heat-timer HTC User manual

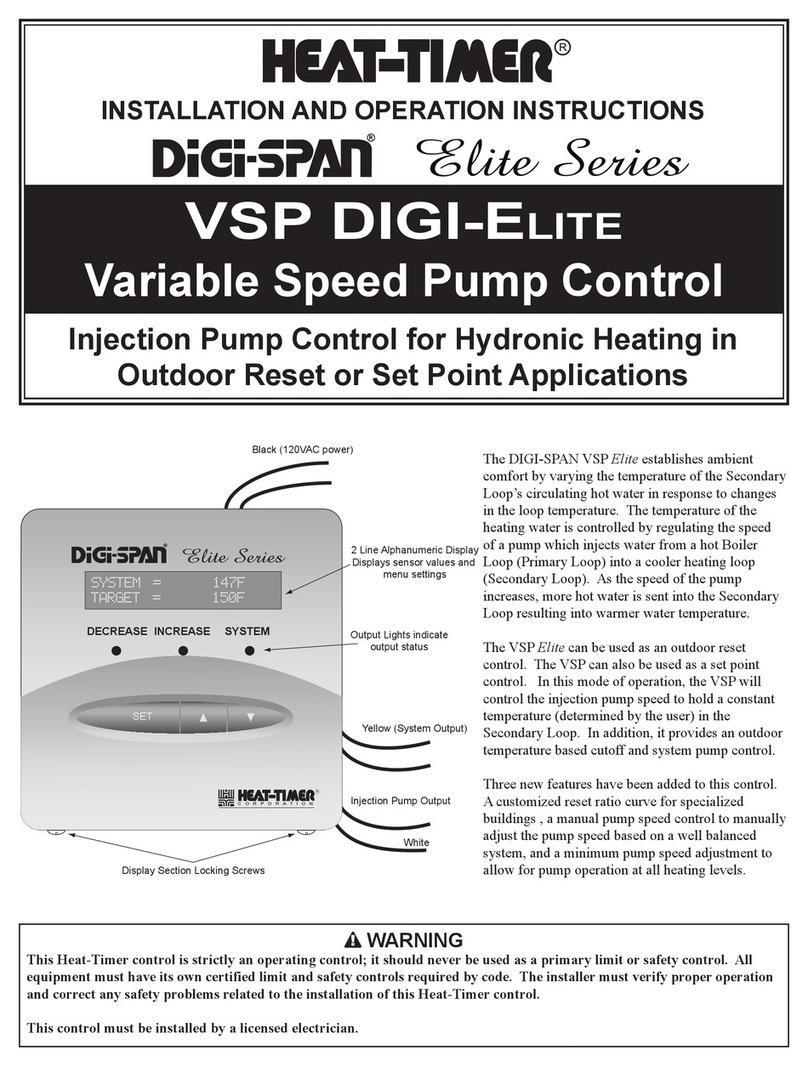

WARNING

This Heat-Timer Motorized Tempering Valve is strictly an operating

valve. It should never be used as a “Fail Safe“ or “Anti-Scald“ valve.

A separate Anti-Scald device can be installed in conjunction with

this motorized tempering valve. All equipment must have their

own certified limit and safety controls required by local codes.

TABLE OF CONTENTS

01

OVERVIEW 4

HTC ACTUATOR ONLY FOR REPLACEMENT 4

ETV STAINLESS VALVE AND ACTUATOR KITS 4

IP 65 RATED HTC ACTUATOR 4

ETV VALVE AND HTC ACTUATOR DIMENSIONAL 5

SPECIFICATIONS 5

02

INSTALLATION GUIDELINES 6

MANUAL OVERRIDE OPERATION 7

WIRE TERMINAL ACCESS 7

03

APPLICATIONS 8

ETV VALVE AND ACTUATOR INSTALLATIONS— 8

DUAL VALVE APPLICATIONS

REPLACEMENT OF THE ETV PLUS M800 ACTUATOR 8

REPLACEMENT OF THE ETV PLUS TR1000 ACTUATOR 10

REPLACEMENT OF AN EXISTING HTC ACTUATOR 12

INSTALLATION ON BRONZE VALVE BODY 14

INSTALLATION ON STAINLESS STEEL VALVE BODY 15

04

WIRING 16

GENERAL WIRING 16

24V FLOATING 17

ETV WIRING 17

ETV PLUS WIRING 18

ETV PLATINUM PLUS WIRING 18

MODULATION CURRENT VOLTAGE 19

MODULATION 4–20mA 19

05

CONFIGURATION AND SETTINGS 20

DIP SWITCHES AND CAPACITOR JUMPER 20

VALVE INSTALLATION— 21

ALTERNATE CONFIGURATION

DIP SWITCH SETTING—OPTIONAL SETTINGS 21

LED STATUS 23

CALIBRATION 23

STARTUP 24

IP 65 INSULATION KIT 24

06

NOTES 25

4|HEAT-TIMER CORP. 059297-00 REV. H

01 OVERVIEW

The HTC (Blue Oval) Actuator is available in 2 main configurations—the standard configuration and the configuration

with the Loss of Power (LOP) Capacitor. The HTC is also available with IP 65 rating that allows outdoor installation

of the valve and actuator, but not the Heat Timer controller. The HTC actuator with IP 65 is only available with

the LOP Capacitor. Finally, the HTC actuator can accept either a current voltage input signal or a floating (OPEN/

CLOSE) signal.

The HTC Actuator is a direct replacement of the earlier actuators, M800 and TR1000 models, found on ETV Plus—

electronic tempering valves installations. The HTC Actuator is also found in the valve and actuator only kits used in

dual valve applications for the current ETV Platinum Plus applications. The following is a listing of part numbers on

the HTC Actuator can be ordered:

HTC ACTUATOR ONLY FOR REPLACEMENT

HTC Actuator Standard (without LOP Capacitor) P/N 905040-00

HTC Actuator with LOP Capacitor P/N 905048-00

HTC Actuator with IP 65 Rating P/N 905048-65

ETV STAINLESS VALVE AND ACTUATOR KITS

STAINLESS STEAL VALVE

AND ACTUATOR CV PART NUMBER

½” 5 915640-00

¾” 7 915641-00

1” 12 915642-00

1 ¼” 18 915643-00

1 ½” 29 915644-00

2” 46 915645-00

2 ½” 73 915646-00

IP 65 RATED HTC ACTUATOR

When ordering an ETV Platinum PLUS complete assembly or an ETV

Valve and Actuator kit (as describe above) or the HTC actuator as a

replacement only, the following part number extension is required: -65.

Example: If you have an application requiring a 2 inch ETV Platinum

PLUS complete assembly (P/N 915675-00) that is to have the valve and

actuator installed outdoors, then you would order the following:

P/N 915675-65.

NOTE

The kits include ETV stainless

steel valve body, the HTC

actuator and a 24V transformer.

NOTE

An IP 65 rate actuator will allow

the valve and actuator to be

mounted outdoors, The Heat-

Timer controller is NOT approved

for outdoor installations.

059297-00 REV. H HEAT-TIMER CORP. |5

MIXED

D

MAINTAIN 18 INCHES

MINIMUM FOR

SERVICING CLEARANCE

MAINTAIN 12 INCHES

MINIMUM FOR

SERVICING CLEARANCE

MAINTAIN 12 INCHES

MINIMUM FOR

SERVICING CLEARANCE

MAINTAIN 12 INCHES

MINIMUM FOR

SERVICING CLEARANCE

MAINTAIN 12 INCHES

MINIMUM FOR

SERVICING CLEARANCE

HOT

COLD

ETV VALVE AND HTC ACTUATOR DIMENSIONAL

01 OVERVIEW

SPECIFICATIONS

Voltage Input 24Vac 60Hz

Power Consumption 18VA max

Capacitor Charging Phase Consumption 32VA/8W

Input Signal Proportional 0–10V (default), 0–5V, 5–10V, 2–10V, 4–20mA

Input Signal 24Vac Floating

Force 1000 N

Weight 2.6 lbs (1.2kg)

ETV

ASSEMBLY

DIMENSION

A B C D

½” 3 ¹/8” 2” 10 ½” 2 ³/8”

¾” 3 ¹/8” 2” 10 5/8”2 ³/8”

1” 4” 2 ¹/8” 10 ³/4”2 ³/8”

1 ¼” 4” 2 ½” 11” 2 ³/8”

1 ½” 4 ³/4”2 ³/4” 11 3/16”2 ³/8”

2” 5 ½” 3 ³/8” 11 ³/8”2 ³/8”

2 ½” 6 5/16” 4” 11 ³/4”2 ³/8”

B

C

A

7 ¾”

4 ¾”

6|HEAT-TIMER CORP. 059297-00 REV. H

02 INSTALLATION GUIDELINES

FIGURE 1

ALLOWABLE MOUNTING POSITION FOR THE HTC ACTUATOR STANDARD AND HTC ACTUATOR WITH

LOP CAPACITOR

FIGURE 2

HTC ACTUATOR WITH IP 65 RATING MOUNTING POSITION

NOTE

The HTC Actuator with IP 65

Rating can only be mounted

in the vertical position to

avoid potential penetration of

water into the motor circuit.

NO

OK OK

NO

059297-00 REV. H HEAT-TIMER CORP. |7

MANUAL OVERRIDE OPERATION

1 The HTC Actuator can be manually position by lowering the Manual tab (1) down.

2 Once the Manual tab is lowered (2), rotate the tab to lower or raise the actuator.

3 Prior to mounting the HTC Actuator, the actuator must be in its lowest position.

4 To return the HTC Actuator back to automatic operation simply return the Manual tab to its upward position.

WIRE TERMINAL ACCESS

To gain access to the HTC Actuator wire terminals, dip switches and on those actuators with a LOP Capacitor the

Capacitor Jumper, the cover must be remove.

1 To remove the actuator cover remove the mounting screw (1) using a Phillips screwdriver.

2 Lift the actuator cover and slide toward the mounting screw direction disengaging the actuator cover clip

from the actuator housing.

3 To mount the cover once the wiring, calibration of the actuator, any dip switch and Capacitor Jumper settings

are completed, slide the actuator cover tab into the actuator. Ensure the actuator cover is seated on the

actuator housing and secure with the mounting screw.

02 INSTALLATION GUIDELINES

1

1 2

8|HEAT-TIMER CORP. 059297-00 REV. H

1 Disconnect power to the ETV module through a service switch or circuit breaker.

2 Remove the actuator cover to access the wire terminals by unsnapping the front of the black cover and lifting

toward the rear of the actuator.

3 Prior to removing the wires from the terminals, it is a best practice to label the wiring to ensure proper wiring to

the HTC Actuator.

•Label Terminal G wire as 24V

•Label Terminal GO wire as 24V

•Label Terminal MX wire as V(-)

•Label Terminal X1 wire as V(+)

4 Remove the wiring from the bottom of the actuator. If needed remove any electrical NM connector or conduit

attached to the actuator housing.

5 Pull down the Manual Tab on the actuator and manually lower the actuator and valve stem to the lowest position.

6 Loosen and remove the (2) locking nuts from the U-bolt. Then remove the U-bolt from the actuator and valve body.

7 On the bronze valve body it may be require to loosen the jam nut from the U channel on the actuator. See

Figure 3A page 9.

ETV VALVE AND ACTUATOR INSTALLATIONS—DUAL VALVE APPLICATIONS

In applications where the ETV valve and actuator kit is applied in a dual application with an ETV Platinum Plus

complete assembly, reference the ETV Platinum Plus installation manual for guidelines on installing the valve and

the wiring of the actuator and 24V transformer.

REPLACEMENT OF THE ETV PLUS M800 ACTUATOR

03 APPLICATIONS

WARNING

ELECTRICAL SHOCK HAZARD! Disconnect electrical power to the device before servicing or making any

electrical connections. Failure to do so may result in severe personal injury or death.

Follow all local and state electrical codes when installing the unit. All wiring must meet or exceed local,

state, federal codes and requirements.

WARNING

SCALD HAZARD! To avoid any potential of a scald hazard it is recommended to isolate the valve from the

system by closing at a minimum the isolation valve on the HOT supply to the valve.

059297-00 REV. H HEAT-TIMER CORP. |9

8 Slide the actuator off the valve, removing the U channel of the actuator from the valve stem.

9 To assemble the new HTC Actuator reference the following pages:

•For bronze valve body reference page 14.

•For stainless steel valve body reference page 15.

10 For wiring of the new HTC actuator reference page 16.

11 For Dip Switch and Capacitor Jumper (if applicable) settings based on valve configuration reference page 20.

12 For installation completion and calibration of the HTC actuator reference page 23. To remove the actuator

cover remove the mounting screw (1) using a Phillips screwdriver as shown on page 7.

13 Lift the actuator cover and slide toward the mounting screw direction disengaging the actuator cover clip from

the actuator housing.

14 To mount the cover once the wiring, calibration of the actuator, any dip switch and Capacitor Jumper settings

are completed, slide the actuator cover tab into the actuator. Ensure the actuator cover is seated on the

actuator housing and secure with the mounting screw.

03 APPLICATIONS

FIGURE 3A

ASSEMBLY OF THE M800 ACTUATOR TO A

BRONZE BODY VALVE

FIGURE 3B

ASSEMBLY OF THE M800 ACTUATOR TO A

STAINLESS STEEL BODY VALVE

LOCKING

NUTS

U-BOLT

LOCKING

NUTS

BRONZE

VALVE

U-BOLT

U-BOLT

JAM NUT

LOCKING CLIP

SQUARE NUT

MANUAL TAB

MANUAL TAB

U-CHANNEL

U-CHANNEL

10 |HEAT-TIMER CORP. 059297-00 REV. H

1 Disconnect power to the ETV module through a service switch or circuit breaker.

NOTE: Although the TR1000 actuator contains a service switch it is not recommended for this type of

servicing to use it as power will still be present on the wiring from the ETV module and a shock hazard

is still present.

2 Remove the actuator cover to access the wire terminals by removing the (2) mounting screws on the front

red cover.

3 Prior to removing the wires from the terminals, it is a best practice to label the wiring to ensure proper wiring to

the HTC Actuator.

•Label Terminal B wire as 24V.

•Label Terminal O (right of Terminal B) wire as 24V.

•Label Terminal O (left of Terminal E) wire as V(-).

•Label Terminal E wire as V(+).

4 Remove the wiring from the bottom of the actuator. If needed remove any electrical NM connector or conduit

attached to the actuator housing.

5 Push the Red Manual Crank Handle down and lift the lever. With the Crank Handle pushed down, rotate the

handle counterclockwise to lower the actuator and valve stem down to its full position.

6 Loosen and remove the (2) screws from the Actuator Stem Locking Bracket and remove the bracket from the

valve stem.

7 Loosen and remove the (2) screws from the Actuator Valve Locking Bracket and remove the bracket from the

valve body.

REPLACEMENT OF THE ETV PLUS TR1000 ACTUATOR

03 APPLICATIONS

WARNING

ELECTRICAL SHOCK HAZARD! Disconnect electrical power to the device before servicing or making any

electrical connections. Failure to do so may result in severe personal injury or death.

Follow all local and state electrical codes when installing the unit. All wiring must meet or exceed local,

state, federal codes and requirements.

WARNING

SCALD HAZARD! To avoid any potential of a scald hazard it is recommended to isolate the valve from the

system by closing at a minimum the isolation valve on the HOT supply to the valve.

059297-00 REV. H HEAT-TIMER CORP. |11

8 Slide the actuator bracket out the valve groove.

9 To assemble the new HTC Actuator reference the following pages:

•For bronze valve body reference page 14.

•For stainless steel valve body reference page 15.

10 For wiring of the new HTC actuator reference page 16.

11 For Dip Switch and Capacitor Jumper (if applicable) settings based on valve configuration reference page 20.

12 For installation completion and calibration of the HTC actuator reference page 23.

FIGURE 4

ASSEMBLY OF THE TR1000 ACTUATOR TO A STAINLESS STEEL BODY VALVE

03 APPLICATIONS

ACTUATOR COVER

MANUAL LEVER

ACTUATOR BRACKET

POWER SWITCH

ACTUATOR STEM

LOCKING BRACKET

ACTUATOR LOCKING BRACKET

12 |HEAT-TIMER CORP. 059297-00 REV. H

1 Disconnect power to the ETV module through a service switch or circuit breaker.

2 Remove the actuator cover to access the wire terminals by removing the mounting screw on the top cover.

See page 7.

3 Prior to removing the wires from the terminals, it is a best practice to label the wiring to ensure proper wiring

to the HTC Actuator.

•Label Terminal LN wire as 24V.

•Label Terminal L1 wire as 24V.

•Label Terminal M wire as V(-).

•Label Terminal Y wire as V(+).

4 Remove the wiring from the bottom of the actuator. If needed remove any electrical NM connector or conduit

attached to the actuator housing.

5 Pull down the manual tab on the actuator and manually lower the actuator and valve stem to the lowest

position. See figure 5 page 13.

6 Loosen and remove the (2) locking nuts from the U-bolt. Then remove the U-bolt from the actuator and

valve body.

7 Slide the actuator off the valve, removing the U channel of the actuator from the valve stem.

REPLACEMENT OF AN EXISTING HTC ACTUATOR

WARNING

ELECTRICAL SHOCK HAZARD! Disconnect electrical power to the device before servicing or making any

electrical connections. Failure to do so may result in severe personal injury or death.

Follow all local and state electrical codes when installing the unit. All wiring must meet or exceed local,

state, federal codes and requirements.

WARNING

SCALD HAZARD! To avoid any potential of a scald hazard it is recommended to isolate the valve from the

system by closing at a minimum the isolation valve on the HOT supply to the valve.

03 APPLICATIONS

059297-00 REV. H HEAT-TIMER CORP. |13

8 To assemble the new HTC Actuator reference the following pages:

•For bronze valve body reference page 14.

•For stainless steel valve body reference page 15.

9 For wiring of the new HTC actuator reference page 16.

10 For Dip Switch and Capacitor Jumper (if applicable) settings based on valve configuration reference page 20.

11 For installation completion and calibration of the HTC actuator reference page 23.

FIGURE 5

ASSEMBLY OF THE HTC ACTUATOR TO A STAINLESS STEEL BODY VALVE

03 APPLICATIONS

U-CHANNEL

HTC ACTUATOR

LOCKING NUTS VALVE STEM GROOVE

U-BOLT

STAINLESS VALVE BODY

14 |HEAT-TIMER CORP. 059297-00 REV. H

INSTALLATION ON BRONZE VALVE BODY

1 Ensure the HTC Actuator is at the lowest position by manual positioning it. See page 7.

2 Ensure the valve stem is at its lowest position by pressing down on the stem.

3 Ensure the valve stem contains both a Jam Nut and a Square Nut. It may be require to loosen the Jam Nut

further down the valve stem as shown in figure 6.

4 Mount the HTC Actuator onto the valve body making sure the Square Nut is in the U-channel of the actuator.

5 Insert the U-bolt aligning the valve body groove with the actuator. If needed adjust the position of the

actuator manually.

6 Secure the U-bolt in place with two locking nuts, ensuring the locking nuts are tightened evenly.

NOTE: The actuator may make a grinding noise if the locking nuts are not tightened evenly and

resulting in potential damage to the actuator motor.

7 Tighten the Jam Nut against the bottom of the U channel on the actuator.

8 For wiring of the new HTC actuator in replacement of a M800 or a TR1000 actuator reference page 16.

9 For Dip Switch and Capacitor Jumper (if applicable) settings based on valve configuration reference page 20.

10 For installation completion and calibration of the HTC actuator reference page 23.

03 APPLICATIONS

LOCKING

NUTS

BRONZE

VALVE

U-BOLT

JAM NUT

SQUARE NUT

HTC ACTUATOR

U-CHANNEL

FIGURE 6

ASSEMBLY OF THE HTC ACTUATOR

TO A BRONZE BODY VALVE

059297-00 REV. H HEAT-TIMER CORP. |15

INSTALLATION ON STAINLESS STEEL VALVE BODY

1 Ensure the HTC Actuator is at the lowest position by manual positioning it. See page 7.

2 Ensure the valve stem is at its lowest position by pressing down on the stem.

3 Mount the HTC Actuator onto the valve body making sure the U-channel of the actuator aligns with the valve

stem groove.

4 Insert the U-bolt aligning the valve body groove with the actuator. If needed adjust the position of the

actuator manually.

5 Secure the U-bolt in place with two locking nuts, ensuring the locking nuts are tightened evenly.

NOTE: The actuator may make a grinding noise if the locking nuts are not tightened evenly and

resulting in potential damage to the actuator motor.

6 For wiring of the new HTC actuator in replacement of a M800 or a TR1000 actuator reference page 16.

7 For Dip Switch and Capacitor Jumper (if applicable) settings based on valve configuration reference page 20.

8 For installation completion and calibration of the HTC actuator reference page 23.

03 APPLICATIONS

STAINLESS

VALVE BODY

U-BOLT

VALVE STEM

GROOVE

HTC ACTUATOR

U-CHANNEL

FIGURE 7

ASSEMBLY OF THE HTC ACTUATOR

TO A STAINLESS STEEL BODY VALVE

LOCKING

NUTS

16 |HEAT-TIMER CORP. 059297-00 REV. H

1 Disconnect power to the ETV module or control through a service switch or circuit breaker.

2 Route all wiring through the bottom of the actuator. Use the proper NM connector to secure the wiring and

avoid potential damage to the wiring.

NOTE: On HTC Actuator with IP 65 rating the actuator is provided with a Liquid Tight Conduit

Connector fitting, see figure 8. Liquid Tight conduit is required for any outdoor installations. Check

local, state electrical codes for compliance.

3 Terminal designations for current voltage proportional modulation input see ETV and Modulation wiring on

pages17–19.

4 Terminal designations for floating signal input see page 17.

5 Once all wiring is complete return power to the ETV module or control, placing the actuator into service.

6 If the actuator contains a LOP Capacitor it will require about 2 minutes of power being supplied to fully charge.

GENERAL WIRING

04 WIRING

WARNING

ELECTRICAL SHOCK HAZARD! Disconnect electrical power to the device before servicing or making any

electrical connections. Failure to do so may result in severe personal injury or death.

Follow all local and state electrical codes when installing the unit. All wiring must meet or exceed local,

state, federal codes and requirements.

LIQUID TIGHT CONDUIT

CONNECTOR FITTING

FIGURE 8

HTC ACTUATOR—IP 65 VERSION

WITH LIQUID TIGHT FITTING

059297-00 REV. H HEAT-TIMER CORP. |17

24V FLOATING

ETV WIRING

04 WIRING

NOTE

On existing wiring with a M800 actuator an external 24V transformer provided power to the actuator. This

transformer can be eliminated with the HTC actuator and 24V power can be supplied through the ETV panel.

HTC ACTUATOR

24V

TRANSFORMER

120V

POWER

SUPPLY

V+ MU Y1 LnY Y2 L1

OPEN

CLOSE

COMMON

VALVE CONTROLLER

N

L

V+ MU Y1 LnY Y2 L1

0–10 VOLTAGE

MODULATING SIGNAL

REFERENCE 24V FLOATING DIP SWITCH

SETTING, ON FIGURE 12, PAGE 21

24 VAC

ACTUATOR POWER

059297-00 REV. H HEAT-TIMER CORP. |19

MODULATION CURRENT VOLTAGE

MODULATION 4–20mA

04 WIRING

HTC ACTUATOR

HTC ACTUATOR

24V

TRANSFORMER

24V

TRANSFORMER

120V

POWER

SUPPLY

120V

POWER

SUPPLY

V+ MU Y1 LnY Y2 L1

V+ MU Y1 LnY Y2 L1

GND

+ VLT

+ mA

VALVE CONTROLLER

GND

+ VLT

+ mA

VALVE CONTROLLER

N

N

L

L

REFERENCE MODULATION 4–20MA DIP

SWITCH SETTING, ON FIGURE 13, PAGE 22

REFERENCE MODULATION CURRENT

VOLTAGE DIP SWITCH SETTINGS,

FIGURE 14–16, PAGE 22

20 |HEAT-TIMER CORP. 059297-00 REV. H

DIP SWITCHES AND CAPACITOR JUMPER

05 CONFIGURATION AND SETTINGS

FIGURE 9

LOCATION OF THE DIP SWITCHES AND

CAPACITOR JUMPER (IF APPLICABLE)

When the ETV valve is installed as shown in the Factory Default Configuration, the following applies:

1 Dip Switch 1 must be in the ON position as shown.

2 The Capacitor Jumper (if applicable) must remain as installed by the factory. On loss of power the actuator

will push the valve stem downward to the full COLD position.

FIGURE 10

VALVE INSTALLATION AND DIP SWITCH SETTING—FACTORY DEFAULT

CAPACITOR JUMPER

ACTUATOR DIP SWITCHES

OFF

HOT BHOT A

SEQ

5–10, 6–100–5, 2–6

INCMOD

2–100–10

4–20mA

MANAUTO

ON

1234567

COLD PORT

A

MIXED PORT

AB

HOT PORT

B

Table of contents

Other heat-timer Controllers manuals