heat-timer TR1000 User manual

HT# 059292-00 F

Motorized Tempering Valves

without Transformers for

2” and 2½” Stainless-Steel Valves

WARNING

This Heat-Timer Motorized Tempering Valve is strictly an operating

valve. It should never be used as a “FailSafe” or “Anti-Scald” valve.

A separate Anti-Scald device can be installed in conjunction with

this motorized tempering valve. All equipment must have their own

certified limit and safety controls required by local codes.

Installation and Operation Manual

ACTUATOR TR1000

HT# 059292-00 F

2Motorized Tempering Valve without Transformer Installation

OVERVIEW

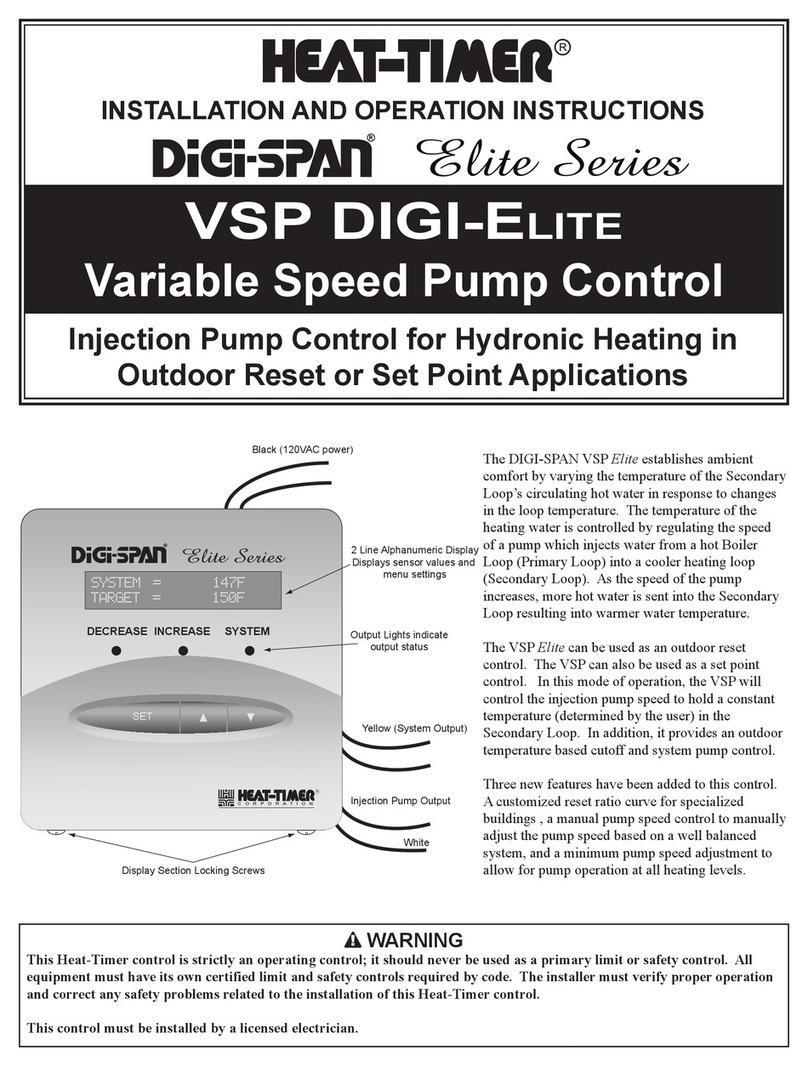

The Heat-Timer electronic tempering valves are 3-way valves. They are components of the Heat-Timer ETV control package.

Though the ETV control is used primarily in domestic hot water temperature regulation, it can be used in other applications as

well. Heat-Timer offers two types of electronic tempering valve actuators: an actuator that requires external power (M800) using

a transformer and an actuator that uses the ETV control 24 VAC power (TR1000). The selection of the actuator depends on the

size and type of valve material selected. This manual demonstrates the actuator using the ETV power source (TR1000) only. This

actuator is used with larger size stainless-steel tempering valves (2” and 2 ½”). These stainless-steel tempering valves are primarily

used in areas adhering to strict Lead-Free codes.

ETV PACKAGES

Bronze ETV

Package

Bronze ETV

Actuator CvValve Size Stainless-steel

ETV Package

Stainless-steel

ETV Actuator Cv

915520-00

Actuator (M800)

Requires External

Power

4.7 ½” 915620-00

Actuator (M800)

Requires External

Power

4.7

915521-00 7.3 ¾” 915621-00 7.3

915522-00 11.6 1” 915622-00 11.6

915523-00 18.5 1-¼” 915623-00 18.5

915524-00 29 1-½ 915624-00 29

915525-00 46.3 2” 915625-00 Actuator (TR1000)

Uses ETV Power

46.3

--- --- 2-½” 915626-00 69

ETV OPERATING CONCEPT

The ETV control modulates the electronic motorized mixing valve to maintain a temperature set point. It does that by mixing two

different water temperatures from two different sources; a hot water source and a cold-water source. The hot water source can be

a hot water boiler, a hot water coil in a steam boiler, or a hot water storage tank. On the other hand, the cold water comes from the

city water system. The cold-water inlet is joined with the circulating loop return pipe to help maintain ow in the valve during no

usage periods. The ETV operation requires the use of a circulating loop pump to maintain a circulating loop temperature.

DESIGN CONSIDERATIONS

CIRCULATING RETURN LOOP

The ETV is designed to operate in a system that has a Circulating Return Loop with a circulating pump. The Circulating Return

Loop temperature must be at least 7°F less than the ETV set point temperature. This temperature differential prevents the mixed

temperature from rising continuously. In addition, the temperature of the hot water entering the valve must be at least 20°F hotter

than the ETV set point temperature.

VERTICAL LOOP

The cold water feeding the hot water supply source MUST have a Thermal Heat Loop. This loop prevents the higher temperature

water in the hot water supply source from backing up and entering the cold-water inlet side of the mixing valve during low ow

periods. The Thermal Heat Loop can be installed either up or down, but must be a minimum of 32 inches as measured from pipe-

center to pipe-center.

Content

Overview. . . . . . . . . . . . . . . . . . . . . . . . . 2

ETV Packages. . . . . . . . . . . . . . . . . . . . . . 2

ETV Operating Concept . . . . . . . . . . . . . . . . 2

Design Considerations . . . . . . . . . . . . . . . . . 2

Valve Installation . . . . . . . . . . . . . . . . . . . . 3

Electronic Tempering Valve Piping . . . . . . . . . . 3

Actuator to Stainless-Steel Valve Assembly . . . . . 4

Wiring the Actuator . . . . . . . . . . . . . . . . . . . 5

Actuator Calibration . . . . . . . . . . . . . . . . . . 5

Dip Switches . . . . . . . . . . . . . . . . . . . . . . 5

Display Messages. . . . . . . . . . . . . . . . . . . . 6

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Troubleshooting . . . . . . . . . . . . . . . . . . . . 6

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . 7

Specifications . . . . . . . . . . . . . . . . . . . . . . 8

HT# 059292-00 F

Motorized Tempering Valve without Transformer Installation 3

ACTUATOR

SIGNAL

SYSTEM= 128oF

TARGET= 130oF

ETV

Control Module

BACK MENU/SET

▼▲

INPUTRATINGS: 120VAC 60HZ, 48VA

▼▲

32” Minimum

Vertical Drop

Thermal Heat

Loop

ETV

Control

ETV

Sensor

Tempered Water

Tempered Water

Circulating Return

Circ. Pump

(Contiuous Running)

Cold Water

Hot Water

HOT

WATER

Actuator

3-way

Valve

Isolation

Valve

ELECTRONIC TEMPERING

VALVE PIPING

VALVE INSTALLATION

1. Close the isolation valve feeding the hot port of the 3-way valve.

2. Pipe the valve. Make sure to follow the port letter designation or

the valve ow direction label.

3. Close the 3-way valve by manually pushing its stem down.

4. The valve and actuator can be mounted vertically or horizontally.

However, they must not be mounted upside down. Hot Port

B

Cold Port

A

Mixed Port

AB

ACTUATOR POWER SWITCH

• The (TR1000) actuator is equipped with a power switch to help in installation and

maintenance.

• The Power Switch must be turned off before assembling the valve and actuator.

• The Power Switch must be turned off prior to manually opening or closing the valve.

WARNING

Every time the actuator is powered on, it will go through a PARTIAL CALIBRATION.

Make sure to close the glove valve feeding the hot port prior to powering the actuator.

Power

Switch

HT# 059292-00 F

4Motorized Tempering Valve without Transformer Installation

ACTUATOR MANUAL OPERATION

2

Switch from

Auto to Manual

Push Handle Down

3

Get ready for

Manual Operation

Flip the Lever

4

Manually Adjust Valve

by Turning Lever

Turn Lever Clockwise

to Close

1

Switch Actuator

Power Off

Power Switch is located

under the Actuator base

5

Switch Actuator

Power On

When done, Turn Actuator

Power Back On

The actuator has a Red Manual Crank Handle to help open or close the valve during assembly or to override automatic operation.

1. Turn the Actuator Power Switch Off.

2. Lower the Red Manual Handle to start the Manual Mode.

3. Flip the lever of the Manual Crank Handle open to open or close the valve.

4. While pressing the handle down, turn the lever clockwise to bring the actuator stem down (Close the Valve). Turning the lever

counter-clockwise bring the actuator stem upwards (Open the Valve).

5. After nishing manual operation, turn the Actuator Power Switch back On.

ACTUATOR TO STAINLESS-STEEL VALVE ASSEMBLY

After installing the valve on the piping system, follow

these instruction to mount the actuator to the valve:

1. Close the isolation valve feeding the hot port of the

3-way valve.

2. Manually close the valve by pushing down on its stem.

3. Turn the actuator power Off using the Power Switch.

4. Manually move the actuator to the open position. See

“Actuator Manual Operation” on page 4.

5. Loosen the Actuator Stem Locking Bracket and remove

the Actuator Body Locking Bracket.

6. Mount the actuator to the valve.

7. Install the Actuator Body Locking Bracket making sure

to align the valve groove with the bracket protrusions.

Secure the bracket in place by tightening its two hex

screws.

8. Gradually, bring the actuator stem down until the valve

stem is aligned with Actuator Stem Locking Bracket.

Then, tighten the bracket’s two hex screws.

9. Turn the actuator Power Switch on. Then wait until the

valve nishes it partial calibration.

10. Calibrate the Actuator to the valve. See “Actuator

Calibration” on page 5.

11. Open the isolation valve feeding the hot port.

WARNING

After assembling the actuator to the valve and

wiring the actuator to the ETV, the actuator

MUST be fully calibrated. Failure to CALIBRATE

the actuator motor before operation may

damage the valve and actuator. Heat-Timer

warranty does not cover these damages

Manual Lever

Actuator

Cover

Calibration Button

Dip Switches

Power

Switch

Valve Flow

Direction Label

Stainless-Steel

3-Way Valve

Actuator Body

Locking Bracket

Actuator Stem

Locking Brackets

Valve

groove

Actuator

Bracket

HT# 059292-00 F

Motorized Tempering Valve without Transformer Installation 5

WIRING THE ACTUATOR

This actuator accepts a 0-10V modulation signal from the ETV control.

In addition, it requires 24 VAC power that is also supplied by the ETV

control.

ACTUATOR MODULATION SIGNAL WIRING

• Wire actuator terminal (E) to ETV terminal (15).

• Wire actuator terminal (O next to the E) to ETV terminal (16).

ACTUATOR POWER WIRING

• Wire actuator terminal (B) to ETV terminal (4).

• Wire actuator terminal (O next to the B) to ETV terminal (3).

• Failure to observe actuator power polarity may damage equipment.

WARNING

To avoid damage to the equipment, DO NOT replace or install

wires when power is connected to the actuator or the control.

▼▲

24VAC

4-20mA

Set Point

Shutdown Setback Sys

Temp

Aux

Temp Voltage 1 Voltage 2 4-20mA Auxiliary

~~+-+-+-+-

Output

34 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22

YEOOB

Actuator Accepts

0-10 Voltage Signal

0-10V Modualting

Voltage Signal

24 VAC

Actuator Power

ACTUATOR CALIBRATION

RED PUSH BUTTON

WARNING

After assembling the actuator to the valve and wiring the actuator

to the ETV, the actuator MUST be fully calibrated. Failure to

CALIBRATE the actuator before operation may damage the valve and

actuator. Heat-Timer warranty does not cover these damages

Each time the actuator is assembled to the valve, the actuator must be calibrated using the

following steps:

1. Close the isolation valve feeding the tempering valve hot port.

2. Make sure that the actuator Power Switch is set to On.

3. Power the actuator. See ETV installation manual.

4. Start the calibration by holding down the Calibration Button for over 3 seconds. The

actuator will fully open and then fully close the valve. During this process, both LEDs

will blink at the same time.

5. When the actuator returns to its normal operating position, the calibration has ended.

6. Open the isolation valve feeding the tempering valve hot port.

Calibration Button

DIP SWITCHES

The actuator dip switches are preset in the factory. However, it is important to have the

factory settings when troubleshooting.

•. All dip switches are set to Off except for Dip Switch 6 and 8 that are set to ON.

Dip Switches

HT# 059292-00 F

6Motorized Tempering Valve without Transformer Installation

DISPLAY MESSAGES

• This actuator has a 4 letter alphanumeric display.

• Under normal operation, the left most letter will be followed by a number. The

character can be either a “C” or an “F”.

• The letter “C” represents the current input signal. Example: C 97.

• The letter “F” represents the current valve position . Example: F 98.

• The actuator will alternate the display of both C and E values.

• When “ERR “ is displayed, it indicates an error in the actuator positioning. In this

case, the actuator needs to be re-calibrated.

LEDS

• The LEDs indicate the actuator movement direction.

• When the actuator is being calibrated, both LEDS will blink at the same time until

the process ends.

• The White LED is lit when the actuator opens the valve.

• The Red LED is lit when the actuator closes the valve.

LEDs

TROUBLESHOOTING

Valve calibrates but does not move afterwards

• Check the modulation signal wiring to the actuator (terminals O and E). If the modulation signal wiring is not connected or is

wired incorrectly, the valve will not move after calibration. See “Wiring the Actuator” on page 5.

• Check the modulation signal value. It may be that the modulation signal matches the valve location after calibration. See

“Display Messages” on page 6.

• Check the AC voltage going to the actuator. The actuator is designed to work between 19 and 26 VAC. If the voltage above or

below this range the valve may stop responding to the modulation signal.

Valve does not move

• Make sure that there is power going to the actuator (terminals B and O). The actuator power is polarity sensitive.

• The valve may be jammed with debris. This can be tested by removing the actuator and testing the valve movement manually by

pushing and pulling on the valve stem.

• If the previous tests proved no problems, then the actuator may need to be replaced.

Actuator Display Reads ‘ERR’

• Re-calibrate the actuator to the valve. See “Actuator Calibration” on page 5. If the problem persists, contact the factory.

HT# 059292-00 F

Motorized Tempering Valve without Transformer Installation 7

WARRANTY

WARRANTIES AND LIMITATIONS OF LIABILITY AND DAMAGE: Heat-Timer Corporation warrants that it will replace,

or at its option, repair any Heat-Timer Corporation manufactured product or part thereof which is found to be defective in

material workmanship within one year from the date of installation only if the warranty registration has been properly lled out

and returned within 30 days of the date of installation. Damages to the product or part thereof due to misuse, abuse, improper

installation by others or caused by power failure, power surges, re, ood or lightning are not covered by this warranty. Any

service, repairs, modications or alterations to the product not expressly authorized by Heat-Timer Corporation will invalidate

the warranty. Batteries are not included in this warranty. This warranty applies only to the original user and is not assignable or

transferable. Heat-Timer Corporation shall not be responsible for any maladjustments of any control installed by Heat-Timer

Corporation. It is the users responsibility to adjust the settings of the control to provide the proper amount of heat or cooling

required in the premises and for proper operation of the heating or cooling system. Heat-Timer Corporation shall not be required

to make any changes to any building systems, including but not limited to the heating system, boilers or electrical power system,

that is required for proper operation of any controls or other equipment installed by Heat-Timer Corporation or any contractor.

Third Party products and services are not covered by this Heat-Timer Corporation warranty and Heat-Timer Corporation makes

no representations or warranties on behalf of such third parties. Any warranty on such products or services is from the supplier,

manufacturer, or licensor of the product or service. See separate Terms and Conditions of Internet Control Management System

(“ICMS”) services, including warranties and limitations of liability and damages, for ICMS services.

THE FOREGOING IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED AND HEAT-TIMER

CORPORATION SPECIFICALLY DISCLAIMS ANY AND ALL WARRANTIES OF MERCHANTABILITY FOR A

PARTICULAR PURPOSE. UNDER NO CIRCUMSTANCES SHALL HEAT-TIMER CORPORATION, ITS AUTHORIZED

REPRESENTATIVES, AFFILIATED OR SUBSIDIARY COMPANIES BE LIABLE FOR SPECIAL, CONSEQUENTIAL

OR INCIDENTAL DAMAGES, EXCEPT AS SPECIFICALLY STATED IN THESE TERMS AND CONDITIONS OF

SALE. THE SOLE REMEDY WITH RESPECT TO ANY PRODUCT OR PART SOLD OR INSTALLED BY HEAT-TIMER

CORPORATION SHALL BE LIMITED TO THE RIGHT TO REPLACEMENT OR REPAIR F.O.B. FAIRFIELD, NJ.

HEAT-TIMER CORPORATION SHALL NOT BE LIABLE OR RESPONSIBLE FOR LOSS OR DAMAGE OF ANY KIND

RESULTING FROM DELAY OR INABILITY TO DELIVER FOR ANY REASON, INCLUDING BUT NOT LIMITED TO

FIRE, FLOOD, LIGHTNING, POWER FAILURE OR SURGES, UNAVAILABILITY OF PARTS, STRIKES OR LABOR

DISPUTES, ACCIDENTS AND ACTS OF CIVIL OR MILITARY AUTHORITIES.

03122010

HT# 059292-00 F

8Motorized Tempering Valve without Transformer Installation

20 New Dutch Lane, Faireld, NJ 07004

Ph: (973) 575-4004 • Fax: (973) 575-4052

http://www.heat-timer.com

SPECIFICATIONS

TR1000 ACTUATOR

Voltage Input: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 to 26 VAC 60 Hz

Power Consumption: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 VA Max

Operating Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . from 14°F/-10°C to 122°F/50°C

Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .225 Lbf/1000N

Valve Input Signal: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-10V

Manual Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Manual Crank Handle

Clearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Minimum of 4- 6” above the actuator for manual operation

Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Die-Cast Aluminum

Dimensions: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 ⅛”W x 12 ¾”H x 7 ½L”

Weight: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 pound

STAINLESS-STEEL VALVE

Valve Type: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-way Mixing

Valve Sizes: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2” and 2½”

Body and Trim Material: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304 Stainless Steel

Stem Material: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304 Stainless Steel

Maximum Temperature: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180°F/82°C

Maximum Pressure: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225 psi

Port Connection: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . NPT Threaded

Valve Ports: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A (Cold inlet), B (Hot inlet), AB (Mixed outlet)

Table of contents

Other heat-timer Controllers manuals