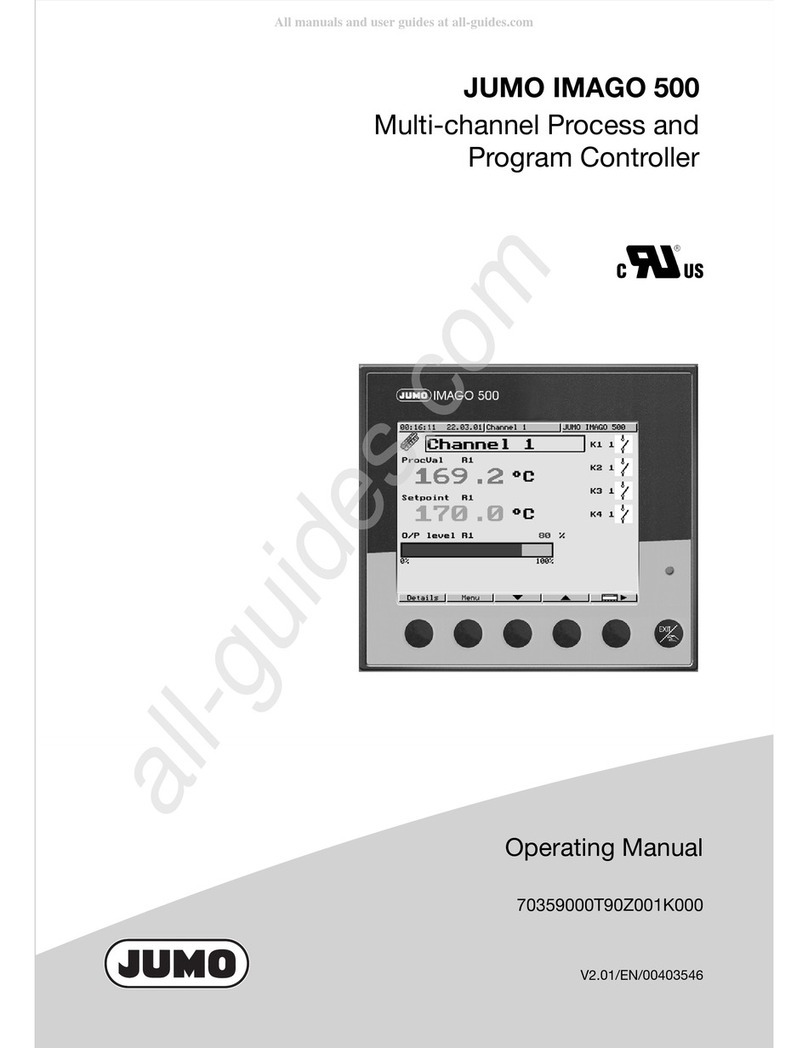

JUMO IMAGO 500 User manual

Other JUMO Controllers manuals

JUMO

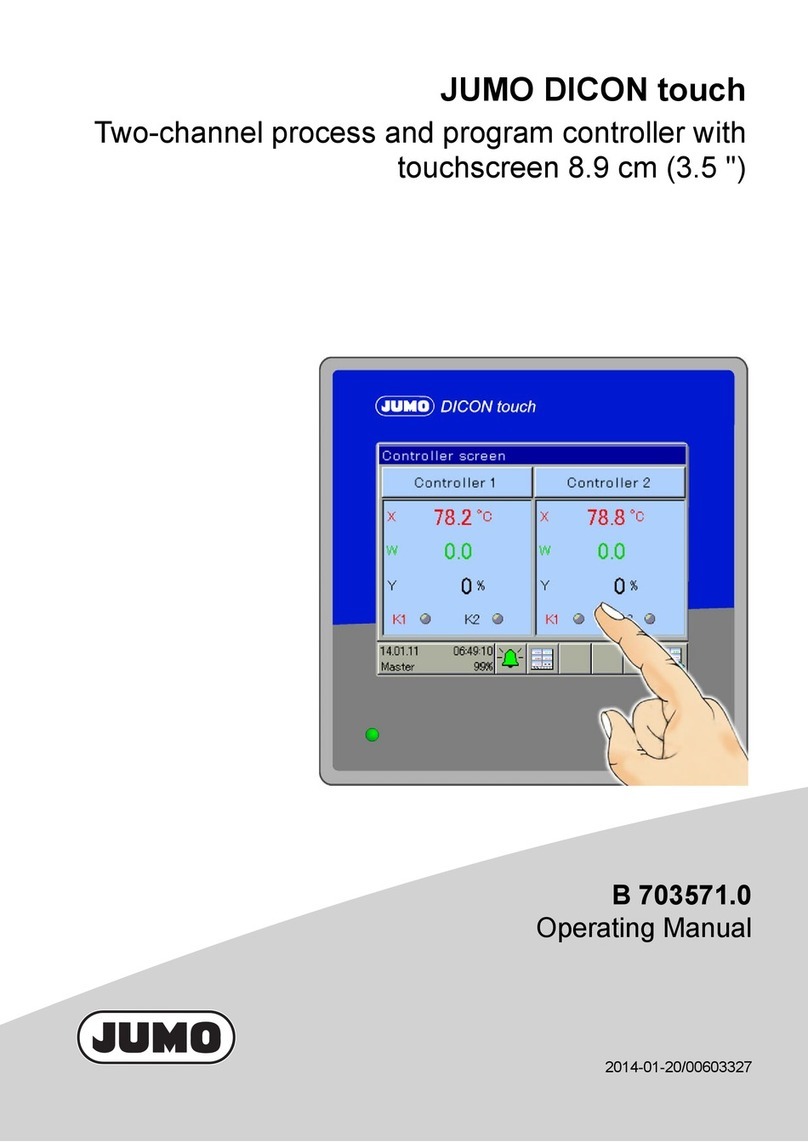

JUMO DICON touch User manual

JUMO

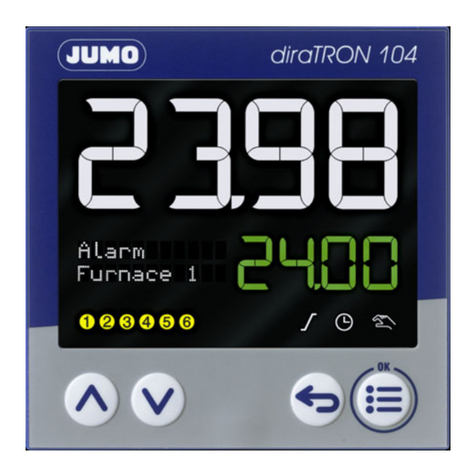

JUMO diraTRON Series User manual

JUMO

JUMO cTRON 04 User manual

JUMO

JUMO DICON touch User manual

JUMO

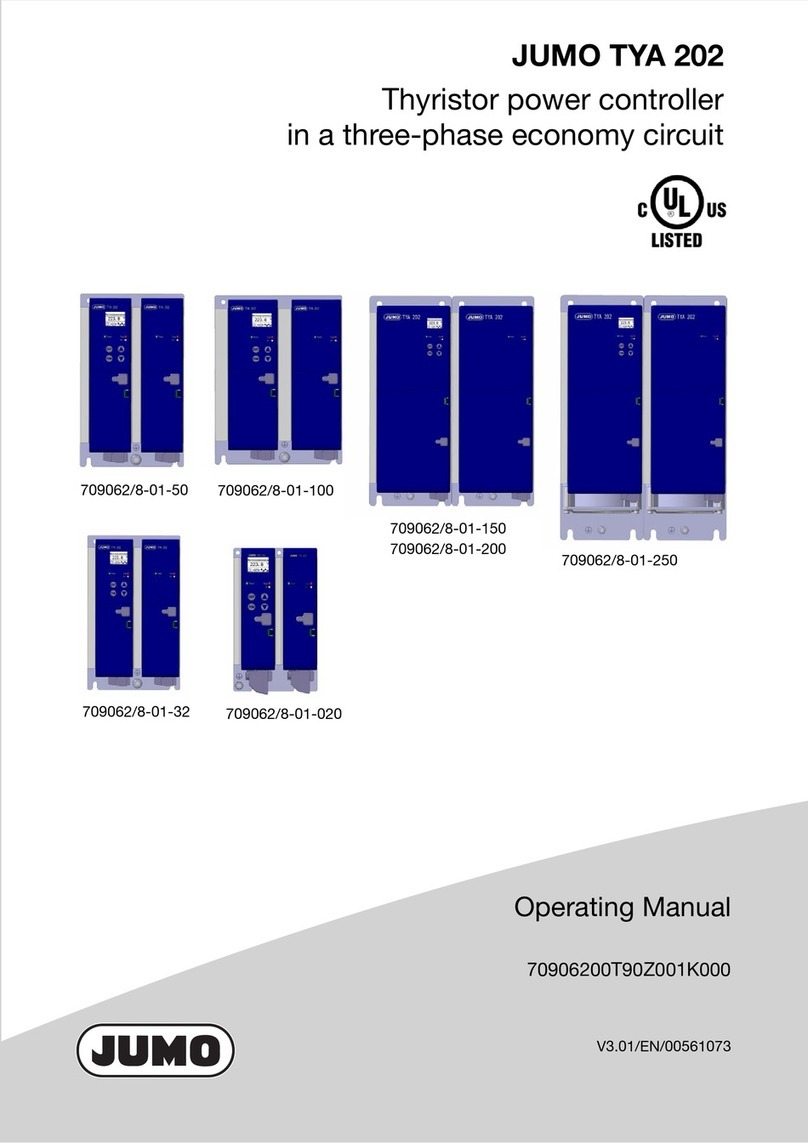

JUMO 709062/8-01-50 User manual

JUMO

JUMO dTRON 304 User manual

JUMO

JUMO cTRON 04 User manual

JUMO

JUMO Quantrol LC200 User manual

JUMO

JUMO B 703571.0 User manual

JUMO

JUMO IMAGO 500 User manual

JUMO

JUMO DICON 400 User manual

JUMO

JUMO TYA 202 User manual

JUMO

JUMO eTron M 100 User manual

JUMO

JUMO iTRON DR 100 User manual

JUMO

JUMO AQUIS 500 RS User manual

JUMO

JUMO dTRON 304 User manual

JUMO

JUMO IMAGO 500 User manual

JUMO

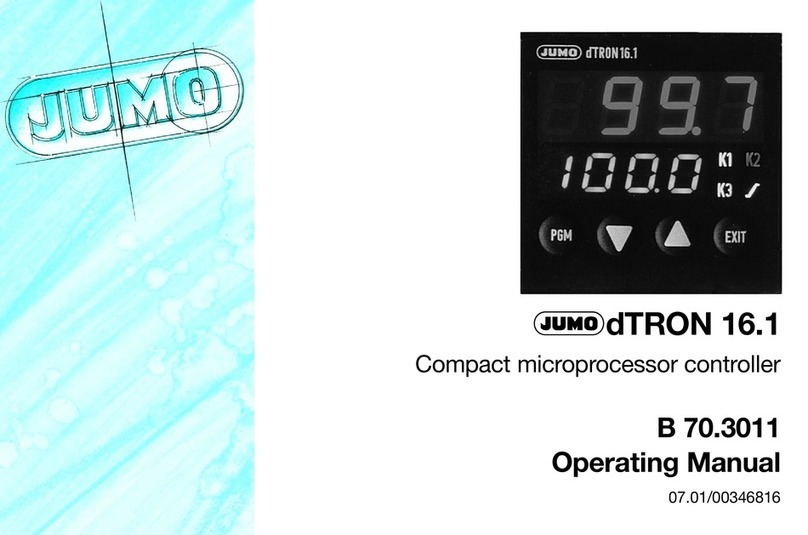

JUMO dTRON 16.1 B 70.3011 User manual

JUMO

JUMO AQUIS 500 pH User manual

JUMO

JUMO dTRANS CR 02 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions