7

IMPORTANT WARNINGS!

THIS APPLIANCE IS NOT INTENDED FORUSE BY PERSONS (INCLUDING CHILDREN AND

THE INFIRM) WITH REDUCED PHYSICAL,SENSORY OR MENTAL CAPABILITIES,

OR LACK OF EXPERIENCE AND KNOWLEDGE, UNLESS THEY HAVE BEEN GIVEN

SUPERVISION OR INSTRUCTION CONCERNING USE OF THE APPLIANCE

BY A PERSON RESPONSIBLE FOR THEIR SAFETY.

CHILDREN SHOULDBE SUPERVISED TO ENSURE THAT THEY

DO NOT PLAY WITH THE APPLIANCE.

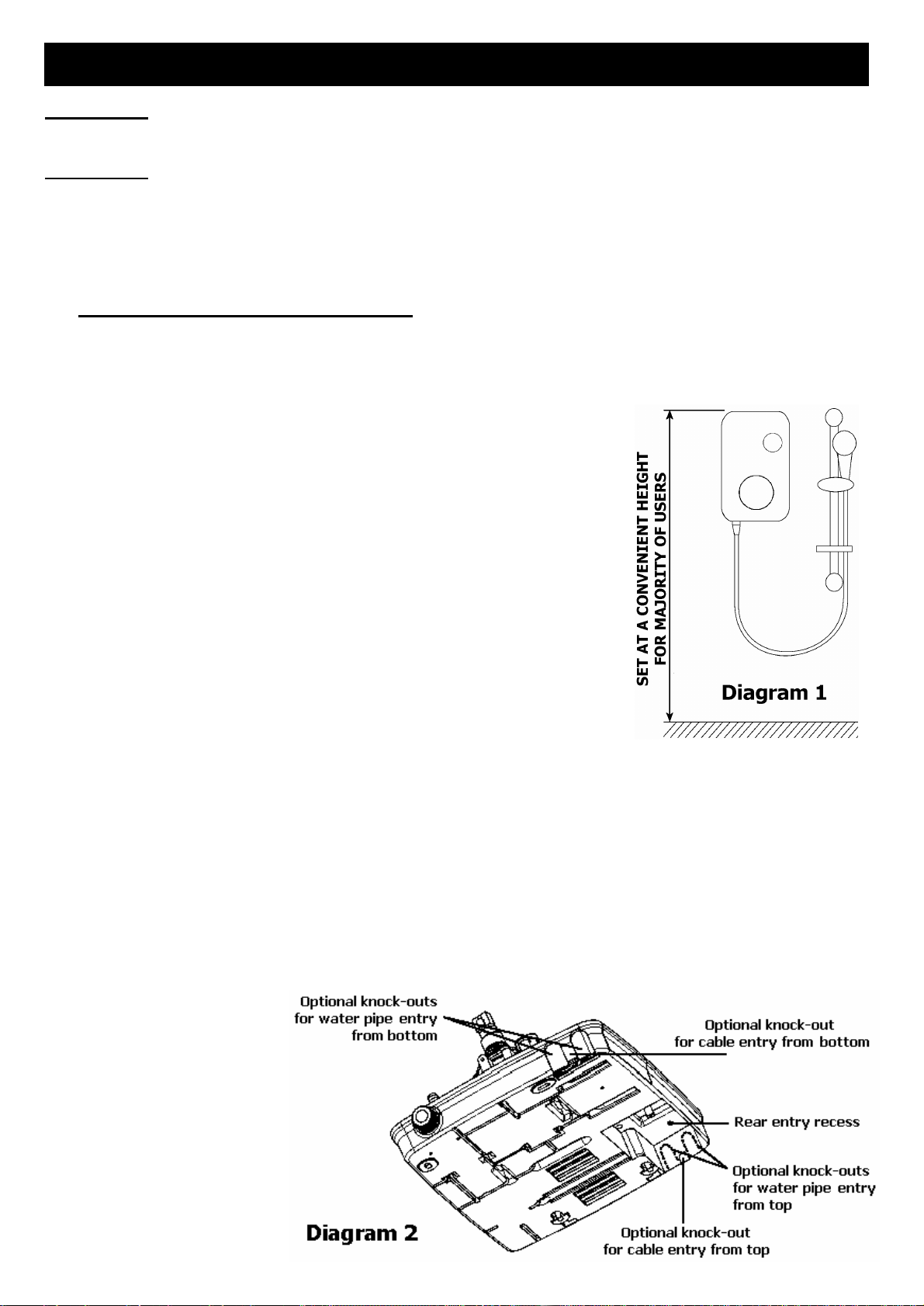

d) FINAL INSTALLATION PROCEDURE AND COMMISSIONING

WARNING: DO NOT SWITCH ONTHE ELECTRICITY SUPPLY UNTIL THE FOLLOWING

PROCEDURE HAS BEEN COMPLETED. FAILURE TO DO SOCOULD CAUSE

THE PUMP TO RUN DRY AND INVALIDATE THE GUARANTEE

1. Fit the hose to the shower unit outlet first without the handset to flush out any remaining debris.

Ensure that the water isolating valves are fully open and that the hose is directed to waste.

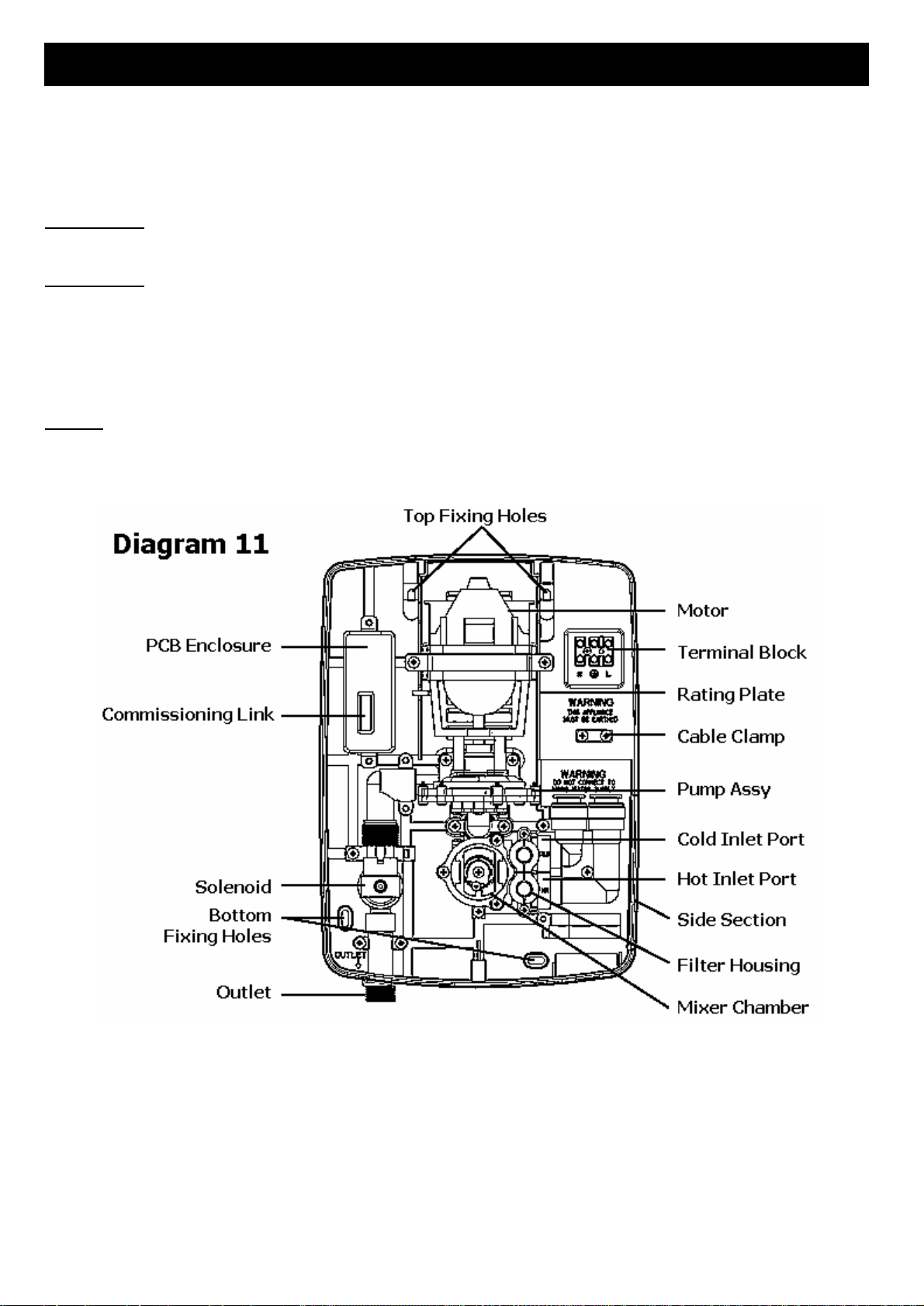

2. The shower unit is factory set in the commissioning mode. A commissioning link is connected to

the PCB (Diagram 11), which opens the solenoid without switching on the motor.

This allows water to flow through the pump, thus ensuring that all air is removed.

The cover is not required to be fitted at this stage but be aware of live parts when the

electricity is temporarily switched on.

3. Switch on electricity supply. After a few moments water should drip from the hose.

It may be necessary to hang the hose from the shower unit whilst priming, especially

if the head of water is minimal. This will speed upthe priming process.

When water drips through the hose at a constant rate, stop flow of water by switching off the

electricity supply.

Ensure electricity is switched off.

Remove PCB Commissioning Link and replacewith the connectorattached to the front cover

start/stop/flow control switch.

Store commissioning link ina safe place for future use.

4. Ensure side section is on place (Diagram 11).

Refit cover using 3 fixing screws and attach handset to shower hose.

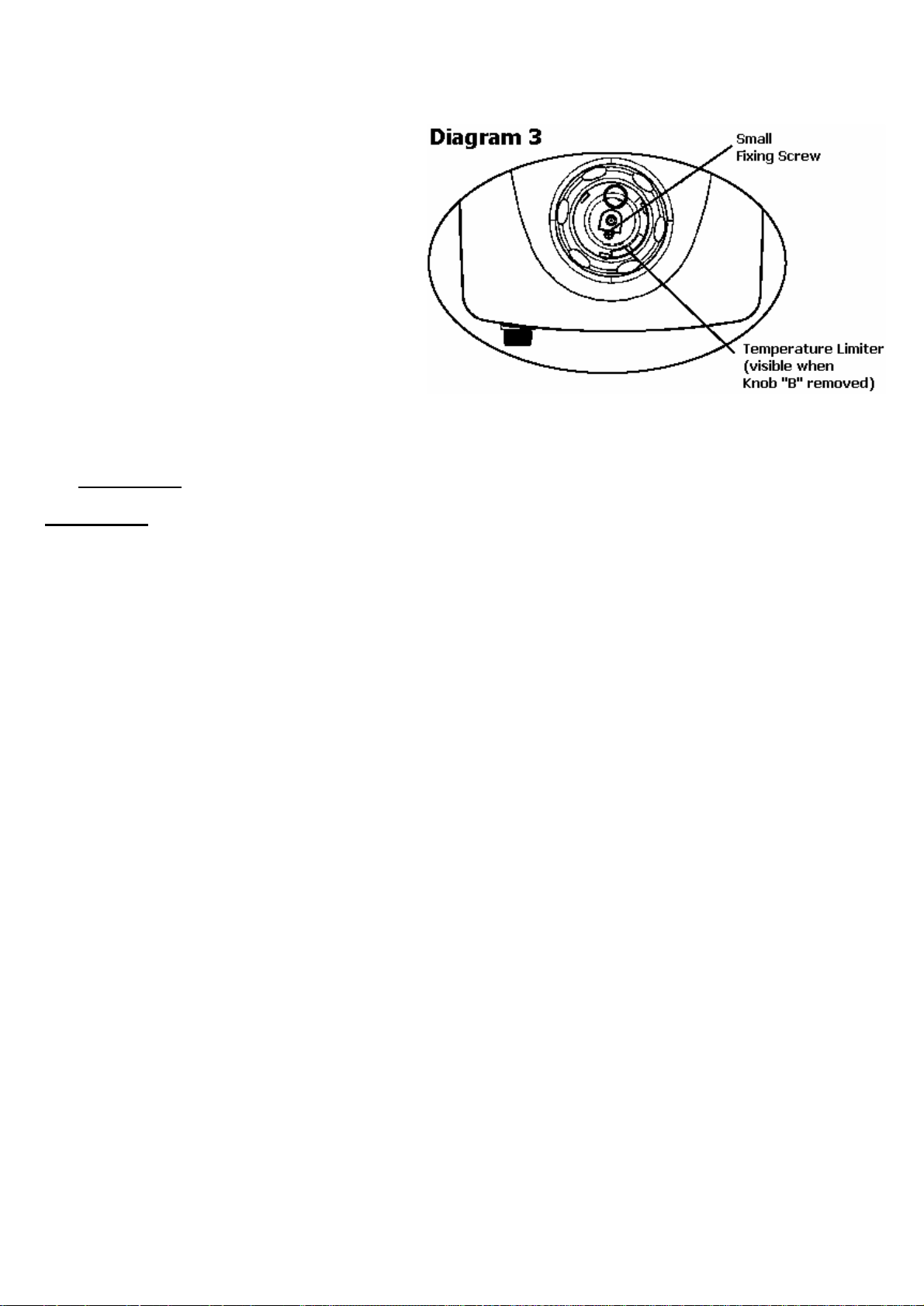

5. A temperature limiter is provided so that the maximum working temperature can be set.

The limiter is factory set, but can be adjusted depending on incoming water conditions.

The limiter is visible when Temperature Control Knob “B” is removed (Diagram 3).

Gently prise away the limiter from the front cover and rotate to new position.

Rotate clockwise for a cooler stop position and anti-clockwise for a warmer stop position.

Ensure that the limiter is pressed firmly home. Re-assemble Temperature Control Knob “B”over

the drive on the mixer unit and fix into place with a screw.

Check that its movement is restricted sufficiently. Also check operation of temperature over-ride

button (Diagram 10). Re-fit controlknob cap by positioning correctly and pressing firmly home.

6. Switch on the electricity supply and then operate the shower as shown on page 8 and check:-

a. The shower switched on when the flow control knob “A” is rotated and that flow is adjustable.

b. Temperature can be adjusted by knob “B”and the limiter position issatisfactorily ie: NOT hot

enough to scald.

c. Operation of over-ride button allows the temperature limiter positionto be overridden.

d. Check again for leaks.

e. That the motor turns off and water stops flowing in the STOP position of knob “A”.

7. PLEASE DEMONSTRATE OPERATION TO USERS