HE&M Hurricane 2030A User manual

1

OMRON CONTROL

TS OPERATIONS

FOR

HURRICANE

2030A SAWS

2

OPERATIONS

How to Energize the Saw

1. Pull the Main Disconnect lever located on the High Voltage Junction Box to the “ON”

position to energize the saw.

NOTE: It is recommended that this entire control operations section be

read completely before energizing the control. Follow the step by step

instructions below while working with the control and saw.

2. Verify that the “Emergency Stop” button located on top left corner of the

control console is raised up in the off position. (If it is pressed down, turn

the button clockwise to raise it.)

3. The “KEYLOCK” switch must be in the "NORMAL" position.

4. Turn the spring-loaded “POWER” switch to the “ON” position. This

energizes the programmable logic controller (PLC), which initiates the

touch screen program.

NOTE: Verify that all of the function switches on the control console are

in the green “STOP/AUTO” position. This position is indicted by the

green font on the switch name labels. (This is a safety feature; the saw

will not start if certain switches are not in the correct position.)

3

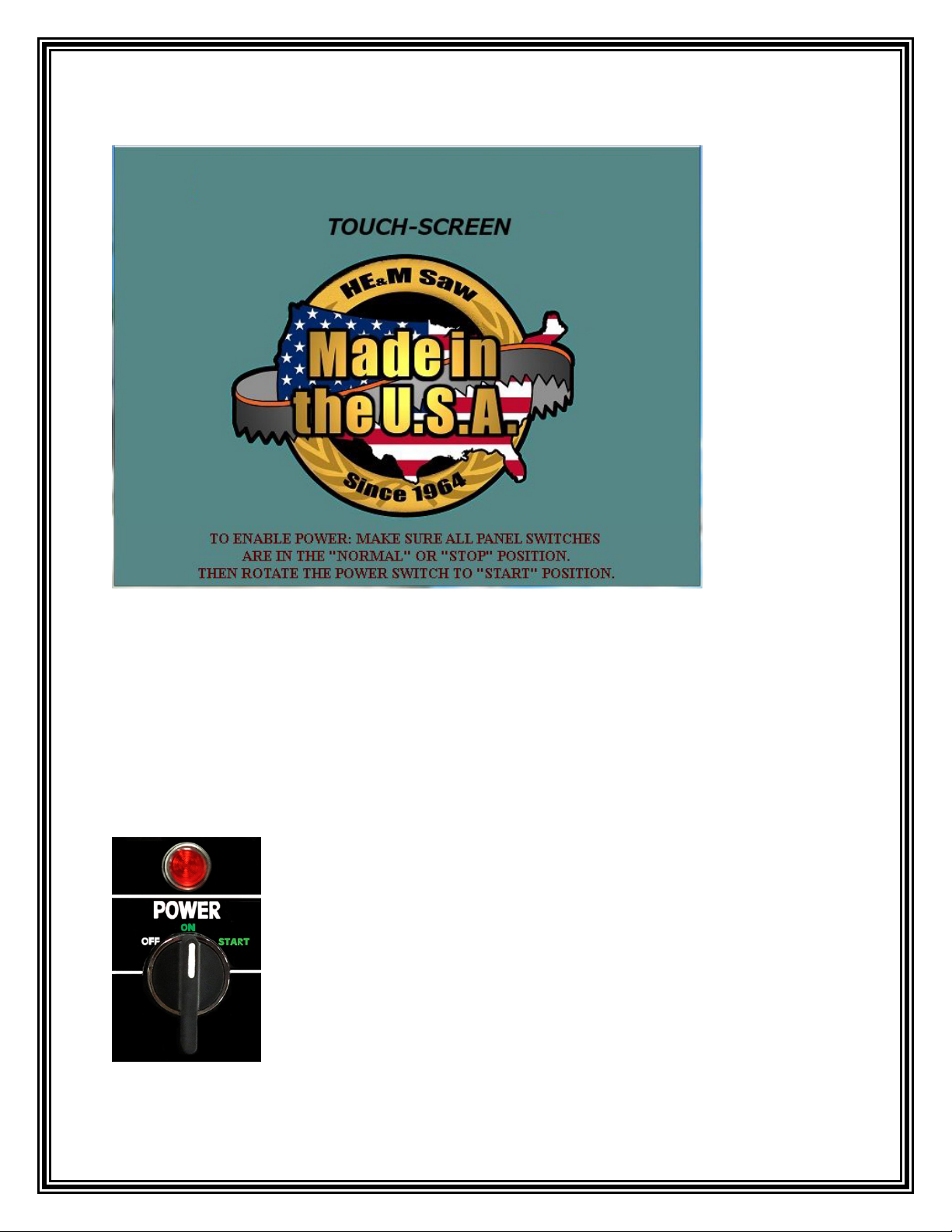

6. After the computer initializes, a “CAUTION” screen will appear. Please read the warnings

before proceeding.

.

7. After reading and understanding the

caution warnings, select the “I HAVE

READ THESE CAUTIONS AND I

WISH TO PROCEED” icon.

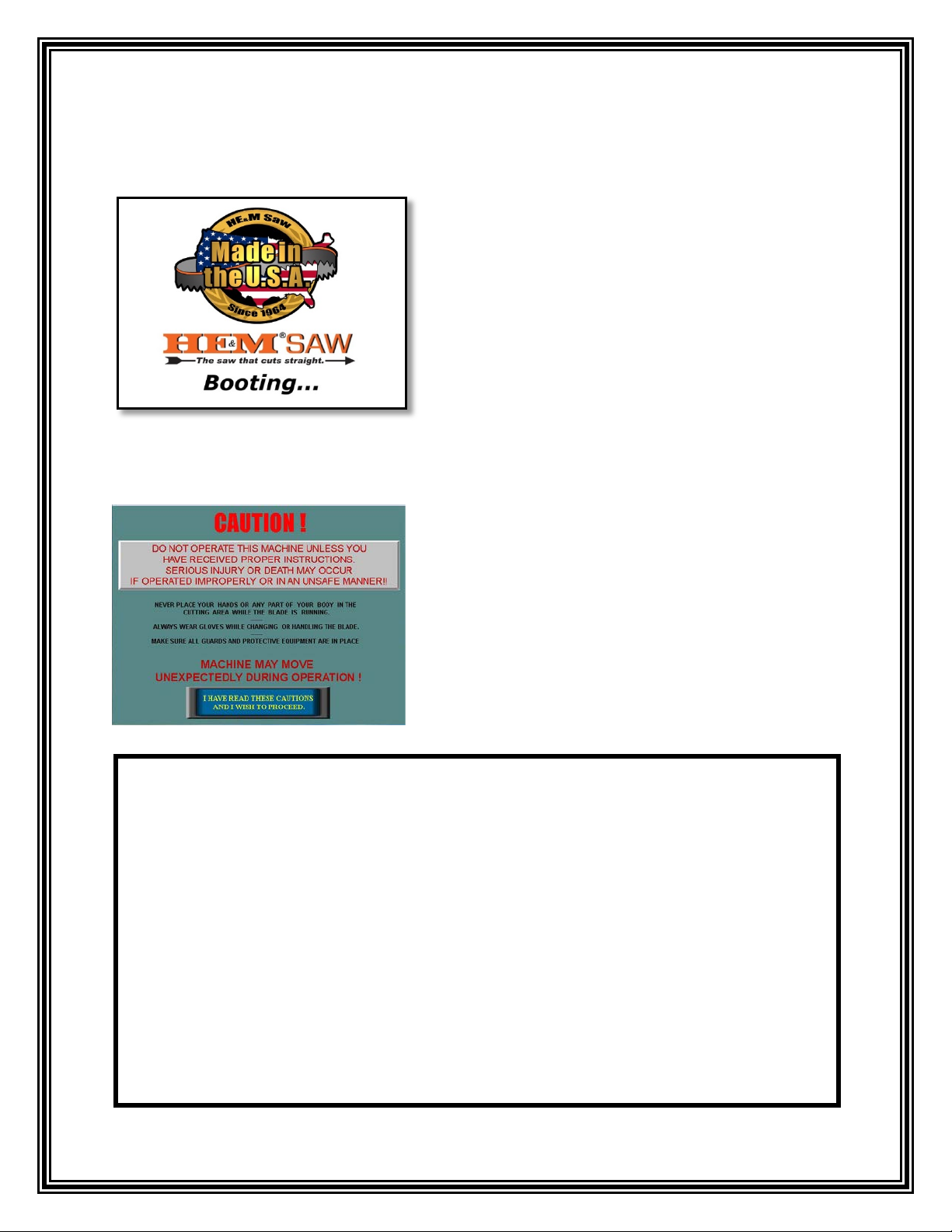

5. The following “Booting” screen will appear on the touch screen as shown below. While

the screen is booting all the console lights will flash for a brief period.

DO NOT OPERATE THIS MACHINE UNLESS YOU HAVE RECEIVED PROPER

INSTRUCTIONS.

SERIOUS INJURY OR DEATH MAY OCCUR IF OPERATED IMPROPERLY OR

IN AN UNSAFE MANNER.

NEVER PLACE YOUR HANDS OR ANY PART OF YOUR BODY IN THE

CUTTING AREA WHILE THE BLADE IS RUNNING.

ALWAYS WEAR GLOVES WHILE CHANGING OR HANDLING THE BLADE.

MAKE SURE ALL GUARDS AND PROTECTIVE EQUIPMENT IS IN PLACE.

MACHINE MAY MOVE UNEXPECTEDLY WHILE OPERATED IN AN

AUTOMATIC MODE!

4

8. The following screen will appear.

9. With all of the function switches on the control console still in the green “NORMAL” or

“STOP/AUTO” position the Hydraulic System can now be energized.

10. Turn the spring-loaded “POWER” switch to the “START” position.

The spring-loaded switch will return to the center “ON” position. The

light above the “POWER” switch will illuminate indicating that the

control is energized. When the “POWER” switch is activated, the

hydraulic pump will start and all control console switches will become

active.

5

13. A pop-up screen will appear on top of the Main Menu of the touch screen asking “Do you

wish to do a “Quick Cal.” at this time?”

14. By pressing the “YES” icon, the

“CONTROL PANEL” screen will appear

and allow for a Quick Calibration of the

Feed Encoder, Height Encoder and Miter

Encoder by following the prompts. (For

more information on Feed and Arm

Calibration refer to the “CONTROL

PANEL” section of the manual.)

15. After the Quick

Calibration is complete

the Main Menu screen

will appear. The Main

Menu screen presents the

operator with several

options of how to proceed.

Note: It is strongly recommended that the Quick Calibration procedure be followed each

time the control is energized or every 24 hours to ensure accuracy of the feed and arm

height.

6

Startup Bypass Procedure

The following procedure describes the “Startup Bypass Procedure” on any touch screen machine.

In the event that the touch screen doesn’t power up for any reason follow the step by step

procedure to power “ON” the hydraulic system.

1. Turn the Machine “OFF” by turning the spring-loaded “POWER” switch to the “OFF”

position and wait 30 seconds.

2. Hold the spring-loaded “POWER” switch in the “START” position and press the

“CONFIRM” button at the same time for 10 seconds.

3. Press the flashing “RESET” button to start the hydraulic System.

4. The machine will use a default blade speed and a default feed rate (for machines with HCCT)

to cut material.

5. The default rates must be set when the machine is being installed according to the customer

specifications.

6. The customer will have the ability to change the default rate parameters under the

“SUPERVISOR LEVEL 3” login.

7. Changing default values will not be included in the user manual. Please call HE&M Saw’s

service department for more information.

How to De-Energize the Control

The control circuit must be de-energized in a particular way if it is to remain de-energized for an

extended period of time, (over two hours). This will allow the saw to rest and not drift from

square or put strain on the hydraulic components.

1. Raise the arm.

2. Turn the “POWER” switch to the “OFF” position.

3. Turn the “KEYLOCK” switch to the “ENGAGED” position.

4. Press down the “Emergency Stop” Button.

NOTICE: The saw must be allowed to complete the cut through the material it is cutting or

the blade must be raised completely out of the material before the saw is de-energized. If the

saw is de-energized with the blade in the cut it may cause irreparable damage to the blade or

the saw and could void the warranty.

7

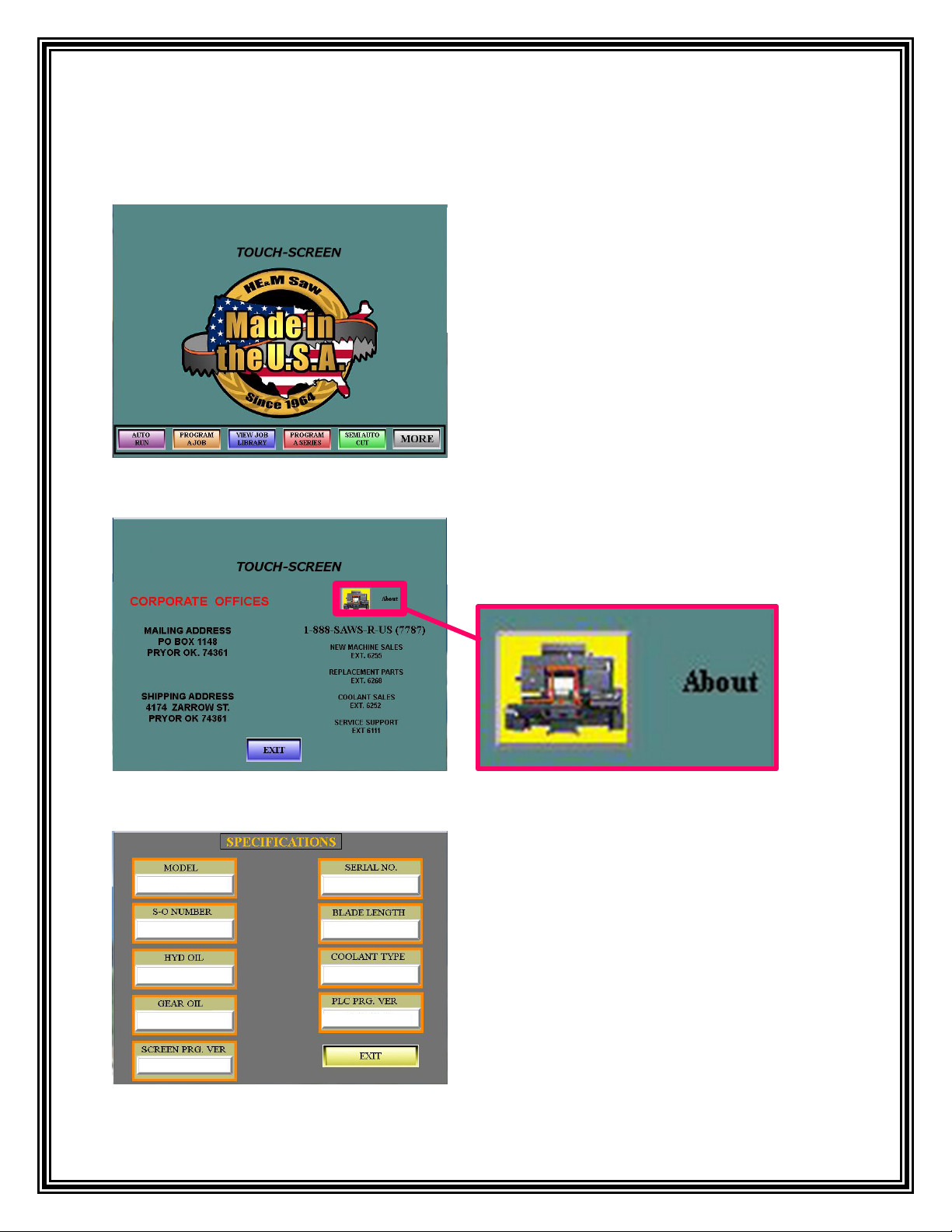

CONTACT INFORAMATION

To access important HE&M Saw phone

numbers, touch the Made in the U.S.A. logo on

the Main Menu and a screen will appear showing

contact information.

To access a list of specifications for the machine

select the “About” icon.

A list of specifications for the machine will

appear.

8

To access the security levels, touch

anywhere on the model number

located at the top of the Main Menu

screen.

A pop-up window will appear displaying the

different Security Levels. Each level adds the

ability to access additional options. To log in,

select a security level and another pop-up

window will appear asking for the password to

the Security Level selected. Enter the correct

password for the level requesting and select the

“OK” icon.

OPERATOR LEVEL 1 allows access to Parameter Settings 1. Parameter Settings 1 allows

access to the adjustments shown in these images.

NOTE: Some settings are “viewable only” and can only be changed with a Higher Level

Login or by the Factory.

9

PREVENTATIVE MAINTENANCE REMINDER

Normal wear and tear can result in lower machine efficiency. Preventative Maintenance

assures optimal working conditions and conserves the life span of the equipment. A planned

preventive maintenance may cause a small burden for production, but nothing compared to

downtime cause by an actual breakdown. All HE&M Saw machines are equipped with a

friendly reminder on when to schedule the next Preventative Maintenance Service

appointment for their machine.

The Main Menu screen

will have a “SERVICE

SOON” icon appear.

Select the “SERVICE SOON” icon and

this “SERVICE WARNING” will appear.

Select the “DONE” icon at the bottom of

the screen to return to the Main Menu.

The “SERVICE SOON” icon will continue to appear until the machine has been serviced.

Contact HE&M Saw service department @ (918)-824-6181to set up your preventative

maintenance appointment.

10

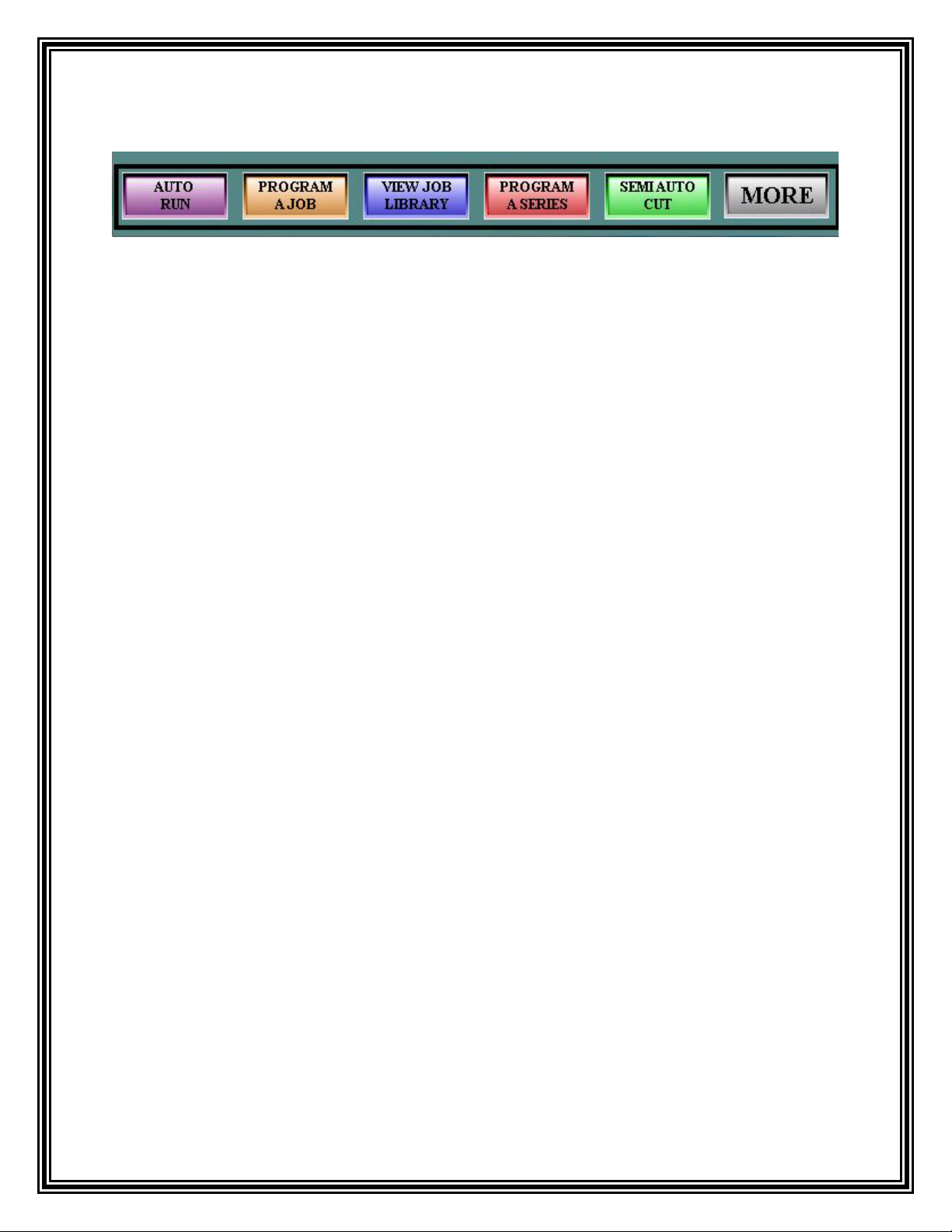

MAIN MENU – Screen Overview

AUTO RUN

This screen allows the operator to run a quick job once the job has been created in the job program screen.

The blade speed, quantity and any cutting operation options, such as extra vises, step feed, etc. can be

adjusted from this screen. Refer to the “Auto Run” section of this manual for further instructions.

PROGRAM A JOB

The operator can create a job program by inputting the desired blade pitch, blade speed, length, height,

and quantity. After creating a job program the operator can run it as a quick job or save it to the Job

Library to recall the information at a later time. Refer to the “Program a Job” section of this manual for

further instructions.

VIEW JOB LIBRARY

The Job Library displays information stored by the operator in an interactive data base that contains up to

1000 jobs including the “Quick Job”, along with specific job information such as length, quantity, blade

speeds, etc. It stores a list of programmed jobs that can be reviewed, edited, or called up to run, either as a

single job, or a series of jobs to be run in consecutive order. Refer to the “View Job Library” section of

this manual for further instructions.

PROGRAM A SERIES

To save time and material, the saw has the ability to run a sequence of up to 12 job numbers (cuts) in a

sequence up to 99 times using the “Program Series” icon. 100 sequences can be saved to recall at a later

time. The operator can enter the job information into the Series Overview screen to create these

sequences. There must be jobs programmed in the “JOB LIBRARY” to program a series. Refer to the

“Program A Series” section of this manual for further instructions.

SEMI AUTO CUT

The Semi Auto Cut allows the operator to make a single, semi-automatic cut without creating a job

number or a job program. This is a good option when performing a one-time cut. Refer to the “SEMI

AUTO CUT” section of this manual for further instructions.

MORE

The “MORE” icon provides access to additional setting and features. The operator can adjust settings for

various functions such as arm and feed calibration, review information on the blade life and motor hours,

or access help files that give instructions on changing the saw blade. Refer to the “Control Panel” and

“Help Files” section of this manual for further instructions.

11

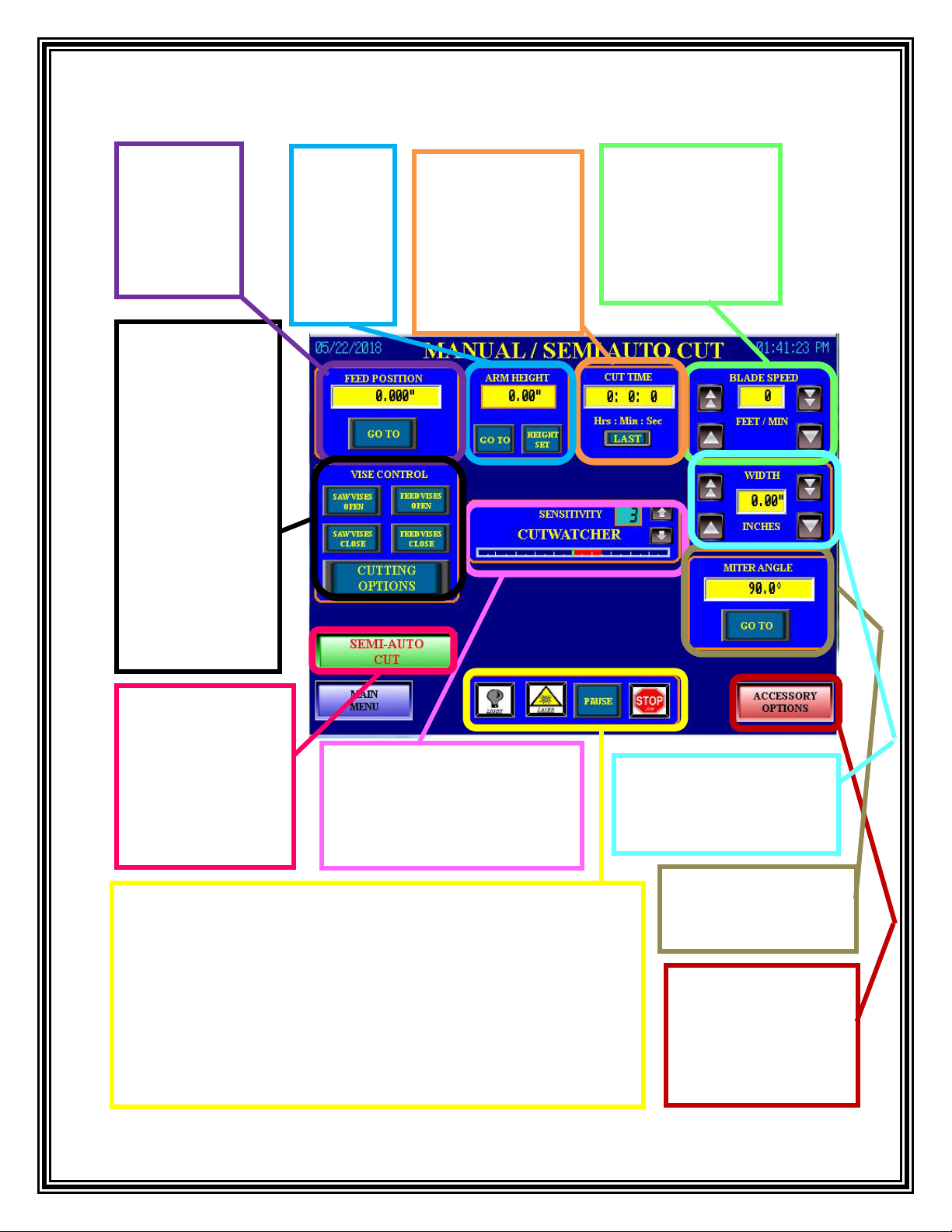

MANUAL/SEMI AUTO CUT – Screen Overview

FEED

POSITION:

Places the feed

into the desired

position before

a cut.

BLADE SPEED:

Displays the Blade

Speed in feet per

minute. This can be

adjusted using the

arrow keys or through

the numeric input.

CUT TIME:

Displays the time

recorded for the

current cut. By

pressing the “LAST”

icon it will show the

time recorded for the

previous cut.

ARM

HEIGHT:

Places the

arm at the

desired

height

before a

cut.

MITER ANGLE: Places

the arm to the desired

angle before a cut.

WORK LIGHT: Turns on or off the work light.

LASER LIGHT: (Optional) Turns the Laser Light on or off. When the laser

alignment beam is activated, the work light will automatically turn off to allow

better laser visibility.

PAUSE: By selecting this, it will pause the active cutting cycle. The operator

will be able to resume the cut by selecting the icon again.

STOP: Stops the cut in progress and cannot restart without restarting the

process.

SEMI-AUTO CUT:

Press “SEMI-AUTO

CUT” and the

“CONFIRM” button to

make a cut in the

material. The Semi-

Auto icon will now

read “CUTTING”.

VISE CONTROL:

Operator is able to

open or close the

selected Saw Vise

and the Feed Vise by

selecting either the

open or close icons.

CUTTING

OPTIONS: Allows

the operator to select

various aspects of

saw operation such as

Vise Selection, Arm

Retract, and Cut

Watcher.

ACCESSORY

OPTIONS:Select to

access the Coolant, Chip

Auger, and other various

option settings. (For more

information refer to the

CUT WATCHER: The Cut watcher

displays when the saw is cutting out

of square. The sensitivity level can

be adjusted using the arrows or

through the numeric input.

WIDTH: Displays the width

of the material. This can be

adjusted using the arrow keys

or through the numeric input.

12

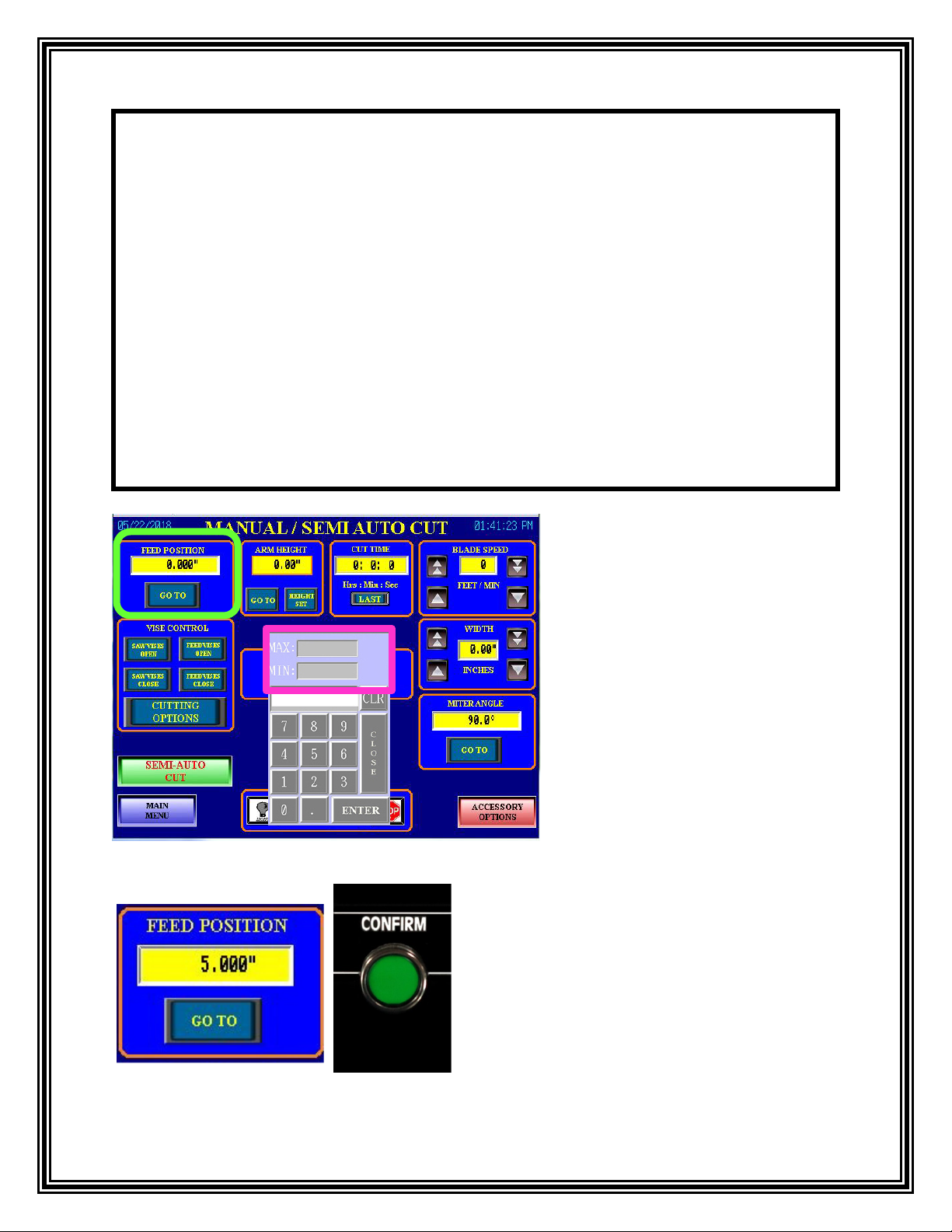

Semi Auto Cut

1. Press the “SEMI AUTO CUT” icon on

the Main Menu.

NOTE: The “CONFIRM” button is used

in conjunction with many of the saw’s

operations. When performing an

operation that works in conjunction with

the “CONFIRM” button the

“CONFIRM” button will flash and light

up to indicate that it must be pressed

while performing the operation.

2. The “MANUAL/SEMI AUTO CUT”

screen will appear. This screen allows for

adjustments to the cutting operation.

NOTE: Most operations will allow the operator to change the

job parameters by touching the numerical box. This will open a

pop-up keypad that allows the operator to enter in new job

parameters. The keypad will have a Minimum and Maximum

value displayed at the top. The keypad will not allow the

operator to enter a number and continue the process if the value

entered is higher or lower than what is displayed in the “MAX”

and “MIN” fields.

13

3. To adjust the feed shuttle

position select the numerical box

in the “FEED POSITION”

window and a pop-up keypad will

appear. Input the desired length

and select the “ENTER” icon.

The new feed position value will

display and the keypad will

disappear.

MAX – Table Length

MIN - 0

4. Press the “GO TO” icon on the touch

screen and the “CONFIRM” button on the

control console at the same time and the

feed shuttle will adjust to the position

entered.

Note:

HE&M Saw machines with the Omron touch screen have strict safety controls.

Therefore every pinch point operation is a “Two Hand” operation. This means the

operator must initiate the desired operation and press the “CONFIRM” button at the

same time.

Pinch Point Operations are:

•Vises “OPEN” and “CLOSE”

•Arm “RAISE” and “LOWER”

•Guide “OUT” and “IN”

•Feed shuttle “FORWARD” and “RETRACT”

•Turning Motor “ON”

•Turning the Chip Removal System “ON”

•Starting a Manual/Semi Auto Cut

•Miter Angle “INCREASE” and “DECREASE”

14

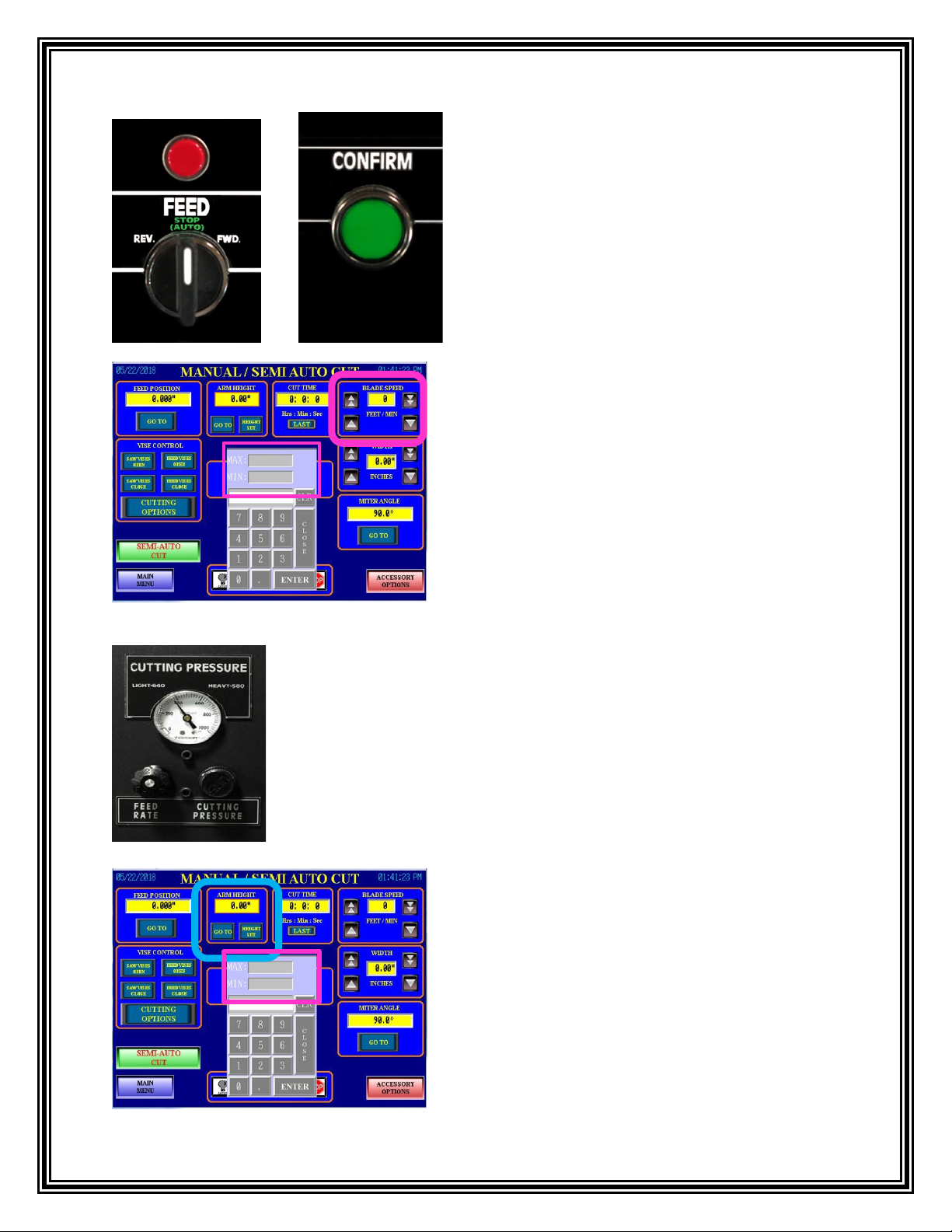

6. To adjust the Blade Speed use the arrows in

the “BLADE SPEED” window. Using the

single up and down arrows will increase or

decrease the blade speed by 1. Using the

double up and down arrows will increase or

decrease the blade speed by 10’s. Or select the

numerical box in the middle of the arrows and

a pop-up keypad will appear. Input the desired

blade speed and select the “ENTER” icon and

the keypad will disappear.

MAX – 300

MIN - 60

8. To adjust the arm height select the numerical

box under the “ARM HEIGHT” window and a

pop-up keypad will appear. Input the desired arm

height and select the “ENTER” icon. The new

arm target position value will be displayed and

the keypad will disappear.

MAX – Maximum height of the machine

MIN- 0.5

7. “Knobs and Gauges” are used to set the “FEED RATE” and

“CUTTING PRESSURE” (Traverse Control). For more

information refer to the Feed Rate and Cutting Pressure section in

this manual.

5. To adjust the feed shuttle position

manually use the “FEED” switch and the

“CONFIRM” button located on the control

console to move the feed forwards or

backwards.

15

10. To adjust the arm height manually move the

spring-loaded “ARM” joystick on the control

console up into the “RAISE” position while

pressing the “CONFIRM” button. Hold the

“ARM” joystick in the “RAISE” position until the

appropriate height has been reached the operator

can let go of the spring-loaded “ARM” joystick

and it will return to the “STOP/AUTO” position.

9. Then press the “GO TO” icon on the touch

screen and the “CONFIRM” button on the control

console at the same time. Once the arm has

reached the arm height position previously entered

the arm will stop moving and the operator can

select the “HEIGHT SET” icon. This will set the

height that the arm will return to after each cut.

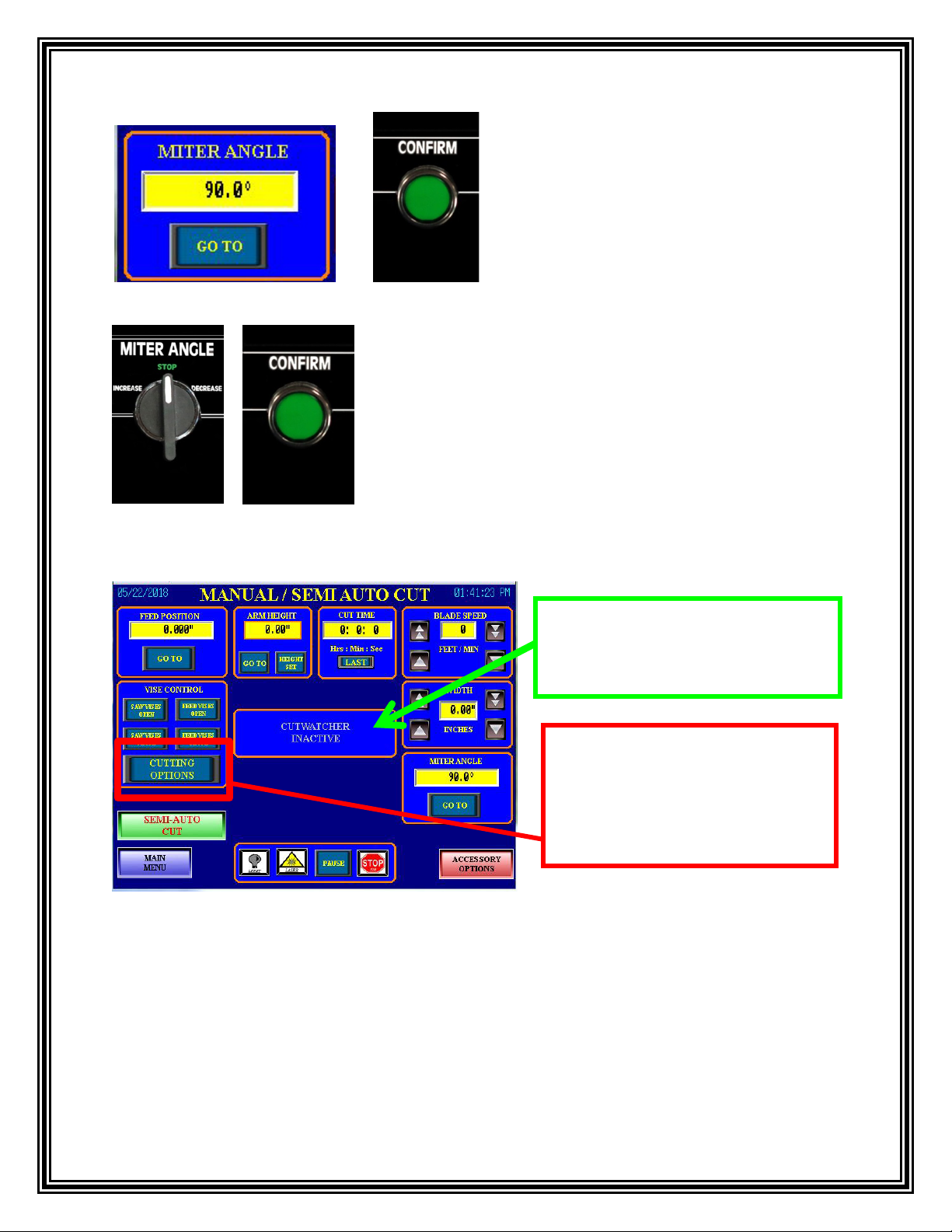

12. To adjust the miter angle select the

numerical box in the “MITER ANGLE”

window and a pop-up keypad will appear.

Input the desired angle and select the

“ENTER” icon. The new angle will be

displayed and the keypad will disappear.

MAX – 90°

MIN- 30°

11. Press the “HEIGHT SET” icon on the touch screen. This will

set the height that the arm will return to after each cut and now the

present arm height will be displayed.

16

Cut Watcher: Monitors blade deviation, and is useful in detecting when the blade begins to cut

dull and/or starts cutting out of square. A sensor mounted on the adjustable guide arm is

connected to a precision carbide guide that rides on one side of the saw blade. If the blade begins

to deviate at any time, a digital display on the touch screen panel will indicate the deviation. As

the saw blade continues to dull, the deviation may increase. The readout on the screen is helpful

to detect a cutting problem due to a dull blade or over-feeding the saw blade through the

material. For more information, refer to the Cut Watcher section in this manual. NOTE: The Cut

Watcher is not a standard feature on all saw models.

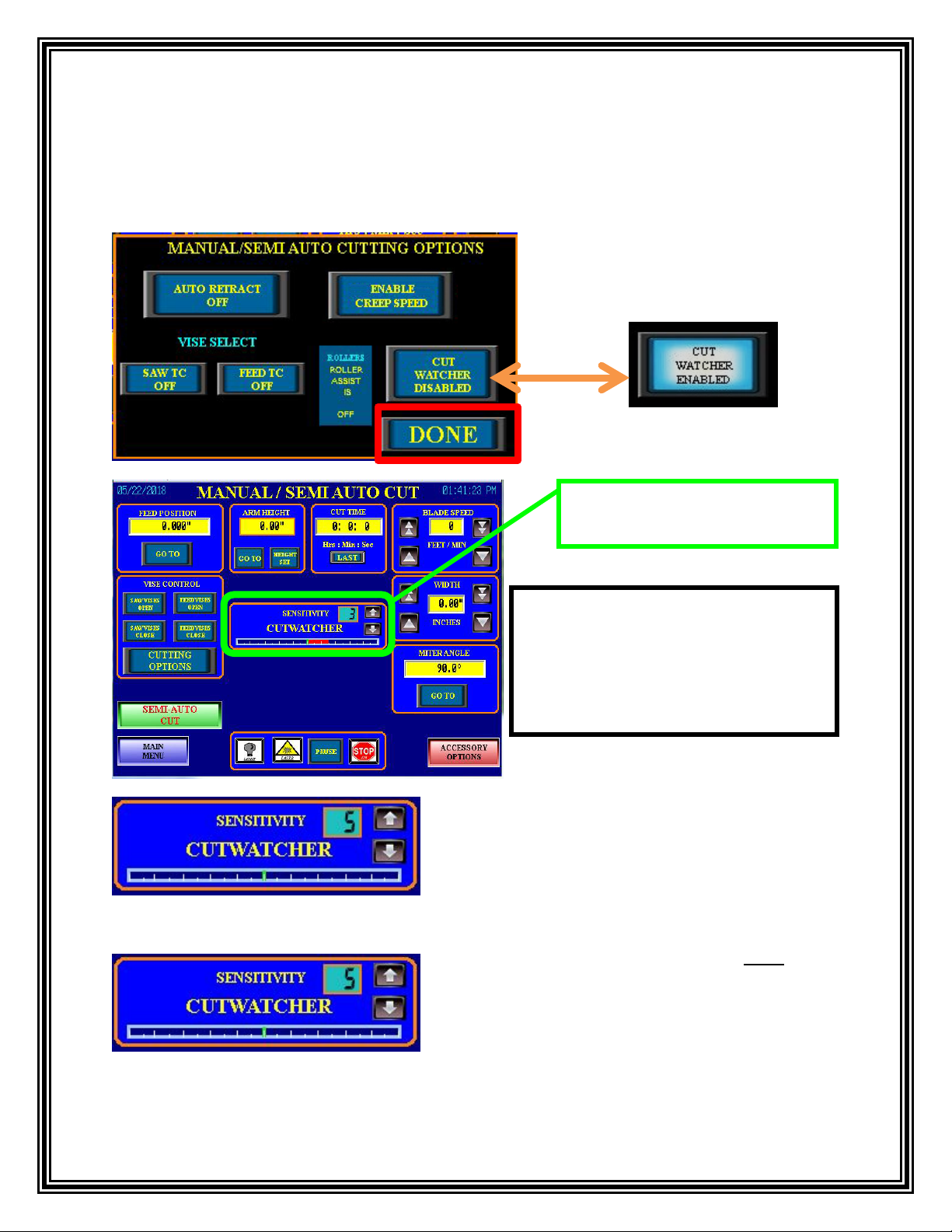

16. To activate the cut watcher,

select the “CUTTING OPTIONS”

icon. The “MANUAL/SEMI

AUTO CUTTING OPTIONS”

screen will appear.

15. This image shows the “CUT

WATCHER” is currently

“INACTIVE”.

13. Press the “GO TO” icon on the touch

screen and the “CONFIRM” button on

the control console at the same time and

the arm will adjust to the angle entered.

14. To adjust the Miter Angle manually use the

“MITER ANGLE” switch and the “CONFIRM”

button located on the control console to increase or

decrease the degree of the angle.

17

17. To “Enable” the Cut Watcher select the “CUT WATCHER DISABLED” icon. The icon

will now show “CUT WATCHER ENABLED”. Then select the “DONE” icon. The

“MANUAL/SEMI AUTO CUTTING OPTIONS” screen will close.

18. The Cut Watcher function is

now enabled and active.

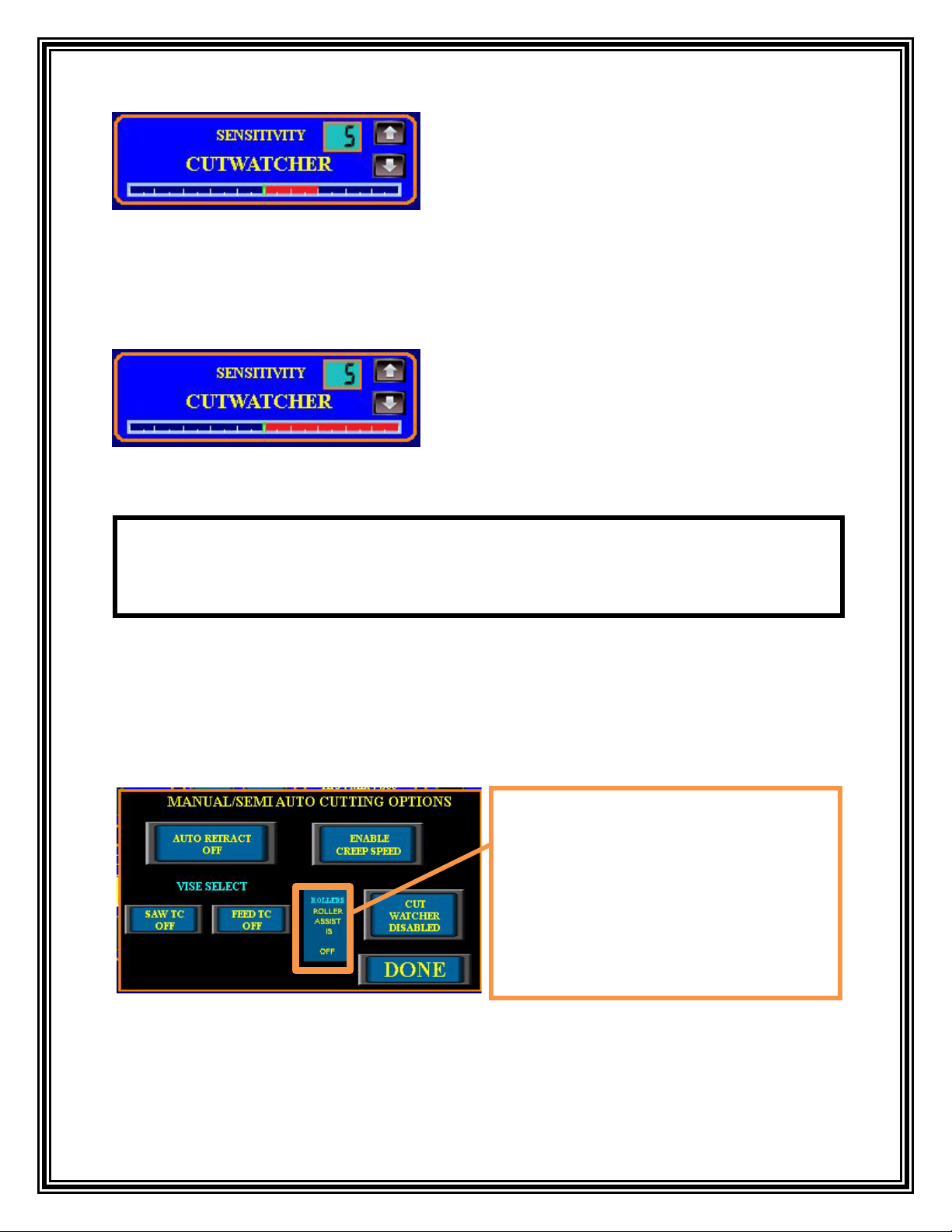

20. When the Cut Watcher centerline is NOT

displaying a red bar to either one side or the other,

this indicates that the Cut Watcher is calibrated

and the blade is cutting straight as shown in this

image. This is the desired appearance that is

obtained by adjusting the Cut Watcher after a new

blade is installed.

19. The Operator can now use the ↑↓ arrows to

adjust the sensitivity of the Cut Watcher. Or they

can select the numerical box and input the number

of sensitivity from the pop-up keypad.

Note: The Cut Watch Sensitivity is in

the lowest degree of sensitivity when

it is set to a “1” and the highest

degree of sensitivity when it is set to

a “10” on the touch screen control.

18

23. From the “MANUAL/SEMI AUTO CUTTING OPTIONS” screen the operator will be

able to activate or deactivate certain features (if available) from this screen. Select the

“CUTTING OPTIONS” icon from the “MANUAL/SEMI AUTO CUT” screen.

22. This image shows the red bar illuminated all the

way to the right of the center. If this condition

remained for approximately 20 seconds while the

saw is cutting, the Cut Watcher function will go into

panic mode.

21. If the blade deviates from cutting straight, a

bar on the appropriate side will appear, indicating

the relative amount of deviation. In this image the

Cut Watcher is starting to read out-of-square with

two red bars to the right of the center. The bar will

grow progressively as the sensor detects deflection

of the blade to either side of the center.

NOTE: Some of the icons shown on the “MANUAL/SEMI AUTO CUTTING

OPTIONS” screen are optional and do not come standard with all saw

models.

ROLLER ASSIST INDICATOR: The

Roller Assist indicator displays if the

roller assist feature is currently ON or

OFF. This feature is controlled from the

“ACCESSORY OPTIONS” screen. Refer

to the “CONTROL PANEL” section of

this manual for further information on

using the Roller Assist.

19

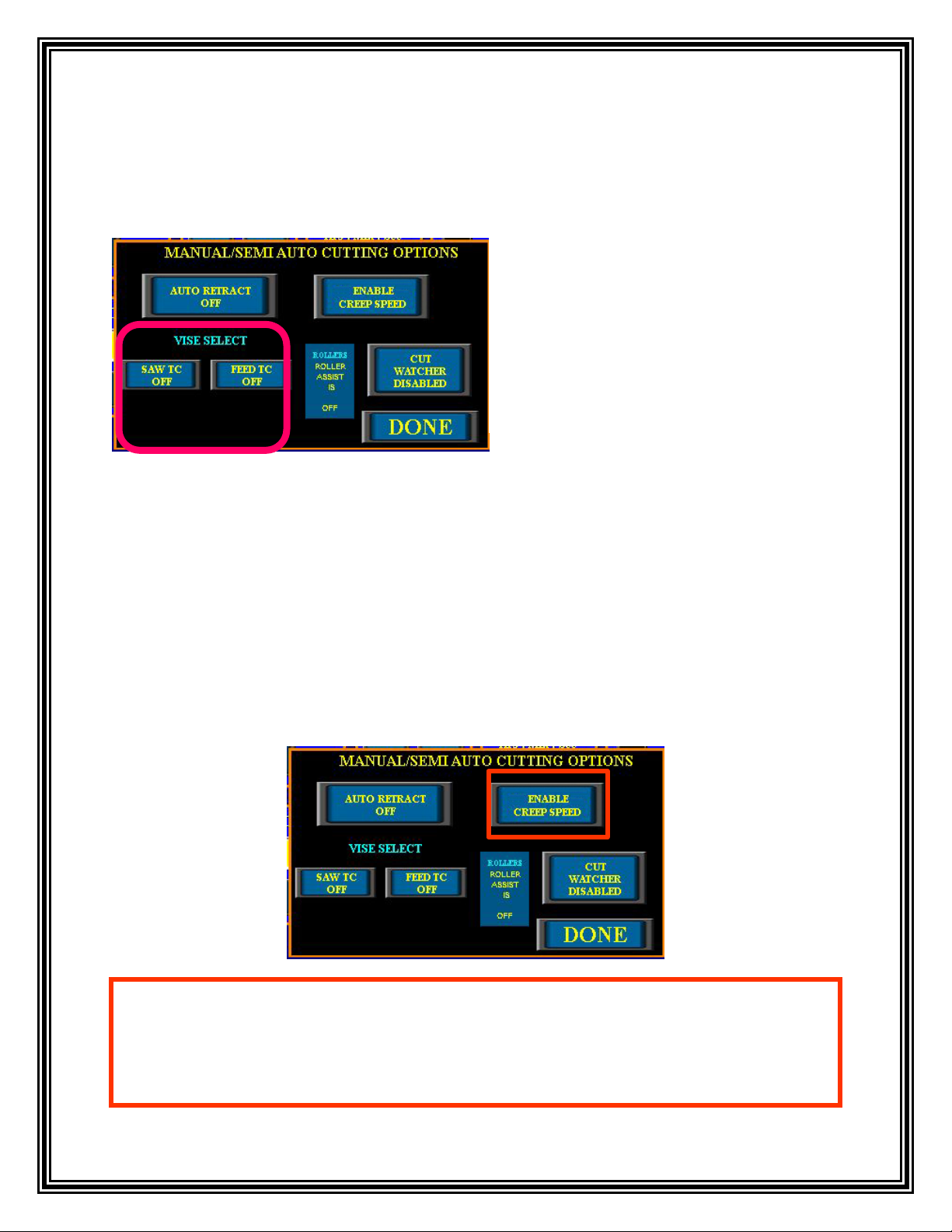

VISE SELECT: The “MANUAL/SEMI AUTO CUTTING OPTIONS” screen allow the

operator to select (or de-select) other vises which may be optionally mounted on the saw system.

These include the discharge vise located on the discharge table, the 3rd vise mounted near the end

of the feed table, and top clamps mounted on the saw, feed, and discharge.

ENABLE CREEP SPEED: The Creep Speed is a function that slows the feed shuttle speed

down when moving material into the cutting. This function is useful when positioning material to

make a Trim Cut. The Creep Speed can also be used to slow the tilt speed down when mitering

the saw blade. This is useful when positioning the blade into the correct position. Once the Creep

Speed is enabled hold the spring-loaded “FEED” switch and the “CONFIRM” button on the

control console at the same time to move the feed/material forwards or backwards at a slower

rate. Or hold the “MITER” switch with the “CONFIRM” button on the control console at the

same time to miter the blade left or right at a slower rate.

24. Under “VISE SELECT” the operator

will be able to select the appropriate icon to

turn “ON” or “OFF” any optional vises or

top clamps. Turning an optional vise or top

clamp “ON” will allow it to open and close

in conjunction with the Main Saw Vise for

a Semi Auto Cut.

25. Select the “ENABLE CREEP SPEED” icon and the speed for the miter or feed will slow

down so the stopping point for either will be more precise. The icon will now read “CREEP

SPEED ENABLED”. To return the miter or feed to the normal speed select the “CREEP

SPEED ENABLED” icon. The “FEED” or “MITER” switch will return to the original speed.

20

AUTO RETRACT: At the end of the Semi Auto Cut, the blade will stop turning. The operator

has the option of leaving the blade down at the end of the cut or automatically retracting the arm

to the home position using the “AUTO RETRACT” icon. While the arm is retracting the blade

will run in a slow “AUTO IDLE” speed.

26. Select the “AUTO RETRACT OFF”

icon and the icon will now read “AUTO

RETRACT ON”. This will activate the auto

retract feature so the arm is automatically

retracted to the home position after each cut.

Select the “AUTO RERACT ON” icon and

it will now read “AUTO RETRACT OFF”

this will deactivate the auto retract feature

and leave the blade down in the cut.

27. After the operator has made the necessary adjustments to the cutting operations, place the

material onto the cutting area. Verify that the material is lying flat and up against the fixed

side of the vise. If required, open the “SAW VISE” and the “FEED VISE” to allow the

material to pass through. This can be accomplished by pressing the icons located in the

“VISE CONTROL” window on the touch screen or by using the “SAW VISE” AND “FEED

VISE” switches located on the control console. When using the spring-loaded “SAW VISE”

switch and “FEED VISE” switch the operator must hold the switch in the “OPEN” or

“CLOSE” position while pressing the “CONFIRM” button.

Table of contents

Other HE&M Saw manuals