HE&M H90A-1 User manual

1

BLADE CHANGE

FOR

HORIZONTAL

AIR SAW

MACHINES

2

Changing the Blade

NOTE: The procedure described is applicable to all Air Saws but may not visually reflect some

saw models.

REMOVING THE BLADE

CAUTION!!!!

Wear gloves to protect hands while

changing blades. Band Saw blades are extremely sharp

and can cause serious cuts, amputation, or death unless

necessary precautions are taken.

1. Adjust the Upper Stop Limit Collar to raise

the arm about 6”, or enough that the band wheel

doors can be opened over the vise. In some

cases, especially if the saw is equipped with

optional top clamps, it may be easier to swing

the arm slightly to a miter position, if it is a

mitering band saw.

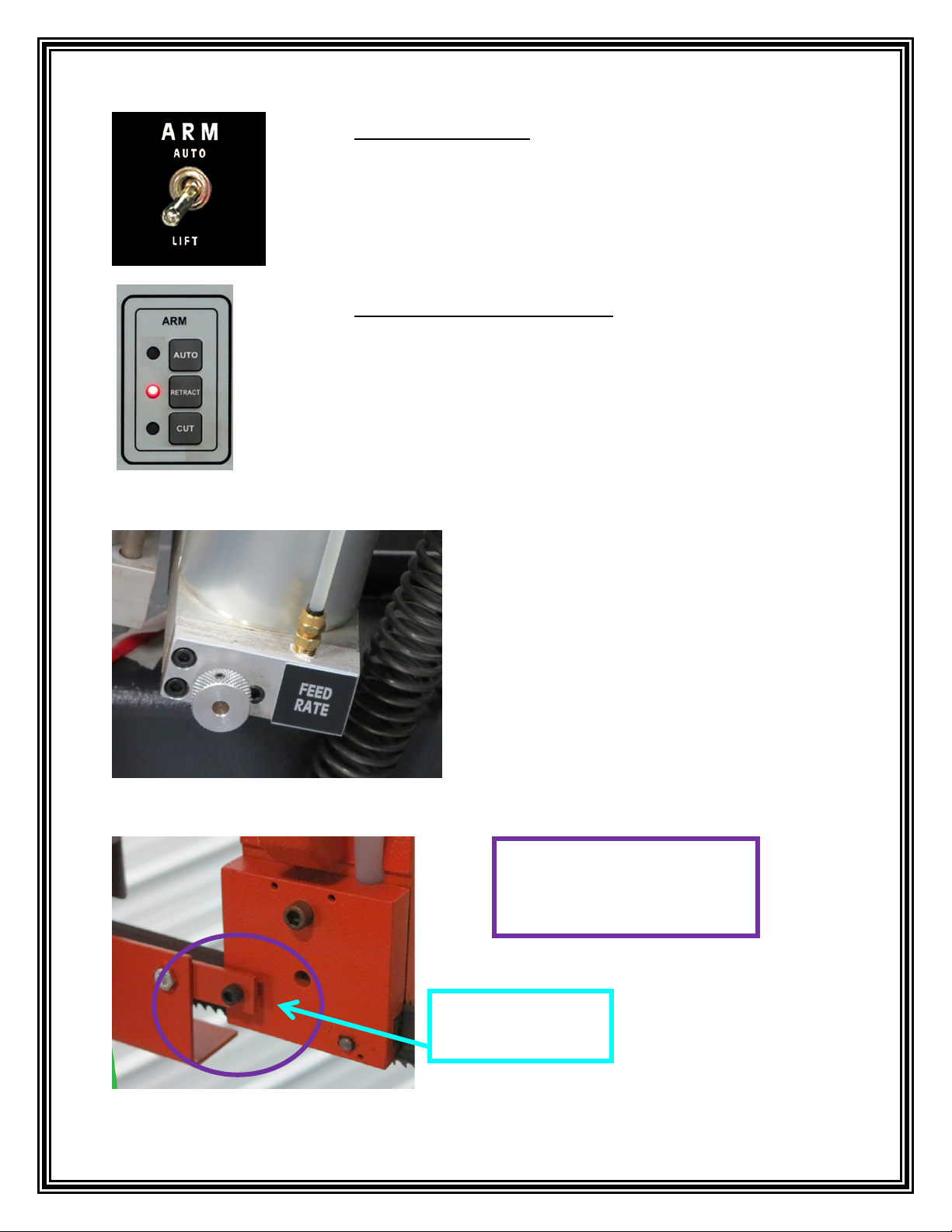

2. FOR MANUAL AIR SAWS: Place the ARM Switch into the

“LIFT” position on the control panel to raise the arm to the

position previously set by the Upper Stop Limit Collar.

3

2. FOR A-4 AND A-C AIR SAWS: Press the ARM

“RETRACT” button on the control panel to raise the arm to the

position previously set by the Upper Stop Limit Collar.

4. Raise the Sliding Blade

Guard Latch.

SLIDING BLADE

GUARD LATCH

2. FOR A-1 AIR SAWS: Move the ARM Switch down to the

“LIFT” position to raise the arm to the position previously set by

the Upper Stop Limit Collar.

3. Turn the Feed Rate Knob completely to the

right by turning the knob clockwise. This will

close the Feed Rate air flow out from the

cylinder to prevent the saw arm from falling

during a blade installation/change.

4

Sliding Blade Guard

6. Slightly loosen the Guide Cap Allen Bolts located on both sides of the saw blade.

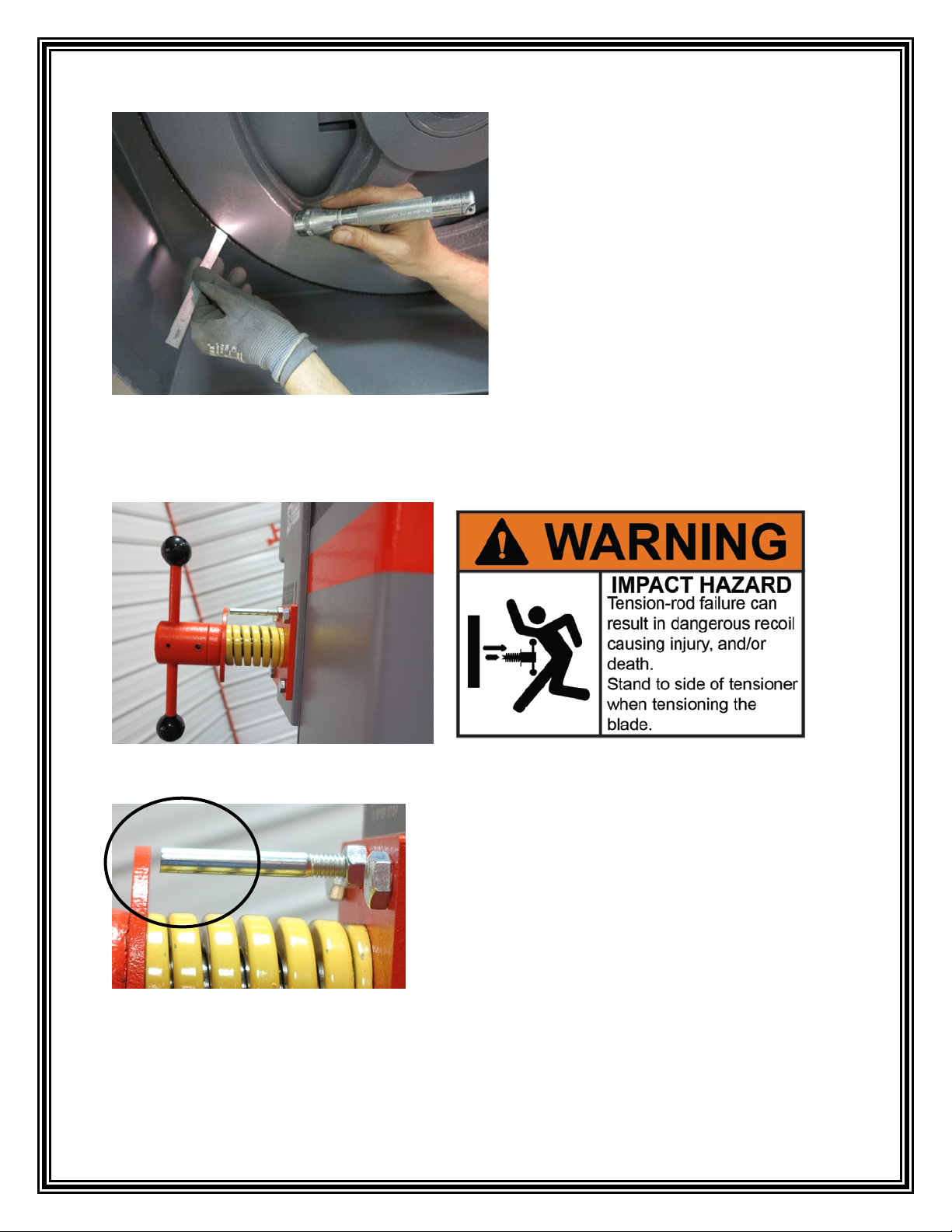

7. Turn the Blade Tension Handle to remove the blade tension. Turn the handle counter

clockwise to loosen and clockwise to tighten. Stand aside when doing this. DO NOT STAND

IN FRONT OF THE TENSION HANDLE. The tension handle is under great tension and

will cause injury if it comes out.

BLADE TENSION

HANDLE

Tension on the blade

is released.

5. Move the Sliding Blade Guard out of

the way.

5

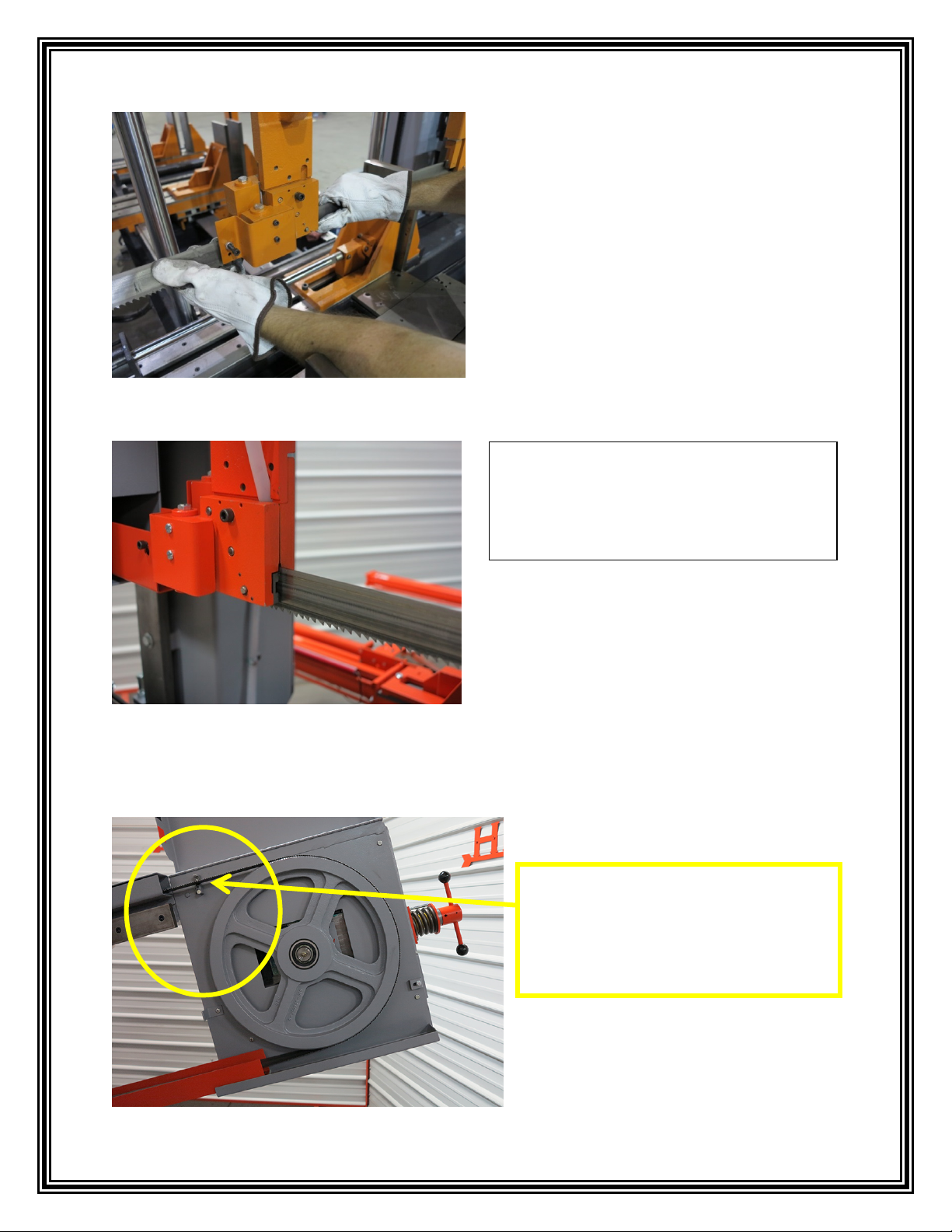

9. Using both hands, push the saw

blade down and out of the guide caps.

CAUTION!! Be careful as the blade

will attempt to un-twist when it

comes out of the guides.

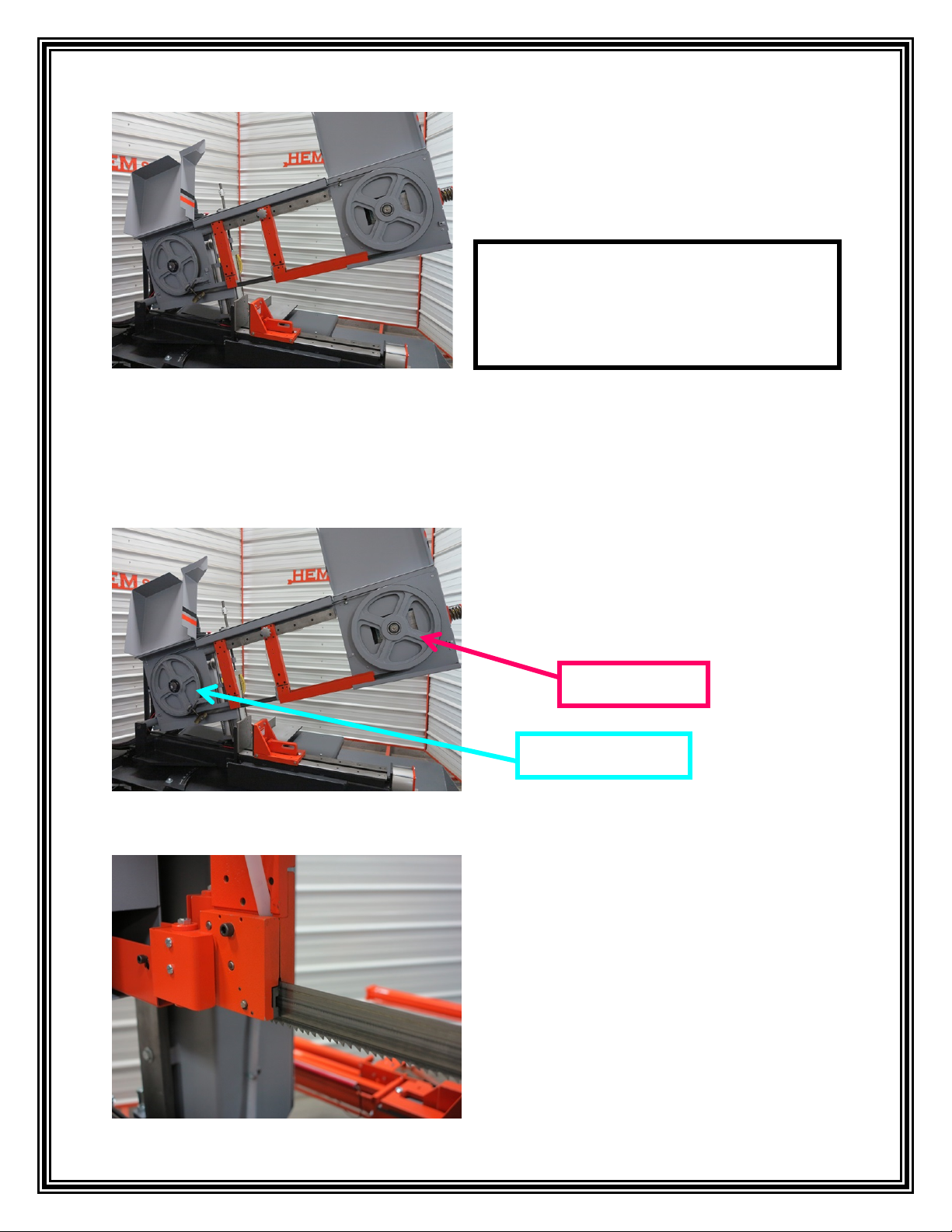

10. To remove the blade the Drive and Idle Wheel

Covers must be open. To open the Drive and Idle

Wheel cover there are door handles located on each

wheel cover. Lift up on the door handles to open the

wheel covers.

DOOR HANDLE

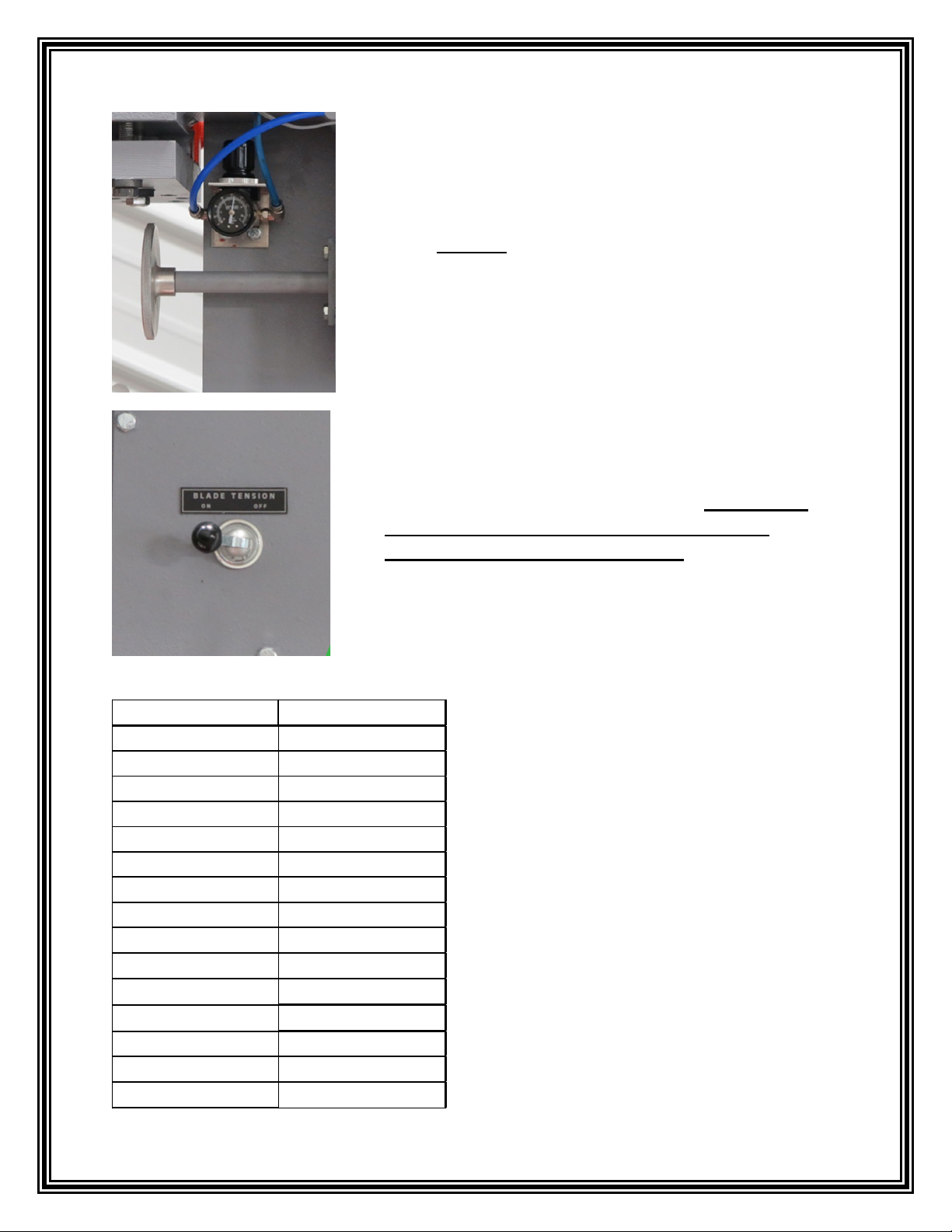

8. When changing the blade on

models with the Optional Air-

Powered Blade Tensioner, first turn

the Blade Tension lever to “OFF”.

Then turn the Blade Tension Knob

to loosen the blade enough to be

removed from the band wheels.

NOTE: This step is ONLY for

Saw Models equipped with the

Optional Air Powered Blade

Tension.

BLADE TENSION

SWITCH

BLADE TENSION

KNOB

6

INSTALLING A NEW BLADE

11. Once the wheel covers have been raised,

slip the blade off of both wheels and

carefully remove the blade from the saw.

1. Once the old blade has been removed

the new blade can be installed. Place the

blade around the Drive and Idle Wheels

with the blade teeth facing outward.

IDLE WHEEL

DRIVE WHEEL

NOTICE!!!! Be careful when handling saw

blades so that the tooth edge is not damaged.

A chipped or broken tooth will cause cutting

problems.

2. If Guide Caps have been removed to

clean the Blade Guides, replace the Guide

Caps but leave them loose enough to be

enable sliding the blade up between the

Carbide Blade Guides.

7

3. Twist the blade into a vertical position and

then insert the blade into the Guide Caps and

between the carbide blade guides. If the Cut

Watcher© feature is present the blade will

have to be maneuvered around that carbide

as well.

NOTE: Make sure the blade is installed

with the teeth pointing down and facing

in the correct direction.

4. Before turning the Blade Tension Handle, make the following checks:

•Make sure the blade is located

properly on the Bumper Block

Carbide near the Idle Wheel.

8

•Check the position of the blade

on the wheels. The teeth of the

blade must NOT touch the

wheel and the blade must NOT

ride on the wheel flanges.

5. Twist the Blade Tension Handle to put tension on the blade. As the blade is tensioned, be

sure to recheck that the blade is still located inside the Bumper Block Carbide.

6. Tension the “T” handle down to within 1/8”

of a flat washer. Do not over-tension the blade.

9

BLADE TENSION CHART

SAW MODEL BLADE TENSION

H90A-1 25,000 PSI

H90A-4 25,000 PSI

H90A-C 25,000 PSI

H105A-4 20,000 PSI

H105A-C 20,000 PSI

H105M 20,000 PSI

H105LA-4 20,000 PSI

H105LA-C 20,000 PSI

H105LM 20,000 PSI

CYCLONE A-4 20,000 PSI

CYCLONE A-C 20,000 PSI

CYCLONE M 20,000 PSI

SIDEWINDER A-1 25,000 PSI

SIDEWINDER A-C 25,000 PSI

SIDEWINDER M 25,000 PSI

7. For saw models with the Optional Air Powered Blade

Tension turn the Blade Tension Knob to tighten the manual

tension till the blade fits snug on the wheels. The Blade

Tension switch will finish the blade tension process.

NOTE: DO NOT over tension the blade with the Blade

Tension Slide Knob. This process is just to make the blade

snug on the wheels.

8. Turn the “Blade Tension” switch to the “ON” position.

This will automatically tension the blade to the proper

setting. After the blade is installed the “Blade Tension”

switch should be left in the “ON” position. NOTE: This

step is ONLY for Saw Models equipped with the

Optional Air Powered Blade Tension.

NOTE: Refer to the Blade Tension Chart to

the left when checking the blade tension

using a blade tension gauge.

10

9. Tighten the blade Guide Caps on

both sides of the saw.

Refer to the Guide Cap Torque

Chart found in the “TIGHTENING

THE GUIDE CAPS” section of this

manual for the correct torque

specifications for this model.

10. Close the wheel covers.

11. Place the Sliding Blade Guard back

into position.

11

12. FOR A-4 AND A-C AIR SAWS: Press the MOTOR “ON”

button and the “Safety Start” on the control panel. The saw has a

self-tracking system that will adjust the blade in or out as the

wheels start rotating. Let the blade run for about 30 seconds, to

allow the blade to track itself on the wheels.

12. FOR MANUAL AIR SAWS: Move the spring-loaded

MOTOR Switch to the “START” position to start the Band Motor.

The saw has a self-tracking system that will adjust the blade in or

out as the wheels start rotating. Let the blade run for about 30

seconds, to allow the blade to track itself on the wheels.

13. FOR MANUAL AIR SAWS: Then place the MOTOR

Switch in the “OFF” position.

12. FOR A-1 AIR SAWS: Move the MOTOR switch on the

control panel to the “ON” position. The saw has a self-tracking

system that will adjust the blade in or out as the wheels start

rotating. Let the blade run for about 30 seconds, to allow the blade

to track itself on the wheels.

12

15. Check the blade brush assembly. Set

the brush to make light contact with the

blade. The wires on the brush should only

sweep through the gullet of the teeth. If the

blade brush is not set properly, it may

cause dulling of the blade on one side and

premature wear of the brush. (Refer to the

“ADJUSTING THE BLADE BRUSH”

section in this manual for additional

information.)

13. FOR A-4 AND A-C AIR SAWS: Then press the MOTOR

“OFF” button.

14. Open the Drive and Idle Wheel Covers and

verify that the blade is still properly located on

the Bumper Block Carbide and the blade is now

in the correct position on the wheel. It is

advisable to recheck the Guide Cap tightness.

13. FOR A-1 AIR SAWS: Move the MOTOR switch to

the “OFF” position.

This manual suits for next models

14

Table of contents

Other HE&M Saw manuals

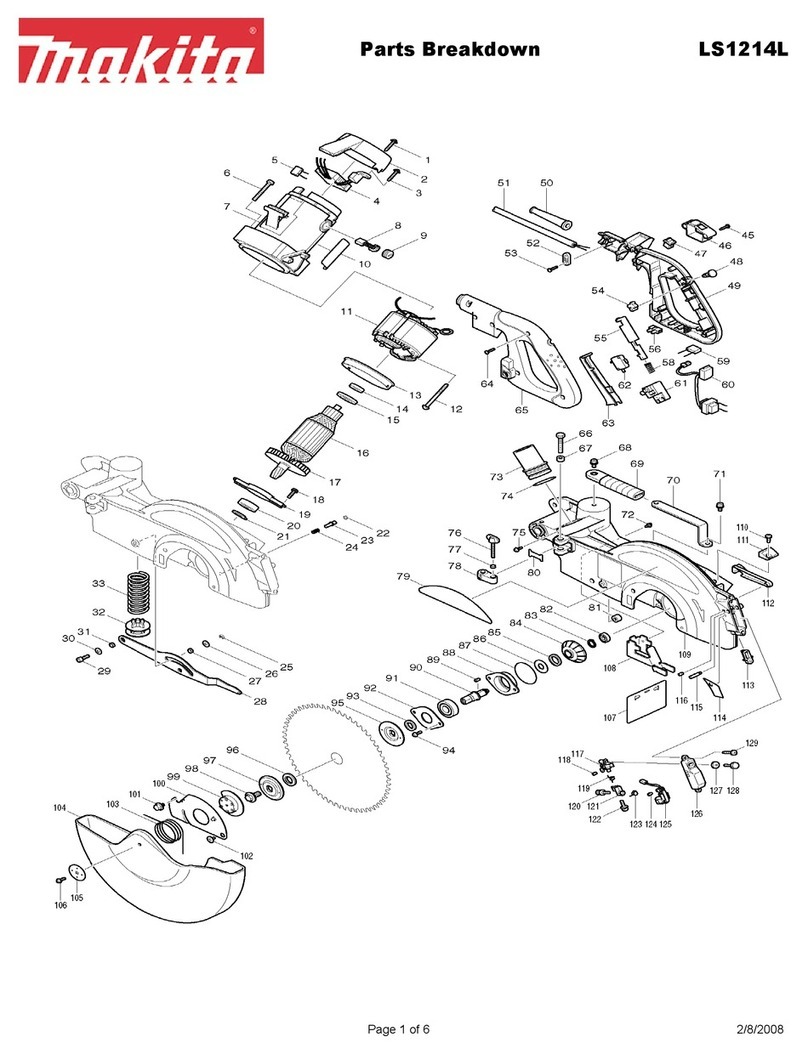

Popular Saw manuals by other brands

Porter-Cable

Porter-Cable 423MAG instruction manual

Bosch

Bosch GCB 18 V-LI Professional Original instructions

Cengar

Cengar CL50 operating instructions

Bosch

Bosch GCO 14-24 J Original instructions

Parkside

Parkside PAAS 12 A2 Translation of the original instructions

Hitachi

Hitachi C 10FCH2 Handling instructions