Heathus OMD User manual

1

OMD™ USER’SOMD™ USER’S

OMD™ USER’SOMD™ USER’S

OMD™ USER’S

Manual

Heath Consultants Incorporated

Houston, TX

713/844-1300

Fax: 713/844-1309

1-800-HEATH-US

www.heathus.com Heath....Leadership, Innovation, Performance

Then, Now and Tomorrow

RevD

2

3

TABLE OF CONTENTS

SPECIFICATIONS ............................................................................5

CHAPTER I

OVERVIEW ......................................................................................7

CHAPTER II

INSTALLATIONPROCEDURE ...................................................... 10

Crossbar Installation ......................................................................10

Additional Notes On Crossbar Installation..................................... 11

Power Box Installation ................................................................... 12

Cable Assemblies Installation ........................................................13

Display Installation .........................................................................14

Display Connectors ........................................................................15

Vehicle Grounding Strap ................................................................15

Protective Cage..............................................................................16

CHAPTER III

OPERATING PROCEDURE ...........................................................18

Start Up..........................................................................................18

Display Function.............................................................................20

HOLD ........................................................................................20

LIGHT........................................................................................21

SAMPLE....................................................................................22

PPM Range....................................................................................23

Alarm Set Point ..............................................................................25

Error Messages..............................................................................26

Shut Down......................................................................................27

CHAPTER IV

ALIGNMENT PROCEDURE...........................................................28

Lamp Alignment .............................................................................29

Receiver Alignment ........................................................................30

CHAPTER V

CALIBRATIONCHECK .................................................................31

Verifying Calibration With Internal Cell ..........................................31

Verifying Calibration With External Cell .........................................32

4

CHAPTER VI

MAINTENANCEINFORMATION...................................................34

General .........................................................................................34

Recommended Spare Parts..........................................................34

Troubleshooting.............................................................................34

CHAPTER VII

SERVICEINFORMATION .............................................................37

Warranty and Warranty Repairs ....................................................37

Customer Assistance and Service Locations ................................38

Appendix A

SURVEY PROCEDURES - MOBILE OMD™ ................................40

Appendix B

DRAWINGS...................................................................................55

USINGADOBE ACROBAT READER ............................................60

5

SYSTEM SPECIFICATIONS

OMDTM System Specifications

Configuration: Double - ended

Sensitivity: 1 PPM / meter CH4

Measurement Range: 1 to 200 PPM

Accuracy: ± 10% (1 to 100 PPM range)

± 20% (100 to 200 PPM range)

Above 200 PPM = Not relatively

accurate

Display Ranges: 10, 30 and 90 PPM

Self - test: During boot – up

Calibration/Test: Via operator, self - contained

Calibration: Via RS-232 through software

Base - Line Compensation: Via RS-232 through software

Display: Back-lit 2" x 6" graphics LCD,

adjustable contrast

Operator Interface: Sealed membrane switch overlay

Operator Alarms:

Signal: High pitch audible with

adjustable set point, pitch

increases with concentration.

Adjustable volume.

Error: Low pitch audible with

adjustable set point

Error alarms

provided for: Warm-up,LowLight,

CommunicationFailure&

Batterylow

SystemPower: 72 Watts @ 12 VDC

System Voltage: 12 - 16 VDC

NOTE: To avoid damage to the OMD™power box, the fuse

must be removed prior to charging or jumping the battery

in the survey vehicle!

6

SYSTEM SPECIFICATIONS

SystemWeight:

External Sub - Systems: 17 pounds

Power Box 6 pounds

Internal Display 3 pounds

Cables 4 pounds

CrossbarAssemblyLength: 63.25, 32, 51.25in. ±2in.

MechanicalMounting: Strutbracketmount

Installation Time: 2 hours, typical

External Housing Rating: NEMA 3S and IP 54

Display Housing Rating: Spill proof

External Sub -

System Materials: Aluminum and plastic

Environmental PCB Control: Conformal PCB coating

Operating Temperature

Range: - 22°F to 122°F

Operating Humidity Range: 5 to 100 % RH, non-condensing

7

Chapter I

OVERVIEW

The Optical Methane Detector (OMD™), is the first of the

“next generation” leak detection systems which address the

high cost presently associated with leak surveying. This new

technology combines sensitivity, selectivity and speed through

the combined use of optics and electronics. The OMD is

mounted on the front of a survey vehicle and detects the pres-

ence of methane in air. It provides for the detection of gas

leaks down to 1 part per million (PPM). It has no moving parts

that will prevent the instrument from operating. It requires no

support gases and is virtually maintenance free.

Based on the absorption of infrared (IR) radiation by methane,

the OMD consists of an IR light source directed at an IR

optical detector. These two are spaced approx. four feet apart

across the width of the vehicle. An optical filter in front of the

detector transmits primarily methane specific IR wavelengths

from the light source. In the absence of methane, these wave-

lengths are unaffected and produce a steady output signal from

the detector. When the vehicle passes through a plume of

natural gas, methane in the plume will absorb some of the IR

light reaching the detector. As a result there is a sudden de-

crease in IR light at the detector causing a decrease in detector

output. This change in detector output is transmitted to the

display panel located next to the vehicle’s driver and becomes

a signal, both audio and visual. Gas concentration is calculated

in the OMD by converting the methane to light ratio to PPM.

The data is displayed in both analog and digital form. The

analog display appears as a peak scrolling across the display

screen. The OMD will also detect other hydrocarbons such as

ethane and propane but with less than half the sensitivity.

8

TheOMDoperatesreliablyunderavarietyof environmental

conditions including dry weather, snow, ice and temperatures

from-22° F to+122° F. Itssensitivity,calibration or response|is

notaffectedbysmall fluctuations in thelightbeamorbyreasonable

amountsofdust,or snow ontheoptics. Aninternalcalibrationtest

cellisincludedso the operatorcanverifyproperoperationfrom the

vehiclecabat any timebefore,duringor after aleaksurvey. An

InstallationMountingKitisavailableformountingtheOMDtothe

frontofavehicle. Allinterconnectingcablingisprovidedwith the

OMDincludingthecableto obtain powerto operatetheinstrument

fromthesurveyvehicle 12 voltbattery. AnRS232 port isincluded

wherebya personal computermaybe connected toacquire and

save the survey data with the appropriate software.

Depending on local meteorological conditions, a given amount

of gas escaping from the ground will produce a plume that

varies in size and uniformity of concentration levels. The

plume, of its very nature, defies quantification by fixed or

moving detectors. Regardless of these uncertainties, it is of

paramount importance to be able to detect gas when gas is

present. Concentration levels of the measured gas are of

interest, but are of secondary importance. Consequently, the

ability of a detector to detect the plume with accuracy and

precision is not as important as its ability to do so with good

sensitivity (or a low detection limit) and with a minimum of

false alarms.

There are two kinds of false alarms: false negatives and false

positives. False negatives occur when a leak is missed. The

detector is saying there is no gas present when, in fact, a leak

was present but undetected. False positives occur when the

detector says that a gas leak is present when it really is not.

Examplesoffalsepositives experienced includethedetectionof

OVERVIEW

9

autoexhaust and swamporsewer gas. Due totheselectivity of the

OMD,falsepositivescausedbyauto exhaust are greately mini-

mized.

NEW

Experienced operators should use their discretion. Operators

should take into account that the wind must be favorable,

towards the path of the OMD light bar, to obtain the optimum

results. Increased speed from FID survey comes from the

instantaneous response of the OMD; however, there are a

variety of factors to consider such as, legal limits, terrain and

inclement weather for the OMD operation. Please refer to

the GPTC Guide for Transmission and Distribution Piping

Systems: 1998-2000 Guide Material Appendix G-192-11

Section 4 Leak Detection, 4.4 Leakage surveys and test

methods (a) Surface Gas Detection Survey. Part (3) Utiliza-

tion. The use of this survey method may be limited by ad-

verse conditions (such as excessive wind, excessive soil

moisture or frost or surface sealing by ice water). The survey

should be conducted at speeds slow enough to allow an

adequate sample to be continuously obtained by placement of

equipment intakes over the most logical venting locations,

giving consideration to the location of the facilities and any

adverse conditions which might exist.

OVERVIEW

10

Chapter II

INSTALLATION PROCEDURE

It is virtually impossible to predict the exact installation proce-

dure for every different type of vehicle on the market. There

are some details that will have to be worked out on the spot

with your particular vehicle and here are a few ideas to con-

sider.

There are five parts to consider when installing the OMD: 1)

The crossbar assembly, 2) The power box, 3) The cable assem-

blies, 4) The display unit, and 5) Vehicle Grounding Strap.

Crossbar installation:

The OMD components are pre-aligned at the factory and

should not require re-alignment when the system is installed on

the vehicle. It is, however, important that the u-bolts be at-

tached in such a way that they do not bend the support rod.

The u-bolts should be tight enough to hold the OMD crossbar

securely in place, but not so tight as to distort the crossbar. If

that happens, re-alignment may be required. We recommend

using only two insulated u-bolts to mount the OMD crossbar to

minimize the possibility of distorting the crossbar. The follow-

ing procedure will generally work best.

For your convenience, we have put together an OMD mounting

kit, which includes strut channels, shelf brackets, u-bolts and

mounting hardware (Heath P/N 2510651).

Use two strut channels that are approx. 24” long each (Heath P/

N 2510652). These strut channels are mounted vertically to

the front bumper of your vehicle, parallel to each other and

approx. three feet apart. It is most fortunate if you have a front

bumper that is relatively flat vertically, in which case the strut

channels can be mounted directly to the bumper. If the bumper

11

INSTALLATION

is not flat, some other type of brackets, supports, etc. will need

to be used to attach the strut channels to the front of the ve-

hicle. Mount the two strut channels approx. one-foot from the

ground to the bottom of each strut channel. A drawing is

included in Appendix A.

Once the strut channels are mounted, use standard strut chan-

nel shelf brackets (Heath P/N 2510654) to mount to the strut

channels with two bolts (Heath P/N 2510655) and channel-nuts

(Heath P/N 2510653) each. The OMD crossbar can then be

attached to the shelf brackets with the insulated u-bolts pro-

vided (Heath P/N 2510657).

Once this installation is complete, the height of the OMDcan

easily be adjusted by loosening the bolts attaching the shelf

brackets to the strut channel and sliding the OMD up or down

to the desired position. In addition, the shelf brackets can be

mounted facing upward so that the OMD can be extended

another 10” up toward the hood. The shelf brackets can also

be mounted downward so that the OMD can be extended

another 10” down toward the ground.

Additional Notes On Crossbar Installation:

One of the most important points to consider when installing

the crossbar assembly is air- flow. Unlike the flame ionization

technology, which has a vacuum pump to bring the sample to

the analyzer, the OMD relies strictly on the flow of gas through

the optical path. Therefore, it is of the utmost importance that

you install the OMD in such a way as to allow the gas to flow

continuously through the optical path. It is important that you

don’t configure your mounting brackets in a way that creates a

dead space thus preventing gas from flowing freely across the

optical path. A drawing illustrating this problem is included in

12

INSTALLATION

Appendix A at the end of this manual. Many vehicles have

vents below the bumper to allow airflow into the engine com-

partment. This is a good place for the optical path. If you

attach the OMD crossbar at bumper height, then hang the

optical path slightly below the bumper and gas will flow across

the optical path then on into the engine compartment.

The best location for your OMD crossbar assembly will vary

from vehicle to vehicle. However, one principle remains the

same, install the crossbar in such a way as to allow gas to

freely flow across the optical path.

Power box installation:

The original suggestion was if the vehicle had sufficient room,

that the Power Box should be mounted under the hood. This

reasoning was to eliminate the need for routing multiple cables

into the vehicle cab. However, field experience indicates that

in some instances, heat from the vehicle engine coupled with

high ambient temperatures can result in Power Box failures.

The current suggestion is to mount the Power Box inside the

cab of the vehicle. The first thing to consider when mounting

the power box inside the cab is cable length. The standard

cables are at least long enough to mount the power box directly

behind the front seat on most vehicles. If you desire to mount

it further back, check the length from the desired mounting

position to the OMD crossbar assembly mounted in front of the

front bumper.

After determining where you want to mount your power box,

simply place the box in the desired spot and mark through the

mounting holes on the ears of the box with a pencil. Drill

starter holes, then attach the box with four # 8 x ½” sheet metal

screws.

13

Cable assemblies installation:

Each cable assembly for the OMD is uniquely constructed so

that it cannot be connected to the wrong mating connector.

First, you will need to determine which cable goes where. If

you mounted the power box under the hood, then you will only

need to route the display cable either through the firewall or

through the floorboard. If you mounted the power box inside

the cab, you will need to route the other three cables into the

cab as well.

INSTALLATION

Unless a hole large enough to route the cabling through already

exists, you will need to drill one. A hole approximately 1-1/8

inches in diameter should be sufficient to route one or three

cables. A 1-1/8 inch rubber grommet should be used in this

hole to protect the cables from damage. A 1-1/8 inch rubber

grommet may be purchased from Heath as P/N 2510686.

14

INSTALLATION

Whenroutingcablesfromthecab to the frontofvehicle,fastenthe

cablestofixed parts ofyourvehicle with tiewraps. Tiewraps are

available from Heath as P/N 9996350 for 4” (per 1,000) and P/N

0419180for 8”(each). Be sure toroute cablesaway from exhaust

componentsandshiftlinkages.

TheOMDrequires six amperesofcontinuouscurrent. So connect

thesystem power cabletothe vehicle’sbattery. Donot connect

thesystempowercable to thecigarettelighteroranywhereelse

thatis not ratedforat least sixamperes. Whenconnecting power,

polaritymustbe observed. If thepositiveand negative leadsare

reversed,thefusewillblowimmediately. Theredwireshouldbe

connectedtothepositive terminal andtheblackwireconnected to

thenegativeterminal ofthebattery.

Note:

Connectthe battery cableup last. Be surethat the receivercable is

connectedpriorto making thebatteryconnection. Damagetothe

electronicsmayoccurifnotproperlyconnected

Displayinstallation:

Therequirementsforinstallingthedisplayincludemountingthe

displayatan operatorfriendlyheightandpositionandthenplugging

inthedisplay cable. A floorboardmountingpedestalor adash-

boardconsoleare two possiblemountingmethods. Thesetypes of

devicesareavailable fromsuppliersofcellularphoneequipment.

15

Vehicle Grounding Strap

A vehicle-grounding strap is included in the OMD mounting

kit. The purpose of this strap is to prevent the buildup of an

Electro-static charge, thereby preventing any condition of

Electro-static discharge between the operator and the display

unit, which can cause a reset condition of the display unit. The

ground strap mounting location on the vehicle is at the discre-

tion of the customer. To ensure proper operation, however,

certain conditions need to be observed.

·Ground strap must be mounted to the vehicle chassis. Avoid

mounting to any surface that is painted or plated.

·Ground strap should have a minimum of three inches of the

strap in contact with the surface being traveled over.

INSTALLATION

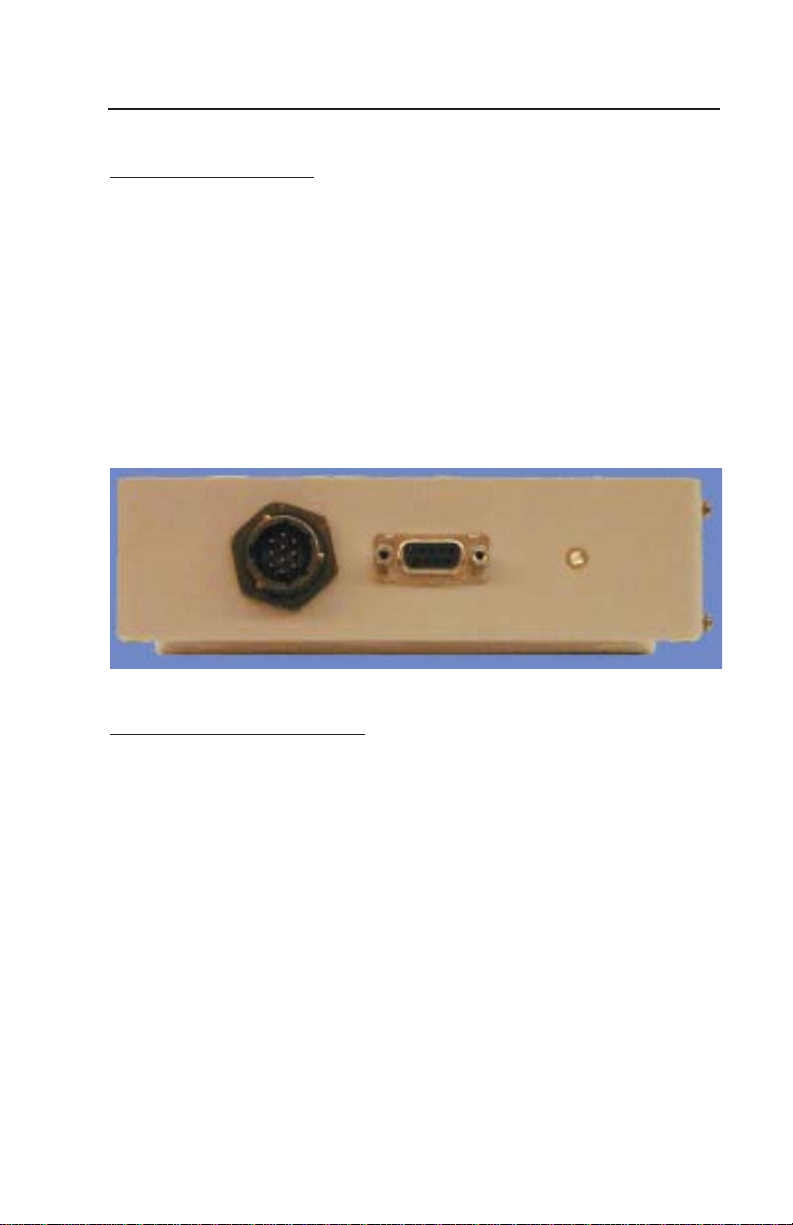

DisplayConnectors:

There are three connectors on the side of the display box. The

first is for the system cable which comes from the power box

connector marked “Display.” Next is the RS-232 connector,

which is to connect a computer for data logging, etc. Then

there is a 1/8” phone jack for connecting an external speaker.

When a phone plug is plugged into the speaker jack the inter-

nal alarm speaker is disabled.

16

·Verify that the mounting location of the strap will not cause

it to come in contact with any rotating parts, such as drive

wheels or drive shaft.

NOTE: Ground strap mounting hole is .475”ID and strap length

is 30”.

Protective Cage

Because the main part of the OMD is located on the front

bumper of the survey vehicle, it is in danger of being damaged

due to the possibility of bumping into something. We recom-

mend that a cage be built around the OMD to protect it.

It would be nearly impossible to build one cage that would fit

on every type of vehicle used for mobile surveying. Therefore

Heath does not offer one at this time. We recommend that you

take your vehicle to a local fabrication shop to custom build

one for your vehicle.

Following are a few photos of typical protective cages presently

in use.

INSTALLATION

17

Photos of Protective Cages

INSTALLATION

18

Chapter III

OPERATING PROCEDURES

Start Up:

1) Turn on the SYSTEM POWER by pressing the “SYSTEM

POWER” button. The red LED above the SYSTEM POWER

button will light up and a message will appear on the screen

stating, “PUSH DISPLAY FUNCTION TO CONTINUE.”

Press the Display Function button twice to enter the normal

operating mode.

If the system has been off for more than several seconds, a

“SYSTEM WARMING UP,” message will be displayed. The

systemwillrequireuptoapproximately15minutesbeforeabeep

willbeheard and amessageprompting the operatorto,“TURN

ONTHELIGHTSOURCE” will be displayed.

2) Turnon theLIGHT SOURCEif not doneso alreadyby press-

ingthe“LIGHT SOURCE” button. TheredLED above the

LIGHTSOURCEbuttonwilllight up and normaloperationof

thesystemwillbegin. Ifthevehicle will be turned offfora

break, turn off the LIGHT SOURCE to save the automobile

battery, while keeping the System Power on. A message

prompting the operator to turn on the LIGHT SOURCE to

resume operation will be displayed. System current con-

sumption with the light is approximately five amperes

while system current consumption without the light is less

than one and one half amperes, which can be sustained by a

good automobile battery, without the use of the engine, for

at least 12 hours without causing starting problems. How-

ever, extreme cold conditions may require the vehicle to

remain running as battery capacity drops significantly with

reducedtemperature.

3) Allowtimefortheinstrumenttostabalize. Thismaytake 45 to

19

OPERATING PROCEDURES

60minutes. Thesystemis stable whenthePPMreadings

becomeconsistant.

4) Press theCALIBRATIONTEST button. Thered LED above

theCALIBRATIONTESTbuttonwilllightupandasmall

internalcellcontainingmethanewillbeplacedintheoptical

path. Thistestcellwillremaininthelightpathforapproximately

fivesecondsunlessthebutton is held down. Afterfiveseconds

thecellwillreturn to its normalpositionandtheredLEDwill

turnoff. Theincreaseinmethaneabovethe background should

beshownon the calibrationdatasheetthat was shippedwith

yourinstrument. Inotherwords,ifthe baseline on thedisplayat

thetimeofthe calibration is2PPMandthe calibration data

sheetindicatesthat thecalibrationcellcontainstheequivalentof

15PPM of gas,an increase insignal level from2 to 17PPM

willbeexpectedwhenthe CALIBRATIONTEST buttonis

pressed. Somedeviationfromthis exact numberisacceptable

asindicated bythe range onthe datasheet. It is goodpractice

tooccasionallypresstheCALIBRATIONTESTbuttonduring

thedailyoperationofthesystemto insure that the systemis

operatingproperly.

The concentration of the gas within this test cell is actually

much higher than the reading listed on the data sheet. The

reading obtained from this test cell is equivalent to the read-

ing of a gas cloud that fills the entire volume within the light

path, that is, the volume between the lens on the lamp assem-

blyandthelensonthe receiver assembly.

5) Set the Audible ALARM SETPOINT by pressing either the

ALARM SETPOINT UP or DOWN button. The audible

alarm will be sounded if the present methane level is greater

than the ALARM SETPOINT level. Holding either the up or

down ALARM SETPOINT button will enable the auto scroll

20

OPERATING PROCEDURES

6) Set the SPEAKER VOLUME of the alarm to the desired level

by pressing either the SPEAKER VOLUME INCREMENT

or DECREMENT button to raise or lower the SPEAKER

VOLUME. Holding either the up or down SPEAKER VOL-

UME button will enable the auto scroll feature. If needed,

press the CALIBRATION TEST button to introduce a gas

alarm.

7) Adjust the CONTRAST to the desired level by pressing either

the CONTRAST UP or DOWN button to raise or lower the

CONTRAST control to maximize the visibility of the display.

Holdingeither theupor downCONTRAST button willenable

theautoscrollfeature.

DISPLAY FUNCTION:

The DISPLAY FUNCTION has three modes- HOLD, LIGHT &

SAMPLE. These modes are entered by consecutively pressing

the DISPLAY FUNCTION button to scroll through each. Begin-

ning with HOLD, as you continue to press the button the mode

changes from HOLD to LIGHT to SAMPLE and back to HOLD

again, as indicated by the direction of the arrow.

HOLD:

This is the power up default position indicated by the line under

the word HOLD. This position will stop the updating of the

methane level vs. time. This allows the operator to inspect the

display before it scrolls off the screen. This is especially impor-

tant in one-person survey operations as the driver may hold the

display while finding a place to pull off the road. A message

prompting the operator to “PUSH DISPLAY FUNCTION TO

CONTINUE”, will be displayed. The display will be cleared

when the DISPLAY FUNCTION button is pressed again, leaving

Table of contents