HEAVTH HP105 User manual

海斯科技-让切割更精彩

HP105

Plasma Arc voltage torch height

controller

Operation Manual

VISION:1404

HEAVTH SCIENCE&TECHNOLOGY

130# MINGXING ROAD MINGHUANG TOWN

CHANGZHOU CITY JIANGSU.CHINA

TEL:86-0519-89182619 FOX:86-0519-89183619

HP105 Plasma arc voltage height controller

第- 2 - 页 共 23 页

1.IMPORTANT INFORMATION

1.1 SERVICE ASSISTANCE AND CONTACT INFORMATION

For service assistance, have the following information available:

• HP105 model, part and serial number located on a label

• Type of cutting application you are using

1.2 RECEIVING AND UNPACKING

After receiving the HP105 you should:

• Carefully, unpack and inspect the equipment.

• Compare the received shipment with the packing list.

• Report any damage to the carrier and your representative.

• Store equipment that will not be used in a clean, dry location.

• Take appropriate precautions to prevent moisture, dust and dirt

from accumulating in storage and installation areas.

1.3 SAFETY CONSIDERATIONS

Safety practices should not be an after thought. Before installing

or servicing the controller, review and follow applicable policies and

procedures to ensure worker safety. Machinery must be in a safe

state and you must be aware of any additional hazards that can

arise.

1.4 PRE-INSTALLATION CONSIDERATIONS

Before installing the HP105:

• Check to be sure that you have all of the required parts.

• Familiarize yourself with the parts of the HP105.

HP105 Plasma arc voltage height controller

第- 3 - 页 共 23 页

• Check to be sure that the torch lifter motors you are using with

the HP105 are within the acceptable range.

• Review the instructions for Configuring the Lifter Mechanics.

1.5 CONFIGURING THE LIFTER MECHANICS

Proper configuration of the torch lifter mechanism is an

important factor for establishing the accuracy of your cutting system.

Be sure that:

• Gear reduction is selected on the torch lifter so that the

maximum suspension speed does not exceed 3000 mm/min (120

IPM). If higher accuracy is required, maximum suspension speed

should be set to 1500 mm/min (60 IPM).

• Gears, racks and spindles have minimal backlash.

• Oversizing is avoided. The mass of moving parts, including

armature inertia must be as small as possible. Motors with low

nominal RPM are preferred.

2. Brief Intro

2.1 Summarize

HP105 plasma arc voltage height controller is equipped with

constant current plasma . During cutting course, the current

always equals the given current. And the cutting arc voltage will

be changed with the fixed speed being the height of torch changing.

When the distance gets farther ,the arc voltage increases; On

opposite, the arc voltage will decrease. HP105 plasma arc voltage

HP105 Plasma arc voltage height controller

第- 4 - 页 共 23 页

height controller will inspect the voltage change, then control the

distance between cutting torch and material via the lift motor. So

that the arc voltage is fixed, the same is the height of cutting torch.

Generally, the instruction will list all the cutting parameters for

some type of plasma . The user can refer to these parameters.

Adjust the voltage in arc voltage height controller to match the

selected current. The torch height will keep constant under regular

speed.In fact,the user should set the arc voltage according to the

height of the cutting torch.

In the status of automation ,the arc voltage more high,then the

height of the cutting torch more high

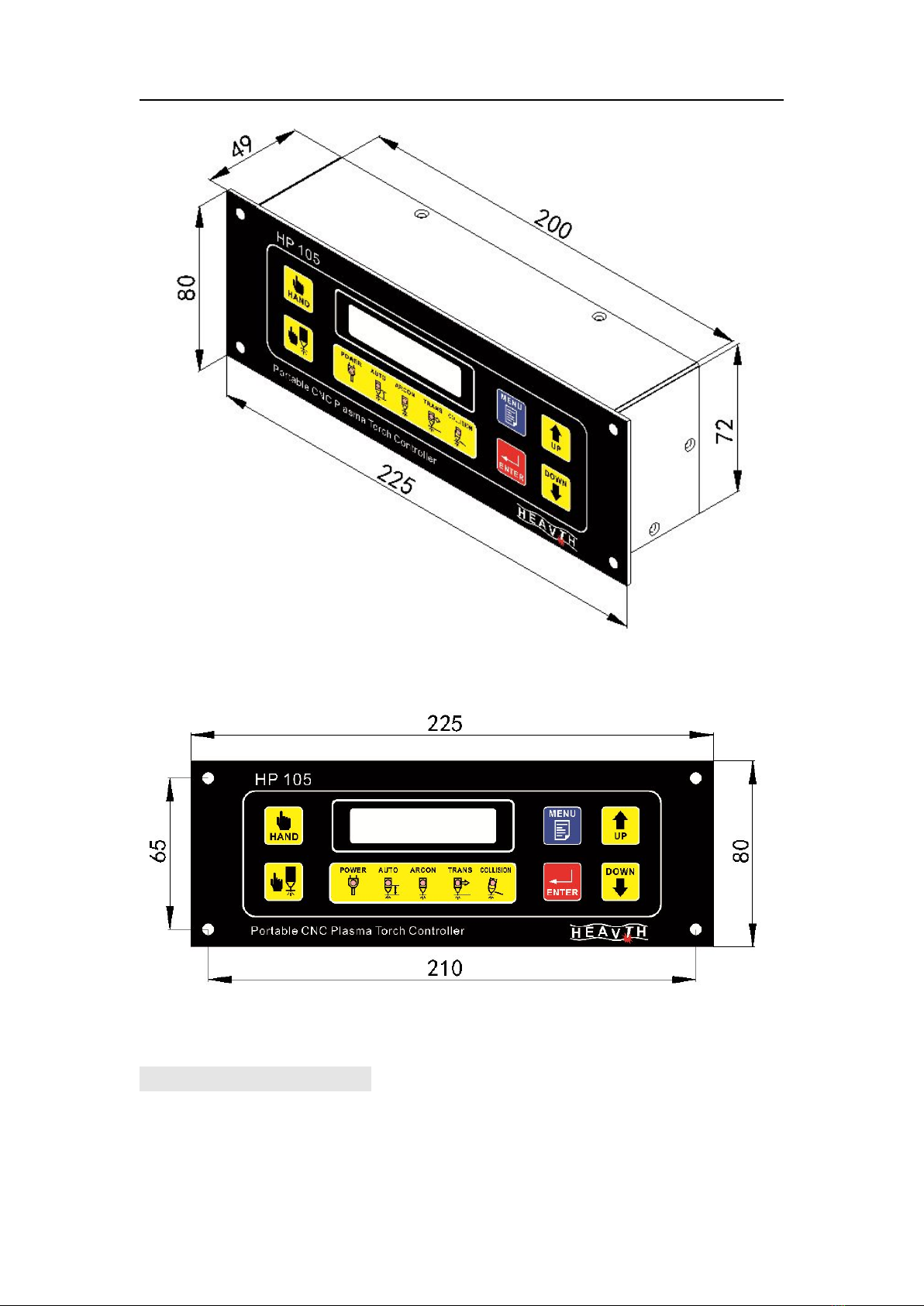

2.2

Dimensions

:

HP105 Plasma arc voltage height controller

第- 5 - 页 共 23 页

Mounting Hole Size:

2.2 Technical parameter

Working voltage: DC24±10%,50Hz/60Hz,Please prepare a

isolated power, do not shared with others such as electronic

HP105 Plasma arc voltage height controller

第- 6 - 页 共 23 页

valve . Especial Pay more attention the DC 24V

Lift motor: DC24V DC motor

Drive mode: PWM

Output current:1A-4A.

Working temperature: Height controller -10∽60℃

IHS style: Switch inspecting IHS (suitable for all plasma

both above-water and under-water cutting),Plasma Shield

Protector IHS (suitable for above-water cutting’s touch

leading arc voltage plasma)

Running transfer: Alternative Arc transfer and pierce transfer

Divided voltage ratio:100:1

Accuracy: ±1V∽±5V,adjustable

Outer Dimension: Length X Width X Height:

225mmX50mmX80mm

Weight: 0.8kg

Protection class: IP64, to prevent dust from entering.

Installation connector: 2-pin, 4-pin, 5-pin, DB-9 core

Installation position: Keep away from heat, air convection good place.

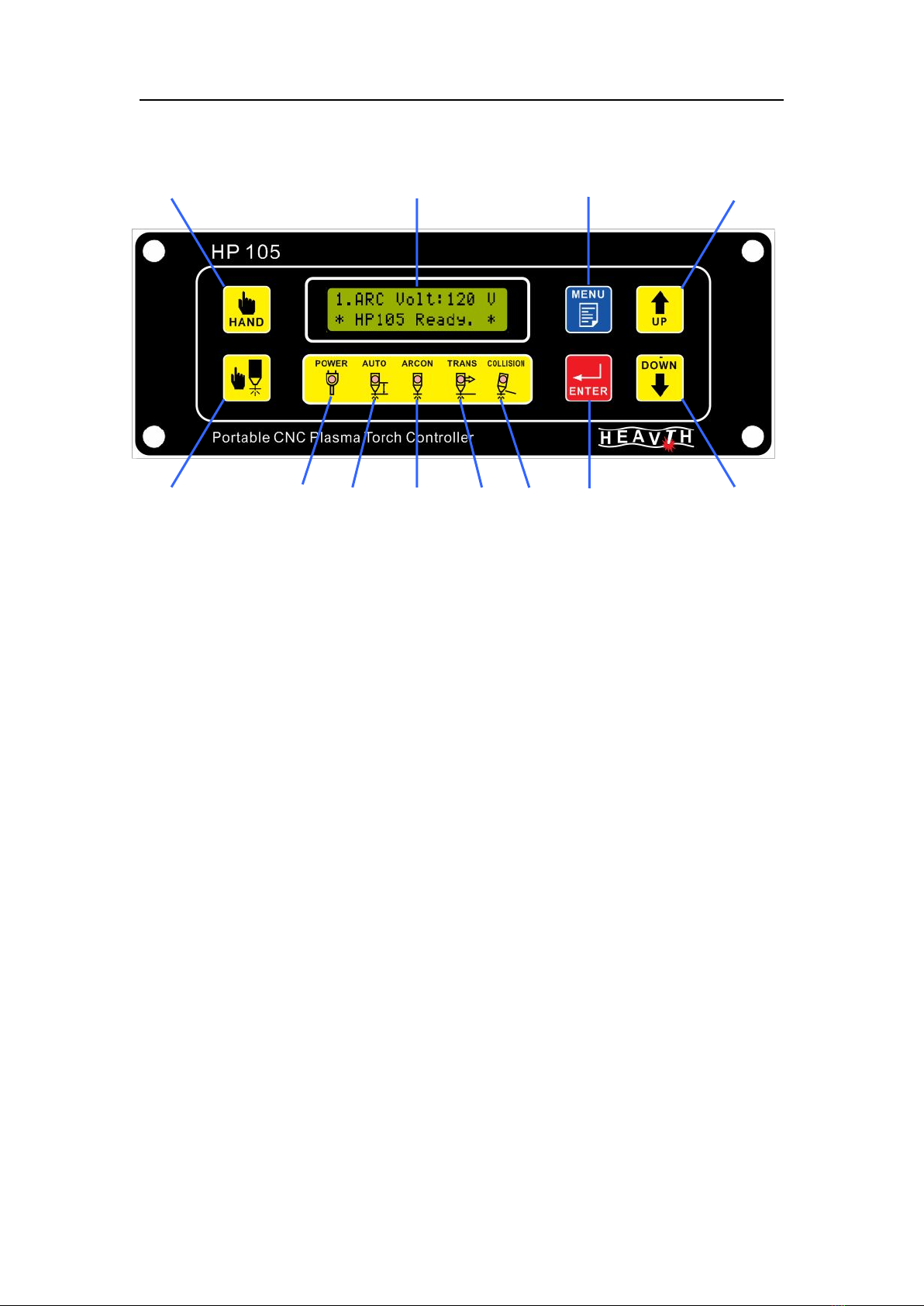

2.4

Operation Panel Features

Rise

Menu

LCD

HP105 Plasma arc voltage height controller

第- 7 - 页 共 23 页

下降

起弧测试

自动

起弧

电源

反馈

碰撞

Manually

确认

Function Description:

LCD: display the working status and parameters.

Manual: Auto / Manual mode selection increase, alternating work.

Arc test: standby press, arcing into the test mode.

When arcing test, press to return to standby mode.

Menu: In standby mode press to enter the parameter setting mode.

When the parameter setting Press to return to standby.

Confirmation: parameter setting mode, confirm that the set

parameters.

Rise / fall: In standby mode, manual lifting torch.

When parameter setting, subtraction parameter values.

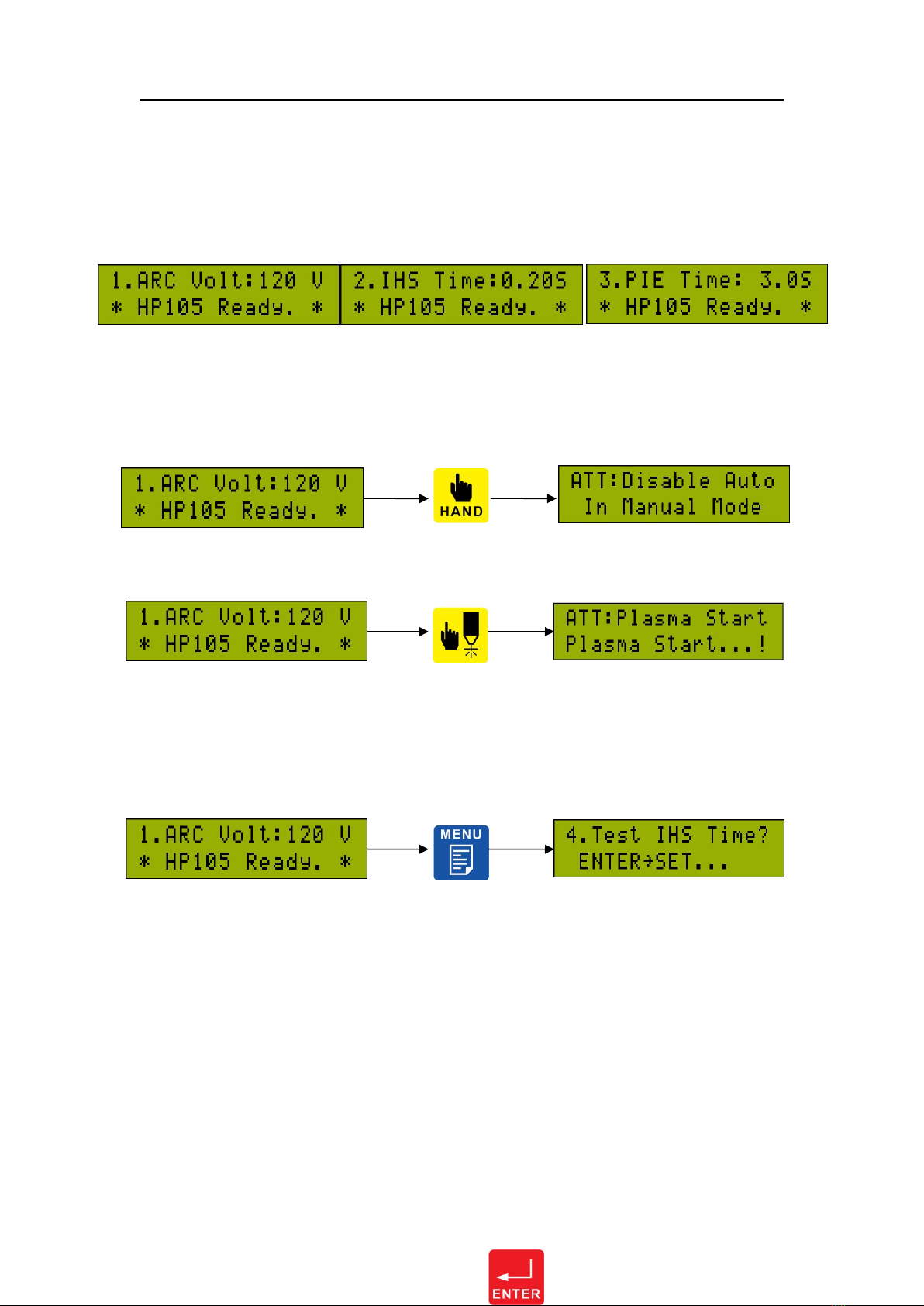

2.5

parameter settings

HP105 Plasma arc voltage height controller

第- 8 - 页 共 23 页

Automatic standby state, the LCD second planetary number flashing, and

cycles through the following parameters:

Standby mode, press the manual key to enter the manual mode,

then you must manually control the cutting height:

Standby mode, press arcing test, arcing into the test mode:

Standby mode, press the Menu key, select 4, press the Enter key to enter the positioning test

mode:

Set Arc Voltage:

This parameter is set automatically track ions and other torch

height.

Arc voltage value, the higher the torch distance. Arc voltage

value, the lower the torch distance.

Standby interface

1.Setting arc voltage

2. When initial positioning

3. When arcing perforation

HP105 Plasma arc voltage height controller

第- 9 - 页 共 23 页

Set the initial positioning time:

This parameter sets the arc height, before and after start cutting torch fell across the workpiece,

elevation time.

Positioning higher the value, the higher the arc height. Positioning the smaller the value, the lower

the arc starting height.

Press the Menu

key

Enter key to enter

Up and Down keys to

adjust the parameters

ENTER to

confirm

The arrow keys to

select the parameter

Menu key to

return

Standby interface

Press the Menu

key

Up and Down keys to adjust

the parameters

The arrow keys to

select the parameter

HP105 Plasma arc voltage height controller

第- 10 - 页 共 23 页

Set perforation time:

When this parameter is set arc torch perforation time,

according to the workpiece

thickness is set.

Perforation higher the value, the longer the piercing

time. Perforated smaller the

value, the smaller the perforation time.

Standby interface

Press the

Menu key

Enter key to enter

Up and Down keys to adjust

the parameters

ENTER to confirm

The arrow keys to select the

parameter

Menu key to

return

Enter key to enter

ENTER to

confirm

Menu key to

return

HP105 Plasma arc voltage height controller

第- 11 - 页 共 23 页

3. installation and commissioning

3.1 Work process:

When CNC system’s output arc signal to the HP105’s interface J2-4,

the height controller should process the IHS firstly; Secondly

auto-control the Arc-on, the height controller will send the signal of

arc transfer and pierce transfer to the NC system after producing

the transfer arc. At the mean time, the controller delay time to put

the arc voltage into the single chip system. If “Auto Permitted is

available in height controller and NC system has sent out AUTO

height adjusted signal, the controller is on status of “Height Auto

adjusted”

ATTN: When the cNC system that you use can not receive the

signal of arc-on and pierce, please delay the time to control the NC

system’s running. It just means that the cNC system send arc-on

signal to the height controller, delay time to run the cNC system.

3.2 INSTALLATION CONTROLER

:

The following section provides you with the procedure to follow

when installing the HP105 Some of the steps direct you to other

sections in this manual that provide you with more detailed

instruction.

HP105 Plasma arc voltage height controller

第- 12 - 页 共 23 页

1. Determine a mounting location for the HP105. Keep the

following points in mind:

To avoid overheating and potential damage to the control box

from cutting process fumes, DO NOT choose a mounting location

directly above the torch.Find a mounting location away from the

torch lifter unit.

2. Attach the wires from the CNC,the plasma,the lifter motor and

lifter limit switches to a connector and then to the control box at the

receptacle. To reduce noise emission, 20 AWG (0.5 mm2) shielded

cable is recommended. Filters consisting of a resistor and capacitor

can be connected only directly to the motor.

3. Connect a 12 AWG (2.5 mm2) ground wire to the ground

screw located on the control box and then, to the machine ground

rail of your cutting system.

3.3 Divided voltage board

Controlling the arc voltage must inspect the changing of plasma

arc voltage. The plasma arc voltage equals the voltage that is

between the pole and ground. The anticathode which put out the

plasma power is connected to the ground. The Cathode connects

to the pole which is in the cutting gun. So the voltage in the

HP105 Plasma arc voltage height controller

第- 13 - 页 共 23 页

electrode is negative. When process the cutting, the arc voltage

absolute value is usually higher than 100V. If so, the voltage must

be divided in order to process the control in the controlling circuit.

ATTN: the voltage that put into the height controller is negative.

If the polarity is connected in reverse, the Height Auto-adjusted is

not available.

The controller built-in isolation stars platen default input 1:1 Actual

arc voltage (when the partial pressure ratio of 100: 1) 1. For some comes

with 50: 1 non-isolated sub-plate plasma can set the input of 50: 1 low

pressure (in this case the partial pressure ratio of 2: 1).

Enter the arc voltage is set by DIP switch on the back of the controller to

set:

DIP switch to on: Input 1: 1 actual arc voltage.

DIP switch to the next: Enter 50: 1 arc voltage dividing.

初始定位介绍

本公司的调高器设计有两种定位方式,有条件的情况

下,推荐同时使用,以提高定位的可靠性。

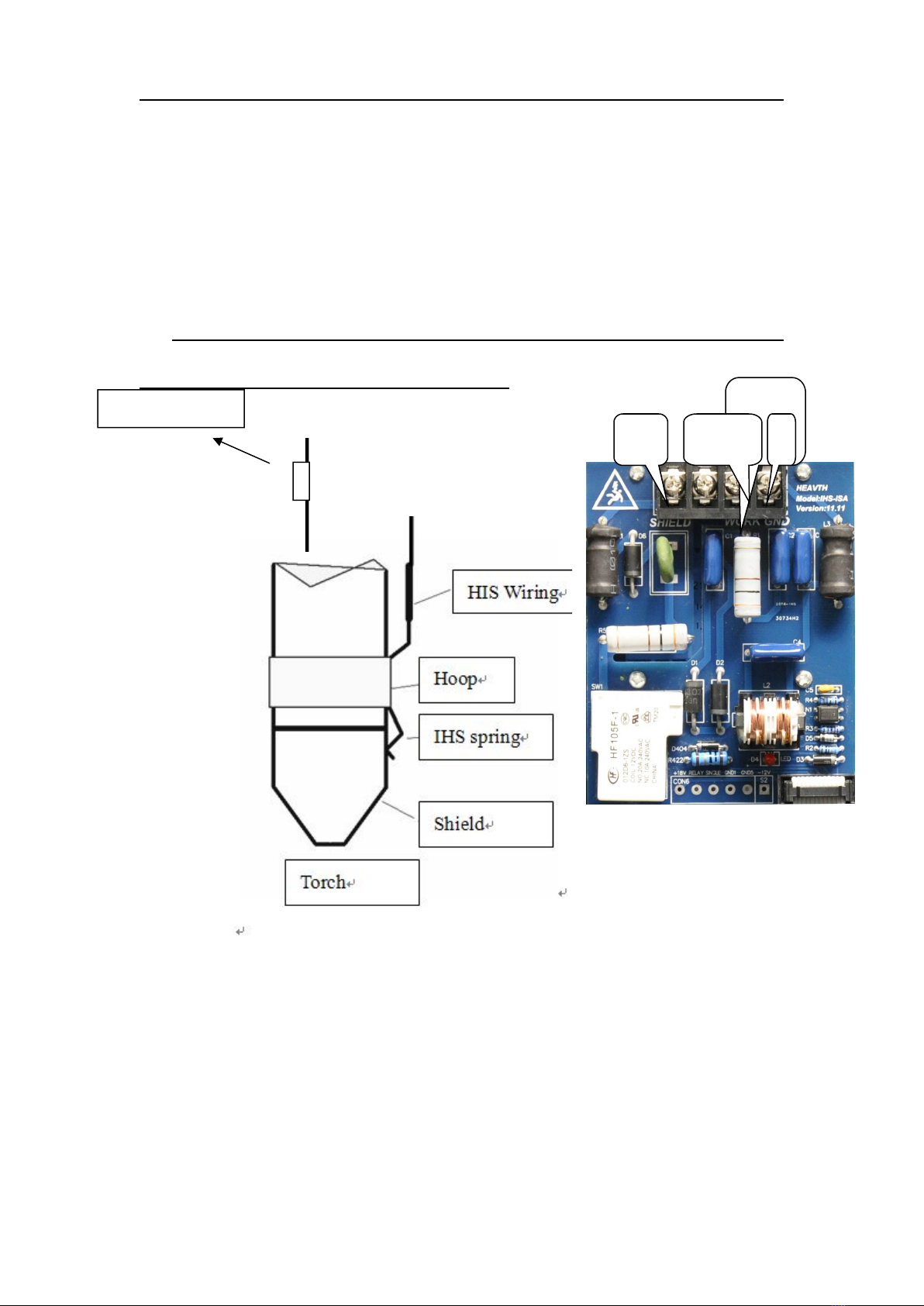

3.4 IHS introduction

Set the input

voltage arc

HP105 Plasma arc voltage height controller

第- 14 - 页 共 23 页

Two types of IHS style of height controller

1. Plasma Shield protector IHS inspecting style

The material of the protector should be metallic. They can

transmit each other when it gets to the material.

ATTN :The cutting torch protector IHS inspecting style is

suitable for abover-water cutting only.

Single

Working process: After the height controller receives the arc-on

signal which is sent out from NC system, the cutting torch will fall

down immediately. When the protector get to the material, the

height controller will receive this signal, and then control the cutting

torch to rise to the given Height of IHS. The height controller will

Magnetism

ring

Workpiece

Shield

GND

Floating

Magnetism ring

HP105 Plasma arc voltage height controller

第- 15 - 页 共 23 页

control the plasma to arc on after IHS.

2. inductive proximity switch IHS style(switch mode: NPN

Mode, 2mm, outer diameter Ф12, the distance of screw

thread:1.0mm)

When this style is adopted, the client should design the tongs

according the IHS cutting torch tongs sketch map which is provided

by our company. All the plasma IHS, whatever over-water cutting

and under-water cutting, can adopt this IHS style. Please adopt the

approach switch IHS style if you use the high frequency input arc

plasma and under-water cutting.

The tongs sketch map: Please see the appendix

Before IHS, the approach switch is on approaching status. The

cutting torch will rise once the switch is broken away.

Working process: After the height controller receives the arc-on

signal which is sent out from NC system, the cutting torch will fall

down immediately. When the cutting torch gets to the material, the

approach switch will break away from the approaching spot. The

height controller receives this signal, and then controls the cutting

torch to rise to the given Height of IHS (the approach switch will

reposition automatically during the rising). The height controller will

control the plasma to arc on automatically after IHS. This IHS style

is suitable for all plasma IHS.

HP105 Plasma arc voltage height controller

第- 16 - 页 共 23 页

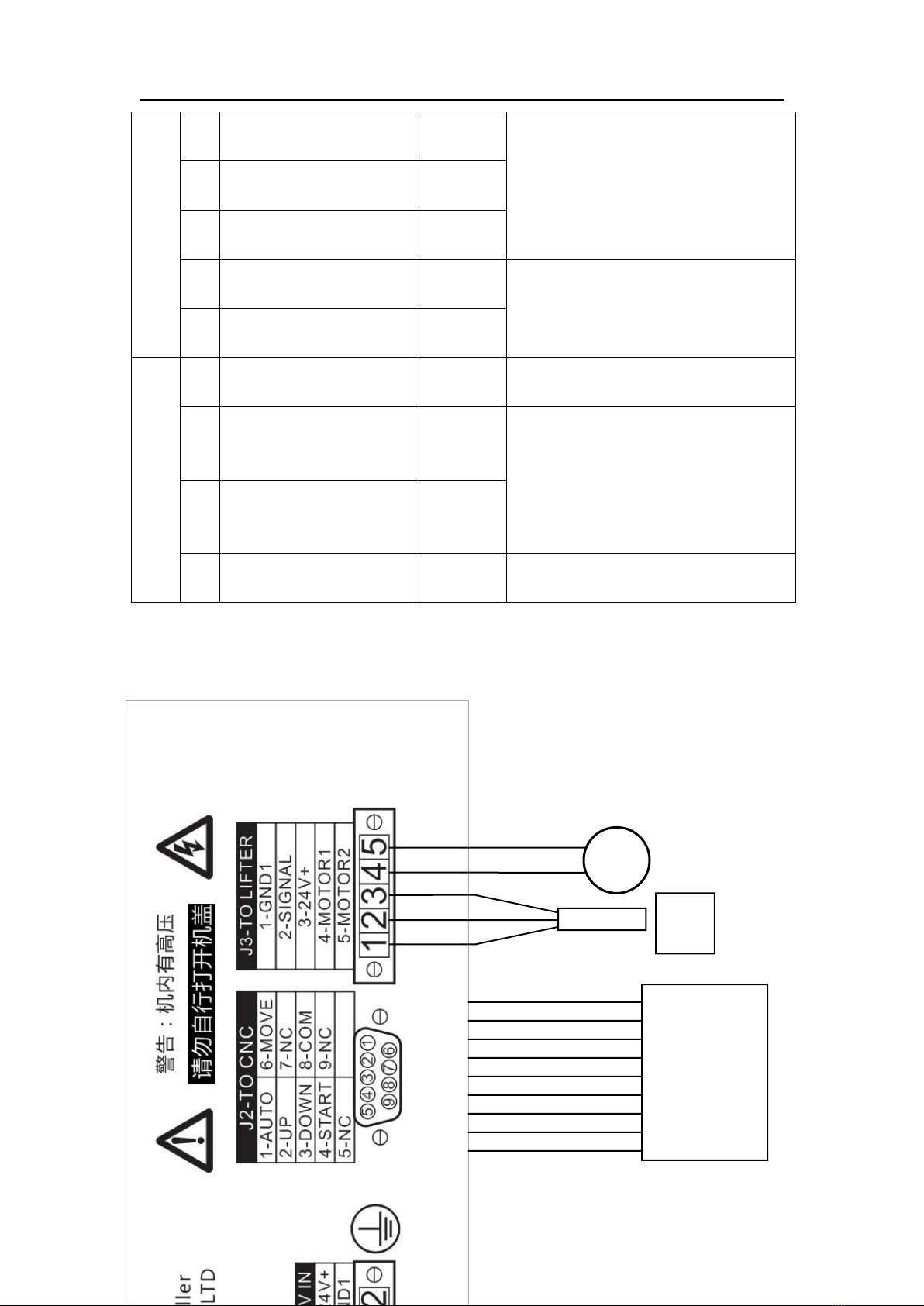

By raising the J3-1,2,3 aviation plug is connected to the proximity

switch.

3.3

Interface Circuit

Interfa

ce

Signal

input

Output

Remark

J1

1

DC 24V +

input

Connect switching power supply.

2

DC 24V -

input

J2

1

Automatic signal (corner

signal)

input

Raised manually (with the

common ON)

2

Manual rise

input

Manual rise (and the common terminal

connected)

3

Manually drop

input

Manually decrease (and common

ON)

4

With locating arcing

input

Start positioning arc (the

common terminal connected)

5

Floating

6

Arcing complete (machine

running)

output

Control machine running

7

Floating

8

Signal common

Common

J2 port signal common

9

Floating

HP105 Plasma arc voltage height controller

第- 17 - 页 共 23 页

J3

1

Proximity switch to

output

Connected NPN type positioning

proximity switches, 1-2 foot signal NC.

When using ordinary mechanical switch

normally closed switch 1-2 pin connector

pin 3 unconnected.

2

Proximity switch signal

input

3

Proximity Switch Power

output

4

DC

output

Permanent magnet motor, maximum

40W

5

DC

output

J4

1

actual arc voltage

negative

input

Plasma arc voltage actual negative

2

Arcing signal

output

Plasma arc switching signal.

3

Arcing signal

output

4

actual arc voltage positive

input

Plasma actual arc voltage positive

p

M

24V

直流电机

Blue

Black

Brown

NPN

接近开关

1foot-automatic

signal (corner signal)

9 feet - vacant

8 feet-input common

7 feet-vacant

6feet-arcing

5 feet - vacant

4 feet - with locating

3feet-Manual fall

2 feet - Manual rise

CNC

数控系统

HP105 Plasma arc voltage height controller

第- 18 - 页 共 23 页

Electric lift body recommended limit switch wiring:

Arc Voltage input Note:

The controller built-in isolation stars platen default input 1: The actual arc

voltage 1. For carrying part 50: a non-isolated sub-plate plasma can be

input is set to 50: 1.

1. Do the actual arc voltage lines connected directly to the ground clip

and the torch cable.

2. The arc voltage height controller to the motor cable should be shielded

cable, shielding connected to the machine ground.

3. plasma power and arc voltage height control must be strictly grounded.

Note Check before arcing torch height and ground clip.

4. Domestic plasma power: its arc voltage must be taken from the

DC24V+

DC24V-

1:1actual arc

voltage+

Plasma arc

Plasma arc

1 : 1 actual

arc voltage-

Plasma

power

supply

DC24V

Switchin

g Power

Supply

HP105 Plasma arc voltage height controller

第- 19 - 页 共 23 页

high-frequency arc-grade and reactor before. Plasma samples from the

position of the rectifier output.

5. Any control cables and a plasma torch cable wiring should be as far

away from (5cm above), to prevent the high-frequency signal is coupled

to control, damage control and CNC systems.

HP105 Plasma arc voltage height controller

第- 20 - 页 共 23 页

Parameter setting screen, hold UP and DOWN at the same time more than three seconds, into the

implicit parameter setting.

NO.

parameter name

Parameter meaning

Factory

Settings

1

MAX_PWM

Maximum pulse width

120

2

MIN_PWM

minimum pulse width

30

3

IHS_UP

initial positioning pulse

width

100

4

IHS_DOWN

initial position by pulse

width

100

5

HAND_PWM

Up and down pulse width

manually

120

6

ARCV_ERR

Arc voltage protection

scope

020

7

EN_BREAK

brake can make

01

8

PWM_AMP

Automatic sensitivity

005

9

UP_BREAK

Increase reverse braking

time

030

10

DN_BREAK

By reverse braking time

080

11

EMG_LIFT

Promotion time of

emergency

020

12

EMG_ PWM

Emergency pulse width

120

13

ADJ_RANGE

Arc pressure intelligent

adjusting range

015

14

ADJ_STEP

The size of arc voltage

intelligent adjustment

002

15

ADJ_EN

Arc pressure intelligent

effective adjustment

000

16

ARC_ACC

Arc pressure precision

01

17

PEI_EN

Perforation signal can

make

01

18

AUTO_UP

Broken arc cutting torch

when hoisting height

10

19

ERR_STOP

Arc pressure anomalies can

stop making

00

20

DELAY_IN

When the arc rolling access

05

21

RESET(18)

Restore the factory value

00

Table of contents