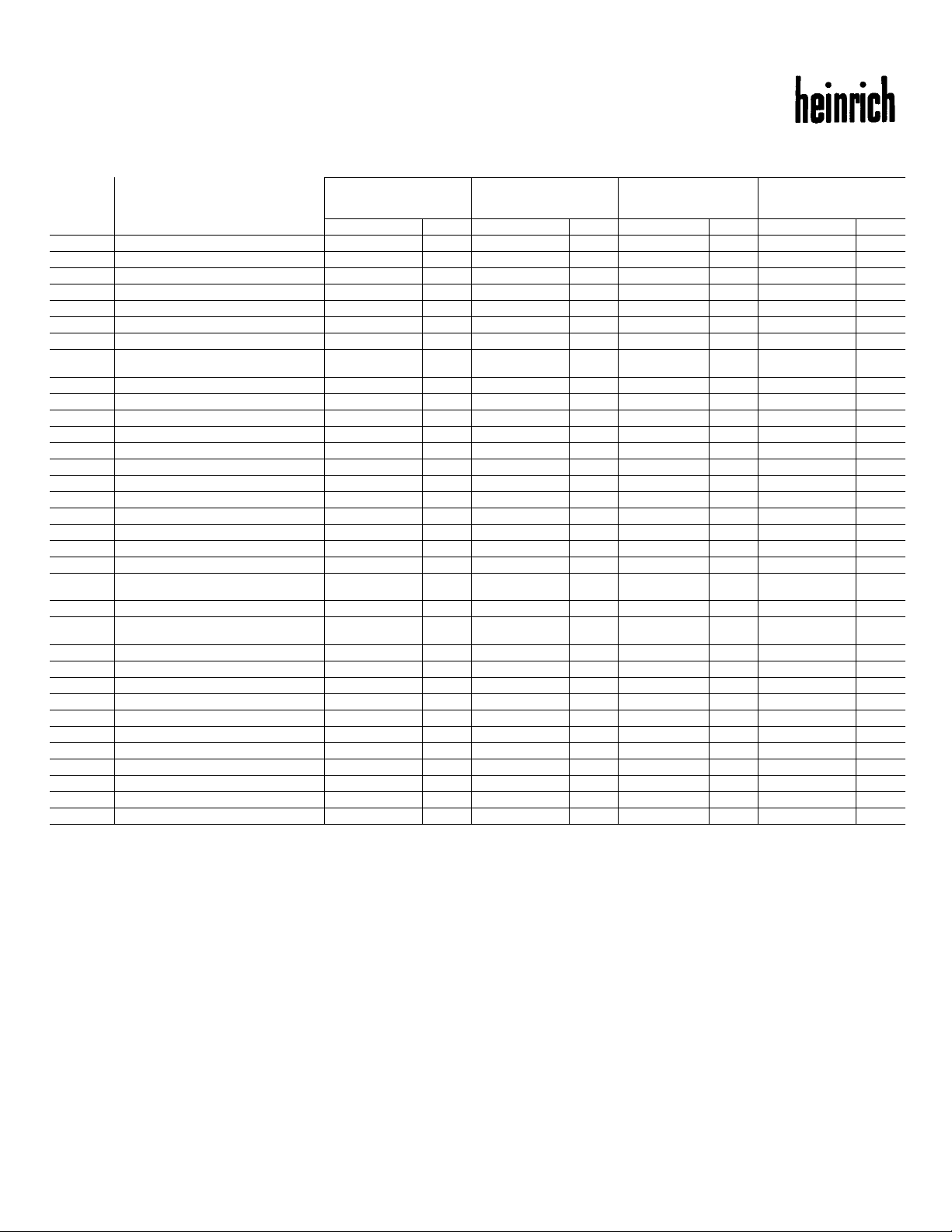

MODEL NUMBER

Index

3-SV

3-TS*

3-PA**

4-GM

4-TS*

4-GMPA**

6-SV

6-PA**

8-SV

8-PA**

No. Part Name Part No. Part No. Part No. Part No.

1

BodyCasting (Note 1)3-SV 4-GM 6-SV 8-SV

1

BodyCasting (Note 1)

3-TS* 4-TS* -- --

2JawCasting3-J 4-J 6-J 8-J

3Center Bar 313 GM-413 613 813

4Guide Bar (2 required) 314 414 614 814

5HandleGM-3415 GM-3415 6815 6815

5HandleTS-3415*TS-3415*-- --

6

Locking Ring SV-3416

(1/2”Hole)

GM-416

(5/8”Hole)

SV-6816

(3/4”Hole)

SV-6816

(3/4”Hole)

7HoldingRingPA-3416**GMPA-416**PA-6816**PA-6816**

8Spring,LockGM-417 GM-417 6817 6817

9Spring, HoldingPA-3417**GMPA-417**PA-6817** PA-6817**

10 Crank GM-3418 GM-3418 GM-6818 GM-6818

10 Crank TS-3418*

TS-3418*-- --

10 Crank, with1/8”RollpinGMPA-3418**

GMPA-3418**GMPA-6818**GMPA-6818**

11 JawInserts, regular (set of 2) 319

419

619 819

11 JawInserts, Hardened(set of 2) 319H

419H 619H 819H

12 Knob, Black -- 1" Dia., 1/4-20 thread SV-3421(*)-- -- --

12 Knob, Red --1" Dia., 1/4-20 threadRSV-3421**-- -- --

12 Knob, Black -- 1 1/2" Dia, 3/8-24 thread -- SV-6821(*) SV-6821 SV-6821

12 Knob, Red --11/2" Dia.,3/8-24 thread-- RSV-6821**RSV-6821**RSV-6821**

13

Knob, Black -- 1 1/8" x 1 7/16" oval,

3/8-16 thread OA-3421 OA-3421 -- --

13 Knob, Black -- 1" Dia., 1/4-20 thread SV-3421* SV-3421* -- --

13

Knob, Red -- 1 1/8" x17/16" oval,

3/8-16 thread ROA-3421**ROA-3421**-- --

13 Knob, Black -- 1 1/2" Dia., 3/8-24 thread -- -- SV-6821 SV-6821

13 Knob, Red --11/2" Dia.,3/8-24 thread-- -- RSV-6821**RSV-6821**

14 Stud3423 6823 6823 6823

15 Screw-- 10-32 x 1/4 (2 required) 27 27 27 27

16 Screw-- 1/4-20 x 5/8(2) 30-5/8-- -- --

16 Screw-- 1/4-20 x 3/4 (2) 30-3/4(6) 30-3/4(6) 30-3/4(6) 30-3/4

17 AdjustingScrewSV-31 SV-31 SV-31 SV-31

18 Adjusting Screw– FemalePA-32**PA-32** PA-32** PA-32**

19 Adjusting Screw– MalePA-33**PA-33** PA-33** PA-33**

20 CoverPlate3437 3437 6837 6837

21 Shoulder Screw39 39 39 39

Note 1. Price not shown, as replacement body castings are not available. View shown is 4-GM with side extension. Models 3-SV, 6-SV and 8-SV do not have

side extensions. 3-TS and 4-TS have both sides ground at right angles to jaw inserts.

WHEN ORDERING PARTS, INDICATE PART NUMBER, MODEL NUMBER AND PRICE.

(Cont. from prev. page) pressure before replacing locking

plate. To assemble Pumping Action "PA" Locking

Mechanisms, the following steps must be carefully followed:

1. Insert crank (10), keeping handle lever (5) in vertical position

during entire assembly.

2. Insert rear portion of adjusting screw (18), screwing same in

as far as it will go.

3. Place the holding ring (7) behind crank so that the pin

extending from the crank fits into the slot of the holding ring.

4. Insert center bar (3) through the holding ring far enough so

that the holding spring (9) can be slipped on.

5. Insert front portion of the adjusting screw (19) as far as it will

go.

6. Insert locking ring (6) and push center bar through same.

7. Insert locking spring (8), locating same correctly in relation

to the center hole.

8. Adjust both adjusting screws until the rear portion (18)

makes contact with the holding ring and the front portion (19)

makes contact with the locking ring.

9. Push center bar through entire unit.

10. Turn adjusting screw front portion (19) a 3/4 turn clockwise,

and adjust rear portion (18) until the bar moves freely – making

sure that the handle lever is in vertical position against stop.

11. Adjust forward portion of adjusting screw (19) until desired

pressure is obtained.