Faulhaber MCDC 3002/03/06 RS/CF/CO Series User manual

WE CREATE MOTION

Technical Manual

Motion Controller

MCBL 3002/03/06 RS/CF/CO

MCDC 3002/03/06 RS/CF/CO

MCLM 3002/03/06 RS/CF/CO

MCBL 3002/03/06 AES RS/CF/CO

EN

Imprint

2

Version:

8th edition, 9-11-2018

Copyright

by Dr. Fritz Faulhaber GmbH & Co. KG

Daimlerstr. 23 / 25 · 71101 Schönaich

All rights reserved, including those to the translation.

No part of this description may be duplicated, reproduced,

stored in an information system or processed or

transferred in any other form without prior express written

permission of Dr. Fritz Faulhaber GmbH & Co. KG.

This document has been prepared with care.

Dr. Fritz Faulhaber GmbH & Co. KG cannot accept any

liability for any errors in this document or for the

consequences of such errors. Equally, no liability can be

accepted for direct or consequential damages resulting

from improper use of the equipment.

The relevant regulations regarding safety engineering

and interference suppression as well as the requirements

specified in this document are to be noted and followed

when using the software.

Subject to change without notice.

The respective current version of this technical manual is

available on FAULHABER's internet site:

www.faulhaber.com

8th edition, 9-11-2018 7000.05038, 8th edition, 9-11-20187000.05038

8th edition, 9-11-2018 7000.05038, 8th edition, 9-11-20187000.05038

Content

3

1 About this document ....................................................................................................... 5

1.1 Validity of this document ...................................................................................... 5

1.2 Associated documents ............................................................................................ 5

1.3 Using this document .............................................................................................. 5

1.4 List of abbreviations ............................................................................................... 6

1.5 Symbols and designations ...................................................................................... 7

2 Safety ................................................................................................................................ 8

2.1 Intended use ........................................................................................................... 8

2.2 Safety instructions .................................................................................................. 8

2.3 Environmental conditions ...................................................................................... 9

2.4 EC directives on product safety ............................................................................. 9

3 Product description ........................................................................................................ 10

3.1 General product description ................................................................................ 10

3.2 Product information ............................................................................................. 11

3.3 Product variants .................................................................................................... 12

3.3.1 Motion Controllers for motors in the lower power range ................. 12

3.3.1.1 MCxx 3002 S RS/CF/CO ........................................................... 12

3.3.1.2 MCxx 3002 F RS/CF/CO ........................................................... 12

3.3.1.3 MCxx 3002 P RS/CF/CO ........................................................... 12

3.3.1.4 MCxx 3003 P RS/CF/CO ........................................................... 13

3.3.2 Motion Controller for motors in the higher power range................. 13

3.3.2.1 MCxx 3006 S RS/CF/CO ........................................................... 13

4 Installation ...................................................................................................................... 14

4.1 Mounting .............................................................................................................. 14

4.1.1 Mounting instructions .......................................................................... 14

4.1.2 Install Motion Controller with housing ............................................... 15

4.2 Electrical connection ............................................................................................ 16

4.2.1 Notes on the electrical connection ...................................................... 16

4.2.2 Screening ............................................................................................... 16

4.2.3 Electrical connection of the Motion Controller .................................. 18

4.2.3.1 Connecting the supply........................................................... 18

4.2.3.2 EMC protective measures ...................................................... 20

4.2.4 Connections ........................................................................................... 21

4.2.4.1 Connections on the supply side (MCxx 3002/3003/3006)..... 21

4.2.4.2 MCDC 3002 connections on the motor side......................... 22

4.2.4.3 MCDC 3003 connections on the motor side......................... 24

4.2.4.4 MCDC 3006 connections on the motor side......................... 25

4.2.4.5 MCBL/MCLM 3002 connections on the motor side.............. 26

4.2.4.6 MCBL/MCLM 3003/3006 connections on the motor side..... 27

4.2.4.7 MCxx 3006 D-sub connector.................................................. 28

4.2.5 I/O circuit diagrams ............................................................................... 29

4.2.5.1 Analogue input...................................................................... 29

4.2.5.2 Digital output ........................................................................ 29

4.2.5.3 Error output ........................................................................... 30

4.2.6 External circuit diagrams (Examples) ................................................... 31

4.2.7 Communication port............................................................................. 33

8th edition, 9-11-2018 7000.05038, 8th edition, 9-11-20187000.05038

Content

4

5 Maintenance ...................................................................................................................35

5.1 Maintenance instructions .................................................................................... 35

5.2 Maintenance tasks ................................................................................................ 35

5.3 Troubleshooting ................................................................................................... 35

6 Warranty ......................................................................................................................... 36

8th edition, 9-11-2018 7000.05038, 8th edition, 9-11-20187000.05038

About this document

5

1 About this document

1.1 Validity of this document

This document describes the installation and use of the following series:

MCBL 3002/03/06 RS/CF/CO

MCDC 3002/03/06 RS/CF/CO

MCLM 3002/03/06 RS/CF/CO

MCBL 3002/03/06 AES RS/CF/CO

This document is intended for use by trained experts authorised to perform installation and

electrical connection of the product.

All data in this document relate to the standard versions of the series listed above. Changes

relating to customer-specific versions can be found in the data sheet.

1.2 Associated documents

For certain actions during commissioning and operation of FAULHABER products additional

information from the following manuals is useful:

These manuals can be downloaded in pdf format from the web page

www.faulhaber.com/manuals.

1.3 Using this document

Read the document carefully before undertaking configuration, in particular chapter

"Safety".

Retain the document throughout the entire working life of the product.

Keep the document accessible to the operating and, if necessary, maintenance person-

nel at all times.

Pass the document on to any subsequent owner or user of the product.

Manual Description

Communications and Functional Manual Interface description – RS232

Communications and Functional Manual Interface description – CANopen with FAULHABER channel

Communications and Functional Manual Interface description – CANopen CiA 402

Software manual Operating instructions for FAULHABER Motion Manager PC soft-

ware

8th edition, 9-11-2018 7000.05038, 8th edition, 9-11-20187000.05038

About this document

6

1.4 List of abbreviations

Abbreviation Meaning

AnIn Analogue Input

AGND Analogue Ground

CAN Controller Area Network

CAN_L CAN-Low

CAN_H CAN-High

CF Controller with CANopen interface (Faulhaber channel)

CLK Clock

CO Controller with CANopen interface acc. to CiA 402

CS Chip Select Cable

Data Data cable

DigIn Digital input

DigOut Digital output

EMC Electromagnetic compatibility

ESD Electrostatic discharge

FAULT Fault output

GND Ground

PLC Programmable Logic Controller

PWM Pulse Width Modulation

RS Controller with serial RS232 interface

RxD Receive data

TTL Transistor Transistor Logic

TxD Transmit data

8th edition, 9-11-2018 7000.05038, 8th edition, 9-11-20187000.05038

About this document

7

1.5 Symbols and designations

CAUTION!

Hazards to persons. Disregard may lead to minor injuries.

Measures for avoidance

CAUTION!

Hazards due to hot surfaces. Disregard may lead to burns.

Measures for avoidance

NOTICE!

Risk of damage.

Measures for avoidance

Pre-requirement for a requested action

1. First step for a requested action

Result of a step

2. Second step of a requested action

Result of an action

Request for a single-step action

Instructions for understanding or optimising the operational procedures

8th edition, 9-11-2018 7000.05038, 8th edition, 9-11-20187000.05038

Safety

8

2 Safety

2.1 Intended use

The FAULHABER Motion Controllers described here are designed for the activation and con-

trol of DC-micromotors (MCDC), linear DC servomotors (MCLM) and brushless DC motors

(MCBL). They feature numerous functions and operating modes which facilitate flexible

adaptation to the respective drive task.

Thanks to their compact design, the units can be used in a wide variety of applications and

require only basic wiring. The flexible connection possibilities open a wide range of applica-

tions in all areas, such as in decentral systems in automation technology and in pick-and-

place machines and machine tools.

The following points must be observed to ensure that the motors are used as intended:

The Motion Controller contains electronic components and should be handled in

accordance with the ESD regulations.

Do not use the Motion Controller in environments where it will come into contact with

water, chemicals and/or dust, nor in explosion hazard areas.

The Motion Controller should be operated only within the limits specified in the data

sheet.

Please ask the manufacturer for information about use under individual special envi-

ronmental conditions.

2.2 Safety instructions

NOTICE!

Electrostatic discharges can damage the electronics.

Wear conductive work clothes.

Wear an earthed wristband.

NOTICE!

Penetration of foreign objects can damage the electronics.

Do not open the housing.

NOTICE!

Inserting and withdrawing connectors whilst supply voltage is applied at the device can

damage the electronics.

Do not insert or withdraw connectors whilst supply voltage is applied at the device.

8th edition, 9-11-2018 7000.05038, 8th edition, 9-11-20187000.05038

Safety

9

2.3 Environmental conditions

Select the installation location so that clean dry air is available for cooling the Motion

Controller.

Select the installation location so that the air has unobstructed access to flow around

the drive.

When installed within housings and cabinets take particular care to ensure adequate

cooling of the Motion Controller.

Select a power supply that is within the defined tolerance range.

Protect the Motion Controller against heavy deposits of dust, in particular metal dust

and chemical pollutants.

Protect the Motion Controller against humidity and wet.

2.4 EC directives on product safety

The following EC directives on product safety must be observed.

If the Motion Controller is being used outside the EU, international, national and

regional directives must be also observed.

Machinery Directive (2006/42/EC)

Because of their small size, no serious threats to life or physical condition can normally be

expected from electric miniature drives. Therefore the Machinery Directive does not apply

to our products. The products described here are not "incomplete machines". Therefore

installation instructions are not normally issued by FAULHABER.

Low Voltage Directive (2014/35/EU)

The Low Voltage Directive applies for all electrical equipment with a nominal voltage of 75

to 1500 V DC and 50 to 1000 V AC. The products described in this technical manual do not

fall within the scope of this directive, since they are intended for lower voltages.

EMC Directive (2014/30/EU)

The directive concerning electromagnetic compatibility (EMC) applies to all electrical and

electronic devices, installations and systems sold to an end user. In addition, CE marking can

be undertaken for built-in components according to the EMC Directive. Conformity with

the directive is documented in the Declaration of Conformity.

8th edition, 9-11-2018 7000.05038, 8th edition, 9-11-20187000.05038

Product description

10

3 Product description

3.1 General product description

The FAULHABER Motion Controllers are based on a high-performance digital signal proces-

sor (DSP) that enables high control accuracy, exact positioning and very low speeds.

The Motion Controllers are designed for various drive applications, which can be config-

ured using the respective communication interface.

Depending on the version, the following tasks can be performed:

Position control with analogue or digital setpoint specification

Speed control with analogue or digital setpoint specification

Detection of reference marks and limit switches

Advanced operating modes such as stepper motor operation, electronic gearheads,

voltage controller mode or current control with analogue current setting

Execution of sequence programs stored in the controller (only with version RS)

Various inputs and outputs are available for implementing these tasks:

The set configuration can be stored permanently.

Input/output Possible applications

Analogue input Setpoint specification via analogue or PWM signal

Digital input for reference marks and limit switches

Pulse input

Incremental encoder connection

Fault output Digital output

Pulse output

Digital input for reference marks and limit switches

Rotation direction input

1 additional digital input Digital input for reference marks and limit switches

Communications interface Depending on the version, as serial RS232 or CAN interface for coupling to PC

or control

Motion Controllers with RS232 interface can also be operated independently of the

communication interface if a pre-programmed function or sequence program has been

programmed without digital command control.

As an option, the motor and control electronics can be supplied with power separately

(important for safety-relevant applications). In this case, the 3rd input is no longer

available.

Special preconfiguration of the modes and parameters is possible on request.

8th edition, 9-11-2018 7000.05038, 8th edition, 9-11-20187000.05038

Product description

11

3.2 Product information

Fig. 1: Designation key

RS 232, serial interface

CAN interface FAULHABER

CAN interface CiA

Max. continuous output current 2 A

Max. continuous output current 3 A

Max. continuous output current 6 A

Max. supply voltage 30 V

DC micromotors

Brushless DC motors

Linear DC servomotors

Motion Controller

... ... ... …MC 30

RS:

CF:

CO:

S:

F:

P:

02:

03:

06:

30:

MC:

DC:

BL:

LM:

…

Housing with screw-type terminal strip

Housing with LIF connector (motor)

Board version with male connectors

Only for brushless DC motors with

absolute encoders

AES:

8th edition, 9-11-2018 7000.05038, 8th edition, 9-11-20187000.05038

Product description

12

3.3 Product variants

3.3.1 Motion Controllers for motors in the lower power range

3.3.1.1 MCxx 3002 S RS/CF/CO

Motion Controller with hot-melt housing and screw terminals on the supply and motor

side.

3.3.1.2 MCxx 3002 F RS/CF/CO

Motion Controller with hot-melt housing and screw terminals on the supply side and with

flexboard connection on the motor side.

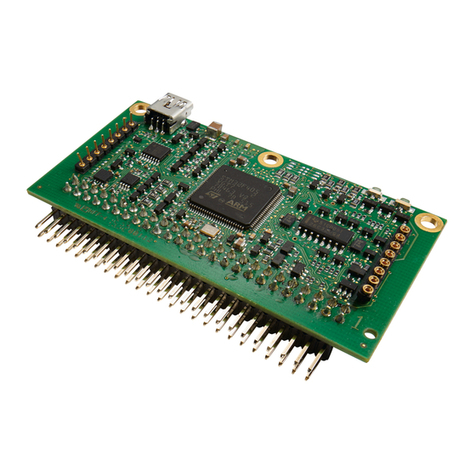

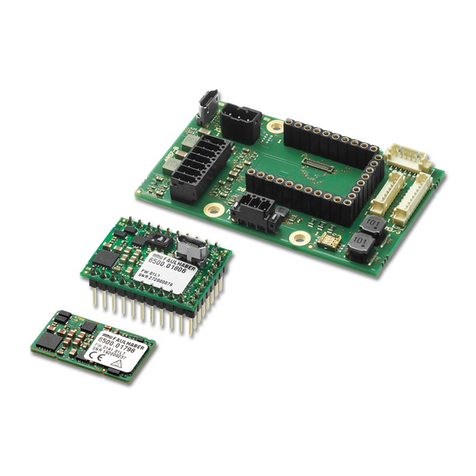

3.3.1.3 MCxx 3002 P RS/CF/CO

Motion Controller without housing (board version) with plug connectors on the supply and

motor side.

1 Assembly sleeves

2 Screw terminal block on the motor side

3 Screw terminal block on the supply side

1 Assembly sleeves

2 LIF plug connector on the motor side for

FFC and FPC, 8-pole

3 Screw terminal block on the supply side

1 Plug connector on the supply side

2 Plug connector on the motor side

8th edition, 9-11-2018 7000.05038, 8th edition, 9-11-20187000.05038

Product description

13

3.3.1.4 MCxx 3003 P RS/CF/CO

Motion Controller without housing (board version) with plug connectors on the supply and

motor side.

3.3.2 Motion Controller for motors in the higher power range

3.3.2.1 MCxx 3006 S RS/CF/CO

Motion Controller with metal housing and screw terminals on the supply and motor side.

1 Plug connector on the supply side

2 Plug connector on the motor side

1 Mounting holes

2 Screw terminal block on the supply side

3 D-sub connector for serial connection (RS)

or CAN connection (CF/CO)

4 Screw terminal block on the motor side

4

8th edition, 9-11-2018 7000.05038, 8th edition, 9-11-20187000.05038

Installation

14

4 Installation

This description must be carefully read and observed before commissioning.

Observe the environmental conditions (see chap. 2.3, p. 9).

Only trained experts and instructed persons with knowledge of the following fields may

install and commission the motors with integrated Speed Controller:

Automation technology

Standards and regulations (such as the EMC Directive)

Low Voltage Directive

Machinery Directive

VDE regulations (DIN VDE 0100)

Accident prevention regulations

4.1 Mounting

4.1.1 Mounting instructions

CAUTION!

The Motion Controller can become very hot during operation.

Place a guard against contact and warning notice in the immediate proximity of the

controller.

NOTICE!

Improper installation or installation using unsuitable attachment materials can damage the

Motion Controller.

Comply with the installation instructions.

NOTICE!

Installation and connection of the Motion Controller when the power supply is applied can

damage the device.

During all aspects of installation and connection work on the Motion Controller, switch

off the power supply.

8th edition, 9-11-2018 7000.05038, 8th edition, 9-11-20187000.05038

Installation

15

4.1.2 Install Motion Controller with housing

NOTICE!

Pressing out of the assembly sleeves.

On a soft or uneven surface, the assembly sleeves can be pushed out while screwing on the

Motion Controller.

Select a smooth and hard surface that supports the assembly sleeves against the screw-

ing forces.

Fig. 2: Mounting (example)

1. Secure the Motion Controller at the assembly sleeves or mounting holes with fastening

screws on a flat and hard surface (for screw size and torque, see Tab. 1).

2. Protect the fastening screws to prevent displacement due to the effect of heat.

Tab. 1: Attachment specifications

Motion Controller Min. tightening torque (Ncm) Max. tightening torque (Ncm)

MCxx 3002 S RS/CF/CO 12 15

MCxx 3002 F RS/CF/CO 12 15

MCxx 3006 S RS/CF/CO 50 60

8th edition, 9-11-2018 7000.05038, 8th edition, 9-11-20187000.05038

Installation

16

4.2 Electrical connection

4.2.1 Notes on the electrical connection

NOTICE!

Electrostatic discharges to the Motion Controller connections can damage the electronic

components

Observe the ESD protective measures.

NOTICE!

Incorrect connection of the wires can damage the electronic components.

Connect the wires as shown in the connection assignment.

NOTICE!

Excessive force can damage the flexboard.

Do not press in the plug connectors by force.

Use a suitable tool (tweezers, flat-nose pliers) if necessary.

Do not pinch the flexboard.

4.2.2 Screening

Fig. 3: MCBL motor wiring

The encoder and signal cables are susceptible to interference. Therefore, a maximum

cable length cannot be specified.

Shielded wires must always be used with cable lengths > 300 mm.

Cable Shield

Motor A Phase A

Sensor C Hall Sensor C

Sensor A Hall Sensor A

Motor B Phase B

U

DD

Sensor B Hall Sensor B

Motor C Phase C

Brushless

DC-Servomotor

SGND

Cable Shield

8th edition, 9-11-2018 7000.05038, 8th edition, 9-11-20187000.05038

Installation

17

Fig. 4: MCDC motor wiring

Connect screen connections for the sensor systems and the motor cables to the Motion

Controller to the earthed mounting plate or the screen connection screw on the Motion

Controller by the shortest available route.

The best screening effect is achieved if the braiding is laid flat for instance on a screen

terminal.

If the installation ensures potential equalisation, the braid can also be attached to an

earthed surface on the motor.

Alternatively equalisation currents can also be suppressed by connected the cable

screen at the motor end via a capacitor (approx. 1μF … 2μF / 50 V).

Mot +

Channel A

Mot –

Channel B

DC-Motor

with Encoder

SGND

UDD

Cable Shield

Cable Shield

8th edition, 9-11-2018 7000.05038, 8th edition, 9-11-20187000.05038

Installation

18

4.2.3 Electrical connection of the Motion Controller

4.2.3.1 Connecting the supply

NOTICE!

Risk of damage caused by inadequately dimensioned power supply unit.

Using an inadequately dimensioned power supply unit can result in malfunctions.

Make sure that the power supply unit is adequately dimensioned.

Tab. 2: Recommended values for the lengths of the motor connection cable

To ensure the allowable emissions or necessary immunity in industrial use, it may be neces-

sary to use an EMC filter and / or shielding or an EMC suppressor circuit.

The connection cables are <3 m

1. Take the appropriate EMC protective measures (see chap. 4.2.3.2, p. 20).

2. Take the appropriate ESD protective measures.

3. Connect wires or flexboard according to pin assignment (see chap. 4.2.4, p. 21).

4. Connect the power supply as described in the explanation below.

There are 2 options for supplying power to the motor and the FAULHABER Motion Control-

ler:

With the exception of the power supply, all connection cables on the supply side must

not exceed a length of 3 m. The maximum permissible length of the motor connection

cable is dependent on the used encoder type (see Tab. 2). Whether or not a longer

motor connection cable may be used must be checked on a case-by-case basis.

Encoder

type

Length of the motor connection cable, unshielded Length of the motor connection cable,

shielded

Analogue

Hall

0.3 m 2.0 m

IE2/IE3 0.5 m On request

IE3L Several meters, dependent on speed and resolution On request

AES 0.3 m On request

8th edition, 9-11-2018 7000.05038, 8th edition, 9-11-20187000.05038

Installation

19

Power supply with common electronics supply

In the case of power supply with common electronics supply, the controller and motor are

switched off simultaneously if a fault occurs. After interruption of the power supply, the

reference run must be performed again.

Fig. 5: Circuit diagram – common electronics supply

Power supply with separate electronics supply (option 3085)

In the case of power supply with separate electronics supply, the motor supply can be

switched off (e.g. by means of a safety relay) in the event of a fault while the controller

continues to be supplied. As a result, the reference run does not need to be performed

again after a fault because the sensor supply of the motor was maintained during the fault.

In the case of a separate electronics supply, power is supplied using the connection 3.In /

UEL in addition to the connection UB. Motion Controllers with a separate electronics

supply do not therefore have a third digital input.

Fig. 6: Circuit diagram – separate electronics supply

GND

Motor

Int. Supply

UB

GND

3. In

+24 V

Motor

Int. Supply

8th edition, 9-11-2018 7000.05038, 8th edition, 9-11-20187000.05038

Installation

20

4.2.3.2 EMC protective measures

To reduce the effects on the DC power supply network, L1 ferrite sleeves (such as WE 742

700 790) can be used on the supply cables.

To protect against overvoltage on the supply side (surge), it is recommended to additionally

connect an external diode D1 (e. g. NTE 4934, 1500 W).

Fig. 7: EMC suppressor circuit

NOTICE!

Risk of damage caused by EMC interaction in the case of separate electronics supply

In the case of a separate electronics supply, the suppressor circuit (see Fig. 7) must be

such that it protects both supply connections.

Mcxx 3003/3006 protective measures

The devices are intended only for use in industrial applications. If the devices are used in

the home, in business, in commerce or in a small business, appropriate measures must be

taken to ensure that the emitted interference is below the permissible limit value.

Tab. 3 shows which additional EMC measures can be implemented to optimise the behav-

iour of the equipment in the intended environment with regard to transient emission and

interference resistance.

Tab. 3: EMC measures

EMC filter (MCDC 3006 S and MCBL 3006 S only):

The supply and motor supply cables must be installed directly at the device with two

windings through a suitable ferrite sleeve (e.g. Würth Elektronik No.: 74270090).

EMC suppressor circuit (MCBL 3006 S and MCLM 3006 S only):

The signal cables of the MCBL 3006 S and MCLM 3006 S must be installed directly at the

device with two windings through a star ring (e.g., Würth Elektronik No.: 7427153).

To provide the required interference resistance in industrial applications, it may be

necessary to use an EMC filter or a screen and an EMC suppressor circuit.

L1

D1

GND

Motor

Int. Supply

UB

Motion Controller Operational environment Interference type Action

MCDC 3006 S Industrial area Transient emission EMC filter

MCBL 3006 S Industrial area Transient emission EMC filter

MCBL 3006 S Industrial area Interference resistance EMC suppressor circuit

This manual suits for next models

3

Table of contents

Other Faulhaber Controllers manuals

Faulhaber

Faulhaber MC 5010 Use and care manual

Faulhaber

Faulhaber MC 3001 B User manual

Faulhaber

Faulhaber MC 5010 Owner's manual

Faulhaber

Faulhaber SC 1801 Series User manual

Faulhaber

Faulhaber MCLM 300x CO Series Parts list manual

Faulhaber

Faulhaber MC 5010 User manual

Faulhaber

Faulhaber SC 1801 User manual

Faulhaber

Faulhaber MC 5004 User manual

Faulhaber

Faulhaber MCLM 300 RS Series Parts list manual

Faulhaber

Faulhaber Series MCBL 3002/03/06 RS/CF /CO User manual