Heatport H2 User manual

USER MANUAL

HEATPORT H2 / H4

EnControl

Version 1.00 - 06/2021 Made in New Zealand

1. NORMAL OPERATION

NORMAL START

Click the “Rotary switch” or “ON” button on the Wireless Remote Controller in the shutdown state to turn

the heater on. The screen will show the ambient temperature, battery voltage and the local altitude.

The unit will start pre-heating and once it reaches the required temperature, the fuel pump will start

pumping fuel. After the successful ignition, the heater will start running in about 5 minutes. The settings of

the working modes will not be initiated until completing the startup process which can take a couple of

minutes.

Note: If the pump stops ticking and the display shows OFF, error code E1, it means that the fuel did not reach the heater. You

may fulfill the fuel lines using the fuel filling mode OR repeat this Start-up process again. If the unit continues providing the same

error code, please review the placement of the fuel lines, fuel filter and fuel pump.

WORKING MODE SELECTION

●Fixed Power Mode:

To switch into the Fixed Power Mode, click the “Rotary

switch”. Turn the “Rotary switch” on the wired

controller clockwise to increase or anticlockwise to

decrease the heating power. The display will show

values between P1-P5, with P5 as the highest heating

power. The same adjustment can be achieved by short

pressing the “+” or “-” button on the Wireless Remote

Controller. After a few seconds the buzzer will beep

once as settings confirmation.

●Thermostatic Mode

To switch into the Thermostatic mode, click the

“Rotary switch”. Turn the “Rotary switch” on the wired

controller clockwise to increase or anticlockwise to

decrease the preset ambient temperature. The display

will show values in degrees celsius. You may adjust

the temperature from 10°C to 35°C. The same

adjustment can be achieved by short pressing the “+” or “-” button on the Wireless Remote

Controller. After a few seconds the buzzer will beep once as settings confirmation.

Note: The above modes are only available if the unit is in ON state. The thermostatic mode will automatically adjust the heating

power within the range of the minimal heating power and maximal heating power. The controller allows full shut-down of the

heating process after reaching the preset temperature to avoid overheating of the heated space. The unit waits fully off and

initiates the next heating cycle again once the room temperature drops a couple of degrees below preset temperature. The

temperature sensor is located in the wired LCD Switch. The two modes can only be switched and can’t coexist. For example, the

previous setting of the thermostatic mode would be invalid after switching into power mode.

SHUTDOWN

To shutdown, press and hold the “Rotary switch” or press “OFF” button on the wireless remote controller to

execute the shutdown command. The buzzer beeps once, the screen displays OFF and the heater enters the

shutdown process. It can take several minutes until the heat exchanger is fully cooled down and ready to shut

down. When the screen displays ----, the screen turns off and the heater shuts down.

Note: Never turn off the unit by disconnecting the power supply while the unit is running or before finishing the cooling

process as it may cause permanent damage to the internal components. Warranty does not cover damages like this.

2. ADVANCED FUNCTIONS

FUEL PUMPING MODE

After installation of the heater the fuel line needs to be filled up

with diesel. Press and hold the “Rotary switch” in the

shutdown state, the screen lights up and buzzer beeps once.

When the screen displays “Polr”, release the button for

executing the fuel pumping procedure. The fuel pump will

enter the state of rapid pumping (500 rapid pulses). When the

fuel enters the heater pumping frequency will be set to normal

and the heater will run automatically.

Note: This process should not be performed for regular start of the heater,

there is risk of flooding the combustion chamber.

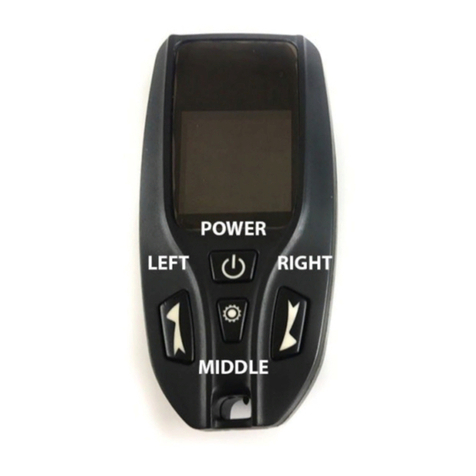

REMOTE CONTROLLER PAIRING

For pairing the wireless remote controller the heater has to be

running in “Thermostatic mode”. Keep turning the “Rotary

Switch” anticlockwise until the screen will display “Stu”. Now

you can press the “OFF” button on the wireless remote

controller to pair it. After pairing is successful the screen will

display “433”. Now you can adjust the temperature back to the

designated value via wireless remote controller.

FUEL TANK VOLUME SETTINGS

This controller is able to measure the fuel flow and

approximate how much fuel is left in your fuel tank. You can

switch between 5l, 8l and 10l preset tanks. When the heater is

running press and hold “Fuel volume settings key”. Screen will

display the size of the tank. If you want to change the size of

the fuel tank you have to wait for the buzzer to beep and

repeat the procedure.

When you fulfill your tank you can reset the fuel gauge by

pressing the “Fuel volume settings key”.

3. NOTES

4. FAULT CODES / TROUBLESHOOTING

Note: This fault code book is designed for an easy identification of any issue. Any repairs/replacements of the internal components of the

heater unit described below must be consulted and pre-approved first with the supplier of the product. The warranty will be voided if

there are any repairs/modifications or unauthorised changes in the hardware or firmware of the product without the approval of the supplier or

any replacement of non-original parts or components that are not supplied by the supplier.

E0

CONTROL UNIT

●Fault of the ECU

○Replace ECU.

●Incorrect ECU / Wired controller

○Replace ECU / Wired controller.

E1

FAILED IGNITION

●No fuel entering the heater unit

○This can happen when you run out of fuel in the individual fuel tank or the fuel level of

the main tank dropped just under the tip of the suction pipe. You must fill the tank and

then fulfill the fuel line using the Fuel pumping mode or repeat the start-up process again

and again until the successful ignition or until you remove all the bubbles appearing in

the fuel line.

●The wrong placement of fuel lines/fuel filter/fuel pump

○Problem especially on the intake side of the fuel line before the fuel pump, which is the

most vulnerable for creation of the airlock. Review the placement of the fuel line /filter/

fuel pump exactly as per the provided instructions.

If you are unsure if the problem is caused by the placement of the fuel lines (this can

happen on long horizontal fuel line), you may try to place the fuel pump directly under

the heater and suck the fuel straight from the jerry can to determine if the problem is

caused by the fuel line placement.

●Wrong diameter of the fuel lines

○The fuel lines supplied are a special size with very small internal diameter. Never use any

other type of fuel line.

●Blocked or compressed air intake / exhaust pipe

○Check the air intake / exhaust pipe for the blockage, dirt, snow, mud.

●Condensed / rain water staying in the air intake / exhaust pipe

○Reinstall the pipes per instructions to allow water to escape naturally down by gravity.

●Blocked fuel line or fuel filter

○Replace the fuel line or fuel filter.

●Bad quality of fuel

○Replace the diesel for new.

●Carbon deposition inside the burner

○Replace the burner.

●Carbon deposition in heat exchanger / exhaust pipe / exhaust silencer

○Pressure clean with water the heat exchanger/ exhaust pipe / exhaust silencer.

●Dirt on the atomising net of the glow plug

○Replace the atomising glow plug net

●Dirt on the glow plug

○Replace the glow plug

●Faulty blower motor / heat exchanger gasket OR burner / heat exchanger gasket

○Replace the gasket

●Fault of the Fuel Pump

○Replace the Fuel Pump.

●Fault of the ECU * please see above

E2

FLAME

EXTINCTION

*Same as E1

E3

UNDERVOLTAGE

OR

OVERVOLTAGE

●Undervoltage

○System minimum voltage is 10.5 volts (22.5V for 24V unit). Verify battery voltage.

Connect the multimeter to the positive and negative terminals of the wiring harness and

set to volts DC. If the wiring harness has been extended for a longer distance, check the

voltage at the main ECU connector.

○Record the voltage. If the voltage is less than 12.6 (flooded cell) 12.8 (AGM), connect the

battery charger and log off the job until the batteries are fully charged. Otherwise, turn on

the unit while watching the multimeter.

●Overvoltage

○System maximum allowed voltage is 15 volts for the 12V version and 30 volts for the 24V

version. The possible causes of this code are: 1) Battery charger in boost mode 2)

Alternator overcharging 3) Solar panel controller overcharging

●Wrong connection in connectors

○Check the connector of the main ECU board for any dirt or corrosion or the positive and

negative terminal at the wiring harness.

●Fault of wiring harness

○Inspect wiring for damage or short circuiting with the chassis of the vehicle. Check

continuity from the ECU board to the connector of the wired switch. In case of wrong

connection, replace a wiring harness.

●Fault of the ECU * please see above

E4

PREMATURE

IGNITION

IDENTIFICATION

●Residual fuel in the heater

○If the heater did not finish the shutdown procedure (eg. caused by voltage drop) there

might be some residual fuel left. Leave the heater on a warm and well vented place to

evaporate fuel leftovers.

E5

THERMAL

EFFICIENCY

FAILURE

●Bad quality of fuel

○Replace the diesel for new.

●Fuel filter is blocked

○Clean or replace fuel filter.

●Fuel inlet is blocked

○Clean fuel inlet and fuel tank.

●Carbon deposition inside the burner

○Replace the burner.

●Temperature sensor fault

○Replace the Pt1000 temperature sensor.

●Fault of the Fuel Pump

○Replace the Fuel Pump.

●

E6

TEMPERATURE

SENSOR

●Temperature sensor on controller is damaged

○Replace the controller

E7

FUEL PUMP

●Wrong connection in connectors

○Check the connectors of the fuel pump or main ECU board for any dirt or corrosion.

●Fault of the wiring harness * please see above

●Fault of the Fuel Pump * please see above

●Fault of the ECU * please see above

E8

BLOWER

MOTOR

●Blower motor interrupted

○Check heating air intake for obstructions, ensuring the blower turns freely. Run the unit

and listen if there is any suspicious sound or rubbing. Turn the blower by hand checking

for hard spots.

●Damage of the impeller

○Possible causes: 1) Physical obstruction 2) Ducting clamp over-torqued

3) Floor mat or debris under the heater when mounted. Replace the blower motor.

●Blower motor short circuit

○Connect the multimeter to the positive and negative terminals of the fan and check the

resistance. Check if the wiring to the fan is not damaged.

●Blower motor speed failure

○This motor speed varies from specification by more than 10% for longer than 30

seconds.

●A loose ECU casing

○Wrongly positioned ECU or magnetic sensor on ECU can cause inaccurate readings. Fix

the position of the ECU. If the ECU is loose, tighten the screw.

●Fault of the ECU * please see above

E9

GLOW PLUG

●Short circuit of the wiring of glow plug

○Replace the glow plug.

●Fault of glow plug

○Replace the glow plug.

●Fault of the ECU * please see above

E10

OVERHEAT

●Excess temperature is measured at the overheat sensor

○Check if the fan is not blocked/damaged and is spinning without any suspicious noise.

○Check airflow ensuring the ducting is free from obstructions.

●Wrong connection of the temperature sensor

○Remove the PT1000 sensor, check connections, wiring and reinstall.

○If the wiring is damaged or the connection is corroded, replace the temperature sensor.

●Faulty temperature sensor

○Replace the PT1000 sensor

●Fault of the ECU * please see above

E11

PT1000

TEMPERATURE

SENSOR

●Temperature sensor connection malfunction

○Check the connection of PT1000 temperature sensor to ECU.

●Temperature sensor is damaged

○Replace the PT1000 temperature sensor.

●Short circuit of the wiring of temperature sensor * please see above

●Wrong connection of the temperature sensor * please see above

●Faulty temperature sensor * please see above

●Fault of the ECU * please see above

E12

GLOW PLUG

●Disconnection of the glow plug

○Connect the glow plug to the ECU.

●Fault of glow plug* please see above

●Fault of the ECU * please see above

E14

PT1000

TEMPERATURE

SENSOR

●Temperature sensor is not positioned correctly

○Install the PT1000 temperature sensor correctly

© LF Bros NZ Pty Limited 2021

No part of this manual may be copied or reproduced in any form

without the express permission of LF Bros NZ Pty Limited.

This publication was correct at the time of going to print; however,

LF Bros NZ Pty Limited has a policy of continuous improvement

and reserves the right to amend any specifications without prior

notice.

LF Bros NZ Pty Limited

39B Pawsons Valley Road

Duvauchelle, 7581

Canterbury

New Zealand

www.heatport.co.nz

This manual suits for next models

1

Table of contents

Other Heatport Controllers manuals