HEAVY MOTIONS HM589 Series Operating instructions

[INSTALLATION & OWNERS’ MANUAL - POWER TAKE-OFFs]

HM589Series

www.HeavyMotions.com

CONTENTS

SAFETYINFORMATION

PTOSAFETYLABELS

PTOINSTALLATION

CHECKINGBACKLASH

AIRSHIFTINSTALLATION

PTOANDPUMP/DRIVENUNITASSEMBLY

DirectMountPump

PTOMAINTENANCE

PTOOPERATION

1

2

3

6

8

12

12

15

16

PTO589‐IOM‐1512 HeavyMotions,Inc.|HM589SeriesPTOs 1

SAFETYINFORMATION

Pleasereadthismanualcarefullyuntilyouunderstanditbeforeinstallingor

usingthePowerTakeOff(PTO).

ThePTOmustbeproperlymatchedwiththevehicle’stransmissionand

thedrivenequipmentoritcouldcauseseveredamagetotheequipment

and/ormaycauseseriouspersonalinjurytotheoperatorandothers

nearby.

Exposedrotatingdrivingshaftsmusthavesomeformofguardtoensure

safety.

DONOTgounderthevehiclewhentheengineisrunning.

DONOTworkonornearanexposedrotatingshaftwhentheengineis

running.

DONOTuseworn‐outordamagedcomponents.

DONOTworkalonewhileinstalling,repairing,ormaintainingany

equipmentunderthevehicle.

Followtheproperprocedureandusethepropertoolsandsafety

equipment.

TheoperatorshouldreceivepropertrainingregardingthePTOoperation.

2HeavyMotions,Inc.|HM589SeriesPTOsPTO589‐IOM‐1512 2

PTOSAFETYLABELS

1. Frameraillabel.Twoframeraillabelsaresupplied.Placeonthetruck

framerails,oneoneachside,inaplacewhereitcouldbeeasilyseenby

anyonegoingunderthetrucknearthePTO.

2. PTOControlLabel.PlaceclosetothePTOcabincontrolvalveordevice.

3. VisorLabel.Placeonthevisornearthedriver.

PTO589‐IOM‐1512

HeavyMotions,Inc.|HM589Series

PTOs 3

PTOINSTALLATION

1. Draintheoilfromthetransmission

andcleanthecoverplateandthe

surroundingarea.

2. Removethecoverplatefromthe

PTOapertureonthetransmission

(Fig.1).

3. InspectthetransmissionPTOdrive

geartomakesureitisingood

condition.

4. Withyourhand,rockthePTOdrive

gearinthetransmissionandthe

inputgearinthePTOassemblyto

establishtheamountofbacklashin

eachunit.

5. Inordertopreventdirtfrom

enteringthetransmission,putarag

intheaperturehole.

6. Removethegasketonthe

transmissionopeningandcleanthe

apertureusingaputtyknifeorwire

brush(Fig.2).

Fig.1

Fig.2

4

HeavyMotions,Inc.|HM589SeriesPTOs

PTO589‐IOM‐1512 4

7. Installthestudsintothetapped

holesofthetransmission’sPTO

aperture(Fig.3).Makesurethe

studsdonotinterferewiththe

gearsofthetransmission.

8. Torquethestudsto18‐22lbs.ft

(24‐30N.m).Overtighteningthe

studsmaydamagethethreadsin

thetransmissionhousing.

9. Placetheproperamountofgaskets

(Useatleastonegasketbutdonot

stackmorethan3gasketstogether)

(Fig.4).Usuallyone0.020”gasket

willberequired,butmoregaskets

mayberequiredwhenestablishing

properbacklash.Donotusegasket

sealerbecauseyoumayneedto

addorremoveagasketwhen

adjustingthebacklash.

Fig.3

Fig.4

PTO589‐IOM‐1512

HeavyMotions,Inc.|HM589Series

PTOs 5

10. Removetheshiftcoverfromthe

PTOandmountthePTOonthe

transmission(Fig.5).Makesure

thattheoutputshaftisonthe

desiredposition.

11. Installthewashersandnuts(Fig.

6).Torquethenutsto:

30‐37lbs.ft(40‐50N.m)on

6‐boltapplications

50‐60lbs.ft(68‐80N.m)on

8‐boltapplications.

Fig.5

Fig.6

6

HeavyMotions,Inc.|HM589SeriesPTOs

PTO589‐IOM‐1512 6

CHECKINGBACKLASH

1. RemovethePTOshiftcoverifitisstillonthePTO.

2. MountthedialindicatoronthebodyofthePTOorthebodyofthe

transmissionsoitmeasuresthemovementofthePTOinputgear.See

Figure7fortheproperlocationofthedialindicatorcontactpoint.Two

commontypedialindicatorsshown.

Fig.7.

3. MakesurethatthePTOdrivegearinthetransmissioncannotmove.

Holditwithascrewdriverorbar.

PointerIndicatesSide

Movement(0.006”/0.012”)

PlungerTypePointer

IndicatesDepth

RockPTO

InputGear

GasketPack

IndicatorOptions

PTO589‐IOM‐1512 HeavyMotions,Inc.|HM589SeriesPTOs 7

4. MovethePTOinputgearbackandforthwithyourhand.Readinthedial

indicatorthemeasurementofthebacklash.

5. Theproperbacklashshouldbe0.006”to0.012”(0.15mmto0.30mm).If

thebacklashisoutsidethisrange,adjustitbyaddingorremoving

gaskets.

Ifthebacklashistoolarge,removegasketsorselectathinner

gasket.

Ifthebacklashistoosmall,addgasketsorselectathickergasket.

8

HeavyMotions,Inc.|HM589SeriesPTOs

PTO589‐IOM‐1512 8

AIRSHIFTINSTALLATION

1. Placetheshiftcovergasket

onthePTOaperture(Fig.8).

Donotusesiliconeonthe

gasket.

2. InstallthePTOshiftcoverso

thattheforkisonthesame

sideoftheoutputshaft.

3. Makesuretheforkslides

intotheoutputgeargroove

(Fig.10).

Fig.8

Fig.9

Fig.10

Fork

Groove

PTO589‐IOM‐1512

HeavyMotions,Inc.|HM589Series

PTOs 9

4. ApplyadropofLoctite290

oneachcoverbolt.Install

bolts(Fig.11).

5. Torqueboltsto16‐20lbs.ft

(22‐27N.m).

6. Screwtheairfittingintothe

shiftcover(Fig.12).

7. Installthenylontubingthat

comesfromthecabin

controlvalveintothefitting

(Fig.12)

Important:

Makesuretheairsystem

hasinstalledapressure

protectionvalvebetween

theairsourceandthe

cabincontrolvalve.It

shouldopenat60‐70PSI.

Connectthepressure

protectionvalvedirectly

totheairsupplyusinga

nipple.Donotusetubing.

Fig.11

Fig.12

Wheninstallingthenylon

tubing,avoidsharpangles,

sharpedges,exhaustand

manifoldsystems.

Nylon

Tube

Fitting

10

HeavyMotions,Inc.|HM589SeriesPTOs

PTO589‐IOM‐1512 10

9. Connectthenylontubetothecabinsinglecontrolvalveorcombo

controlvalveairoutput(Seetheschematicsuppliedwiththevalve).

10. Connecttheswitchconnectorwiretothesinglecontrolvalveorcombo

valveindicatorlightconnectorsusingbuttconnectors(Seethe

schematicsuppliedwiththevalve).

8. Connecttheswitch

connectorintotheindicator

switch(Fig.13).

Fig.13

Indicator

Switch

Switch

Connector

PTO589‐IOM‐1512

HeavyMotions,Inc.|HM589Series

PTOs 11

Fig.14

DONOTFORGETTOREFILLTHETRANSMISSIONWITHCLEANOILUP

TOTHEPROPERLEVEL.

Tosingleor

combocabin

controlvalve

airoutput.

Tosingleor

combocabin

controlvalve

indicatorlight.

12

HeavyMotions,Inc.|HM589SeriesPTOs

PTO589‐IOM‐1512 12

PTOANDPUMP/DRIVENUNITASSEMBLY

DirectMountPump

1. Greasetheinnersplines

surfaceofthePTOoutput

shaftwithanti‐fretting,high

temperature,highpressure

grease.

2. Installthepumpintothe

PTO(Fig.15).Aftermaking

thepumpandPTOsplines

match,insertthepump

ensuringthatthecontact

withtheflangeopeningis

good.

3. Rotatethepumpsothatthe

holesfortheboltsonthe

pumpflangeandonthePTO

flangearealigned(Fig.16).

Fig.15

Fig.16

PTO589‐IOM‐1512

HeavyMotions,Inc.|HM589Series

PTOs 13

4. ApplyadropofLoctite290

oneachbolt,installwashers

andbolts(Fig.17).

5. Tightentheboltsin

oppositeangles,notin

sequence.Torqueboltsto

60‐70lbs.ft(82‐94N.m).

Fig.17

14

HeavyMotions,Inc.|HM589SeriesPTOs

PTO589‐IOM‐1512 14

Important:Useapumpbracketontherearofthepumptohelpsupportthe

weightofthepumpif:

Thecombinedweightofthepump,itsfittings,andhosesexceeds

40pounds(18Kg).

6. ThedistancebetweenthecenterlineofthePTOtotheendofthepump

is18inches(45cm)orlonger(Distance“D”Fig.18).

Fig.18

Thebracketmustbeattachedtoatleast2transmissionboltlocations

andatleast2pumplocations.Makesurethatthebracketdoesnot

preloadthepump/PTOmounting.

D

PTO589‐IOM‐1512 HeavyMotions,Inc.|HM589SeriesPTOs 15

PTOMAINTENANCE

Toensureasafeandtroublefreeoperation,theownerand/oroperatormust

performthefollowingperiodicmaintenance:

Daily:

Lookforairleaks,hydraulicleaks,andmakesurethemechanismsare

workingproperly.Performrepairsasrequired.

Monthly:

Tightenallair,hydraulicandhardwaretothepropertorque.

DirectMount:EnsurethatthePTOandPumpshaftsplinesareproperly

greased.Useanti‐fretting,hightemperature,highpressuregreaseonly.

RemoteMount:CheckthePTOdrivelinecomponentsforanoutofphase

condition,excessivevibration,excessiveu‐jointanglesorwornparts.

Performrepairsasrequired.

16HeavyMotions,Inc.|HM589SeriesPTOsPTO589‐IOM‐1512 16

PTOOPERATION

Important:FailuretofollowtheproperPTOoperationwillresultinpremature

PTOfailure.

StationaryApplications:ChockthewheelsbeforeengagingthePTO.

ManualTransmissions:

1. Pushintheclutchpedaltodisengagetransmissionandwaitafew

secondssothetransmissionstopsturning.

2. Shiftthetransmissionintoneutral.

3. EngagethePTOusingthedashmountedvalve.

4. Letclutchpedalout.

AutomaticTransmissions:

1. Letengineidle.

2. Applybrakes.

3. Placeshiftselectorinanydriverange.

4. EngagethePTOusingthedashmountedvalve.

5. Shifttransmissiontoneutralorpark.

NOTE:ExpectaslightincreaseinPTOnoiselevelasoilthinsoutatoperating

temperature.

PTO589‐IOM‐1512 HeavyMotions,Inc.|HM589SeriesPTOs 17

HeavyMotions,Inc.

Tollfree:1‐866‐865‐8889

Tel:909‐627‐1000

Fax:909‐498‐0468

www.HeavyMotions.com

Table of contents

Popular Power Tools manuals by other brands

Hilti

Hilti GX 3 operating instructions

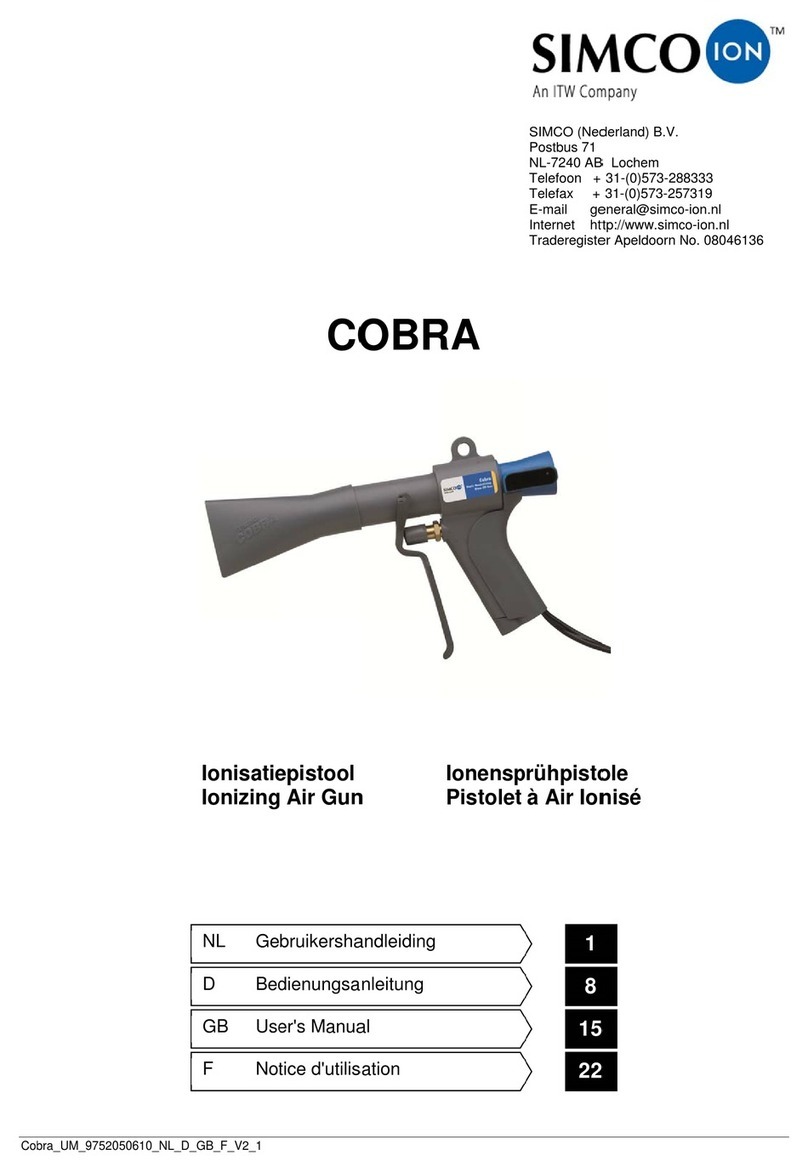

Simco

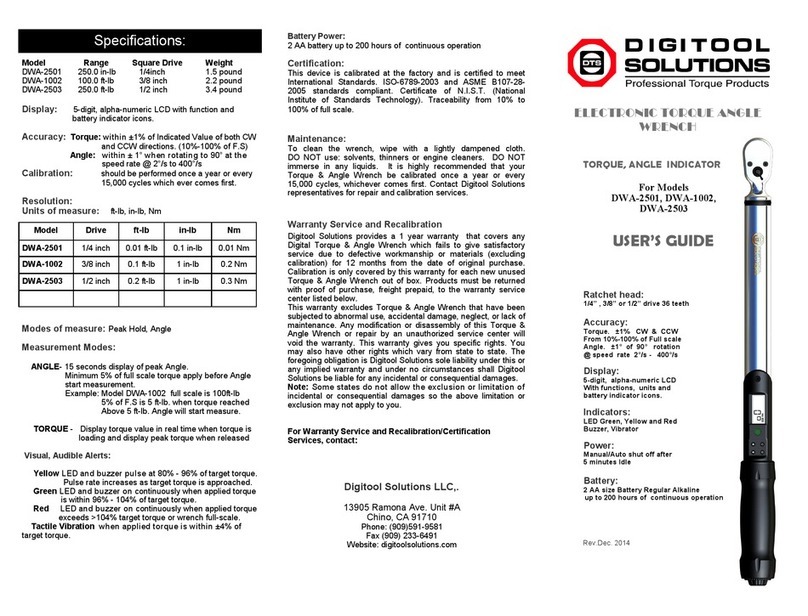

Simco COBRA user manual

Chicago Electric

Chicago Electric 61687 Operation manual and safety instructions

Clarke

Clarke STRONG-ARM CSA4B Operation & maintenance instructions

Bosch

Bosch GOP 30-28 Professional Original instructions

Graphite

Graphite 59G524 instruction manual