Table of Contents

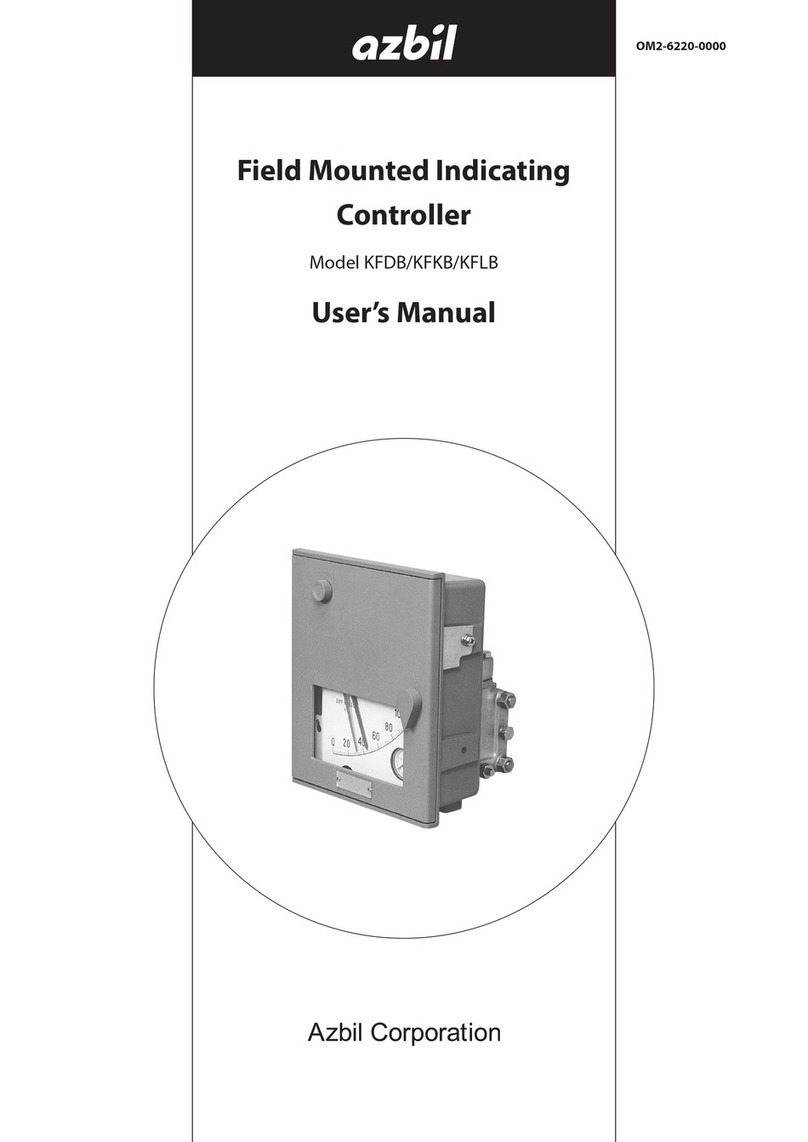

1: Description

1-1: General.............................................................................................................. 1

1-2: Structure ........................................................................................................... 1

1-3: Specifications................................................................................................... 2

1-3-1: Common specifications.............................................................................................. 2

1-3-2: Specifications of pressure element............................................................................ 3

1-3-3: Specifications of temperature element ...................................................................... 3

1-3-4: Specifications of accessories..................................................................................... 4

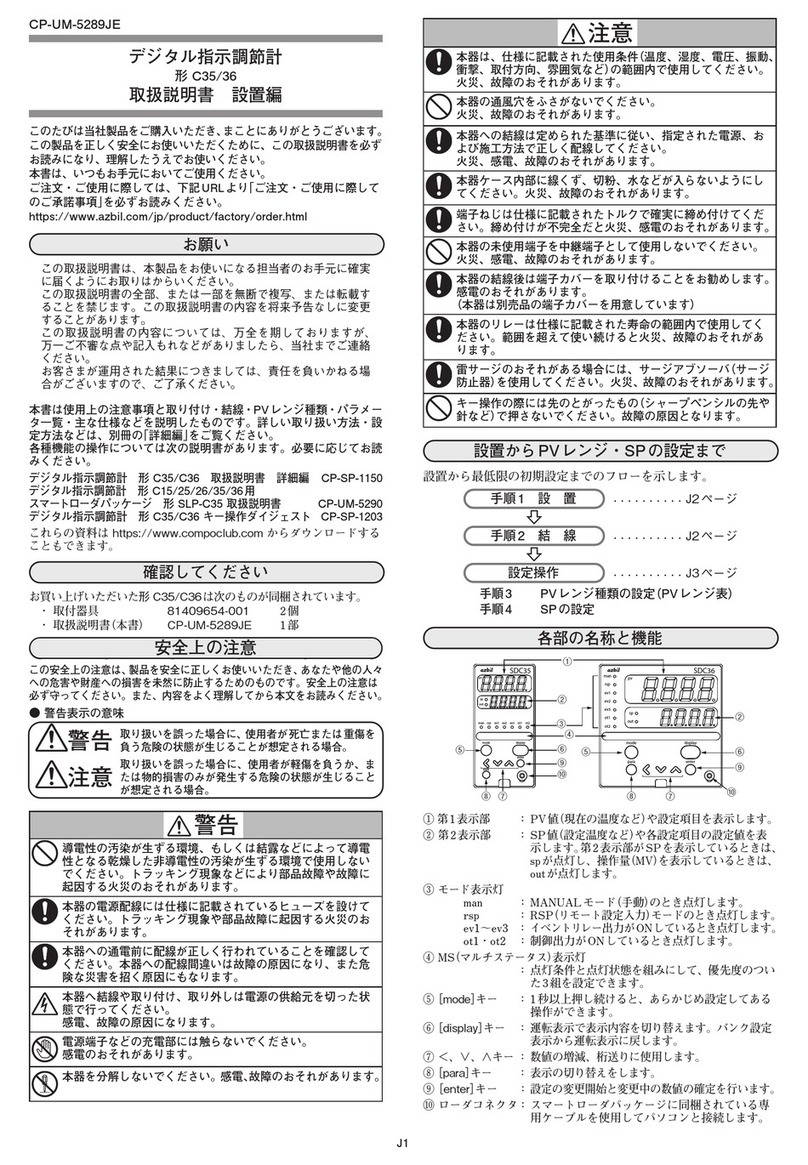

2: Indicating controller section

2-1: General.............................................................................................................. 5

2-2: Descriptions of mechanisms .......................................................................... 5

2-2-1: Deviation generating mechanism .............................................................................. 5

2-2-2: Control mechanism.................................................................................................... 6

2-2-3: Manual controller unit ................................................................................................ 9

2-2-4: Pneumatic signal receiver unit (set point pointer)...................................................... 10

2-2-5: Batch switch unit ........................................................................................................ 10

3: Installation

3-1: Air piping .......................................................................................................... 11

3-2: Connection method ......................................................................................... 11

3-3: Pressure element............................................................................................. 12

3-4: Temperature element....................................................................................... 13

4: Operation

4-1: Preparations for operation.............................................................................. 15

4-2: Pressure control .............................................................................................. 15

4-2-1: For liquid or gas measurement .................................................................................. 15

4-2-2: For steam measurement............................................................................................ 16

4-3: Manual operation ............................................................................................. 18

4-4: Automatic operation ........................................................................................ 18

4-5: Unusing the rate action................................................................................... 19

4-6: Setting of batch switch.................................................................................... 19

5: Calibration and adjustment

5-1: Deviation generating mechanism................................................................... 20

5-2: Controller mechanism ..................................................................................... 21

5-2-1: Balance adjustment for controller proportional band ................................................. 21

5-2-2: Calibration of reset and rate units.............................................................................. 22

5-2-3: Other calibration and adjustment procedures............................................................ 24

5-3: Adjustment of set point indication................................................................. 28

5-4: Transmitter unit................................................................................................ 29