HEAVTH HP103 User manual

HP103Focuson NC cutting heightcontrolfield

PortableCNC

Plasma Torch Height Control

Operation Manual

VISION 1211

Created in Master PDF Editor

HP103PlasmaTorchHeightController

--2--

1.IMPORTANT INFORMATION

1.1SERVICEASSISTANCEAND CONTACTINFORMATION

For serviceassistance, havethefollowing informationavailable:

HP103model,part andserialnumberlocatedonalabel

Type ofcuttingapplicationyou are using

You can contact ourat:

TEL:086-0519-89182619

FOX:086-0519-89183619

1.2RECEIVINGAND UNPACKING

Afterreceiving theHP103 you should:

Carefully, unpackand inspectthe equipment.

Compare the received shipmentwiththe packing list.

Report anydamage tothe carrier andyour representative.

Storeequipmentthat will not beusedin aclean, drylocation.

Takeappropriateprecautionstopreventmoisture,dustand

dirtfromaccumulating instorageandinstallationareas.

1.3SAFETYCONSIDERATIONS

Safety practicesshould notbe anafterthought. Before installing

or servicingthecontroller,reviewand followapplicablepoliciesand

procedurestoensure workersafety.Machinerymust beinasafe

stateandyou mustbeaware ofanyadditionalhazardsthatcan

arise.

1.4PRE-INSTALLATIONCONSIDERATIONS

Created in Master PDF Editor

HP103PlasmaTorchHeightController

--3--

BeforeinstallingtheHP103:

Check tobesure that you haveall ofthe required parts.

Familiarizeyourself withtheparts ofthe HP103.

Checktobe surethatthe torchlifter motorsyou are using with

the HP103 arewithintheacceptablerange.

Reviewthe instructionsforConfiguring theLifterMechanics.

1.5CONFIGURINGTHELIFTERMECHANICS

Properconfiguration ofthetorchliftermechanismisan

importantfactor for establishingtheaccuracyofyour cuttingsystem.

Be sure that:

Gearreductionisselectedon thetorchliftersothatthe

maximumsuspension speed doesnotexceed 3000mm/min (120

IPM).Ifhigheraccuracyisrequired,maximumsuspension speed

shouldbesetto1500 mm/min(60IPM).

Gears,racks andspindles haveminimal backlash.

Oversizing isavoided.The massofmoving parts,including

armatureinertia mustbe assmallaspossible.Motorswithlow

nominal RPMare preferred.

OnlyDC motorswiththefollowing ratings areused:

MOTORRATINGS:DC MOTOR

MOTORVOLTAGE:DC24V

MAX CURRENT:4A

Created in Master PDF Editor

HP103PlasmaTorchHeightController

--4--

2. BriefIntro

2.1Summarize

HP103 plasmaarcvoltage heightcontrollerisequippedwith

constantcurrentplasma.Duringcuttingcourse,thecurrent

alwaysequalsthegiven current.Andthe cutting arcvoltage will

be changedwiththefixed speedbeingtheheightoftorchchanging.

When the distancegetsfarther,thearcvoltage increases; On

opposite,thearcvoltage will decrease.HP103 plasmaarcvoltage

heightcontroller will inspectthevoltage change,then control the

distancebetween cuttingtorchandmaterialvia theliftmotor.So

that the arcvoltage isfixed,the sameistheheight ofcutting torch.

Generally,theinstruction will listallthecuttingparametersfor

sometype ofplasma.Theusercanrefertotheseparameters.

Adjustthe voltage in arcvoltage heightcontroller tomatchthe

selectedcurrent.The torchheightwill keepconstantunder regular

speed.Infact,theusershouldsetthearcvoltage according tothe

heightof the cutting torch.

Inthestatusofautomation,thearcvoltage morehigh,thenthe

heightof the cutting torchmorehigh

2.2Technical parameter

lWorkingvoltage:DC24 orAC24±5%,50Hz/60Hz,Please

prepareaisolated power,donotshared withotherssuchas

electronic valve. Especial Paymore attentiontheAC24V

Created in Master PDF Editor

HP103PlasmaTorchHeightController

--5--

lLiftmotor:DC24V DC motor

lDrivemode: PWM

lOutputcurrent:1A-4A.

lOutput power: 100W.

lWorkingtemperature: Heightcontroller - ∽℃10 60

lIHSstyle:SwitchinspectingIHS(suitableforallplasma

bothabove-water and under-water cutting),PlasmaShield

Protector IHS(suitableforabove-water cutting’stouch

leading arcvoltage plasma)

lRunning transfer:AlternativeArctransfer andpiercetransfer

lDivided voltage ratio:100:1

l∽Accuracy: ±1V ±5V,adjustable

lOuterDimension:LengthXWidthXHeight:

272mmX225mmX80mm

2.3Application

HP103 Supportsalmostallplasmacuttersonmarketlike

Hypertherm, Kjellberg,ThermalDynamics...

And itsupportsallCNC cuttingcontrollerson marketlike

Hypertherm,Burnyindustrial level controllersorMach3suchDIY

controllers.

Created in Master PDF Editor

HP103PlasmaTorchHeightController

--6--

2.4Operationpanel

ArcVoltage

BeforeArcStartitshowstheSetArcVoltage.afteritshowsthe

ActualArcVoltage

3. INSTALLATION

3.1workingprocess:

Mode 1:WhentheArc-ONsignalwith “IAON”(theArc-On signal

withIHS)isavailable ,theheightcontrollershouldprocess theIHS

firstly;Secondlyauto-controltheArc-on,the heightcontrollerwill

send the signalof arctransferand piercetransfertotheNC system

afterproducingthetransfer arc.Atthemean time,thecontroller

delaytimetoputthearcvoltage intothesingle chipsystem.If “Auto

Permitted isavailable in heightcontroller and NC systemhassent

outAUTOheightadjusted signal,thecontrollerison statusof

“HeightAutoadjusted”

HIS Height Piercing Delay

IHS TEST Arc Test

Arc Voltage Up

DownSet Voltage

Down

Up

Arc On

Auto Trans

Collision

Auto/Manual

Created in Master PDF Editor

HP103PlasmaTorchHeightController

--7--

Mode 2:WhentheArc-ONsignalwith “EAON”(theArc-On

signalwithoutIHS) isavailable, theheightcontrollerwill notprocess

theIHSbutcontrol theplasmatoArc-ondirectly;theheight

controller will send the signal ofarctransferand piercetransfer to

the NC systemafterproducing thetransferarc.Atthe mean time,

thecontrollerdelaytimetoputthearcvoltage intothesingle chip

system. If “AutoPermittedisavailableinheightcontroller andNC

systemhassentoutAUTOheightadjustedsignal,the controlleris

on statusof “HeightAutoadjusted

ATTN:When the NCsystemthatyou usecan notreceivethe

signalofarc-onandpierce,pleasedelaythe timetocontrol the NC

system’srunning.Itjustmeansthatthe NC systemsendarc-on

signaltothe heightcontroller,delaytimetorunthe NC system.

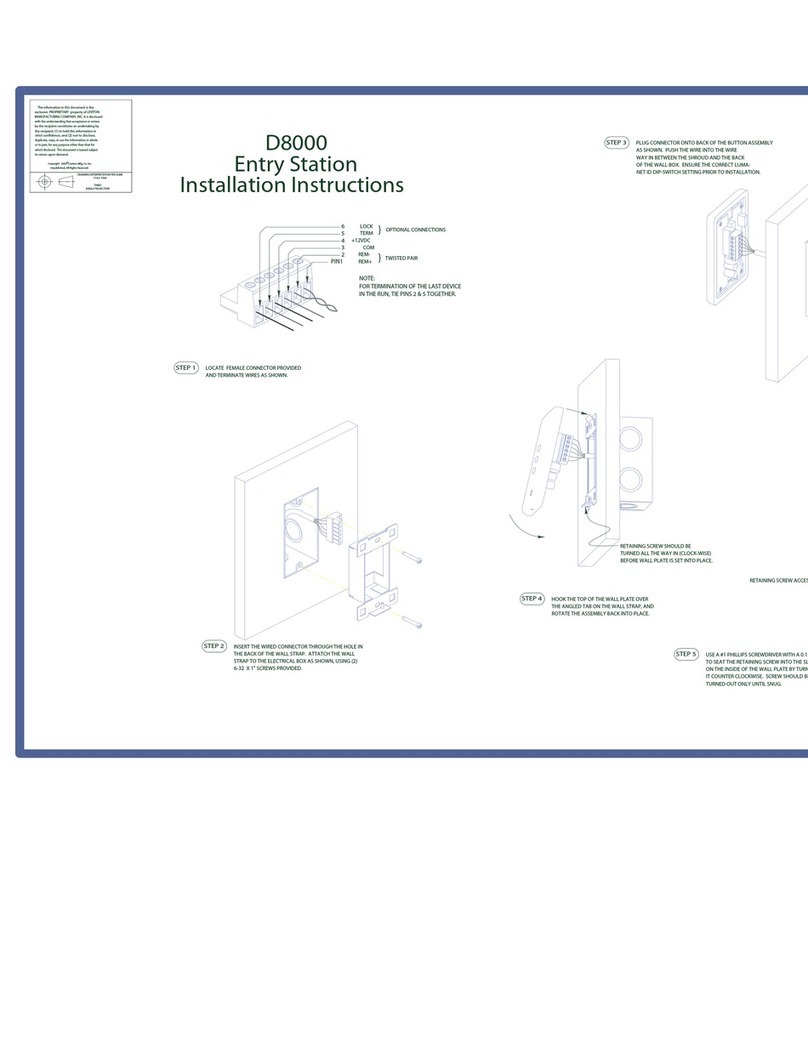

3.2INSTALLATIONCONTROLER

The following section providesyou withtheproceduretofollow

when installingthe HP103.Someofthe stepsdirectyou toother

sectionsin thismanual thatprovide you withmoredetailed

instruction.

1.Determine amountinglocationfortheHP103.Keepthe

following pointsin mind:

Toavoid overheating and potentialdamage tothe control box

fromcuttingprocessfumes,DONOTchooseamountinglocation

Created in Master PDF Editor

HP103PlasmaTorchHeightController

--8--

directlyabovethetorch.Findamounting locationawayfromthe

torchlifterunit.

2.AttachthewiresfromtheCNC,the plasma,thelifter motorand

lifterlimitswitches toaconnectorandthen tothecontrolboxatthe

receptacle.Toreducenoiseemission, 20 AWG(0.5mm2)shielded

cableisrecommended.Filtersconsisting ofaresistorandcapacitor

can be connected onlydirectlytothemotor.

3.Connect a12 AWG(2.5mm2) ground wire totheground

screwlocatedonthe control boxand then,tothemachineground

rail of your cuttingsystem.

3.3Dividedvoltageboard

Controllingthearcvoltage mustinspectthechangingofplasma

arcvoltage.The plasmaarcvoltage equalsthe voltagethatis

between the poleand ground.The anticathodewhichputoutthe

plasmapower isconnected totheground.The Cathodeconnects

tothe polewhichisinthecutting gun.Sothevoltage in the

electrode isnegative.Whenprocess thecutting,the arcvoltage

absolutevalue isusuallyhigher than 100V.If so,the voltage must

be divided in ordertoprocessthecontrol inthecontrollingcircuit.

ATTN:the voltage thatputintothe heightcontroller isnegative.

Ifthepolarityisconnectedinreverse,theHeightAuto-adjustedis

not available.

Created in Master PDF Editor

HP103PlasmaTorchHeightController

--9--

Our company’sisolateddivided voltage ratiois100:1.The

divided voltage ratioissetupas100:1beforeourcompany’sheight

controllerleavefactory.

3.4IHSintroduction

Twotypes ofIHSstyle of heightcontroller

1. PlasmaShieldprotectorIHSinspecting style

The materialoftheprotectorshouldbemetallic. Theycan

transmiteachotherwhen itgetstothematerial.

ATTN:The cuttingtorchprotector IHSinspectingstyle is

suitableforabover-water cuttingonly.

Single

Working process: After the heightcontroller receivesthe arc-on

signalwhichissentoutfromNC system,the cuttingtorchwill fall

downimmediately.Whentheprotector gettothematerial,the

Workpiece

Shield GND

Torch

Shield

IHS spring

Hoop

HISWiring

Magnetismring

Created in Master PDF Editor

HP103PlasmaTorchHeightController

--10--

heightcontrollerwillreceivethissignal,and thencontrolthecutting

torchtorisetothe given HeightofIHS.Theheightcontroller will

control theplasmatoarc onafterIHS.

2.inductiveproximityswitchIHSstyle(switchmode:NPN

Mode,2mm, outer diameter Ф12,the distanceofscrew

thread:1.0mm)

Whenthisstyle isadopted,theclientshoulddesignthetongs

accordingtheIHScuttingtorchtongssketchmap whichisprovided

byour company.All theplasmaIHS,whatever over-water cutting

and under-water cutting,can adoptthisIHSstyle. Pleaseadoptthe

approachswitchIHSstyle ifyou usethe high frequencyinputarc

plasmaand under-water cutting.

The tongssketchmap:Pleaseseetheappendix

BeforeIHS,theapproachswitchisonapproachingstatus.The

cuttingtorchwill riseoncetheswitchisbroken away.

Working process: After the heightcontroller receivesthe arc-on

signalwhichissentoutfromNC system,the cuttingtorchwill fall

downimmediately.When the cutting torchgetstothe material,the

approachswitchwill breakawayfromtheapproachingspot.The

heightcontroller receivesthissignal,and then controlsthe cutting

torchtorisetothegiven HeightofIHS(theapproachswitchwill

reposition automaticallyduring the rising).Theheightcontrollerwill

Created in Master PDF Editor

HP103PlasmaTorchHeightController

--11--

control theplasmatoarconautomaticallyafter IHS.ThisIHSstyle

issuitable forallplasmaIHS.

The approachswitchisconnectedtotheheightcontroller via

the SWITCH-IHSaviation socket.

3.5Socket

1、Thepower portsofarc voltage heightcontroller

The power ofarcvoltageheightcontroller isAC24V,connectsto

the height controllerJP2.

2、Theportconnectedtotheplasmacuttingtorch.

The motoroutputport:

The positionlimitedportsforLiftup anddropdown:

TO LIFTER TO CNC TO PLASMA

Workpiece Shield

inductive proximity

GND

AC24V

THCinside

Created in Master PDF Editor

HP103PlasmaTorchHeightController

--12--

ATTN:Position limited switchshouldmeetthe cutting –offspot

usually. setJP2,JP3canusethecutting –nospotusually。

3、Theportconnectedtoplasma

CON-PLASMAwith4core socketconnectstothe portJP6 in

main board.

PlasmaArc onsignal iscontrolledbymain board relayinheight

controller.Thearcvoltage will be postponed toenter intothe main

board.

4、TheportstotheNC system,theportcircuitbetween height

controllerandNC system.

Up

Down

Microcontroller

Arcrelay

Inputdelayrelay

Tomicrocontroller

Inputvoltage

Created in Master PDF Editor

HP103PlasmaTorchHeightController

--13--

There are 6portswithphotoelectricityinsulated style between

singlechipandNC system

A、AUTO/MANUALsignal(EXAUTO):AUTOdependsonhigh

electricitylevel,HAND withlowelectricitylevel.Can usetheJP7

set totheoppositestate

B、UP:It will risewhen lowelectricitylevel isavailable.

C、DOWN: It will drop when lowelectricitylevel isavailable.

D、IHSArc-onsignal (IHSARCON):Itisavailable forlow

electricitylevel.IHSshouldbeprocessed before working.The

arc-onwill be automaticallyonceIHSfinished.

E、The arc-on signal withoutIHS(EXARC ON):Itisavailable

for lowelectricitylevel.Arc-on directly.

F、Arctransfer1andPiercetransfer2 (ARCTRANS1、

ARCTRANS2):

Signal type :relay

5、InductiveProximityswitchIHSport

Microcontroller

Created in Master PDF Editor

HP103PlasmaTorchHeightController

--14--

6.Isolated divided voltage board wiring diagram.

ATTN:

1.Toreducenoiseemission,20AWG(0.5mm2) shielded

cableisrecommended.

2.The arclead inTHC isnegative,ifthepole mis-connected,

THC can notwork.

3.HF plasmamustuseisolationvoltage divide.Theactualarc

outputshould be connected atplasma’srectifier output,better

notconnectdirectlytoElectrodeand workwhere haveserious

HF interferenceduring arcstartingtime.

4.Non IsolationVoltage Divide isbackupforIsolationvoltage

divide.On non isolation voltage divide.AC220V power can be

unconnected.

Proximity switch

Created in Master PDF Editor

HP103PlasmaTorchHeightController

--15--

Electrical Schematic

Chat 2

Created in Master PDF Editor

HP103PlasmaTorchHeightController

--16--

Chat3

Created in Master PDF Editor

HP103PlasmaTorchHeightController

--17--

Chart 4

Created in Master PDF Editor

HP103PlasmaTorchHeightController

--18--

Chart 5

AC220VPOWER Voltage- Voltage+

Out- Out+

Isolate vol-div out

100:1None

isolation

vol-divide

output

Created in Master PDF Editor

HP103PlasmaTorchHeightController

--19--

3.4Parameter adjusted:

Clockwiserotation becomesbigger,counterclockwiserotation

becomessmaller.

RP402:Inputarc voltage amplifyset.

RP401:Internalimitationarc voltage set.

RP104:Arc maxerror setup.Initialization:030

Duringthe cuttingcourse,thecuttingtorchhavethe cuttingcrack (out-inline),

the arcvoltagewillbe raised immediately.IfnoARC_MAX_ERROR,the

cuttingtorchwill bumptothematerialwithhighspeed.Thetorchwillbe

damaged.So setupthisparametercanprotect thecuttingtorch.

RP501:AutoPWM amp.

Thisparameterisusedforsettingup thePWMspeedadjustedcoefficient

when the arcvoltageischanging.The parameterisbigger,moresensitivefor

theheightcontroller.Buttherunningstabilityofthecuttingtorchwillgetlower.

RP401RP402 JP1

RP104

RP31

JP2 JP3

RP501 RP102

RP225

JP8

JP5JP6

JP7 SP2

R6012

RP403

Created in Master PDF Editor

HP103PlasmaTorchHeightController

--20--

Onopposite,the parameterissmaller,sensitivewill be lowerand the running

stabilitywillbe higher.Soaappropriatecoefficientselectedcangetagood

balancebetween the sensitiveand stability.

RP102: Controlvoltage zeroadjustment

RP31:Arcvoltage displayvalue adjustment

RP225:Arc voltage delayinput timesetup.

Thearcvoltagewill beaffected seriouslyduringthe leadingarc.So the arc

voltagewill be delaytoput inthecircuit.

RP403:Torchcutting end,torchrisetime.

JP1:Set downinputtheexternal arc voltage.

Setup inputthe internal imitationarc voltage.

JP2:Selectthetype ofUplimitedswitch.

SetdownusetheNormallyopen spot.

Setup usetheNormallyclosedspot.

JP3:Selectthetype ofDownlimitedswitch.

SetdownusetheNormallyopen spot.

Setup usetheNormallyclosedspot.

JP5:Selectthetype ofproximityswitch.

Setup useNPNnormallyclosed.

SetdownusePNPnormallyopen.

JP6:Set isolationshielddelay.

JP7:AUTO/MANUALsignal(EXAUTO)

SetupAUTOwithlowelectricitylevel.

SetdownAUTOwithhighelectricitylevel.

Created in Master PDF Editor

Table of contents

Other HEAVTH Controllers manuals