heat-timer Mini-MOD-CNC User manual

HT# 059102-00 B

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

Extension Module

Full Modulation Sequencing Extension

F

H

J

Power

CAUTION:

Risk of Electric Shock.

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PWR

L N

1 2

E

3 4

F

5 6

G

7 8

H

9 10

I

11 12

EXTENSION

MODULE

RS-485

Ext A

INPUT RATINGS:

115VAC 60Hz, 12VA MAX

Use Copper Conductors Only.

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY, 15A TOTAL

FOR ALL CIRCUITS

E

G

I

Comm

Ext B

K

M

O

L

N

P

1716

VLTmA

CUR / VLT

201916

VLTmAGND

CUR / VLT

232219

VLTmAGND

CUR / VLT

262522

VLTmAGND

CUR / VLT

J

13 14

K M OL N P

E F G H

K ML N

15

GND

18

GND

21

GND

24

GND

2928

VLTmA

CUR / VLT

323116

VLTmAGND

CUR / VLT

27

GND

30

GND

I J

O P

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

RUNPROGRAM

12 13 15

14 17

16 18 22

20

19 21 24

23

-+

+

mA

GND VLT

CUR / VLT

A

-+

+

mA

GND VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

OD=25oF SYS= 145oF

<<A>> B <C> D

100% 52% --- ---

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

29

25 27

26 28 32

30 31

TT

OO

TEMP

OUTDOOR

OO

TEMP

SYSTEM

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

12345678910 11

LN

RS-485

SYS ABCD

PWR

EXTENSION

MODULE

Mini-MOD-CNC

2 Heat-Timer Corp.

. . . . . . . . . . . 3

. . . . . . . . . . . . .4

. . . . . . . . . . . . . 5

Features . . . . . . . . . . . . . . . . . . . . .6

Outdoor Reset Concept . . . . . . . . . . . . . 7

Reset Ratio/Outdoor Reset . . . . . . . . . . . . 7

Make Sure You Have the Right Control . . . . .8

. . . . . . . . . . . . . . . . . . .8

Selecting the System Features. . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . 9

Mounting the Enclosure . . . . . . . . . . . . . 9

Install the Sensors . . . . . . . . . . . . . . . 10

System Sensor (HSS) Installation . . . . . . . . 10

Outdoor Sensor Installation . . . . . . . . . . . 10

Wiring . . . . . . . . . . . . . . . . . . . . . 11

Wiring the Power. . . . . . . . . . . . . . . . 11

Wiring the Sensors . . . . . . . . . . . . . . . 11

Wiring the Shutdown, Tstat, or Setback . . . . . 11

Wiring the Prove . . . . . . . . . . . . . . . . 12

Wiring the Domestic Hot Water (DHW) Call . . . 12

Wiring the System Output . . . . . . . . . . . 12

Wiring the Boilers . . . . . . . . . . . . . . . 13

Wiring Multi-Stage Boiler Outputs . . . . . . . . 13

Wiring to Modulating Output . . . . . . . . . . 13

Connecting to the Mini-Extension Panels . . . . 14

Connecting to the 4-20mA EMS Interface . . . . 14

. . . . . . . . . . . 15

Startup Settings . . . . . . . . . . . . . . . . 16

Program Change Switch Setting . . . . . . . . 16

Startup Sequence . . . . . . . . . . . . . . . 16

Sensor Type . . . . . . . . . . . . . . . . . . 16

Switch Set Point . . . . . . . . . . . . . . . . 16

Switch Differential . . . . . . . . . . . . . . . 17

Switch Delay. . . . . . . . . . . . . . . . . . 17

Heavy Load Sequence 2nd Group . . . . . . . 17

Condensing Boiler Type . . . . . . . . . . . . 17

Condensing and Non-Condensing Boiler Number 17

Modulating Boiler Settings . . . . . . . . . . . 18

Modulating Output Type . . . . . . . . . . . . 18

Modulating Mode. . . . . . . . . . . . . . . . 18

Sequencing Boiler Settings . . . . . . . . . . 19

Sequencing Output Type . . . . . . . . . . . . 19

Staging Mode . . . . . . . . . . . . . . . . . 19

Prove/Domestic Hot Water (DHW) Priority . . . . 19

Domestic Hot Water Set Point . . . . . . . . . 19

Shutdown/Tstat/Setback Mode . . . . . . . . . 19

Boost Mode . . . . . . . . . . . . . . . . . . 20

Sensor Fault . . . . . . . . . . . . . . . . . . 20

Setting the Control to Factory Defaults. . . . . 20

. . . . . . . . . 21

Operating Settings . . . . . . . . . . . . . . . 22

Program Change Switch Setting . . . . . . . . 22

Season . . . . . . . . . . . . . . . . . . . . 22

Reset Ratio . . . . . . . . . . . . . . . . . . 22

Offset . . . . . . . . . . . . . . . . . . . . . 22

Outdoor Cutoff Temperature . . . . . . . . . . 23

Minimum Water Temp . . . . . . . . . . . . . 23

Maximum Water Temp . . . . . . . . . . . . . 23

System Settings . . . . . . . . . . . . . . . . 24

Setback . . . . . . . . . . . . . . . . . . . . 24

Purge Delay . . . . . . . . . . . . . . . . . . 24

System Run-On . . . . . . . . . . . . . . . . 24

Lead Boiler Rotation . . . . . . . . . . . . . . 25

Standby Time . . . . . . . . . . . . . . . . . 25

Last Stage Hold . . . . . . . . . . . . . . . . 25

Lead Stages . . . . . . . . . . . . . . . . . . 25

Operating Modulating Boiler Settings . . . . . 26

Gain. . . . . . . . . . . . . . . . . . . . . . 26

Lag Delay . . . . . . . . . . . . . . . . . . . 26

Soft-Off Delay . . . . . . . . . . . . . . . . . 26

Operating Staging Boiler Settings . . . . . . . 27

Reaction Time . . . . . . . . . . . . . . . . . 27

Minimum Runtime . . . . . . . . . . . . . . . 27

Day / Night Schedule. . . . . . . . . . . . . . 28

Set Time. . . . . . . . . . . . . . . . . . . . 28

History . . . . . . . . . . . . . . . . . . . . . 28

Maintenance . . . . . . . . . . . . . . . . . . 28

System & Outdoor Sensor Trim . . . . . . . . . 29

Output Modulation Trim. . . . . . . . . . . . . 29

Conguration . . . . . . . . . . . . . . . . . 29

Display . . . . . . . . . . . . . . . . . . . . 30

Boiler Status . . . . . . . . . . . . . . . . . . 30

Display Sequencing Boiler Status . . . . . . . . 30

Display Messages . . . . . . . . . . . . . . . 30

Boiler Stage Settings . . . . . . . . . . . . . . 31

Mode . . . . . . . . . . . . . . . . . . . . . 31

Ignition % . . . . . . . . . . . . . . . . . . . 32

Modulation Start % . . . . . . . . . . . . . . . 32

Copy Settings - Boiler A Only . . . . . . . . . . 32

. . . . . . . . . . . . . . . . 33

. . . . . . . 34

. . . . . . . 35

. . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . 37

. . . . . . . . . . . . . . . . . 40

HT# 059102-00 B

Mini-MOD-CNC & Mini-Extension Installation Manual 3

In response to new advancement in condensing boiler design and size, many applications utilize multiple condensing boilers in

addition to the non-condensing boilers. That triggered Heat-Timer's patent design of the Mini-MOD-CNC . It is intended to manage

the two groups of boilers to maximize system efciency at the lowest operating cost while maintaining the desired comfort. The

Mini-MOD-CNC operates each group based on the Target temperature switching set point.

Depending on the actual Target Temperature, the Mini-MOD-CNC will determine which group of boilers will be the lead and which

group will be the lag group. The Condensing Group of boilers will be the Lead group when the Target Temperature is below the

Switching Set Point. However, when the Target Temperature rises above the Switching Set Point, the Non-Condensing Boiler Group

will be the lead group and the Condensing Group will be the lag group.

Basically, the Mini-MOD-CNC will allow the condensing group of boilers to operate as along as the Target Temperature is below the

Switching Set Point. See "Switch Set Point" on page 16. During that period, if additional output boilers are needed, the Mini-MOD-

CNC will energize the non-condensing boilers to meet the load. See "Heavy Load Sequence 2nd Group" on page 17. When less output

is required the Mini-MOD-CNC will de-energize the non-condensing boilers prior to de-energizing the condensing boilers.

Above the Switch Set Point

Non-Condensing are the Lead Group

Condensing are the Lag Group

Target Switch

Set Point = 120°F

Below the Switch Set Point

Condensing are the Lead Group

Non-Condensing are the Lag Group

120°F

140°F

100°F

SWITCH MODE = Target Temperature

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

12

RUNPROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

34567 8 910 1112 13 15

14 17

16 18 22

20

19 21 24

23 29

25 27

26 28 32

30 31

LN

-+

+

TT

OORS-485

mAGND VLT

SYS ABCD

PWR

CUR / VLT

A

-+

+

mAGND VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

TEMP

OUTDOOR

OO

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

OD=25oF SYS= 145oF

<<A>> B

100% 52%

CONDCOND

NON-

COND

NON-

COND

NON-

COND

NON-

COND

CONDCOND

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

12

RUNPROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

34567 8 910 1112 13 15

14 17

16 18 22

20

19 21 24

23 29

25 27

26 28 32

30 31

LN

-+

+

TT

OORS-485

mAGND VLT

SYS ABCD

PWR

CUR / VLT

A

-+

+

mAGND VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

TEMP

OUTDOOR

OO

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

OD=25oF SYS= 145oF

<<A>> B

100% 52%

Target

Temp

Above the Switch Set Point

Condensing are the Lead Group

Non-Condensing are the Lag Group

Outdoor Switch

Set Point = 30°F

Below the Switch Set Point

Non-Condensing are the Lead Group

Condensing are the Lag Group

30°F

50°F

10°F

SWITCH MODE = Outdoor Temperature

CONDCOND

NON-

COND

NON-

COND

NON-

COND

NON-

COND

CONDCOND

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

12

RUNPROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

34567 8 910 1112 13 15

14 17

16 18 22

20

19 21 24

23 29

25 27

26 28 32

30 31

LN

-+

+

TT

OORS-485

mAGND VLT

SYS ABCD

PWR

CUR / VLT

A

-+

+

mAGND VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

TEMP

OUTDOOR

OO

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

OD=25oF SYS= 145oF

<<A>> B

100% 52%

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

12

RUNPROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

34567 8 910 1112 13 15

14 17

16 18 22

20

19 21 24

23 29

25 27

26 28 32

30 31

LN

-+

+

TT

OORS-485

mAGND VLT

SYS ABCD

PWR

CUR / VLT

A

-+

+

mAGND VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

TEMP

OUTDOOR

OO

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

OD=25oF SYS= 145oF

<<A>> B

100% 52%

Outdoor

Temp

HT# 059102-00 B

4 Heat-Timer Corp.

HT# 059102-00 B

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

RUNPROGRAM

12 13 15

14 17

16 18 22

20

19 21 24

23

-+

+

mA

GND VLT

CUR / VLT

A

-+

+

mA

GND VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

OD=25oF SYS= 145oF

<<A>> B <C> D

100% 52% --- ---

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

29

25 27

26 28 32

30 31

TT

OO

TEMP

OUTDOOR

OO

TEMP

SYSTEM

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

12345678910 11

LN

RS-485

SYS ABCD

PWR

EXTENSION

MODULE

Mini-MOD-CNC

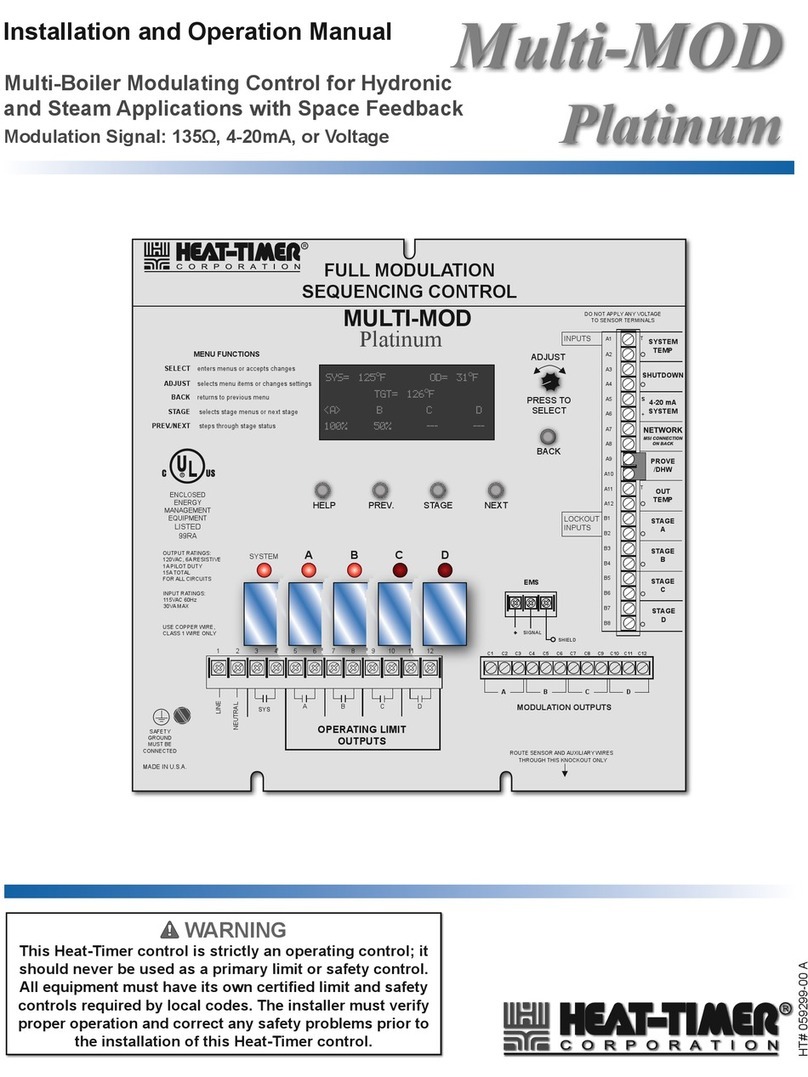

The digital display shows the System and Outdoor temperatures,

the lead stage and lead group <<in brackets>>, and the status of

each stage. To view and adjust settings, press the appropriate buttons.

120VAC Power

Four N.O. Boiler startup relay

outputs. Each is wired in series

with each boiler's limit circuit.

System Output controls

pumps, valves, or other

system components.

Four modulation outputs can be 0-5V,

0-10V, 1-5V, 2-10V, or 4-20ma. Go to

Startup Menu to determine the type of

output for each stage.

LED indicates the

associated relay status.

Button functions are presented on

Bottom Row of display.

When connecting Outdoor and System

Sensors, no Polarity is observed.

Prove terminals must be connected for

the Mini-Mod-CNC to operate the boilers.

Connect Extension panels to

add additional stages using

a phone style cable (cable

provided with Mini-Extension).

Program Switch to restrict access to

function changes. This switch is

covered with the Wiring Enclosure.

Mini-MOD-CNC & Mini-Extension Installation Manual 5

HT# 059102-00 B

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

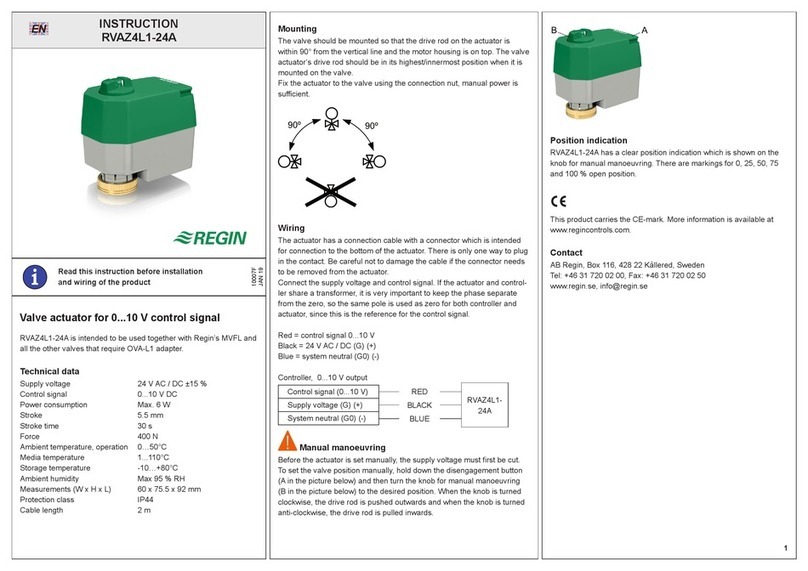

Extension Module

Full Modulation Sequencing Extension

F

H

J

Power

CAUTION:

Risk of Electric Shock.

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PWR

L N

1 2

E

3 4

F

5 6

G

7 8

H

9 10

I

11 12

EXTENSION

MODULE

RS-485

Ext A

INPUT RATINGS:

115VAC 60Hz, 12VA MAX

Use Copper Conductors Only.

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY, 15A TOTAL

FOR ALL CIRCUITS

E

G

I

Comm

Ext B

K

M

O

L

N

P

1716

VLTmA

CUR / VLT

201916

VLTmAGND

CUR / VLT

232219

VLTmAGND

CUR / VLT

262522

VLTmAGND

CUR / VLT

J

13 14

K M OL N P

E F G H

K ML N

15

GND

18

GND

21

GND

24

GND

2928

VLTmA

CUR / VLT

323116

VLTmAGND

CUR / VLT

27

GND

30

GND

I J

O P

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

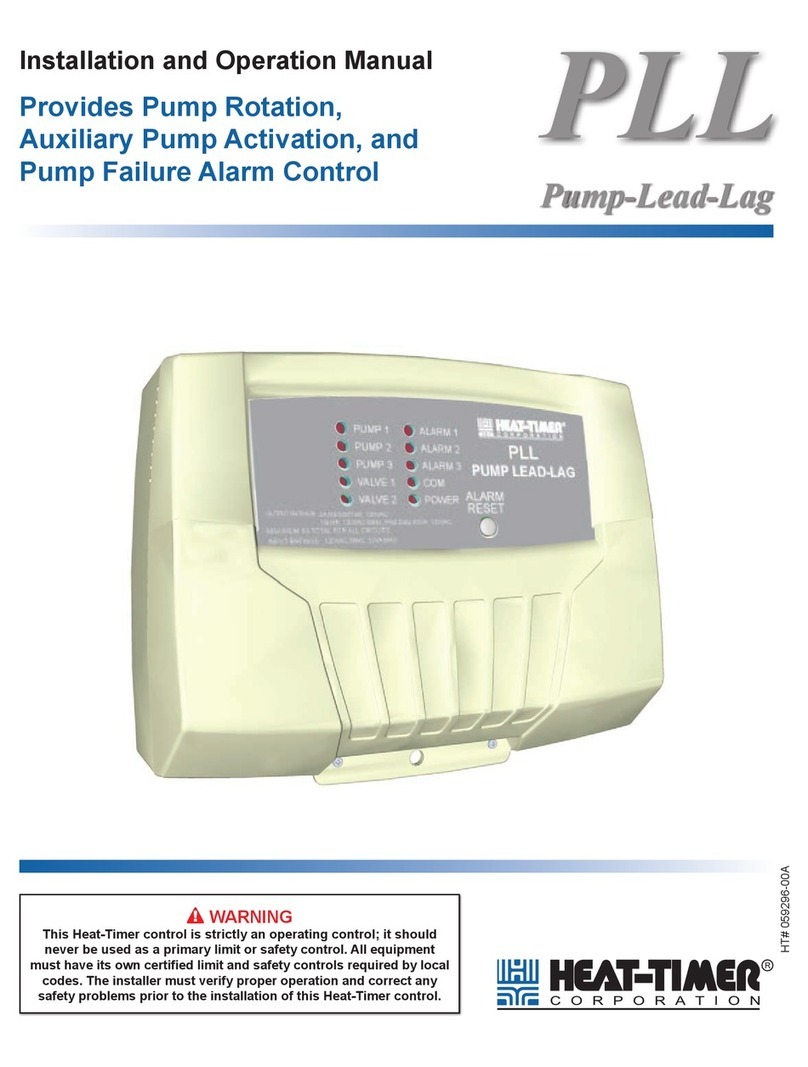

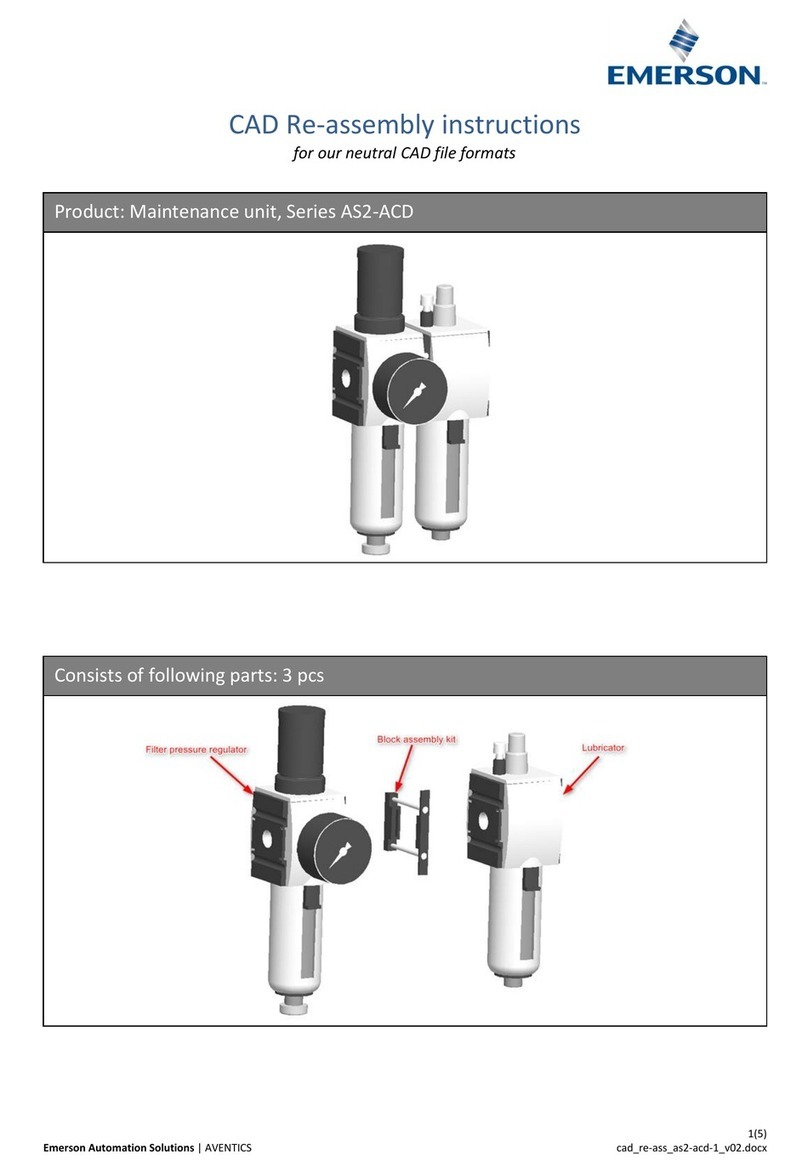

120VAC Power

Six N.O. Boiler startup relay

outputs. Each is wired in series

with the boiler's limit circuit.

Six modulating outputs can be 0-5V,

0-10V, 1-5V, 2-10V, or 4-20ma. Go to

Mini-MOD or Mini-MOD-CNC Startup Menu

to determine the type of output for each stage.

LED indicates the

associated relay status.

Connect to Mini-MOD or Mini-MOD-CNC

and additional Extension panels to add

additional stages using phone style cable

(cable provided with Mini-Extension).

Extension Selection Switch to determine

Stage letters and LED colors.

Ext-A Stages E - J and all LEDs are Green

Ext-B Stages K - P and all LEDs are Red

This switch is covered with the Wiring Enclosure.

6 Heat-Timer Corp.

The Mini-MOD-CNC can operate both modulating and staging boilers. Just specify each of the Condensing and Non-Condensing Boiler

Group type and the Mini-MOD-CNC will activate the groups based on an adjustable set of criteria.

The Mini-MOD-CNC's control algorithms allow it to look at the rate of change in the system. If the system temperature is changing

quickly, the Mini-MOD-CNC will react quickly to adjust the modulating stages’ output. If the system temperature changes slowly, the

Mini-MOD-CNC will make slow and gradual output adjustments. Therefore, the Mini-MOD-CNC adapts to specic system requirements

and minimizes uctuations around the set point.

Whenever any of the Condensing or Non-Condensing Boiler Group type is set to Modulating, the Mini-MOD-CNC will accurately control

the output from 0 to 100% of modulation for each of these different types of motors. Moreover, a single Mini-MOD-CNC can control

multiple modulating burners each with a different modulating signal.

Whenever one of the Condensing or Non-Condensing Boiler Group Type is set to Staging, the Mini-MOD-CNC will accurately sequence

the stages using a PID logic. The sequencing group will have a set of adjustable parameters to help achieve better operation.

The Mini-MOD-CNC’s alphanumeric digital display names each system parameter in simple English and shows its precise value. The

easy to follow menu system allows users to quickly make changes to any system setting without having to learn any specialized codes

or keyboard commands.

Rotating the lead stage of each group promotes even wear. The Mini-MOD-CNC has three modes of rotation: Manual, Last On, or Time.

The Time rotates the lead stage every selected time period from every hour to every 60 days.

The Mini-MOD-CNC has a hydronic outdoor temperature reset function. This allows the Mini-MOD-CNC to change the set point

based on outdoor temperature. Furthermore, additional settings have been added to ne tune this operation, like Offset, Minimum, and

Maximum Water Temperature and night setback schedule.

This output can be used to activate a system pump, combustion air damper, or perform any other function that is required when any stage

is active. It will energize whenever the outdoor temperature is below the Outdoor Cutoff setting. A System Prove input checks the status

of components activated by the System output before stages can be activated.

The Mini-MOD-CNC can stage modulating boilers as needed. In Normal Modulation, it will allow the modulation to increase on the lead

boiler until it reaches its modulation start point adjustment. Then, the Mini-MOD-CNC will start the next boiler and so on. Moreover,

the Mini-MOD-CNC allows for a parallel mode that can modulate several boilers together as a one large boiler. This mode is useful when

used with condensing boilers as they run more efcient at lower modulation. Thus, it is better to run several boilers at lower modulation

than to run a single boiler at full re.

As a stand-alone, the Mini-MOD-CNC is designed to control four stages. However, it has the capability of expanding its control to two

extension panels (HT# 926712-00) each with six boiler stages. Thus, the Mini-MOD-CNC can control a total of up to 16 boiler stages.

HT# 059102-00 B

Mini-MOD-CNC & Mini-Extension Installation Manual 7

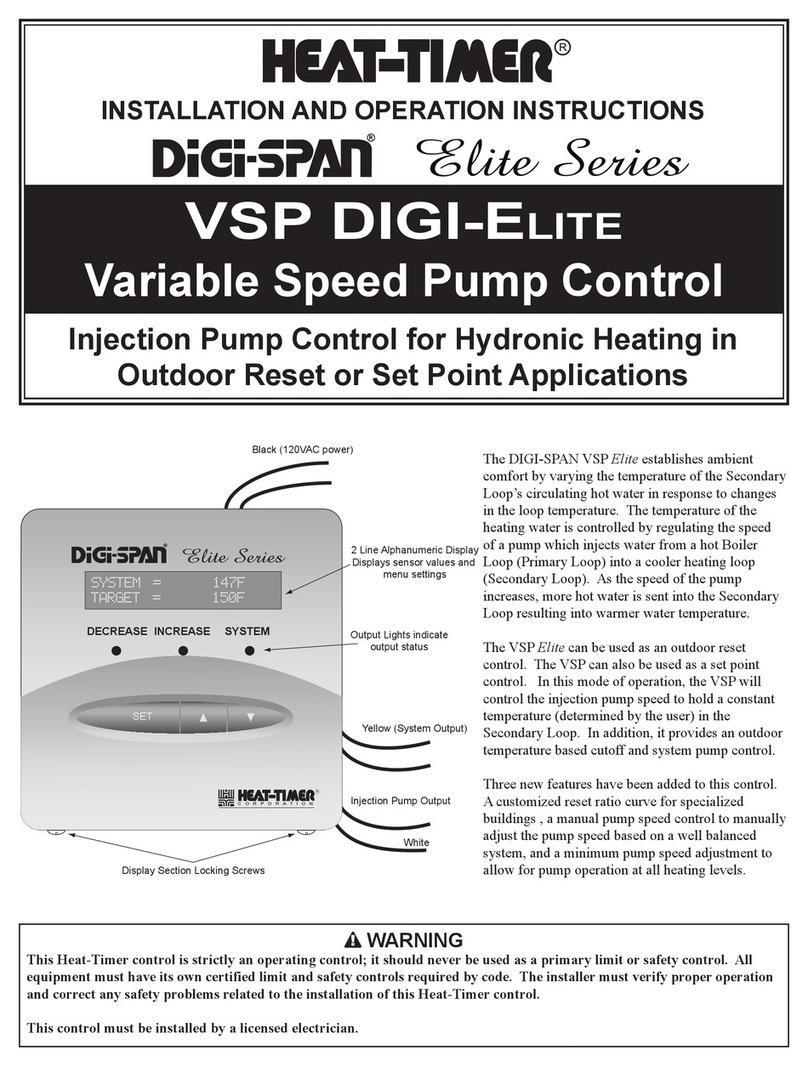

The Mini-MOD-CNC has multiple operating modes that satisfy most hydronic systems.

It changes the System Set Point based on outdoor temperature (Outdoor Reset). The

Mini-MOD-CNC varies the temperature of the circulating heating water in response to

changes in the outdoor temperature. The heating water temperature is controlled through the

modulation or sequencing of the stages.

The Mini-MOD-CNC also controls the system circulating pump with an adjustable Outdoor

Cutoff. When the outdoor temperature is above the Outdoor Cutoff, the pump is off and no

heating water is circulated through the system. When the outdoor temperature drops below

the Outdoor Cutoff, the system pump relay is activated and the heating water circulates

through the system. The temperature of the heating water is controlled by the Reset Ratio,

Water Offset, and changes with Outdoor temperature.

When a building is being heated, heat escapes through the walls, doors, and windows to

the colder outside air. The colder the outside temperature, the more heat escapes. If you

can input heat into the building at the same rate that it is lost out of the building, then the

building temperatures will remain constant. The Reset Ratio is an adjustment that

lets you achieve this equilibrium between heat input and heat loss.

The starting point for most systems is the 1.00 (OD):1.00 (SYS) (Outdoor

Temperature : Heating Water Temperature) ratio. This means that for every

degree the outdoor temperature drops, the temperature of the heating water will

increase one degree. The starting point of the curve is adjustable, but comes

factory selected at 70°F Outdoor Temp. and 100°F Water Temp. For example with

a 1.00 (OD):1.00 (SYS) ratio, if the outdoor temperature is 50°F, this means the

temperature has fallen 20° from the starting point of 70°F. Therefore, the heating

water temperature will increase 20° to 120°F.

Each building has different heat loss characteristics. A very well insulated

building will not lose much heat to the outside air, and may need a Reset Ratio

of 2.00 (OD):1.00 (SYS) (Outdoor:Water). This means the outdoor temperature

would have to drop 2 degrees to increase the water temperature 1 degree. On

the other hand, a poorly insulated building with insufcient radiation may need

a Reset Ratio of 1.00 (OD):2.00 (SYS). This means that for each degree the

outdoor temperature dropped the water temperature will increase 2 degrees. The

Mini-MOD-CNC has a full range of Reset Ratios to match any buildings heat loss

characteristics.

A heating curve that relies not only on Outdoor temperature but also on the type of

radiation will improve heat comfort. The following are suggested initial settings

for different types of radiation based on average building insulation and heat loss.

The contractor can ne tune these adjustments based on the specic building need.

Radiators (Steel & Cast Iron) 1.00 (OD) : 1.00 (SYS) 0˚F

Baseboard (Finned copper tube& Cast Iron) 1.00 (OD) : 1.00 (SYS) 0˚F

Radiant (High Mass/Concrete) 4.00 (OD) : 1.00 (SYS) -10˚F

Radiant (Low Mass/Joists) 2.00 (OD) : 1.00 (SYS) -10˚F

Fan Coils & Air Handlers 1.00 (OD) : 1.00 (SYS) 20˚F

Outdoor Temperature

Water Temperature

70 405060

130

120

110

100

Outdoor Temperature

Water Temperature

70 405060

110

100

90

80

Outdoor Temperature

Water Temperature

70 405060

150

140

130

120

1:4

With a 0° Offset, the

Reset curves begin at

100° Water Temperature.

With a -20° Offset, the

Reset curves begin at

80° Water Temperature.

With a +20° Offset, the

Reset curves begin at

120° Water Temperature.

1:4

1:4 1:1

1:1

1:1

4:1

4:1

4:1

90

100

+20 Offset

-20 Offset

Outdoor Temperature

Water Temperature

70 405060

130

120

110

100

1:4 1:1

4:1

Colder

Warmer

Outdoor Temperature (in °F)

70 60 50 40 20

30 0 -10

10 -20

100

120

110

130

140

150

160

180

170

190

200

210

220

1:3 1:2 1:1.5

1:1.25

1:1

1.25:1

1.5:1

2:1

3:1

4:1

Water Temperature (in °F)

Reset Ratio Curves

Reset Ratio is Presented as

Outdoor Temp. : Water Temp. Ratio

1:4

HT# 059102-00 B

8 Heat-Timer Corp.

If you need the Mini-MOD-CNC to do additional tasks that either are not listed or do not know how to congure them, contact Heat-

Timer Corp. Sales Department either by Phone (973)575-4004, Fax (973) 575-4052, or by E-mail support@Heat-Timer.com.

Setting an Initial Program will ease the conguration of the Mini-MOD-CNC and will give the opportunity to utilize many of the energy

saving features and give more comfortable heat when needed.

The program should consist of the following:

• Selecting the features that your system can utilize.

• Installation: Install the Control, switches and sensors. See "Installation" on page 9

• Setting the System Startup. See "Startup Settings" on page 16

• Setting the System Operating Settings. See "Operating Settings" on page 22

• Setting the Stages. See "Operating Modulating Boiler Settings" on page 26 and "Operating Staging Boiler Settings" on page 27

• Adjusting Reset Ratio and Water Offset (In Reset Mode Only). See "Reset Ratio" on page 22

The Mini-MOD-CNC has been designed with Hydronic building heating, using both condensing and non-condensing boilers, as the

primary purpose. With this in mind, many of the Mini-MOD-CNC features can be utilized to ease, enhance, and improve your system

performance. Some of these features are listed in this section.

• The Mini-MOD-CNC can be congured to control up to 4 condensing and non-condensing boilers. It can control up to 16 boiler

stages using a maximum of two Mini-Extension Panels (HT# 926712-00).

• The Mini-MOD-CNC can stage modulating boilers using one of two methods. Normal Modulation Mode, allows it to increase the

modulation of the lead boiler. When the lead boiler reaches its Modulation Start point adjustment and does not satisfy the load, the

Mini-MOD-CNC will start the next boiler and so on. This mode targets boilers that can run more efcient at higher modulation rates.

• The Parallel Modulation Mode can modulate several boilers together as one large boiler. This mode is useful for boilers that are

more efcient at lower ring rate as in many condensing boilers.

• The Mini-MOD-CNC is designed to accurately control the modulation output from 0 to 100% for either current (4-20mA) or voltage

(0-5V, 0-1V, 1-5V, 2-10V) motors. A single Mini-MOD-CNC can control a combination of the above modulation motors.

• Rotating the rst burner to be activated on a call for output promotes even wear on all burners. The Mini-MOD-CNC has three modes

of rotation: Manual, Last-ON, or Time; automatically rotating every selected time period from every hour to every 60 days.

Two Setback modes are available for the Mini-MOD-CNC:

• The Day/Night Scheduling provides an adjustable time-based schedule for the Setback (only available when Shutdown or Tstat is

selected as the Setback/Shutdown Startup option). See "Shutdown/Tstat/Setback Mode" on page 19.

• The Setback mode uses an external signal to switch the operation of the Mini-MOD-CNC in and out of setback mode.

• This feature lets the Mini-MOD-CNC run the SYS relay for a longer period after the boilers have been turned off. When this relay is

used to control a pump, it helps in dissipating the excess heat from the boilers combustion chamber.

HT# 059102-00 B

Mini-MOD-CNC & Mini-Extension Installation Manual 9

Each of the Mini-MOD-CNC or Mini-Extension consists of three primary enclosure components.

• TheEnclosureDisplayModule: contains the display, buttons, LEDs and electric wiring terminals. It has two screws to hold it to

the base. A program conguration switch, used to adjust Mini-MOD-CNC settings, is placed above the terminals. This switch is

enclosed with the enclosure wiring cover for security. Wiring terminals are of the plug-in type to ease installation and removal.

• TheEnclosureBase: contains the holes to mount and hold the control against the wall or any at surface. All other enclosure

components mount on the base. The bottom section of the Enclosure Base contains the wiring chamber with knockouts on the

bottom to ease installation.

• TheEnclosureWiringCover: seals the wires from the external environment. It has two screws to hold it the base and a hole to

secure a lock on the wiring enclosure. A plastic web that separates the wiring chamber into high and low volt sections has been

provided.

• Select a location near the equipment to be controlled.

• The surface should be at and sufciently wide and strong to hold the Mini-MOD-CNC or the Mini-Extension.

• Keep the control away from extreme heat, cold, or humidity. Ambient operating temperature is from 20 to 120°F.

• Remove the Enclosure Wiring Cover from the control enclosure by removing the two bottom screws.

• Remove the Enclosure Display Module by removing the enclosure middle screws.

• Screw the Enclosure Base to the surface through the upper and lower mounting holes on the back of the enclosure.

• Replace the Enclosure Display Module and replace the enclosure middle screws.

• Do not replace the enclosure wiring cover until all wiring is done.

• When purchasing a padlock for the enclosure, the maximum shank diameter should not exceed ¼"

Enclosure Display Module

Enclosure Wiring Cover Enclosure Base

Hole for optional lock

(not supplied)

Mounting Holes

Display Mounting Screws

Wiring Cover

Mounting Screws

HT# 059102-00 B

10 Heat-Timer Corp.

• Only use a Standard Brass Tube sensor (HT #904250-00).

• The sensor wires can be extended up to 500' using a shielded 2-conductor cable

(Belden #8760 or equivalent). Do not ground the shield at the sensor but at the

panel using one of the terminals marked with an “O”.

• Do not run sensor wires in conduit with line voltage wiring.

• Install a 3/8"ID 1/2"NPT immersion well (HT #904011-00 or equivalent).

• Insert the sensor in a well approximately 10' feet past the last boiler on the

common supply header but before any major takeoffs.

• The sensor must be located where it sees the output of all the boiler stages. If

a boiler is piped so that the sensor does not see its output, the Mini-MOD-CNC

will not sequence the boilers correctly.

• The sensor can also be installed on the return to the boilers after all major returns

and before any boiler. However, when setting the reset ratio and the offset, the

user must consider the temperature drop across the building loop.

Immersion Well

3/8" ID 1/2" NPT

Heating System

Sensor

Common Supply Pipe

Sensor Probe

Immersion Heating System Sensor

Shield

Common Supply Pipe

Sensor Probe

Strap-On Heating System Sensor

Shield

Pipe Insulation

Connect

To control

If the System Sensor can not sense the

correct water temperature, the Mini-

MOD-CNC will not provide comfortable

heat levels.

• Only use the Heat-Timer sensor included with the unit (HT# 904220-00) .

• Locate the sensor in the shade on the north side of the building. The sensor

should never be in direct sunlight.

• Be sure the location is away from doors, windows, exhaust fans, vents, or other

possible heat sources.

• The sensor should be mounted approximately 10' feet above ground level.

• Adhere the Outdoor Label provided to the back of the sensor base.

• Use the Enclosure Base bottom knockout for the conduit. Use the locknut to hold

the conduit and enclosure base together. Screw the cover to the base.

• If screws are used to afx the enclosure to the wall, make sure to seal around the

sensor and wall except from the bottom.

• The sensor wires can be extended up to 500' using shielded 2-conductor cable

(#18/2). Do not ground the shield at the sensor but at the control using the

terminal marked with an “O”.

• Do not run sensor wires in conduit with line voltage wiring.

System Sensor

In Well

Shield

Not connected

Well Locknut

Sensor

in Well

Well

Sensor 2-Conductor

Shielded Cable

System

Strap-On

Sensor

Shield

Not connected

Plastic

Tie-Wraps

Around Pipe

Outdoor

Sensor

snap-in

location

Shield

not connected

Conduit

Outdoor Label

on back of Sensor

Outdoor Sensor

Strap-On Sensor

Immersion Sensor

Mounting

screws

location

Seal around

sensor and wall

Outdoor

drip-hole

HT# 059102-00 B

Mini-MOD-CNC & Mini-Extension Installation Manual 11

• All wiring must enter the enclosure through the bottom knockouts.

• Class 1 voltage wiring must utilize a different knockout and conduit from any Class 2 voltage wiring.

• Bring the 120VAC 60Hz power wires through the bottom left knockout of the enclosure.

• Connect the hot line to terminal marked L.

• Connect the neutral line to the terminal marked N.

• Heat-Timer recommends installing a surge suppressor on the power source to the Mini-MOD-CNC.

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

12

RUNPROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

345678910 11 12 13 15

14 17

16 18 22

20

19 21 24

23 29

25 27

26 28 32

30 31

LN

-+

+

TT

OORS-485

mA

GND VLT

SYS ABCD

PWR

CUR / VLT

A

-+

+

mA

GND VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

TEMP

OUTDOOR

OO

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

OD=25oF SYS= 145oF

<<A>> B

100% 52%

Mini-MOD-CNC

Line

Neutral

120VAC

Power Source

• A Mini-MOD-CNC must be connected to a System temperature sensor (HT #904250-00 provided) located in the

common header. The sensor must be inserted in a 3/8 ID well (HT #904011-00 or equivalent).

• Temperature sensor wires can be extended up to 500’ by splicing its wires with a shielded 2-conductor cable

(Belden #8760 or equivalent (#18/2)).

• Temperature sensors have no polarity. Connect the two wires from the sensor to the Mini-MOD-CNC terminals

marked SYSTEM TEMP 27, 28.

• Connect the sensor shield to the circled terminal 28 with one of the sensor wires.

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

12

RUNPROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

345678910 11 12 13 15

14 17

16 18 22

20

19 21 24

23

29

25

27

26 28

32

30

31

LN

-+

+

T

T

OO

RS-485

mA

GND VLT

SYS ABCD

PWR

CUR / VLT

A

-+

+

mA

GND VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

OD=25oF SYS= 145oF

<<A>> B

100% 52%

Mini-MOD-CNC

System Sensor

Sensor Shield

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

12

RUNPROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

345678910 11 12 13 15

14 17

16 18 22

20

19 21 24

23 29

25 27

26 28

32

30 31

LN

-+

+

TT

OO

RS-485

mA

GND VLT

SYS ABCD

PWR

CUR / VLT

A

-+

+

mA

GND VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

TEMP

OUTDOOR

OO

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

OD=25oF SYS= 145oF

<<A>> B

100% 52%

Mini-MOD-CNC

Outdoor Sensor

Sensor Shield

• The Mini-MOD-CNC will vary the system Set Point based on outdoor temperature. In addition, the outdoor sensor

is used as an Outdoor Cutoff. The Mini-MOD-CNC will disable all boilers when the outdoor temperature is above

the adjustable Outdoor Cutoff temperature.

• For an outdoor sensor use the outdoor sensor provided (HT #904220-00).

• The sensor wires can be extended up to 500’ using shielded 2-conductor cable (Belden #8760 or equivalent (#18/2)).

• Temperature sensors have no polarity. Connect the wires from the outdoor sensor to the Mini-MOD-CNC terminals

marked OUTDOOR TEMP - 25, 26.

• Connect the shield to the circled terminal 26 with one of the sensor wires.

• The Shutdown will be available when selected as the Shutdown/Tstat/Setback mode from the Startup menu. See

"Shutdown/Tstat/Setback Mode" on page 19. This will provide the user with an adjustable Day/Night Schedule. See

"Day/Night Schedules" on page 28.

• The Shutdown feature can be used whenever it is desirable to turn off the Mini-MOD-CNC stage outputs from a

remote location or another controller (i.e. EMS input).

• The Tstat option, when selected from the Shutdown/Tstat/Setback startup menu, offer the capability of controlling

the operation of the Mini-MOD-CNC based on a thermostat input. This will provide the user with an adjustable

Day/Night Schedule.

• The thermostat will send the Mini-MOD-CNC a call for heat by shorting terminals 31 and 32.

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

12

RUNPROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

345678910 11 12 13 15

14 17

16 18 22

20

19 21 24

23 29

25 27

26 28

32

30 31

LN

-+

+

TT

OORS-485

mA

GND VLT

SYS ABCD

PWR

CUR / VLT

A

-+

+

mA

GND VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

TEMP

OUTDOOR

OO

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

OD=25oF SYS= 145oF

<<A>> B

100% 52%

Mini-MOD-CNC

Shutdown,

T-Stat, or

Setback Signal

HT# 059102-00 B

12 Heat-Timer Corp.

• When the Shutdown input is enabled by closing the dry contact, or when the Tstat input is disabled by opening the dry-contact, all

active modulating boilers will immediately modulate down to low for the Soft-Off period, then turn off. All staging boilers will

turn off immediately.

• The System Output relay will remain active until the System Run-On Delay expires and then it will turn off.

• When Setback is selected in the Startup, a BMS/EMS or external clock can provide a Setback signal using these input terminals.

See "Shutdown/Tstat/Setback Mode" on page 19. No Day/Night Schedule will be available when Setback is selected from the

Shutdown/Tstat/Setback mode in the Startup menu.

• The signal must be a dry contact only. No voltage can be placed across the SHUTDOWN/TSTAT/SETBACK terminals.

• Bring the two wires from the dry contact to the terminals marked SHUTDOWN/TSTAT/SETBACK- 31,32.

• The Prove feature is provided to check system component operation and must be selected in the Startup Menu

from the Prove/DHW Sharing menu. See "Prove/Domestic Hot Water (DHW) Priority" on page 19.

• A typical use of this feature is to check for pump ow or combustion air damper status before ring any boiler.

• If the PROVE input is open on a call for heat, the Mini-MOD-CNC will enable only the System Output. All boiler

outputs will be off when the PROVE input is open.

• A factory-installed jumper provides the System Prove signal. Do not remove the jumper unless it will be replaced

by a System Prove signal or these terminals are to be used for DHW call input.

• Bring the two wires from the dry contact to the terminals marked PROVE - 29, 30. No voltage can be placed

across the PROVE terminals

• Prove Input terminals can accept a dry-contact signal only. No voltage can be placed across these terminals.

The PROVE input cannot be used as a safety limit. All equipment must have its own

certied limit and safety controls as required by local codes. If Prove is selected in the

startup menu, no boiler stage will start unless Prove terminals are shorted. DO NOT

remove the PROVE jumper supplied unless replacing it with a Prove signal.

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

12

RUNPROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

345678910 11 12 13 15

14 17

16 18 22

20

19 21 24

23

29

25 27

26

28 32

30 31

LN

-+

+

TT

O

O

RS-485

mA

GND VLT

SYS ABCD

PWR

CUR / VLT

A

-+

+

mA

GND VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

TEMP

OUTDOOR

OO

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

OD=25oF SYS= 145oF

<<A>> B

100% 52%

Mini-MOD-CNC

Prove Signal

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

12

RUNPROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

345678910 11 12 13 15

14 17

16 18 22

20

19 21 24

23

29

25 27

26

28 32

30 31

LN

-+

+

TT

O

O

RS-485

mA

GND VLT

SYS ABCD

PWR

CUR / VLT

A

-+

+

mA

GND VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

TEMP

OUTDOOR

OO

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

OD=25oF SYS= 145oF

<<A>> B

100% 52%

Mini-MOD-CNC

DHW Signal

• DHW can be used to raise system Set Point to the DHW Set Point as well as manage the System Pump according

to the DHW Priority setting. One of the DHW options must be selected from the Prove/DHW Sharing Startup

menu. See "Prove/Domestic Hot Water (DHW) Priority" on page 19.

• Wire an aquastat or a control to provide dry-contact closure on the DHW Call terminals.

• Remove the jumper on the DHW terminals for proper operation.

• DHW Call terminals can accept dry contact signals only. No voltage can be placed across these terminals.

• The SYS output relay will energize whenever the outdoor temperature is below the Outdoor Cutoff.

• The SYS relay will remain constantly energized while the outdoor temperature is below the Outdoor Cutoff.

• When the outdoor temperature rises 2°F above the Outdoor Cutoff, the SYS output will remain energized for the

period set by the System Run-On. See "System Run-On" on page 24.

• In addition, the System output will energize during summer DHW calls when DHW No Priority is selected. See

"Prove/Domestic Hot Water (DHW) Priority" on page 19.

• The SYS output has one Normally Open (N.O.) relay contact rated for (1/8HP).

• The N.O. contacts are dry contacts only. They do not source any voltage.

• Class 1 voltages must enter the enclosure through a different opening from any Class 2 voltage wiring.

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

12

RUNPROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3456

78910 11 12 13 15

14 17

16 18 22

20

19 21 24

23 29

25 27

26 28 32

30 31

LN

-+

+

TT

OORS-485

mA

GND VLT

SYS A

BCD

PWR

CUR / VLT

A

-+

+

mA

GND VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

TEMP

OUTDOOR

OO

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

OD=25oF SYS= 145oF

<<A>> B

100% 52%

Mini-MOD-CNC

System Pump

or Pump Starter

L

N

HT# 059102-00 B

Mini-MOD-CNC & Mini-Extension Installation Manual 13

• When wiring condensing and non-condensing boilers make sure that condensing boilers utilize the rst stages

and non-condensing boilers will utilize the following stages. That is, if the installation had two condensing

modulating boilers and two non-condensing staging On/Off boilers, Stage A and B will be used by the condensing

boilers while C and D will be used by the non-condensing boilers.

• Each boiler output (A through D) has one Normally Open (N.O.) relay contact.

• The N.O. contacts are dry contacts only. They do not source any voltage.

• Wire the N.O. relay contacts in series with the unit’s limit circuit.

• Class 1 voltages must enter the enclosure through a different opening from any Class 2 voltage wiring.

• Note that some modulating boilers may not require the use of these outputs.

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

12

RUNPROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

345678

910 11 12 13 15

14 17

16 18 22

20

19 21 24

23 29

25 27

26 28 32

30 31

LN

-+

+

TT

OORS-485

mA

GND VLT

SYS AB

CD

PWR

CUR / VLT

A

-+

+

mA

GND VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

TEMP

OUTDOOR

OO

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

OD=25oF SYS= 145oF

<<A>> B

100% 52%

Mini-MOD-CNC

Boiler Enable

Output

Boiler

• Each stage output (A through D) has one Normally Open (N.O.) relay

contact that does not source any power.

• Wire each of the N.O. relay contacts to its respective boiler stage.

Note that on the display of the Mini-MOD-CNC each staging boiler

will consist of multiple letters. The letters represent outputs that

should be wired to that boiler. The rst letter should be wired to the

lowest ring stage and the next letter to the next stage and so on. See

"Boiler Status" on page 30.

• Class 1 voltages must enter the enclosure through a different opening

from any Class 2 voltage wiring.

OD=55oF SYS=142oF

<CD> EF

LO ---

STAGE ◄ ► MENU

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

12

RUNPROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

34567

8910 11 12

13 15

14 17

16 18 22

20

19 21 24

23 29

25 27

26 28 32

30 31

LN

-+

+

TT

OORS-485

mA

GND VLT

SYS AB

CD

PWR

CUR / VLT

A

-+

+

mA

GND VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

TEMP

OUTDOOR

OO

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

OD=25oF SYS= 145oF

<<A>> B

100% 52%

Mini-MOD-CNC

2-Stage Boiler

Stage1

Stage2

The Mini-MOD-CNC can modulate any combination of the following boiler signals. The Modulating Output Type

must be selected properly before connecting any output wires to avoid damaging components. See "Modulating

Output Type" on page 18. Some modulating boilers may require the use of the relay stage outputs. See "Wiring the

Boilers"

• The Mini-MOD-CNC can operate up to four 4-20 mA modulating motors.

• The Mini-Extension can operate up to six 4-20 mA modulating motors.

• The Mini-MOD-CNC and the Mini-Extension sources 24VDC excitation voltage for the 4-20mA signal.

• Wire the (-) from the modulating motor to the boiler terminal on the Mini-MOD-CNC marked (GND). That is for

boiler A, the modulating (-) terminal will be 13.

• Wire the (+) from the modulating motor to the boiler terminal on the Mini-MOD-CNC marked (mA). That is for

boiler A, the modulating (-) terminal will be 14.

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

12

RUNPROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

345678910 11 12

13 15

14

17

16

18 22

20

19 21 24

23 29

25 27

26 28 32

30 31

LN

-+

+

TT

OORS-485

mA

GND VLT

SYS ABCD

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

TEMP

OUTDOOR

OO

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

OD=25oF SYS= 145oF

<<A>> B

100% 52%

Mini-MOD-CNC

Boiler 4-20mA

Modulation Output

4-20mA

Burner

Motor

-+

• The Mini-MOD-CNC can operate up to four 0-5V, 0-10V, 1-5V, or 2-10V modulating motors.

• The Mini-Extension can operate up to six 0-5V, 0-10V, 1-5V, or 2-10V modulating motors.

• Wire the (GND) from the modulating motor to the boiler terminal on the Mini-MOD-CNC marked (GND). That

is for boiler D, the modulating (GND) terminal will be 22.

• Wire the (V+) from the modulating motor to the boiler terminal on the Mini-MOD-CNC marked (VLT+). That is

for boiler D, the modulating (V+) terminal will be 23.

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

12

RUNPROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

345678910 11 12 13 15

14 17

16 18

22

20

19

21 24

23

29

25 27

26 28 32

30 31

LN

-+

+

TT

OORS-485

mA

GND VLT

SYS ABCD

PWR

CUR / VLT

A

-+

+

mA

GND VLT

-+

+

mA

GND

VLT

-+

+

mA

GND VLT

+

mA

TEMP

OUTDOOR

OO

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

OD=25oF SYS= 145oF

<<A>> B

100% 52%

Mini-MOD-CNC

Boiler Voltage

Modulation Output

Voltage

Burner

Motor

GND V+

HT# 059102-00 B

14 Heat-Timer Corp.

To set the Mini-Extension to a specic letter, remove the wiring cover and switch the Ext A/Ext B

to the desired letter. DO NOT set both extensions to the same letter to avoid errors.

• The Mini-MOD-CNC is equipped with a 6-pin phone socket (RS485) to connect to extension panels and . The Mini-Extension is

equipped with two 6-pin phone sockets to connect to Mini-MOD-CNC and an additional Mini-Extension.

• Set each Extension to a different letter (EXT-A or EXT-B). The Mini-MOD-CNC will assign the stage letters based on the

extension letter selected.

• Extension A will operate stages E - J and all the LEDs will be Green. However, Extension B will operate stages K - P and all the

LEDs will be Red. See "Mini-Extension Layout" on page 5.

• Congure the Modulating and Sequencing Output Types after connecting the Extension panels to be able to congure their outputs.

See "Modulating Output Type" on page 18

• Only use the cable provided for proper operation.

Extension Module

Full Modulation Sequencing Extension

F

H

J

Power

CAUTION:

Risk of Electric Shock.

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PWR

L N

1 2

E

3 4

F

5 6

G

7 8

H

9 10

I

11 12

EXTENSION

MODULE

RS-485

Ext A

INPUT RATINGS:

115VAC 60Hz, 12VA MAX

Use Copper Conductors Only.

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY, 15A TOTAL

FOR ALL CIRCUITS

E

G

I

Comm

Ext B

K

M

O

L

N

P

1716

VLTmA

CUR / VLT

201916

VLTmAGND

CUR / VLT

232219

VLTmAGND

CUR / VLT

262522

VLTmAGND

CUR / VLT

J

13 14

K M OL N P

E F G H

K ML N

15

GND

18

GND

21

GND

24

GND

2928

VLTmA

CUR / VLT

323116

VLTmAGND

CUR / VLT

27

GND

30

GND

I J

O P

Mini-MOD Extension A

Extension Module

Full Modulation Sequencing Extension

F

H

J

Power

CAUTION:

Risk of Electric Shock.

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PWR

L N

1 2

E

3 4

F

5 6

G

7 8

H

9 10

I

11 12

EXTENSION

MODULE

RS-485

Ext A

INPUT RATINGS:

115VAC 60Hz, 12VA MAX

Use Copper Conductors Only.

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY, 15A TOTAL

FOR ALL CIRCUITS

E

G

I

Comm

Ext B

K

M

O

L

N

P

1716

VLTmA

CUR / VLT

201916

VLTmAGND

CUR / VLT

232219

VLTmAGND

CUR / VLT

262522

VLTmAGND

CUR / VLT

J

13 14

K M OL N P

E F G H

K ML N

15

GND

18

GND

21

GND

24

GND

2928

VLTmA

CUR / VLT

323116

VLTmAGND

CUR / VLT

27

GND

30

GND

I J

O P

Mini-MOD Extension B

SYSTEM

A

B

C

D

12

RUNPROGRAM DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

345678910 11 12 13 15

14 17

16 18 22

20

19 21 24

23 29

25 27

26 28 32

30 31

LN

-+

+

TT

OORS-485

mA

GND VLT

SYS ABCD

PWR

CUR / VLT

A

-+

+

mA

GND VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

TEMP

OUTDOOR

OO

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

PROVE

/DHW

SHUTDOWN

/SETBACK

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

Use Copper Conductors Only.

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

/TSTAT

Cable provided with Extension or 4-20mA EMS Interface

Mini-MOD-CNC

Mini-MOD-CNC

Connecting Mini-MOD-CNC

to Two Extension Panels

and 4-20mA EMS Interface

Condensing / Non-Condensing Control

4-20 mA EMS

4-20mA INPUT

+Signal GND

123

RS485

EXTENSION

CONNECTORS

4-20mA EMS Interface

(-)

EMS/BMS Sources

Excitation Voltage

(+)

EMS/BMS

Temperature

Set PointInput

Cable provided with Extension or 4-20mA EMS Interface

OD=25oF SYS= 145oF

<<A>> B <C> D

100% 52% --- ---

• The Mini-MOD-CNC is equipped with a 6-pin phone socket (RS485) to connect to extension panels and 4-20mA EMS Interface.

The 4-20mA EMS Interface is equipped with two 6-pin phone sockets to connect to Mini-MOD-CNC and an additional

Mini-Extension.

• Set Sensor Type to either of the two EMS options. See "Sensor Type" on page 16.

• The interface must be ordered separately.

• Only use the cable provided for proper operation.

HT# 059102-00 B

Mini-MOD-CNC & Mini-Extension Installation Manual 15

To be able to change the Mini-MOD-CNC

settings the Program/Run Switch must

be set to Program. The switch is located

under the Enclosure Wiring Cover for

security. The Enclosure Wiring Cover

can be securely closed using a lock.

-------- SETTINGS ----

Season Winter

System Target 140oF

<System Settings>

<Maintenance>

<Histories>

<System Startup>

BACK ▲ ▼ SELECT

-- ARE YOU SURE? --

No

Yes

BACK ▲ ▼ SAVE

--- SENSOR TYPE ---

Reset oF

Reset oC

EMS oF

EMS oC

BACK ▲ ▼ SAVE

--- SWITCH DIFF ---

5 oF

[ ]

BACK ▲ ▼ SAVE

CONDENSING

-- OUTPUT A TYPE --

4-20ma

0-10v

0-5v

2-10v

1-5v

Not Installed

BACK ▲ ▼ SAVE

CONDENSING

-- OUTPUT B TYPE --

4-20ma

0-10v

0-5v

2-10v

1-5v

Not Installed

BACK ▲ ▼ SAVE

CONDENSING

- MODULATING MODE -

Normal

Parallel

BACK ▲ ▼ SAVE

NON-CONDENSING

-- BOILER NUMBER --

2

[ ]

BACK ▲ ▼ SAVE

NON-CONDENSING

- STAGING MODE -

LO/HI/LO/HI

LO/LO/HI/HI

BACK ▲ ▼ SAVE

PROVE/DHW SHARING

Prove

DHW Priority

DHW No Priority

No Priority (Summer)

BACK ▲ ▼ SAVE

- DHW SETPOINT -

180 oF

[ ]

BACK ▲ ▼ SAVE

--- BOOST MODE ---

30 Minutes

Disable

BACK ▲ ▼ SAVE

--- SENSOR FAULT ---

All Off

All On

BACK ▲ ▼ SAVE

CONDENSING

-- BOILER NUMBER --

2

[ ]

BACK ▲ ▼ SAVE

Page 17

NON-CONDENSING

-- OUTPUT TYPE --

On/Off

2-Stage

3-Stage

4-Stage

BACK ▲ ▼ SAVE

Page 19 Page 17

Page 20

Page 20

Page 16

CONDENSING

---- BOILER TYPE ----

Modulating

Staging

BACK ▲ ▼ SAVE

Page 17

- SWITCH SETPOINT -

150 oF

[ ]

BACK ▲ ▼ SAVE

Page 16

HEAVY LOAD

-SEQUENCE #2 GROUP-

No

Yes

BACK ▲ ▼ SAVE

Page 17

NON-CONDENSING

---- BOILER TYPE ----

Modulating

Staging

BACK ▲ ▼ SAVE

Page 18

Page 19

- SETBCK/SHUTDOWN -

Shutdown/Disable

Tstat/Enable

Setback

BACK ▲ ▼ SAVE

Page 19

Page 18

Page 19

Page 19

Page 17

--- SWITCH DELAY ---

0.5Hour

[ ]

BACK ▲ ▼ SAVE

Page 17

Page 18 Page 18

HT# 059102-00 B

16 Heat-Timer Corp.

To be able to change the Mini-MOD-CNC settings the Program/Run Switch must be set to

Program. The switch is located under the Enclosure Wiring Cover for security. The Enclosure

Wiring Cover can be secured using a lock.

SYSTEM

A

B

C

D

Full Modulation Sequencing Control

12

RUNPROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

345678910 11 12 13 15

14 17

16 18 22

20

19 21 24

23 29

25 27

26 28 32

30 31

LN

-+

+

TT

OORS-485

mA

GND VLT

SYS ABCD

PWR

CUR / VLT

A

-+

+

mA

GND VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

TEMP

OUTDOOR

OO

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

Mini-MOD

Button: MENU/<System Startup>

• When powered, the Mini-MOD-CNC performs a self diagnostics-test on its components.

• On the rst power up, the System Startup screen will appear after the initialization is

complete. If it doesn’t, the Mini-MOD-CNC has already been congured.

• The System Startup menu sets the main parameters that relate to the heating application.

These settings must be set by the installer.

-------- SETTINGS ----

Season Winter

System Target 140oF

<System Settings>

<Maintenance>

<Histories>

<System Startup>

BACK ▲ ▼ SELECT

Reset°F,Reset°C,EMS°F,EMS°C Default:Reset°F

Button: MENU/<System Startup>/..../Sensor Type

• The same Heat-Timer temperature sensor can display in either °F or °C.

• If any of the Reset options is selected, the control will use outdoor reset to calculate the

Target Temperature.

• If any of the EMS options is selected, the control will require the use EMS 4-20mA Interface

(HT# 926741-00).

• Selecting any of the °F options will display all temperatures in degrees Fahrenheit.

• Selecting any of the °C options will display all temperatures in degrees Celsius.

--- SENSOR TYPE ---

Reset oF

Reset oC

BACK ▲ ▼ SAVE

Above the Switch Set Point

Non-Condensing are the Lead Group

Condensing are the Lag Group

Target Switch

Set Point = 120°F

Below the Switch Set Point

Condensing are the Lead Group

Non-Condensing are the Lag Group

120°F

140°F

100°F

SWITCH MODE = Target Temperature

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

12

RUNPROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

34567 8 91011 12 13 15

14 17

16 18 22

20

19 21 24

23 29

25 27

26 28 32

3031

LN

-+

+

TT

OORS-485

mAGND VLT

SYS ABCD

PWR

CUR / VLT

A

-+

+

mAGND VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

TEMP

OUTDOOR

OO

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

OD=25oF SYS= 145oF

<<A>> B

100% 52%

CONDCOND

NON-

COND

NON-

COND

NON-

COND

NON-

COND

CONDCOND

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

12

RUNPROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

34567 8 91011 12 13 15

14 17

16 18 22

20

19 21 24

23 29

25 27

26 28 32

3031

LN

-+

+

TT

OORS-485

mAGND VLT

SYS ABCD

PWR

CUR / VLT

A

-+

+

mAGND VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

TEMP

OUTDOOR

OO

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

OD=25oF SYS= 145oF

<<A>> B

100% 52%

Target

Temp

Above the Switch Set Point

Condensing are the Lead Group

Non-Condensing are the Lag Group

Outdoor Switch

Set Point = 30°F

Below the Switch Set Point

Non-Condensing are the Lead Group

Condensing are the Lag Group

30°F

50°F

10°F

SWITCH MODE = Outdoor Temperature

CONDCOND

NON-

COND

NON-

COND

NON-

COND

NON-

COND

CONDCOND

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

12

RUNPROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

34567 8 91011 12 13 15

14 17

16 18 22

20

19 21 24

23 29

25 27

26 28 32

3031

LN

-+

+

TT

OORS-485

mAGND VLT

SYS ABCD

PWR

CUR / VLT

A

-+

+

mAGND VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

TEMP

OUTDOOR

OO

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

OD=25oF SYS= 145oF

<<A>> B

100% 52%

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

12

RUNPROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

34567 8 91011 12 13 15

14 17

16 18 22

20

19 21 24

23 29

25 27

26 28 32

3031

LN

-+

+

TT

OORS-485

mAGND VLT

SYS ABCD

PWR

CUR / VLT

A

-+

+

mAGND VLT

-+

+

mA

GND VLT

-+

+

mA

GND VLT

+

mA

TEMP

OUTDOOR

OO

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

OD=25oF SYS= 145oF

<<A>> B

100% 52%

Outdoor

Temp

Adjustablefrom0ºF/-18ºCto200ºF/94ºC Default:150ºF/66ºC

Button: MENU/<System Startup>/..../Sensor Type/Switch Setpoint

• It is the Target Temperature Set Point at which the Mini-MOD-CNC will switch between

Condensing Boiler Group and Non-Condensing Boiler Group.