heat-timer PLL User manual

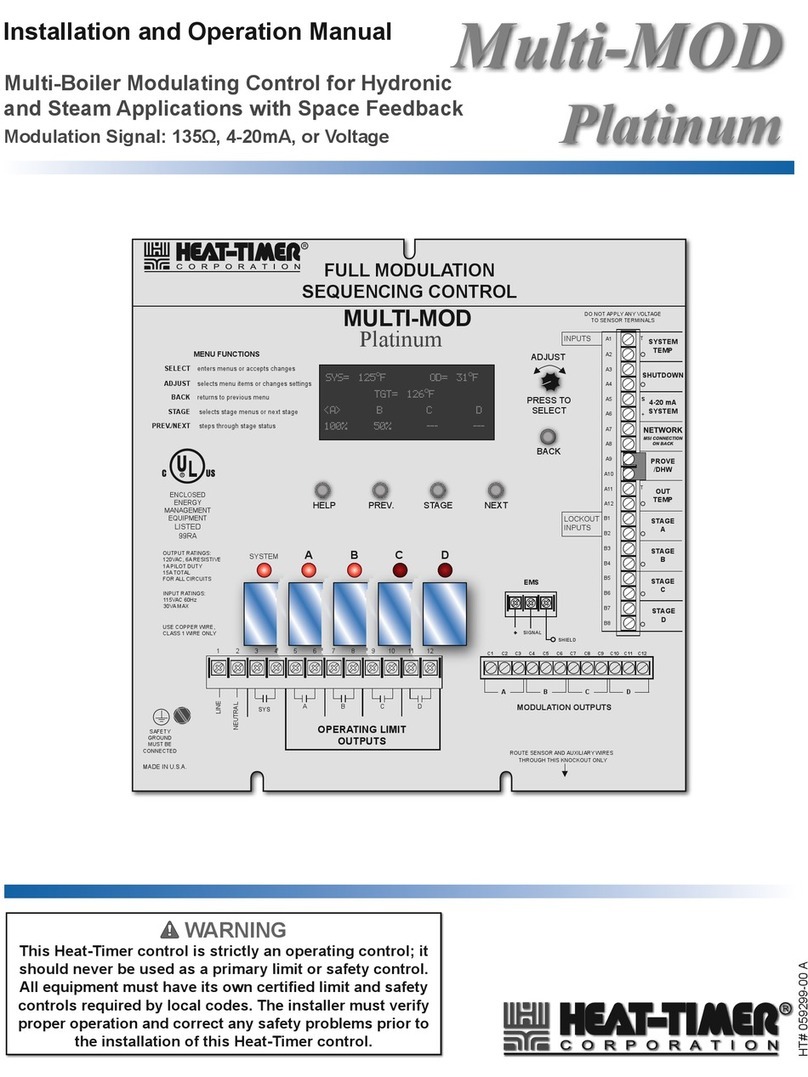

Installation and Operation Manual

WARNING

This Heat-Timer control is strictly an operating control; it should

never be used as a primary limit or safety control. All equipment

must have its own certified limit and safety controls required by local

codes. The installer must verify proper operation and correct any

safety problems prior to the installation of this Heat-Timer control.

HT# 059296-00A

Provides Pump Rotation,

Auxiliary Pump Activation, and

Pump Failure Alarm Control Pump-Lead-Lag

PLL

HT# 059296-00A

2PLL Installation and Operation Manual

CONTENTS

PLL Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Alarming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Alarming on No-Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Ending the Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Rotation options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1-Call / 1-Flow (2-Pump Mode) or (3-Pump Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1-Call, 2-Flow (2-Pump) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Auxiliary Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2-Call, 2-Flow (3-Pump) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Pump Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3-Call, 3-Flow (3-Pump) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Pump exercise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Installation Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Mounting The Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Wiring the Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Pump Call Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Flow Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Pump Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Valve Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Visual/Audio Alarm Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Web or EMS Alarm Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Dip Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Wiring and Piping Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-Pump 1-Call 1-Flow Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-Pump 1-Call 1-Flow Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-Pump 1-Call 2-Flow Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-Pump 1-Call 2-Flow Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3-Pump 1-Call 1-Flow Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-Pump 1-Call 1-Flow Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3-Pump 2-Call 2-Flow Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3-Pump 2-Call 2-Flow Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3-Pump 3-Call 3-Flow Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3-Pump 3-Call 3-Flow Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Specication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

HT# 059296-00A

PLL Installation and Operation Manual 3

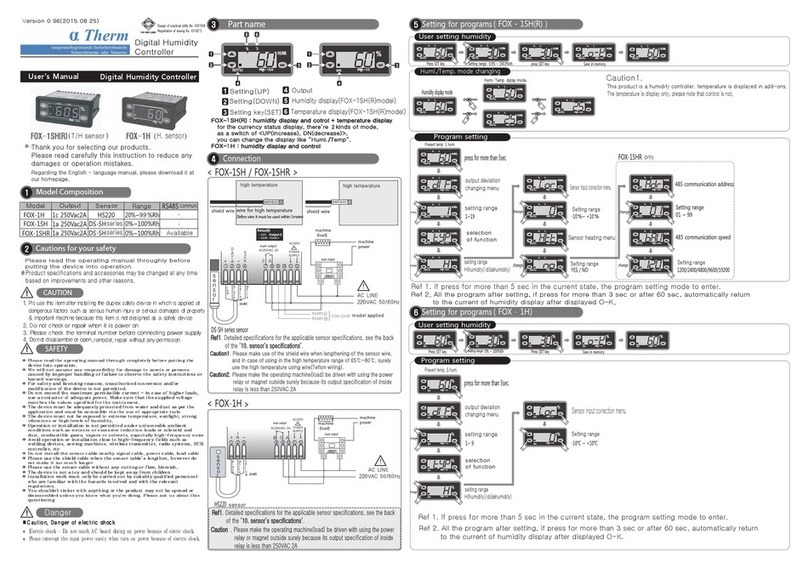

PLL LAYOUT

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

LED indicates the

associated relay status. Alarm Reset Button

120 VAC

Power

Pump and Valve output relays

source 120 VAC power.

Pump Flow Inputs

(Dry-Contact)

Pump Call Inputs

(Dry-Contact)

Alarm output relays

do not source power.

HT# 059296-00A

4PLL Installation and Operation Manual

OVERVIEW

The PLL is a Lead-Lag Pump control. It is designed to operate in different modes to satisfy multiple pumping applications. To

change the operating mode, set the dip switches. See "Dip Switches" on page 10. It can provide pump lead-lag rotation for two or

three pump systems. With its built-in alarm outputs, the PLL can trigger an alarm whenever a pump fails to provide proof-of-ow

within 30 seconds. It can also be used to provide pump ow check and run-on delay.

The PLL can operate up to 3 pumps. It outputs source 120 VAC power to its pump and solenoid valve outputs. However, alarm

outputs require an external power source.

ALARMING

• The PLL is equipped with an alarm output for each of the three available pump outputs.

• For local indication, it also has an LED for each of the alarm outputs.

Alarming on No-Flow

• If a pump fails to provide proof-of-ow for 30 seconds, by shorting the Flow input terminals, the PLL will turn that pump’s alarm

output on and blink its alarm LED.

• If the mode selected offers a rotation option, then the PLL shall turn on the next pump output and its LED.

Ending the Alarm

• If any of the pumps is in alarm, its alarm output will remain on until the Alarm Reset button is pressed. This will cause the Alarm

output to turn off.

ROTATION OPTIONS

• The PLL offers lead-lag pump rotation in many of its modes.

• When an operating mode has rotation options, it will have

multiple time-rotation options and an alternating rotation option.

• You can change the time interval of the time-rotation using

the appropriate dip switches for the mode selected. See "Dip

Switches" on page 10.

1-Call / 1-Flow (2-Pump Mode) or (3-Pump

Mode)

• This mode is designed to rotate two system pumps in a hydronic

application.

• The PLL rotates the pumps based on either timed rotation or

alternating demand (per call). The rotation options are selected

via dip switches.

• The pump call must be connected to Pump 1 input terminals

(C1) (20 and 21). In addition, the ow input must be connected

to Flow 1 input terminals (F1) (26 and 27).

• Alternating demand activates a different pump each time a pump

call is initiated.

• Timed rotation has two options, 1 day, and 7 days rotation.

• When rotation of the lead pump is to take place during a timed

rotation, the operation of both pumps, old lead pump and new

lead pump, will overlap for a few seconds to eliminate a no-ow

period prevent boiler short-cycling.

• In these modes, if a pump fails to provide proof-of-ow for a

period of 30 seconds, the PLL will turn it off. Also, it will turn

on its alarm and turn on the next lead pump.

Flow

Switch

Pump2

Pump1

Boiler or

Heating Source

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2 RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING)

3

G

HT# 059296-00A

PLL Installation and Operation Manual 5

1-Call, 2-Flow (2-Pump)

• This mode is designed to rotate two system pumps in a hydronic

application. It is primarily used with Variable Frequency Drive

(VFD) pumps.

• The operation of this mode is similar to the 1-Call/1-Flow

Mode listed previously. The only exception is that each pump

will have its own ow input. That means that pump call must

be connected to Pump 1 call input terminals (C1) (20 and 21).

Pump 1 ow input must be connected to Flow 1 input terminals

(F1) (26 and 27) and Pump 2 ow input must be connected to

Flow 2 input terminals (F2) (28 and 29).

1 2 3 4 5 6 7 8

On

VFD

Pump2

VFD

Pump1

Boiler or

Heating Source

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2 RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING)

3

G

AUXILIARY PUMP

2-Call, 2-Flow (3-Pump)

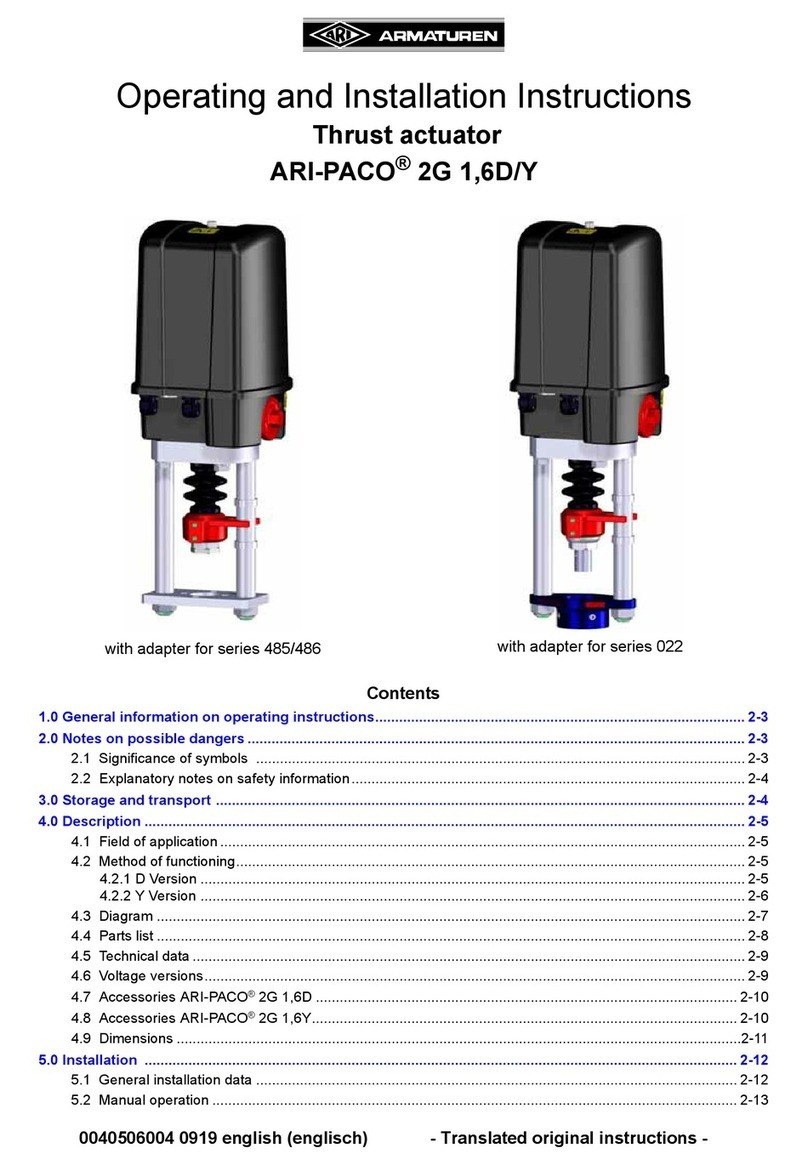

• This conguration is typically used in a two-Boiler Feed

application. It uses an Auxiliary pump / Pump 3 to replace any

failing boiler feed pump. It does that by turning on a normally

closed solenoid valve to direct the ow from the failing pump to

the auxiliary pump.

• No rotation is available in this mode. The PLL control operates

a single pump per boiler.

• A maximum of two boiler pumps can be connected to a single

PLL.

• If any of the boiler pumps fail to provide proof-of ow in 30

seconds, the PLL will switch its operation to the Auxiliary pump

/ Pump 3 (P3).

• The valve outputs are used to operate solenoid valves to switch

the system ow from the failed pump to the Auxiliary pump /

Pump 3 (P3). Valve 1 output (V1) is turned on when Pump 1

fails and goes into alarm. Valve 2 output (V2) is turned on when

Pump 2 fails and goes into alarm. See "Valve Output Wiring" on

page 9..

• If a pump fails, the PLL will turn it off and will turn on its Alarm

output, its Valve output, and the Auxiliary pump / Pump 3 (P3)

output. In addition, it will blink its Alarm LED.

• If the second pump fails for over 30 seconds while the rst

pump is in alarm, the PLL will turn off the 2nd pump and turn

on its relevant solenoid valve and Alarm LED. In this case, the

Auxiliary pump / Pump 3 (P3) replaces both primary pumps

until the situation is rectied and the Manual Reset button is

pressed.

Boiler 2

Flow

Switch 2

Pump 2

Boiler 1

Flow

Switch 1

Pump 1

Aux Pump 3

Solenoid 1Solenoid 2

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2 RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING)

3

G

HT# 059296-00A

6PLL Installation and Operation Manual

PUMP DELAY

3-Call, 3-Flow (3-Pump)

• This conguration is typically used in one, two, or three boiler

pump applications to offer pump delay and alarming. The PLL

control operates a single pump per boiler.

• Each of the pump calls will use a different pump call input (C1,

C2, and C3).

• Also, each of the pump ows will use the respective pump ow

input (F1, F2, and F3).

• No rotation is available in this mode.

• If a pump failed to provide proof-of-ow for over 30 seconds,

the PLL will turn that pump output off and turn on its alarm.

Boiler 1 Boiler 2

Flow

Switch 1

Pump 1

Flow

Switch 3

Flow

Switch 2

Pump 3Pump 2

Boiler 3

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2 RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING)

3

G

PUMP EXERCISE

• This option is recommended for all pumps as it helps protect the pumps from locking due to sediment deposit and rust in the

system. It proves very benecial to wet rotor pumps as it helps lubricate their seals.

• When this feature is enabled, The PLL exercises any pump that did not run for a week. The exercise period is 10 seconds.

INSTALLATION STEPS

Follow these steps to make sure that all aspects of the system installation are done:

1. Mount the PLL control. See "Mounting The Enclosure" on page 7.

2. Wire the PLL control to the power, the pumps, ow inputs, valves, and the alarms. See "Wiring" on page 8.

3. Set the dip switches to match your application. See "Dip Switches" on page 10..

4. Power the control.

HT# 059296-00A

PLL Installation and Operation Manual 7

INSTALLATION

MOUNTING THE ENCLOSURE

• Select a location near the equipment to be controlled.

• The surface should be at and sufciently wide and strong to hold the PLL.

• Keep the control away from extreme heat, cold, or humidity. Ambient operating

temperature is from 20 to 120°F.

• Remove the Enclosure Wiring Cover from the control enclosure by removing the

two bottom screws.

• Remove the Enclosure Display Module by removing its Mounting Screws.

• Screw the Enclosure Base to the surface through the upper and lower mounting

holes on the back of the enclosure.

• Replace the Enclosure Display Module and its Mounting Screws.

• Do not replace the Enclosure Wiring Cover until all wiring is done.

• When purchasing a padlock for the enclosure, the maximum shank diameter should

not exceed ¼”

Warning

The PLL is an operating control

only not a safety control. It is

the responsibility of the installer

to verify that all the safety and

limits required by code are

working properly before and

after the PLL is installed.

Enclosure Display Module

Enclosure Wiring Cover Enclosure Base

Hole for optional lock

(not supplied)

Mounting Holes

Display Mounting Screws

Wiring Cover

Mounting Screws

HT# 059296-00A

8PLL Installation and Operation Manual

WIRING

Warning

Class 1 voltage wiring (low voltage) must use a different knockout

and conduit from any Class 2 voltage wiring (high voltage).

WIRING THE POWER

• Bring the power wires through one of the bottom knockouts of the enclosure.

• Attach 120V 60 Hz wires to their respective Line, Neutral, and Ground terminals.

• Heat-Timer recommends the installation of a Surge Suppressor and a Power Switch

before the Power Line connection for safety and ease of service.

120 VAC

Earth

Ground

L

N

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

INPUT WIRING

Warning

All of the PLL inputs are dry-contact only. DO NOT APPLY POWER TO

ANY INPUT as this may damage the control and void its warranty.

Pump Call Input Wiring

Pump Call (C1 Terminal 20 and 21), (C2 Terminal 22 and 23), (C3 Terminal

24 and 25)

• Depending on the mode selected, the PLL may require the use of one, two, or three

Pump Call inputs. See "Dip Switches" on page 10.

• Wire each Pump input into the corresponding input terminals of the PLL. See

"Overview" on page 4.

Pump 1

Call

Input

Pump 2

Call

Input

Pump 3

Call

Input

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25

29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3

F1 F2 F3

PUMP CALL

FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Flow 3

Input

Flow 2

Input

Flow 1

Input

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25

29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3

F1 F2 F3

PUMP CALL

FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Flow Input Wiring

Pump Flow (F1 Terminal 26 and 27), (F2 Terminal 28 and 29), (F3 Terminal

30 and 31)

• Depending on the mode selected, the PLL may require the use of one, two, or three

ow inputs. See "Overview" on page 4.

• Wire each Flow input to the corresponding input terminals of the PLL.

• If a pump fails to provide a ow signal for over 30 seconds, by shorting the proper

ow input terminal, the PLL will turn off the failing pump’s output and LED and turn

on the its pump alarm output and LED.

• If the mode selected rotates the lead pump or offers an auxiliary pump operation,

the failed pump alarm will cause the lead pump to go the next available pump or the

auxiliary pump.

ALERT

If no ow switch is used, use a jumper on the ow input terminals. (Heat-Timer

recommends using a ow switch for better system response and operation.

OUTPUT WIRING

• The PLL provides 120 VAC 60Hz power to the pump and solenoid valve output

relays. Each relay can power up to 1/4 HP pump (120 VAC 60 Hz) or 80 VA Solenoid

Valves (120 VAC 60Hz).

• The PLL does not provide power to the alarm output relays. A separate power source

must supply the power to the alarm. In this case, the alarm relays act as a power

switches.

Warning

Each of the Pump and Solenoid

valve outputs source 120 VAC.

If the pump used require more

than ¼ HP or if the solenoid

used require more than 80 VA of

120 VAC, use a relay or a starter

to prevent PLL damage.

HT# 059296-00A

PLL Installation and Operation Manual 9

Pump Output Wiring

• Before wiring the pumps, decide on the function of each of the pumps based on the

mode selected.

• Each of the PLL pump outputs sources power to operate a pump up to ¼ HP (120

VAC, 60Hz).

• If the pump requires more power than what the PLL can output, use a pump starter or

an external higher output power relay.

• Wire the Pump output terminals to the pumps or pump starters.

Pump 2

¼HP

Pump 3

¼HP

80 VA

max.

80 VA

max.

Pump 1

¼HP

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8

9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Pump 2

¼HP

Pump 3

¼HP

80 VA

max.

80 VA

max.

Pump 1

¼HP

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Valve Output Wiring

• Valve outputs function only in the 2-Call 2-Flow 3-Pump Mode. See "2-Call, 2-Flow

(3-Pump)" on page 5.

• The valve outputs are used to operate normally closed (N. C.) solenoid valves to

switch the system ow from the failed pump to the Auxiliary pump (Pump 3). Valve

1 output (V1) is turned on when Pump 1 fails and goes into alarm. Valve 2 output

(V2) is turned on when Pump 2 fails and goes into alarm.

• The valve outputs source 120 VAC 60Hz power. Each output can operate an 80 VA

solenoid valve.

• If the valve requires more power than what the PLL can output, use an external higher

output power relay.

• Connect Valve 1 (V1) and Valve 2 (V2) outputs to their respective solenoid valves.

Solenoid

Valve 2

Solenoid

Valve 1

1 2 3 4 5 6 7 8

On

Solenoid

Valve 2

Solenoid

Valve 1

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16

17 18 19

LN

RS-485

VALVES

A1

A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4

5

P1

L

NLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Visual/Audio Alarm Output Wiring

• The PLL has 3 alarm outputs, one for each of the pump outputs. An Alarm output is

triggered when its pump fails to provide proof-of-ow in 30 seconds.

• The Alarm outputs do not source any power. A separate power source must be

supplied. Each set of contacts is capable of switching 1A Inductive, 6A Resistive at

120 VAC.

• Connect the Alarm outputs to an alarm. The Heat-Timer Vis-U-Larm

(HT #925011-00) is a visual-audio alarm that is designed to work with the PLL. It

has both a Red Alarm light in addition to a sound alarm.

• All Alarm outputs can be wired to use the same alarm unit as per the graph.

Web or EMS Alarm Output Wiring

• The Alarm outputs can be used to trigger Internet alarms using a Heat-Timer Internet-

ready Platinum control. It can also be used to trigger a BMS alarm.

• Connect the Alarm output to any of the Aux Temp or Mini-MIG inputs on an Internet-

ready Heat-Timer Platinum heating control.

• Web alarms allows the user of a Platinum heating control to receive the alarm

notication on the web, by E-Mail, or a cellular phone text message. See Internet

Control Manuals.

• An BMS alarm output allows an BMS system to receive an alarm notication.

120

VAC

Alarm

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11

12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1

V2

LN

LN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

HT# 059296-00A

10 PLL Installation and Operation Manual

DIP SWITCHES

The PLL control is designed to operate pumps in multiple modes. Each mode can be activated by adjusting the dip switches.

Mode Pumps Mode Dip Switch

Settings Pump Rotation Dip Switches Pump Exercise

Switch

Inputs Outputs

2-Pump Modes

1 Call -

1 Flow

2 Pumps

Pump 1

¼ HP

Pump 1

Call

Input

Flow 1

Input

120 VAC

Earth

Ground

L

N

120

VAC

Alarm

Pump 2

¼ HP

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Dip1= On

Dip2= Off

Pump 1

¼ HP

Pump 1

Call

Input

Flow 1

Input

120 VAC

Earth

Ground

L

N

120

VAC

Alarm

Pump 2

¼ HP

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Per Call Rotation = Dip4= On, Dip5=Off, Dip6=Off

1 Day Rotation = Dip4= Off, Dip5=On, Dip6=Off

7 Day Rotation = Dip4= Off, Dip5=Off, Dip6=On

Pump 1

¼ HP

Pump 1

Call

Input

Flow 1

Input

120 VAC

Earth

Ground

L

N

120

VAC

Alarm

Pump 2

¼ HP

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Exercise On = Dip7= On

Exercise Off = Dip7= Off

C1

F1

P1, P2

1 Call -

2 Flow

2 Pumps

Pump 1 (VFD)

¼ HP

Pump 1

Call

Input

120 VAC

Earth

Ground

L

N

120

VAC

Alarm

Pump 2 (VFD)

¼ HP

Flow 1

Input

Flow 2

Input

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Dip1= On

Dip2= On

Pump 1 (VFD)

¼ HP

Pump 1

Call

Input

120 VAC

Earth

Ground

L

N

120

VAC

Alarm

Pump 2 (VFD)

¼ HP

Flow 1

Input

Flow 2

Input

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Per Call Rotation = Dip4= On, Dip5=Off, Dip6=Off

1 Day Rotation = Dip4= Off, Dip5=On, Dip6=Off

7 Day Rotation = Dip4= Off, Dip5=Off, Dip6=On

Pump 1 (VFD)

¼ HP

Pump 1

Call

Input

120 VAC

Earth

Ground

L

N

120

VAC

Alarm

Pump 2 (VFD)

¼ HP

Flow 1

Input

Flow 2

Input

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Exercise On = Dip7= On

Exercise Off = Dip7= Off

C1

F1, F2

P1, P2

3-Pump Modes

1 Call -

1 Flow

3 Pumps

Pump 1

¼ HP

Pump 1

Call

Input

Flow 1

Input

120 VAC

Earth

Ground

L

N

120

VAC

Alarm

Pump 2

¼ HP

Pump 3

¼ HP

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Dip1= Off

Dip2= Off

Dip3= On

Pump 1

¼ HP

Pump 1

Call

Input

Flow 1

Input

120 VAC

Earth

Ground

L

N

120

VAC

Alarm

Pump 2

¼ HP

Pump 3

¼ HP

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Per Call Rotation = Dip4= On, Dip5=Off, Dip6=Off

1 Day Rotation = Dip4= Off, Dip5=On, Dip6=Off

7 Day Rotation = Dip4= Off, Dip5=Off, Dip6=On

Pump 1

¼ HP

Pump 1

Call

Input

Flow 1

Input

120 VAC

Earth

Ground

L

N

120

VAC

Alarm

Pump 2

¼ HP

Pump 3

¼ HP

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Exercise On = Dip7= On

Exercise Off = Dip7= Off

C1

F1

P1, P2, P3

2 Call -

2 Flow

3 Pumps

Pump 1

¼ HP

Pump 1

Call

Input

120 VAC

Earth

Ground

L

N

120

VAC

Alarm

Pump 2

¼ HP

Aux Pump

(Pump 3)

¼ HP

Pump 2

Call

Input

Flow 1

Input

Flow 2

Input

Solenoid

Valve 1

Solenoid

Valve 2

1 2 3 4 5 6 7 8

On

80 VA

max.

80 VA

max.

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Dip1= Off

Dip2= Off

Dip3= Off

No Rotation Available

Pump 1

¼ HP

Pump 1

Call

Input

120 VAC

Earth

Ground

L

N

120

VAC

Alarm

Pump 2

¼ HP

Aux Pump

(Pump 3)

¼ HP

Pump 2

Call

Input

Flow 1

Input

Flow 2

Input

Solenoid

Valve 1

Solenoid

Valve 2

1 2 3 4 5 6 7 8

On

80 VA

max.

80 VA

max.

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Exercise On = Dip7= On

Exercise Off = Dip7= Off

C1, C2

F1, F2

P1, P2, P3

3 Call -

3 Flow

without

Delay

3 Pumps

Pump 1

¼ HP

Pump 1

Call

Input

120 VAC

Earth

Ground

L

N

Pump 2

¼ HP

Pump 3

¼ HP

Pump 2

Call

Input

Flow 1

Input

Flow 2

Input

Pump 3

Call

Input

Flow 3

Input

120

VAC

Alarm

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Dip1= Off

Dip2= On

Dip3= On

Dip4= Off

No Rotation Available

Pump 1

¼ HP

Pump 1

Call

Input

120 VAC

Earth

Ground

L

N

Pump 2

¼ HP

Pump 3

¼ HP

Pump 2

Call

Input

Flow 1

Input

Flow 2

Input

Pump 3

Call

Input

Flow 3

Input

120

VAC

Alarm

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Exercise On = Dip7= On

Exercise Off = Dip7= Off

C1, C2,

C3

F1, F2, F3

P1, P2, P3

3 Call -

3 Flow

with 6

minute

Delay

3 Pumps

Pump 1

¼ HP

Pump 1

Call

Input

120 VAC

Earth

Ground

L

N

Pump 2

¼ HP

Pump 3

¼ HP

Pump 2

Call

Input

Flow 1

Input

Flow 2

Input

Pump 3

Call

Input

Flow 3

Input

120

VAC

Alarm

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Dip1= Off

Dip2= On

Dip3= On

Dip4= Off

No Rotation Available

Pump 1

¼ HP

Pump 1

Call

Input

120 VAC

Earth

Ground

L

N

Pump 2

¼ HP

Pump 3

¼ HP

Pump 2

Call

Input

Flow 1

Input

Flow 2

Input

Pump 3

Call

Input

Flow 3

Input

120

VAC

Alarm

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Exercise On = Dip7= On

Exercise Off = Dip7= Off

C1, C2,

C3

F1, F2, F3

P1, P2, P3

HT# 059296-00A

PLL Installation and Operation Manual 11

LEDS

Pump and Valve LEDs

• Each LED is assigned to its respective output operation. When a pump or a valve

output is active, its LED is lit.

Power LED

• The lower right LED is used to indicate the control power.

Alarm LEDs

• Alarm LEDs blink when their respective alarm output is active. The blinking

helps alert the use to their status from a far distance. See "Overview" on page 4.

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

BUTTON

• The PLL has only one button (Alarm Reset). The button is used to reset the alarm

status of any failed pump.

• When a pump fails to provide proof-of-ow within 30 seconds, its alarm output

is activated. The PLL will stop this pump from running and will not make it

available until the Alarm Reset button is pressed. See "Alarming" on page 4.

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

TROUBLESHOOTING

Power LED Not On

Check the power wiring to the PLL using a voltmeter set to AC. The PLL requires 120 VAC power source.

Pump Output Relays do not Turn On

To test any of the pump output relays, energize the relay by rst setting the control to 3-Call 3-Flow mode. See "Dip Switches" on

page 10. Then, initiate a call for the pump in question by shorting its (C) and (F) input terminals. Then test for continuity across the

output terminals using a continuity meter. If continuity exists, the relay is functioning properly. Otherwise, if no continuity exists,

check the fuse on the back of the Enclosure Display Module. The fuse is 20 mm 5 amp may need to be replaced.

Valve Output Relays do not Turn On

To test a valve output, the PLL dip switches must be set to 3- Pump 2-Call 2-Flow mode. See "Dip Switches" on page 10. Then,

initiate a call for the respective pump (C) and wait 30 seconds for the alarm output and valve output to be activated. Then test for

continuity across the output terminals using a continuity meter. If continuity exists, the relay is functioning properly. Otherwise,

if no continuity exists, check the fuse on the back of the Enclosure Display Module. The fuse is 20 mm 5 amp may need to be

replaced.

Alarm Output Relays do not Turn On

To test any of the alarm output relays, energize the respective pump relay by rst setting the control to 3-Call 3-Flow mode.

See "Dip Switches" on page 10. Then, initiate a call for the respective pump (C) and wait 30 seconds for the alarm output to

be activated. Then test for continuity across the output terminals using a continuity meter. If continuity exists, the relay is

functioning properly. Otherwise, if no continuity exists, check the fuse on the back of the Enclosure Display Module. The fuse is

20 mm 5 amp may need to be replaced.

HT# 059296-00A

12 PLL Installation and Operation Manual

WIRING AND PIPING DIAGRAMS

2-PUMP 1-CALL 1-FLOW WIRING

DIP Switch Settings:

Dip1 = ON (2-Pump Mode)

Dip2 = OFF (1-Call + 1-Flow Mode)

Dip4 - 6 = Choose Rotation option

ELECTRIC

Pump 1

¼ HP

Pump 1

Call

Input

Flow 1

Input

120 VAC

Earth

Ground

L

N

120

VAC

Alarm

Pump 2

¼ HP

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Pump 1

¼ HP

Pump 1

Call

Input

Flow 1

Input

120 VAC

Earth

Ground

L

N

120

VAC

Alarm

Pump 2

¼ HP

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Warning

Inputs are dry-contact. No voltage should be placed across

the input terminals.

Ouput sourcing terminals provide 120 VAC. See output

rating prior to connecting equipment to avoid output damage.

HT# 059296-00A

PLL Installation and Operation Manual 13

Flow

Switch

Pump2

Pump1

Boiler or

Heating Source

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION: Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2 RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING)

3

G

ALERT

Heat-Timer is aware that each installation is unique. Thus, Heat-Timer is not responsible for

any installation related to any electrical or plumbing diagram generated by Heat-Timer. The

provided illustrations are to demonstrate Heat-Timer’s control operating concept only.

MECHANICAL

2-PUMP 1-CALL 1-FLOW PIPING

HT# 059296-00A

14 PLL Installation and Operation Manual

2-PUMP 1-CALL 2-FLOW WIRING

DIP Switch Settings:

Dip1 = ON (2-Pump Mode)

Dip2 = ON (1-Call + 2-Flow Mode)

Dip4 - 6 = Choose Rotation option

ELECTRIC

Pump 1 (VFD)

¼ HP

Pump 1

Call

Input

120 VAC

Earth

Ground

L

N

120

VAC

Alarm

Pump 2 (VFD)

¼ HP

Flow 1

Input

Flow 2

Input

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Pump 1 (VFD)

¼ HP

Pump 1

Call

Input

120 VAC

Earth

Ground

L

N

120

VAC

Alarm

Pump 2 (VFD)

¼ HP

Flow 1

Input

Flow 2

Input

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Warning

Inputs are dry-contact. No voltage should be placed across

the input terminals.

Ouput sourcing terminals provide 120 VAC. See output

rating prior to connecting equipment to avoid output damage.

HT# 059296-00A

PLL Installation and Operation Manual 15

ALERT

Heat-Timer is aware that each installation is unique. Thus, Heat-Timer is not responsible for

any installation related to any electrical or plumbing diagram generated by Heat-Timer. The

provided illustrations are to demonstrate Heat-Timer’s control operating concept only.

1 2 3 4 5 6 7 8

On

VFD

Pump2

VFD

Pump1

Boiler or

Heating Source

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2 RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING)

3

G

MECHANICAL

2-PUMP 1-CALL 2-FLOW PIPING

HT# 059296-00A

16 PLL Installation and Operation Manual

3-PUMP 1-CALL 1-FLOW WIRING

DIP Switch Settings:

Dip1 = OFF (3-Pump Mode)

Dip3 = ON (1-Call + 1-Flow Mode)

Dip4 - 6 = Choose Rotation option

ELECTRIC

Pump 1

¼ HP

Pump 1

Call

Input

Flow 1

Input

120 VAC

Earth

Ground

L

N

120

VAC

Alarm

Pump 2

¼ HP

Pump 3

¼ HP

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Pump 1

¼ HP

Pump 1

Call

Input

Flow 1

Input

120 VAC

Earth

Ground

L

N

120

VAC

Alarm

Pump 2

¼ HP

Pump 3

¼ HP

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Warning

Inputs are dry-contact. No voltage should be placed across

the input terminals.

Ouput sourcing terminals provide 120 VAC. See output

rating prior to connecting equipment to avoid output damage.

HT# 059296-00A

PLL Installation and Operation Manual 17

ALERT

Heat-Timer is aware that each installation is unique. Thus, Heat-Timer is not responsible for

any installation related to any electrical or plumbing diagram generated by Heat-Timer. The

provided illustrations are to demonstrate Heat-Timer’s control operating concept only.

Flow

Switch

Pump2

Pump1 Pump3

Boiler or

Heating Source

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2 RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING)

3

G

MECHANICAL

3-PUMP 1-CALL 1-FLOW PIPING

HT# 059296-00A

18 PLL Installation and Operation Manual

3-PUMP 2-CALL 2-FLOW WIRING

DIP Switch Settings:

Dip1 = OFF (3-Pump Mode)

Dip2 = OFF (2-Call + 2-Flow Mode)

ELECTRIC

Pump 1

¼ HP

Pump 1

Call

Input

120 VAC

Earth

Ground

L

N

120

VAC

Alarm

Pump 2

¼ HP

Aux Pump

(Pump 3)

¼ HP

Pump 2

Call

Input

Flow 1

Input

Flow 2

Input

Solenoid

Valve 1

Solenoid

Valve 2

1 2 3 4 5 6 7 8

On

80 VA

max.

80 VA

max.

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Pump 1

¼ HP

Pump 1

Call

Input

120 VAC

Earth

Ground

L

N

120

VAC

Alarm

Pump 2

¼ HP

Aux Pump

(Pump 3)

¼ HP

Pump 2

Call

Input

Flow 1

Input

Flow 2

Input

Solenoid

Valve 1

Solenoid

Valve 2

1 2 3 4 5 6 7 8

On

80 VA

max.

80 VA

max.

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2A RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING 120VAC)

3

G

Warning

Inputs are dry-contact. No voltage should be placed across

the input terminals.

Ouput sourcing terminals provide 120 VAC. See output

rating prior to connecting equipment to avoid output damage.

HT# 059296-00A

PLL Installation and Operation Manual 19

3-PUMP 2-CALL 2-FLOW PIPING

ALERT

Heat-Timer is aware that each installation is unique. Thus, Heat-Timer is not responsible for

any installation related to any electrical or plumbing diagram generated by Heat-Timer. The

provided illustrations are to demonstrate Heat-Timer’s control operating concept only.

Boiler 2

Flow

Switch 2

Pump 2

Boiler 1

Flow

Switch 1

Pump 1

Aux Pump 3

Solenoid 1Solenoid 2

1 2 3 4 5 6 7 8

On

12

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

10 11 12 13 14 15 16 17 18 19

LN

RS-485

VALVES

A1 A2 A3

PWR

24

20 22

21 23 25 29

27

26 28 30

CAUTION:

Risk of Electric Shock. Use Copper Conductors Only.

Wire all circuits as Class I or Electric Ligh and Power Circuits.

2 RESISTIVE, 120VAC

1/4 HP, 120VAC 60Hz, Pilot Duty 80VA, 120VAC

OUTPUT RATINGS:

ALARM 2

ALARM 3

COM

POWER

ALARM 1

PUMP 2

PUMP 3

VALVE 1

VALVE 2

PUMP 1

ALARM

RESET

PLL

PUMP LEAD-LAG

MAXIMUM 6A TOTAL FOR ALL CIRCUITS

INPUT RATINGS: 120VAC 60Hz, 12VA MAX.

DIP SWITCHES

31

C1 C2 C3 F1 F2 F3

PUMP CALL FLOW INPUTS

ALARMS

V1 V2

LNLN

6 7 8 9

P2 P3

LN

4 5

P1

LNLN

PUMPS

OUTPUT (SOURCING)

3

G

MECHANICAL

HT# 059296-00A