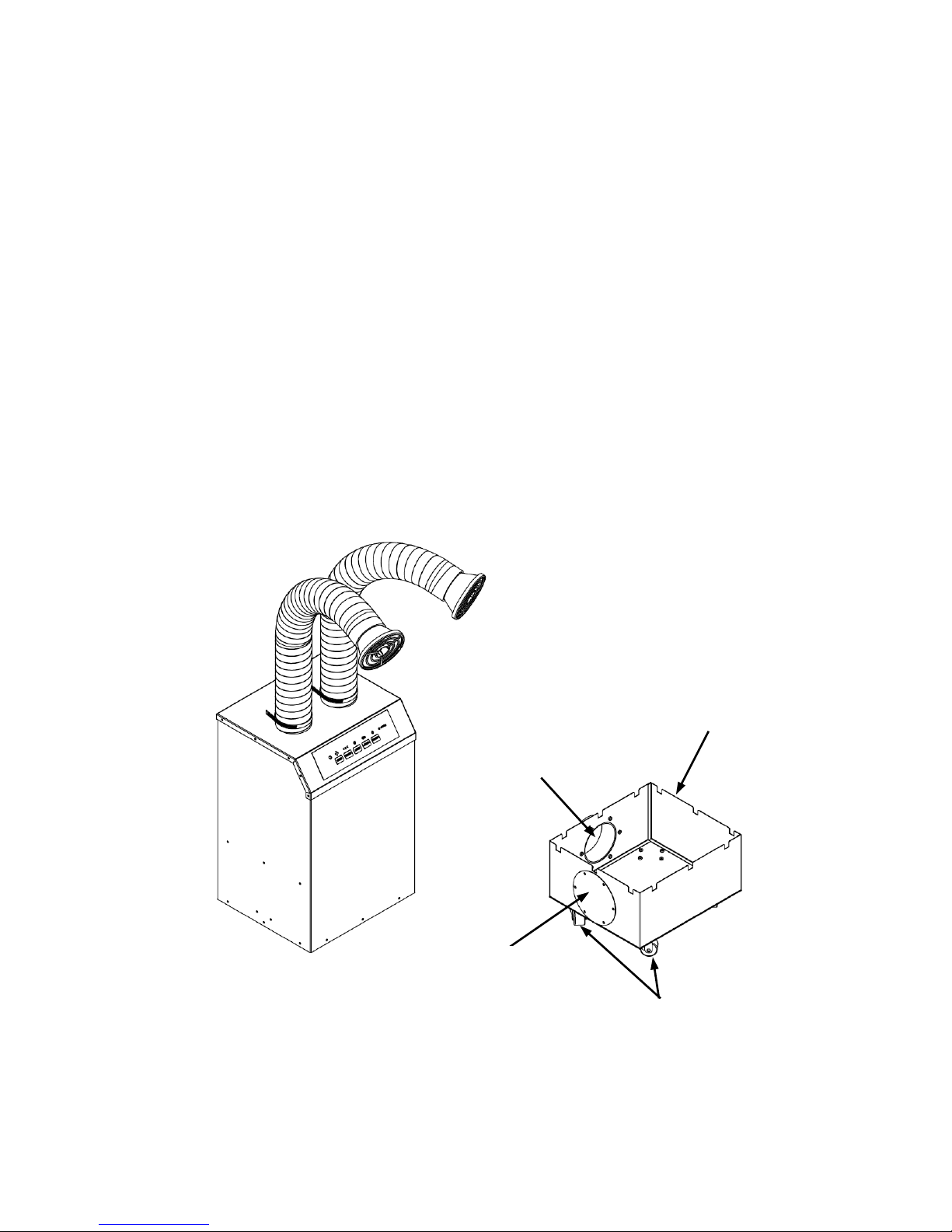

6.4 Install Outside Vent Adapter (Optional)

Note that, the Outside Vent Adapter is an optional feature. To add this feature,

visit www.aerovexsystems.com.

The Outside Vent Adapter comes with one (1) Outlet Flange, one (1) Outlet

Port Cover Plate, and has two (2) Outlet Ports, that enable it to exhaust air

from the back or side depending on which configuration is preferred.

6.4.1 If the Caster Wheels were initially installed on the unit, as described in

Section 6.1, remove each Caster Wheel from the Base Plate, and set

aside the wheels and the mounting screws.

Fig. (4) –Outside Vent Adapter

Outside Vent Adapter

Caster Wheel

Outlet Port

Outlet Port

Cover Plate

11

VI.Assembly Instructions

6.5 Install Outside Vent Adapter (Optional)

6.5.1 Re-install each of the four (4) Caster Wheels to the bottom of the

Outside Vent Adapter, as shown in Fig. 4.

6.5.2 Install the Outlet Flange on one of the Outlet Ports, based a

determination of the ideal setup configuration.

6.5.3 Install the Outlet Port Cover Plate on the Outlet Port that is not being

used. Ensure that the Outlet Port Cover Plate is secure, such that the

seal between the plate and adapter is airtight.

6.5.4 Place the HealthyAir®Source Capture Air Purification System atop the

Outside Vent Adapter, as shown in Fig. 5.

6.5.5 Connect a standard 4’’ diameter Exhaust Duct (not supplied) to the

Outlet Flange of the Outside Vent Adapter, and use a standard hose

clamp to secure the connection.

6.5.6 Run the Exhaust Duct out of the facility per applicable IMC codes.

Fig. (5) –Outside Vent Adapter Installation

Outside

Vent

Adapter

Outlet

Flange

Exhaust

Duct

Outlet Port

Cover Plate

12

VII. Operation Guidelines

7.1 Source Capture System Positioning

Place the HealthyAir®Source Capture Air Purification System in the desired

location and place it on the Acoustic Mat to dampen the sound. Once the unit

is in place, adjust the Flex Hose to position the Hood approximately 6” from the

source of the particulate and fumes.

7.2 Source Capture System Activation

7.2.1 Plug the Power Cord into the Power Socket, located on the bottom of

the side panel of the unit, and then plug the other end of the cord into a

wall power socket.

Once plugged in, the Power indicator light [ ] will turn on and

display a red light.

7.2.2 Activate the unit by pressing the Power button located on the Control

Panel, shown in Fig. 6, or on the Remote Control.

Once the unit is powered, the motor will start with the Fan Speed set to

the Mid-Speed and the eHEPA® indicator will light up and display a

green light, which indicates that the eHEPA® system is activate.

7.3 Source Capture System Controls

Each of the respective control elements shown on the Control Panel Display in

Fig. 6 work as follows:

•SPEED button, on the Control Panel and Remote Control, adjusts the

volume of airflow being taken in through the hood. Airflow speed can be

adjusted to one of three settings: Low –Mid –High Speed.

•eHEPA button, on the Control Panel and Remote Control, turns the

eGrid on and off. When the eGrid is powered the symbol above the

eHEPA button, as well as the eGrid Active light, will turn green.

Pressing the eHEPA button once more will shut off the eGrid and turn

off the indicator light.

13

VII. Operation Guidelines

7.3 Source Capture System Controls

•TIMER button, on the Control Panel and Remote Control, is for

operation of the timing clock. When this feature is in use the unit will

automatically shut off after the set time expires. The system’s default

timing is 4 hours of operation.

To set the timer manually, press the TIMER button once for every hour

you wish to run the machine (i.e. press TIMER once for 1-hour of run

time, press TIMER twice for 2-hours of run time, press TIMER three

times for 3-hours of run time, and press TIMER four times for 4-hours of

run time).

If the TIMER button is pressed five (5) times, such that it passes

through the complete timing schedule, it will run continuously until the

unit is manually turned off.

•LIGHT button, on the Control Panel and Remote Control, turns the

Hood LED Light on and off. When the LED Light is on the symbol above

the button turns green. Pressing the LIGHT button once more will turn

off the LED Light as well as the indicator light.

•eGrid Active indicator light, on the Control Panel, indicates the status

of the eHEPA® and eGrid system. When the eGrid Active indicator light

is on, while the eHEPA button is on, the eGrid is functioning properly. If

the eGrid Active indicator light is off, while the eHEPA button is on, it

signals that the eGrid is malfunctioning and the unit requires service.

Fig. (6) - Control Panel Display

14

VIII. Filter Replacement

8.1 Replacement Filter

The HealthyAir®Source Capture Air Purification System (HA-SCP-G3) utilizes

the HealthyAir® Series 1111 Integrated Filter Module (HA-IFM-1111).

Note that, only manufacturer supplied HealthyAir® Replacement Filters are

compatible with HealthyAir® Source Capture Systems. No other replacement

filters are to be used with this unit. The improper use of non-manufacturer

supplied filters will void any potential warranty claim.

8.2 Filter Change

When the unit has been in operation for 400-hours, the Filter Change indicator

light, on the Control Panel, will begin to flash indicating that the filters must be

replaced as follows:

Note: Depending on usage and contaminates in the environment, the filter

may need to be replaced before the 400-hour default cycle expires. Contact a

representative to determine if you need to replace the filter more frequently.

8.2.1 Turn the Power Off and unplug the Power Cord from the Power Socket.

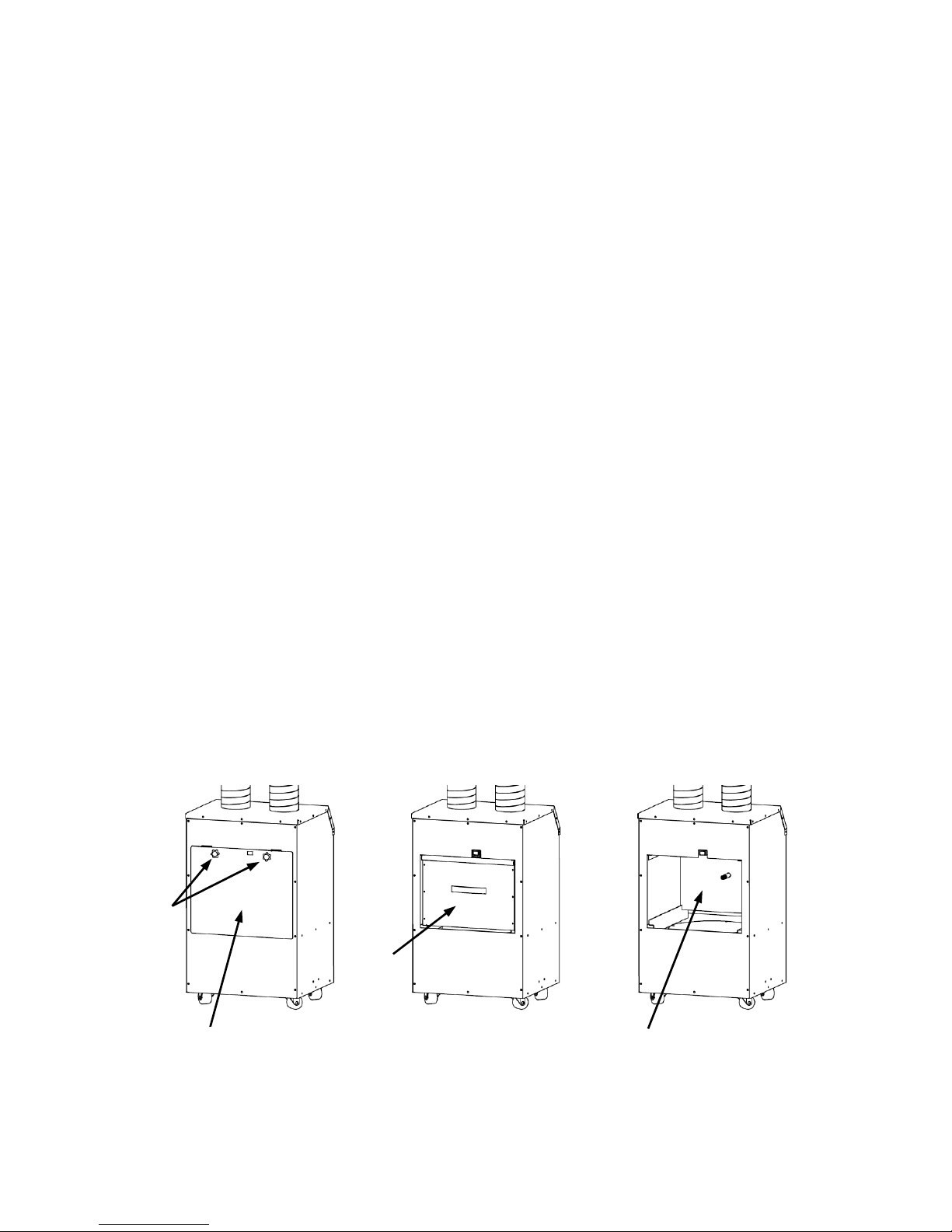

8.2.2 Remove the Access Door by unscrewing the two (2) Thumb Screws, as

shown in shown in Fig. 7.

Fig. (7) –Access Door Removal

Thumb

Screw

Access Door

Filter

Filter Compartment

15

VIII. Filter Replacement

8.2 Filter Change

8.2.3 Remove the used Integrated Filter Module.

Caution: The HV Contact Spring may store a slight charge even after

the unit is powered off. Avoid direct contact with the HV Contact Spring.

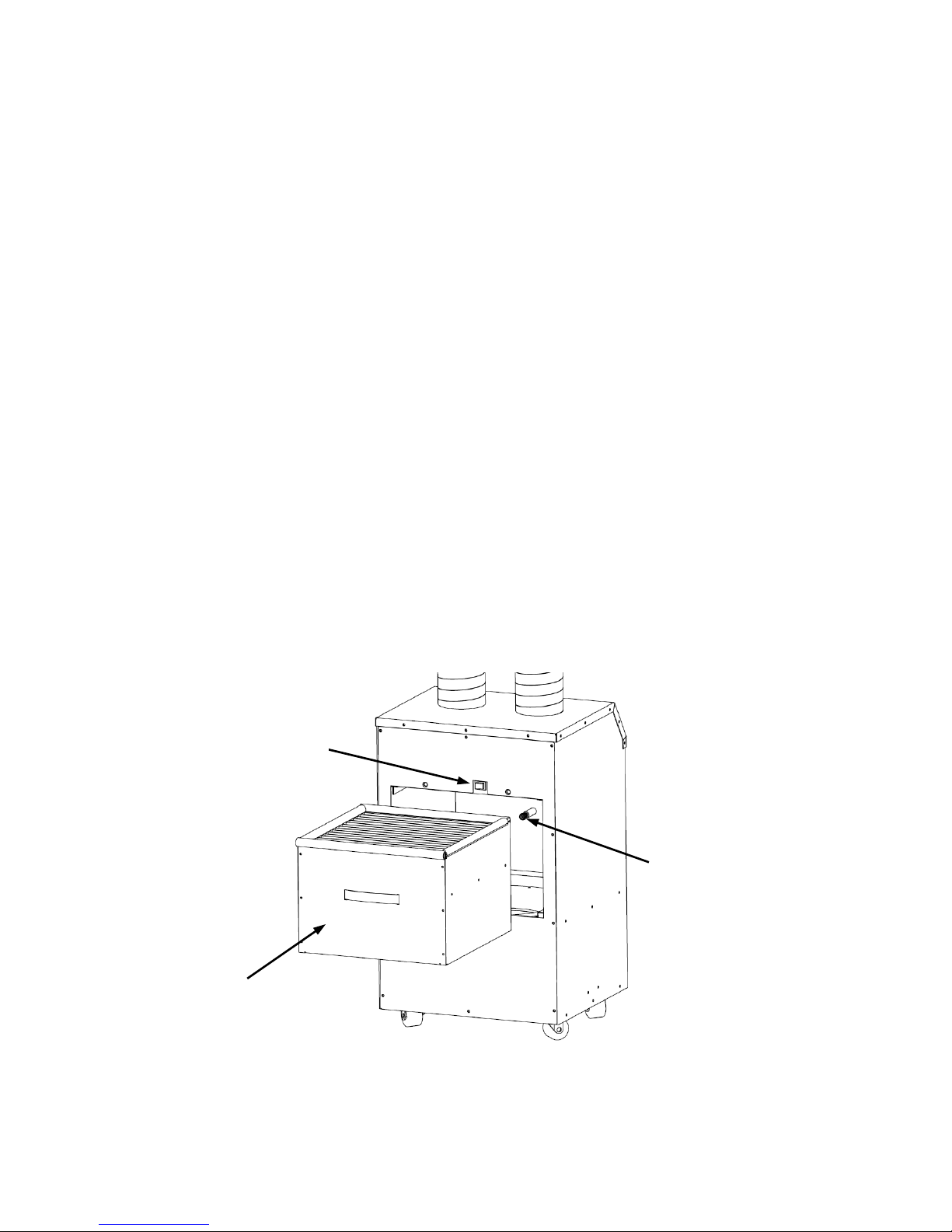

8.2.4 Install a new Integrated Filter Module (HA-IFM-1111) into the Filter

Compartment, as shown in Fig. 8. Ensure that the plastic wrap is

removed prior to installing the replacement filter.

8.2.5 Reinstall the Access Door, ensuring that the Access Door is properly

inserted back into its track. Once the Access Door is properly aligned

and set in place, secure it by screwing in the Thumb Screws.

Note that, if the Access Door must be properly installed to engage the

Safety Switch. If the Safety Switch is not engaged, the unit will not

power on.

8.2.6 Plug the Power Cord back into the Power Socket and wall socket.

Fig. (8) –Replacement Filter Installation

Integrated Filter Module

HA-IFM-1111

HV Contact Spring

Safety Switch

16

VIII. Filter Replacement

8.3 Filter Change Indicator Light Reset

Once the filter has been replaced and the unit is powered on, the Filter Change

indicator light may continue to flash. To reset the filter change timer and

deactivate the flashing light, go through the following reset procedure:

8.3.1 Unplug the Power Cord from the Power Socket, wait a couple seconds

and plug the Power Cord back into the Power Socket.

8.3.2 Press and hold down the Power Button [ ] on the Control Panel (not

the Remote Control) for five (5) seconds.

8.3.3 After five (5) seconds, release the Power Button. The filter change

timer will reset to 400-hours, after which the Filter Change indicator

light will shut off.

Fig. (9) - Filter Change Indicator Light Reset

Filter Change

indicator light

flashing

Press and Hold

Power button for

5 seconds

17

IX. Maintenance

Caution: The HV Contact Spring may store a slight charge even after the unit

is powered off. Avoid direct contact with the HV Contact Spring.

9.1 Cleaning Filter

To extend the effective life of the Integrated Filter Module, remove the filter

from the unit and use a standard vacuum to remove collected particulate from

the Pre-Filter section.

9.2 Cleaning Filter Compartment

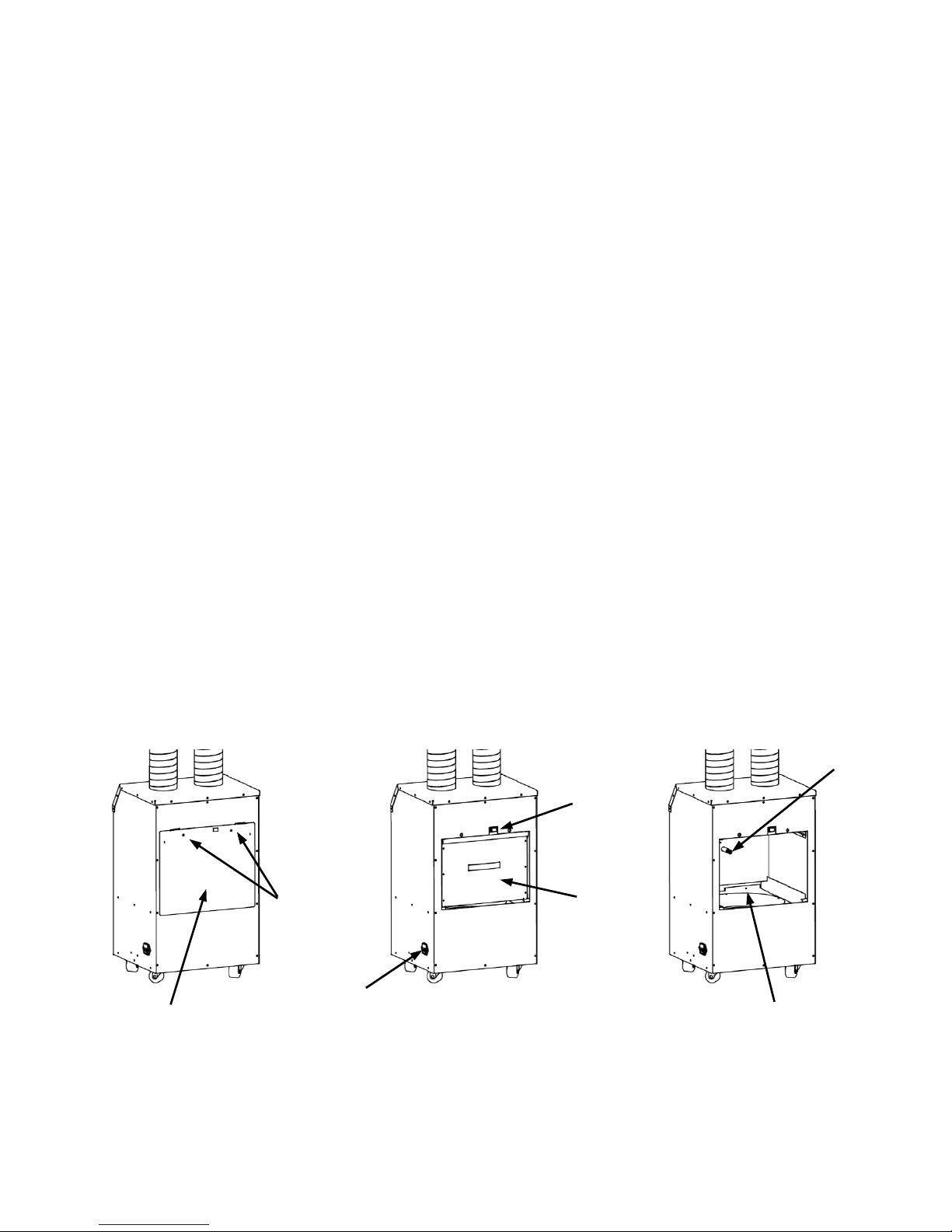

Visually inspect the interior of the Filter Compartment when the filter is

removed from the unit during the filter replacement process. If particulate has

accumulated in the Filter Compartment, clean the interior of the unit as follows:

9.2.1 Turn the Power Off, unplug the Power Cord from the Power Socket,

remove the Access Door, and remove the filter from the unit.

9.2.2 Vacuum and remove any debris that has accumulated in the filter

compartment and adjacent accessible areas of the interior of the unit.

9.2.3 Properly replace the Access Door, as described in Section 8.2.

Fig. (10) –Cleaning Filter Compartment

Power

Socket

Thumb

Screw

Access Door

Filter

Filter Compartment

HV

Contact

Spring

Safety

Switch

18

X. Basic Service and Troubleshooting

The Basic Service Guide should cover most performance issues. If you continue

to experience issues after referring to this list, please contact Healthy Air Inc.

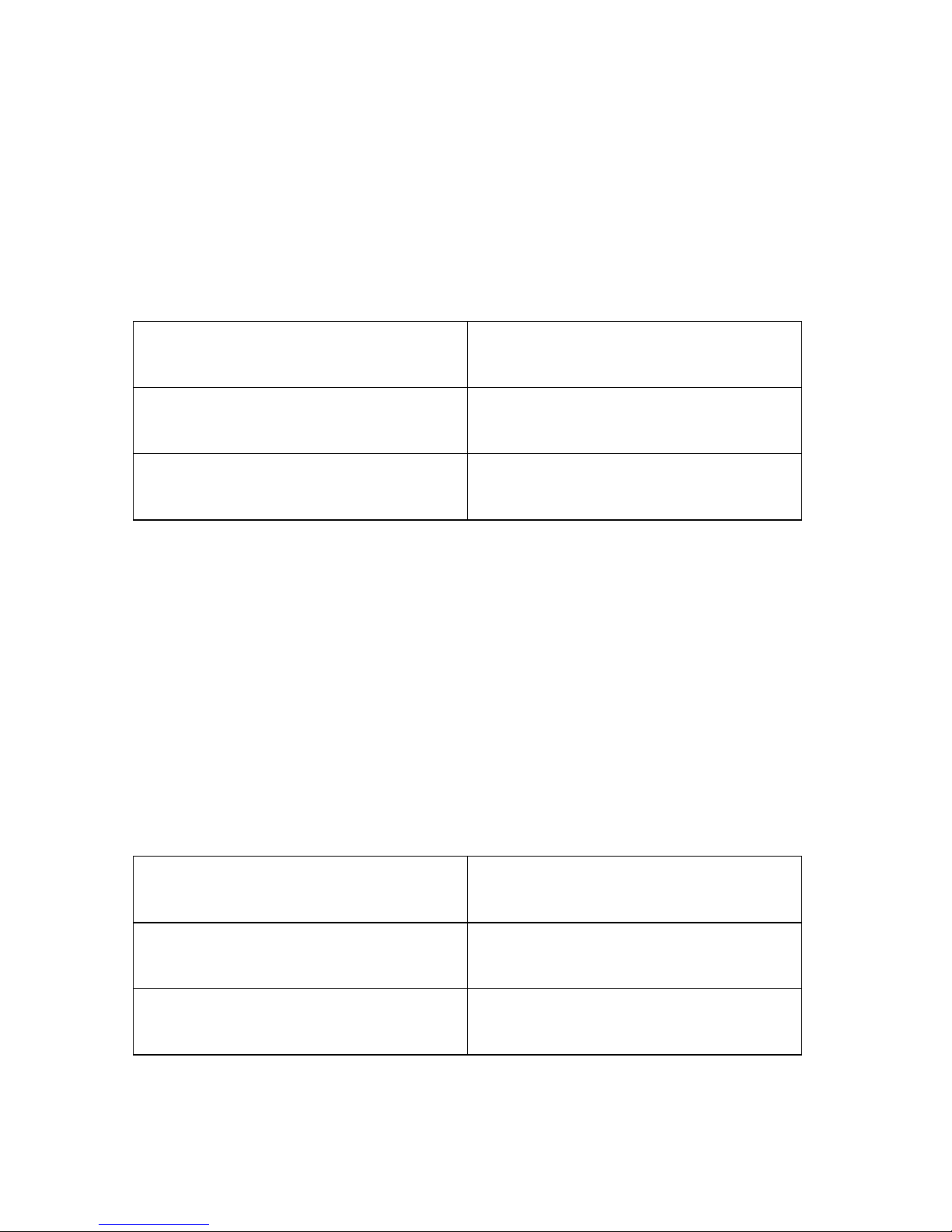

10.1 Air Purification System is Inoperable

If the unit fails to power on, the issue may be the result of one of the following

causes. In some cases, the unit will require service by the manufacturer or a

professionally licensed electrician.

Possible Cause

Solution

Blown Fuse

Replace the Fuse

Safety Switch not engaged

Properly close the Access Door

Safety Switch malfunction

Replace the Safety Switch

HV Board malfunction

Replace the HV Board

PCB Board delay function

Unplug and re-plug Power Cord

10.2 Air Purification System Powers On but Unit is Inoperable

If the unit powers on but fails to operate properly, the issue may be the result of

a faulty electrical board and will require service by the manufacturer or a

professionally licensed electrician.

Possible Cause

Solution

PCB Board malfunction

Reconnect/Replace PCB Board

19

X. Basic Service and Troubleshooting

10.3 Air Purification System Powers On but Fan is Inoperable

If the unit powers on but the fan fails to operate, the issue may be the result of

a faulty motor and will require service by the manufacturer or a professionally

licensed electrician.

Possible Cause

Solution

Fan/Motor malfunction

Replace the Fan/Motor

PCB Board malfunction

Replace the PCB Board

10.4 Fan Speed Cycle Error

If the unit does not properly cycle through all three (3) fan speed settings, or

the unit shuts off when cycling through the fan speed settings, the issue may

be the result of one of the following causes.

Contact the manufacturer for the Control Panel reset instructions. If that does

not resolve the issue, the unit will require service by the manufacturer or a

professionally licensed electrician.

Possible Cause

Solution

Control Panel program error

Control Panel reset procedure

Display Board malfunction

Replace Display Board

This manual suits for next models

2

Table of contents