20 New Dutch Lane, Fairfi eld, NJ 07004 973-575-4004 • Fax 973-575-4052 • http://www.heat-timer.com

Description:

A Multiple-Boiler Modulating Control for Hydronic Heating

Systems Based on Outdoor Reset or a Set Point. The Mini-

MOD Control provides buildings with comfortable, even heat,

while maximizing fuel savings. In addition, it incorporates many

additional features and fl exibilities that can be customized to each

application’s unique characteristics.

•

Hydronic Heating using Outdoor Reset or Set Point. The

Mini-MOD control is designed to modulate multiple hot water

boilers. It can operate based on Outdoor Reset or a Set Point.

Each of the options has a set of pre confi gured, but adjustable

settings to meet the precise needs of each heating application.

•

Multiple Rotation Options. The Mini-MOD can rotate the

lead boiler to promote even wear on each boiler. It has three

rotation options; Timed rotation that is adjustable from One

hour to 60 Days, Manual rotation, and Last-On/Last-Off.

• Current Voltage Signal Modulation. Each of the outputs can

be confi gured independently. That is, a single Mini-MOD can

control multiple boilers different modulation requirements.

•

Adding Boilers. The Mini-MOD controls up to four boilers.

However, it can be connected to up to two additional Mini-

Extension panels, each with 6 stages. This allows the Mini-

MOD to modulate and manage up to 16 total boilers.

•

Parallel or Normal Modulation. An advanced PID logic has

been developed to provide an effi cient, smooth, and adjustable

modulation that can fi t most applications whether the boilers

are to sequence normally, one after the other, or in parallel.

With numerous confi gurable parameters like; Last Stage Hold

and Soft-Off to eliminate the lead boiler short cycling; Lag

Delay to eliminate lag boilers short cycling. The PID logic can

be adjusted to meet your specifi c heating application.

• System Output with Adjustable Run-On Delay. The Mini-

MOD has a System Output relay the can be confi gured to run

a system pump or combustion air damper. The relay can be

adjusted to operate during boiler operation or when below a

specifi ed Outdoor Cutoff.

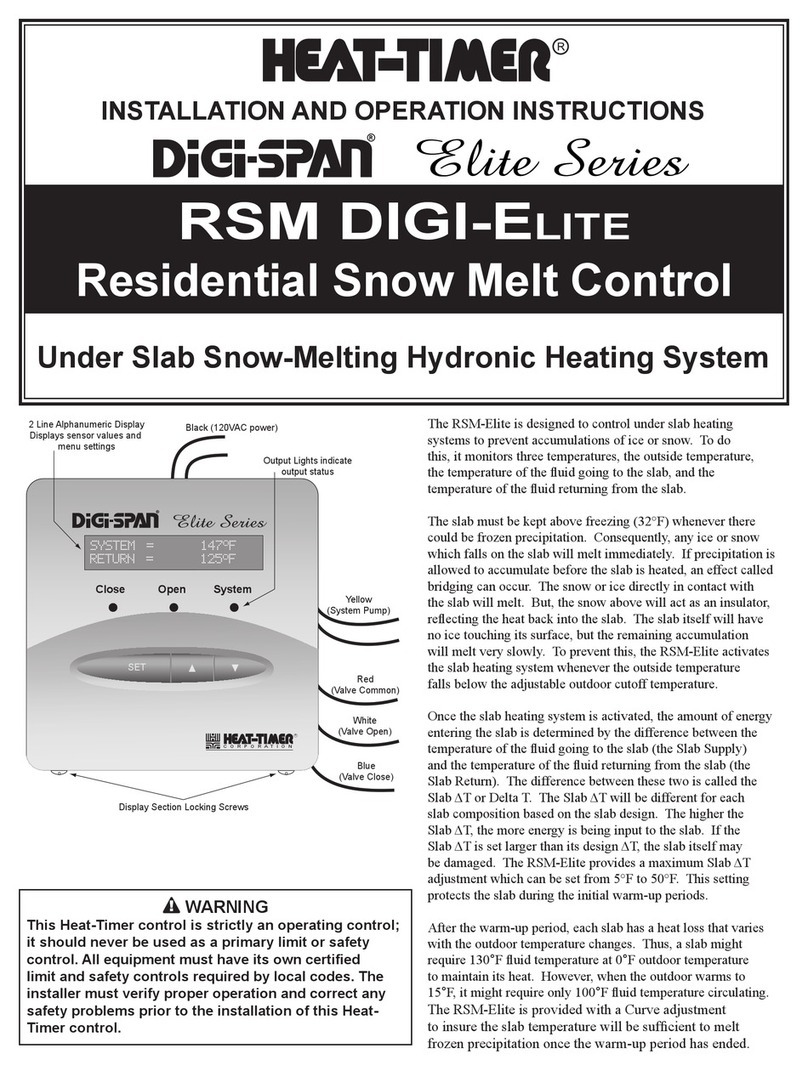

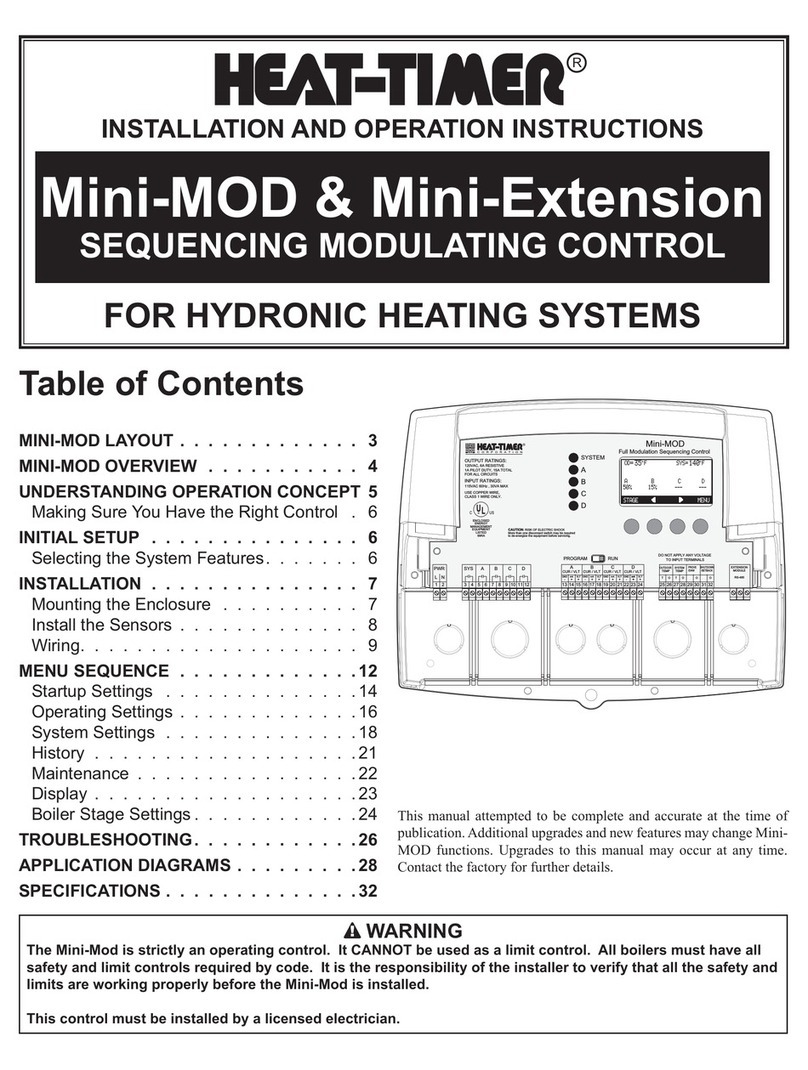

• Digital Display. The Mini-MOD’s bright graphical digital

display names each system parameter in plain English and

shows its precise value. The easy to follow menu system allows

users to quickly make changes to any system setting without

having to learn any codes or keyboard commands. The new

brightly lit LCD display can be viewed from a distance in

dimly lit boiler rooms.

•

Communicate with EMS (Energy Management Systems) The

Mini-MOD with its built-in Shutdown and Prove inputs, is

capable of connecting to and being controlled by an EMS or

other controller.

•

Day and Night Schedule. The control has an adjustable Night

Setback setting to help reduce fuel consumption. The built-

in schedule can be used to customize the operation for even

further temperature control and fuel savings.

•

Boost. To bring a building quickly back to comfortable

temperatures after the cooler night period, the control has a

built-in Boost feature. The Boost allows the system to rise to

an increased temperature for a period of time.

•

Standby Boilers. Each boiler can be set individually to be

automatically operated, fully on, manually adjusted, off, or be

considered a Standby boiler. The Standby boiler option puts

the boiler in as a backup with an adjustable standby delay. This

feature is great for less effi cient boilers that can be used in

periods of high demand.

• Domestic Hot Water. It can be confi gured with Domestic Hot

Water call option. It will increase system water temperature

when Domestic Hot Water is needed. In addition, it allows for

optional priority of the domestic hot water over heating.

HYDRONIC MODULATING SEQUENCING CONTROLS

With • Modulate 4-Boilers using PID Logic • Parallel or Normal Modulation

• Sequence Boilers based on Reset or Set Point • Domestic Hot Water with Priority Option

• Outputs 4-20mA, 0-10V, 0-5V, 2-10V, and 1-5V Signals • Add more Boilers using Mini-Extensions up to 16 Boilers

Mini-MOD and Mini-Extension

users to quickly make changes to any system setting without