Hedman EDP2000 User manual

HEDMAN EDP 2000

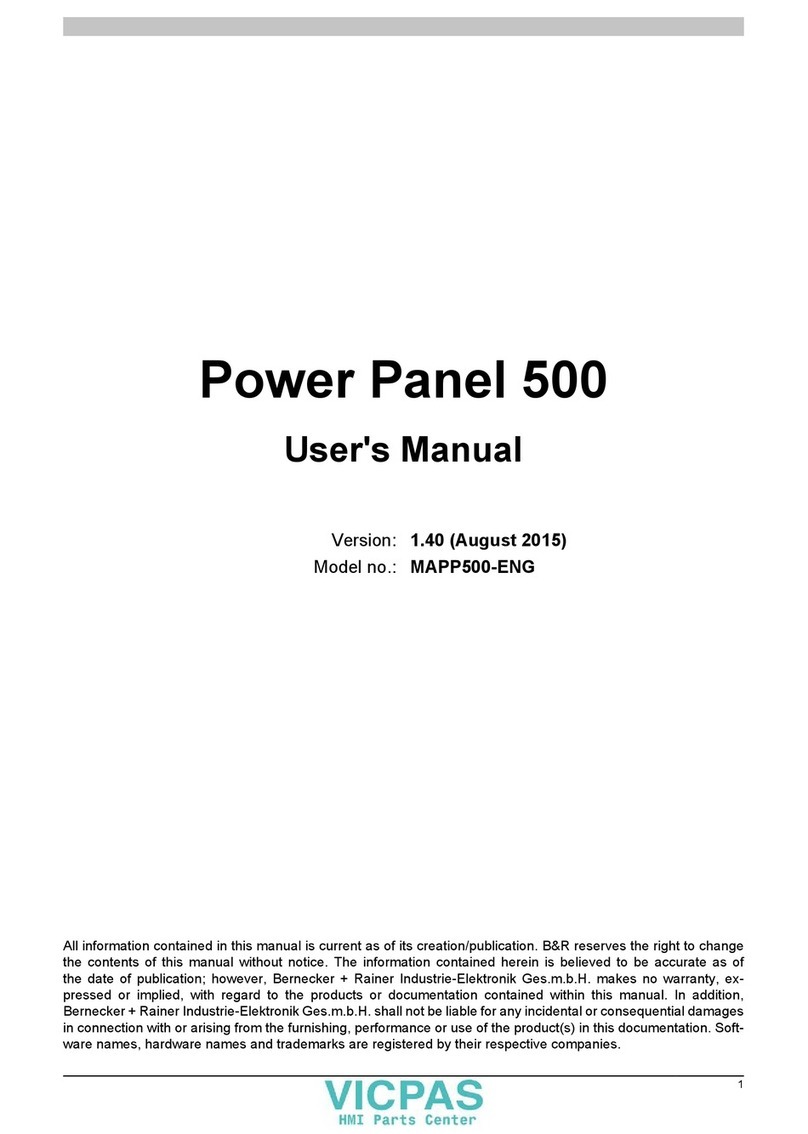

COUNTER 00000

RESET

AUDIT

COUNTER

START

STOP

3-1/2”

7”

CHECK

SIZE

00000

OFF/ON

OPERATING INSTRUCTIONS

EDP1000

&

EDP2000

CONTINUOUS

FORM SIGNER

HEDMAN

®

MODEL EDP1000 & EDP2000 DIFFERENCES

FEATURE MODEL EDP2000 MODEL EDP1000

ON/OFF Key Lock Power Switch

Form Size Key Lock None

Select 3-1/2" or 7"

Audit 6 Digit None

Counter Non-resettable

Stop Push Button None

PLEASE BE SURE THAT YOU CAREFULLY

READ ALL INSTRUCTIONS BEFORE

OPERATING YOUR CONTINUOUS FORM SIGNER.

SPECIFICATIONS

UNIT

Width 25-1/4" (64.1 cm)

Depth 9" (22.9 cm)

Height 14-3/4" (37.5 cm)

Weight 39 lbs. (17.7 kg)

Electrical 115 Volts, 60 Hz.

FORMS

3-1/2" or 7" High up to 17" Wide

Multiple carbon or carbonless interleaved forms

Weights up to 125 lbs (56.7 kg).

Your Continuous Form Signer is fully assembled

except for the ink roll, which must be installed before operating the

signer. Refer to Page 8, Figure 10, for ink roll installation instructions.

Manufactured by: The Hedman Company

189 Gordon Street

Elk Grove Village, IL 60007-1118

(847)718-6500

FAX (847)718-0603

© 1990 The Hedman Company

Printed in U.S.A.

Form No. 198228HF (Rev.B)

Manufactured by:

The Hedman Company

189 Gordon Street

Elk Grove Village, IL 60007-1118

(847)718-6500

FAX (847)718-0603

1

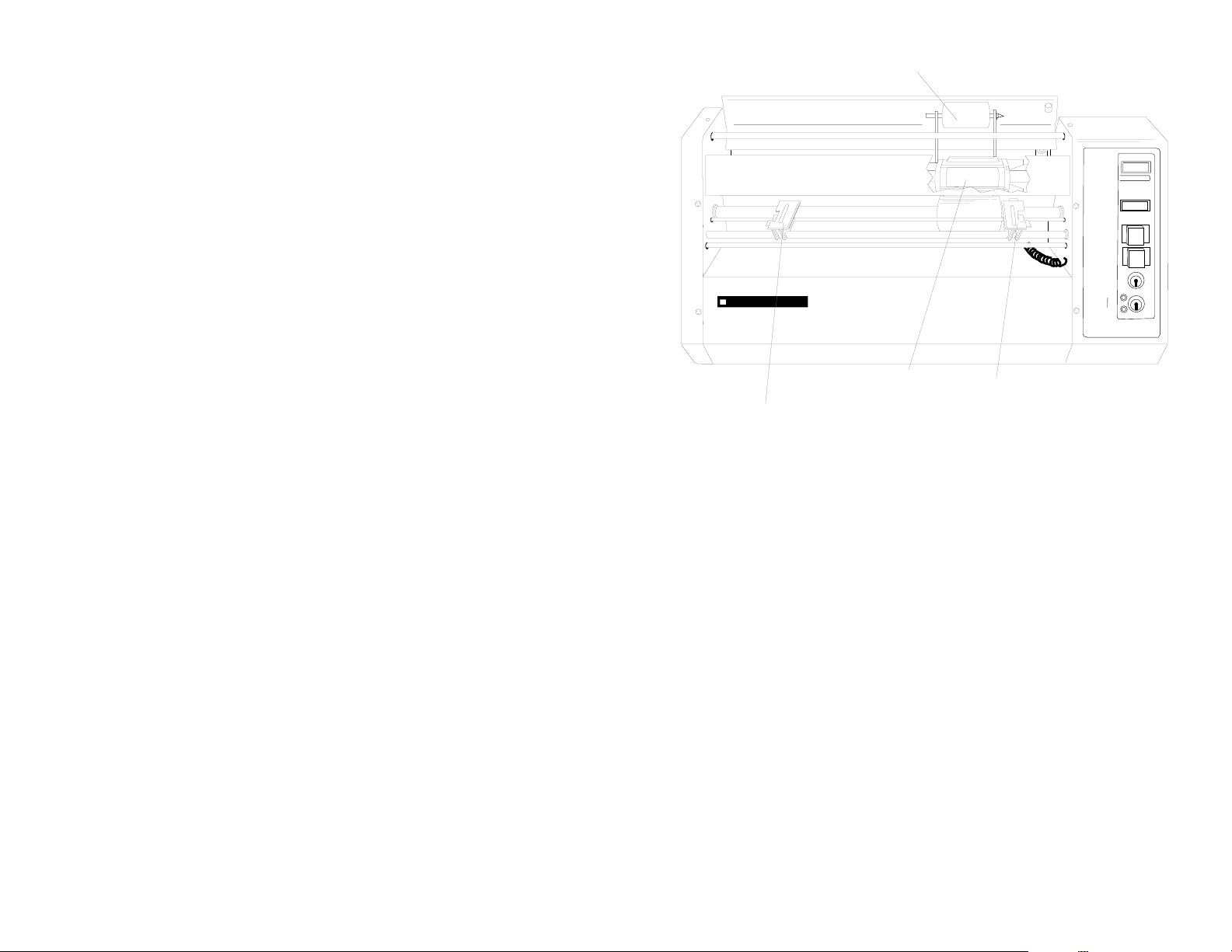

Figure 1

SECTION 1. MODEL EDP2000 OPERATING INSTRUCTIONS

NOTE:

Refer to Pg. 9 for differences in Model EDP1000 operating instructions.

To sign 3-1/2" checks you must use two (2) signature plates.

To sign 7" checks with top or bottom vouchers you must use ONLY one (1) signature

plate.

The signature plate holder on your machine has two (2) signature plate positions.

These are marked POSITION A and POSITION B. Proper signature plate positions

are dictated by the type of check that you are using. Refer to Pages 3 & 4, Step C.

A. TO OPERATE THE CONTINUOUS FORM SIGNER (See Figure 2)

1. Insert the ON/OFF key into the ON/OFF lock, turn to the left to turn on

machine. The yellow light near the Check Size Lock will illuminate. This

light indicates the machine is ON, also what size check the machine will

sign.

2. Insert the Cover key into the Cover lock, turn it to the right to open the

cover.

Ink Roll

Right

Tractor

Signature

Plate

Holder

Left

Tractor

HEDMAN EDP 2000

COUNTER

00000

RESET

AUDIT

COUNTER

START

STOP

3-1/2”

7”

CHECK

SIZE

00000

OFF/ON

2

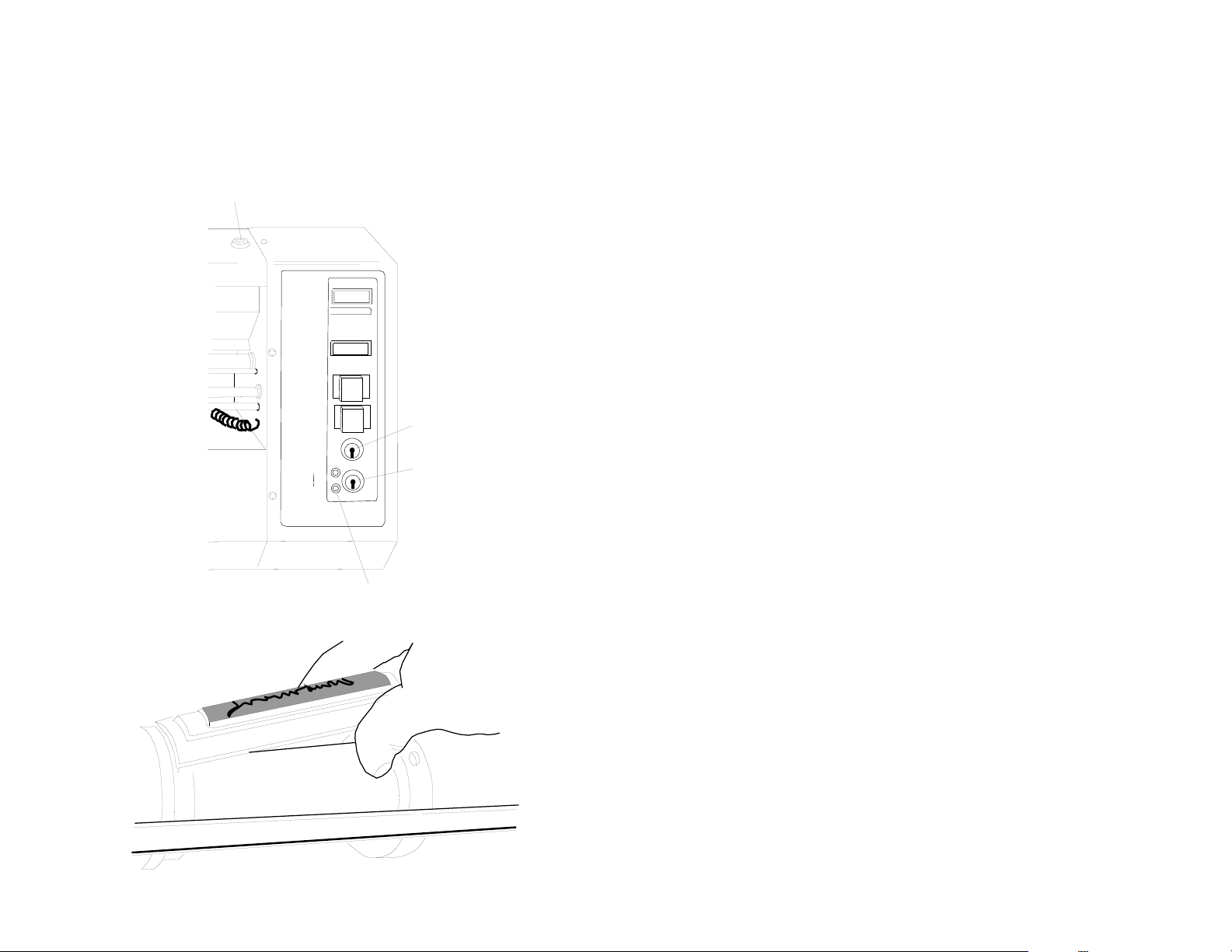

B. LOADING SIGNATURE PLATES (See Figure 3)

1. Grasp the signature plate with your left hand - the notch should be

pointed to the left.

2. Slip the signature plate down, sliding it to the left so that the plate holder

pin locates into the signature plate notch.

Cover Lock

OFF/ON

Lock

00000

RESET

AUDIT

COUNTER

START

STOP

3-1/2”

7”

CHECK

SIZE

COUNTER

00000

OFF/ON

Check Size

Lock

Check Size

Lights

Figure 3

Figure 2

3

3. Holding the signature plate with your left hand, use your right index

finger (or the eraser end of a pencil held in your right hand) to press

down on the signature plate holder latch. (See Figure 4).

4. Press the signature plate down into position and release the latch. The

latch will position itself into the beveled slot on the signature plate and

lock the plate firmly into position.

C. HOW TO SIGN VARIOUS TYPES OF CONTINUOUS FORM CHECKS

SIGNING 3-1/2" CHECKS

1. Turn Check Size key to the 3-1/2" position and remove key. The yellow

light next to the 3-1/2" check size will illuminate.

2. Either plate POSITION A or POSITION B can be loaded first. Load

either plate A or B following instruction "B" - Loading Signature Plates.

3. To load second signature plate, momentarily tap the START button

once. The signature plate holder will rotate 1/2 turn - load the second

plate.

4. Proceed to Step D.

SIGNING 7" BOTTOM VOUCHER CHECKS (Check at top - Voucher at

bottom).

1. Load one (1) signature plate into POSITION A ONLY.

Figure 4

4

If POSITION A is not visible on signature plate holder, momentarily tap the

START button once. The signature plate holder will rotate 1/2 turn and you

can then load the signature plate into POSITION A.

2. Load signature plate into POSITION A following instruction "B" -

Loading Signature Plates.

3. Set Check Size key to 7" positon - remove key.

4. Proceed to Step D.

SIGNING 7" TOP VOUCHER CHECKS (Voucher at top - Check at bottom).

1. Load one (1) signature plate into POSITION B ONLY.

2. Load signature plate into POSITION B following instruction "B" -

Loading Signature Plates.

3. Again tap START button. See that the plate you loaded rotates to the

lower printing position.

4. Set Check Size key to the 7" position - remove key.

5. Proceed to Step D.

NOTE:

Machine will stop with the signature plate "down". To remove the

plate, set Check Size key to the 3-1/2" position and momentarily tap the

START button once. This will bring the signature plate holder up for easy

signature plate removal.

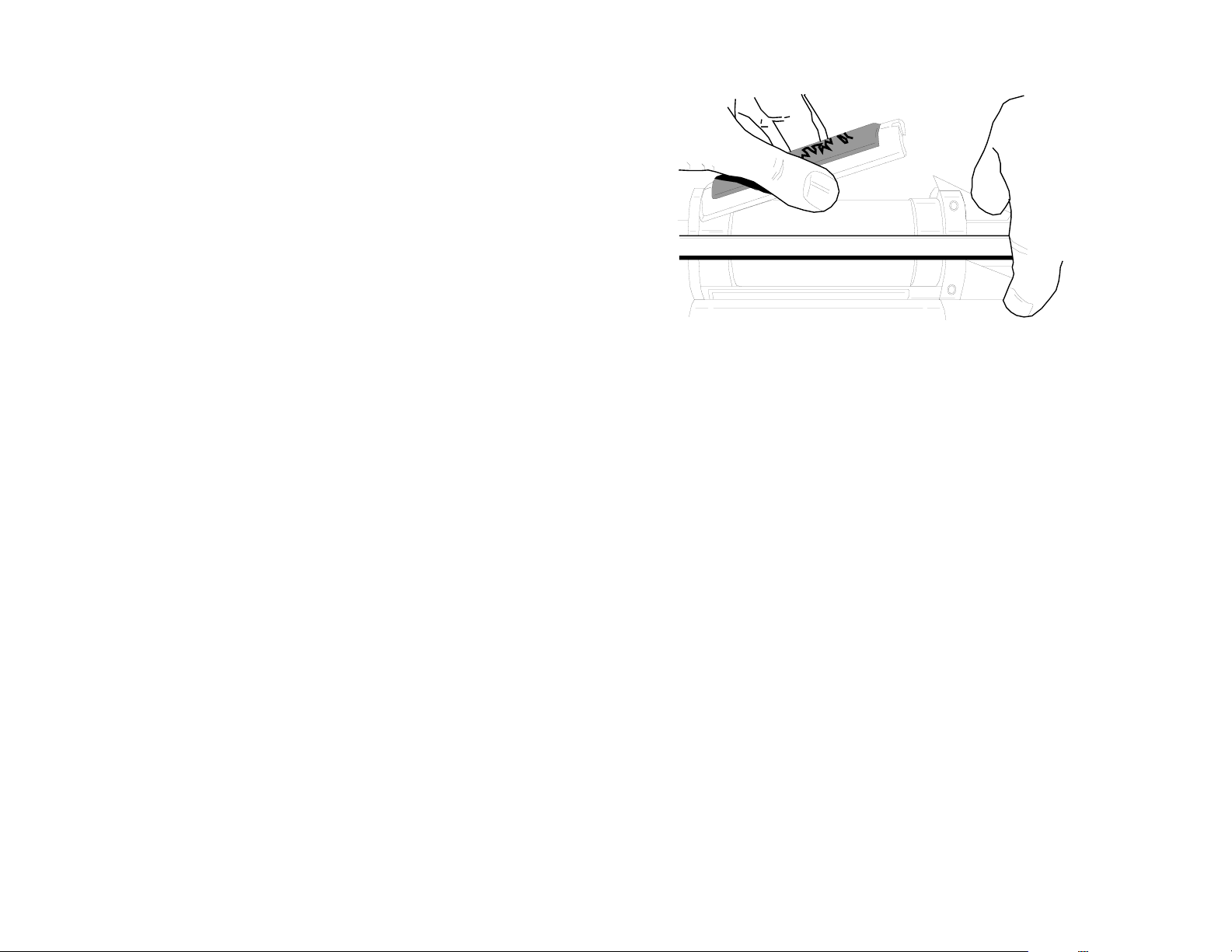

D. LOADING AND POSITIONING OF CONTINUOUS FORM CHECKS (See

Figure 5).

1. Open left and right tractor covers.

2. Align the top right edge of the continuous form with top edge of right

tractor. Align check carrier strip holes with tractor pins. Close tractor.

3. Release left tractor lock. Lift up on locking lever. (See Figure 6)

5

Figure 6

Figure 5

NOTE: Be sure corner

of form is not torn or

wrinkled

6

Figure 5

4. Using both hands, one on the tractor the other on the paper, slide

tractor right or left so that the tractor pins line up with the holes in check

carrier strips.

a. Align top of check form with top of tractor - insert left check carrier strip

into feeder pins and close tractor cover. (See Figure 7).

b. GENTLY pull tractor to the left to eliminate any sagging of the forms - -

- forms must be taut between the tractors. Lock the left tractor in place

by pushing down on the locking lever. (See Figure 8).

NOTE:

Continuous forms of some manufacturers may vary in width from

box to box or even within the same box. Whenever loading continuous

forms, always check to make sure that the feeder strips line up with the

tractor pins AND that the paper is taut between the tractors.

E. Close cover on machine. LOCK and REMOVE key.

F. Reset Run Meter by pressing in firmly on CENTER of RESET bar. Make

sure all zeros (00000) appear and line up across the face of the meter.

G. Press START button. Allow approximately 12 checks to run through the

machine. Press STOP button. Model EDP1000 checks will run until they are

all signed - there is no STOP button. The Model EDP1000 can be stopped

for stacking by the power switch.

1. Make sure that the checks are stacking properly at the rear of the

machine. The first check should be pointing toward the rear of the

machine. If not, manually refold the checks along the natural fold lines.

Place the stack of refolded checks about 6" from the rear of the

machine.

7

2. Press START button and sign checks or forms. The machine will stop

automatically when the last check has been signed.

FOR OPTIMUM SIGNING OPERATION, IT IS SUGGESTED THAT A STACK OF

CHECKS NO HIGHER THAN 4" BE PROCESSED IN ONE RUN.

Figure 8

Figure 9

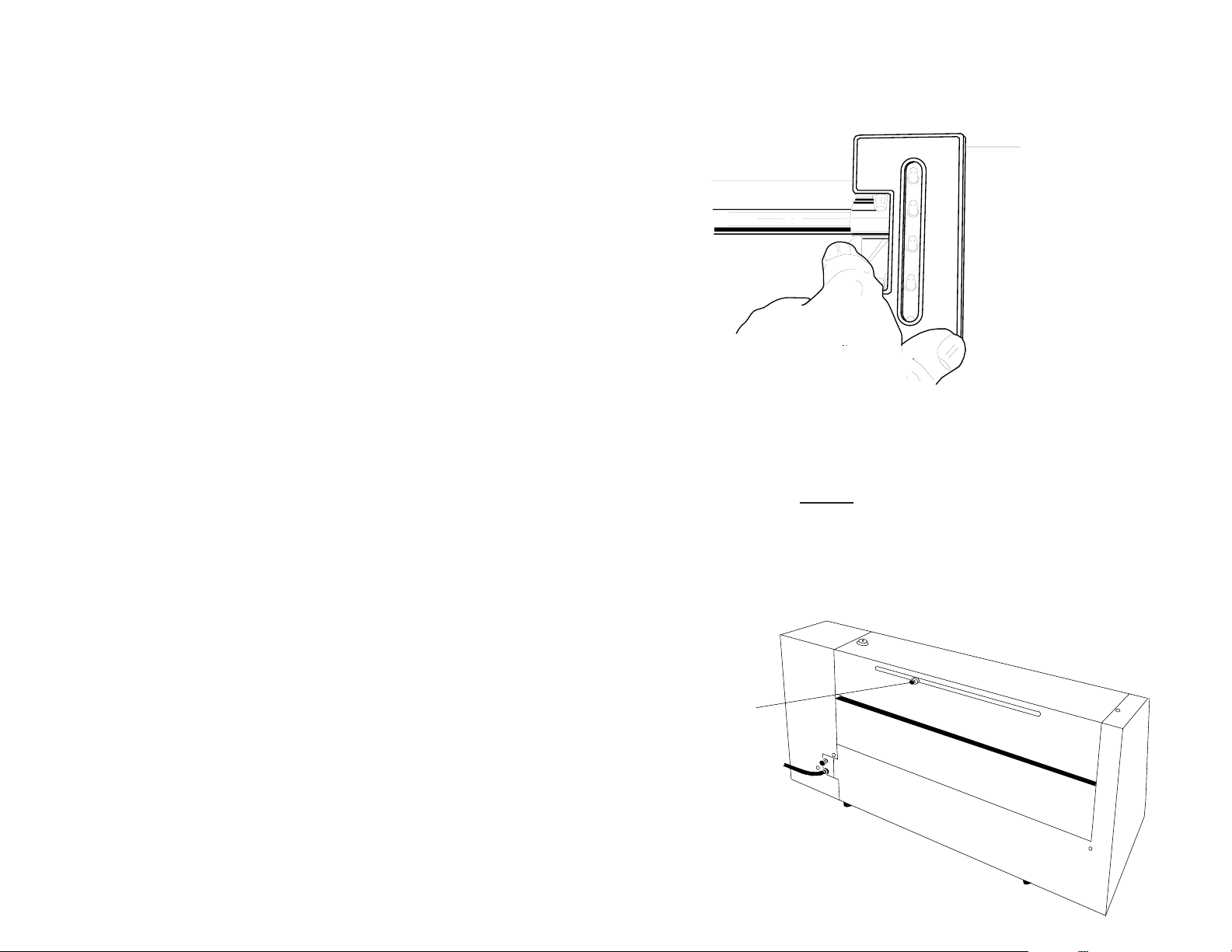

H. INKING SYSTEM

Your Continuous Form Signer is equipped with an ink roll that will sign up to

150,000 signatures, depending upon age and usage. The ink roll is located inside

the top cover.

CAUTION: Do Not touch ink roll.

1. INK ROLL PRESSURE

The ink roll must not place too much pressure on the signature plates.

Adjust the ink roll to just "kiss" the signature plates but with enough

pressure for a good printed impression. Ink roll pressure is adjusted by

turning the RED adjustment knob located at the rear of the form signer

(See Figure 9). Turning this knob to the right DECREASES ink roll

pressure - a lighter signature imprint. Turning the knob to the left

INCREASES ink roll pressure - a darker signature imprint.

Ink Roll

Adjustment

Knob

8

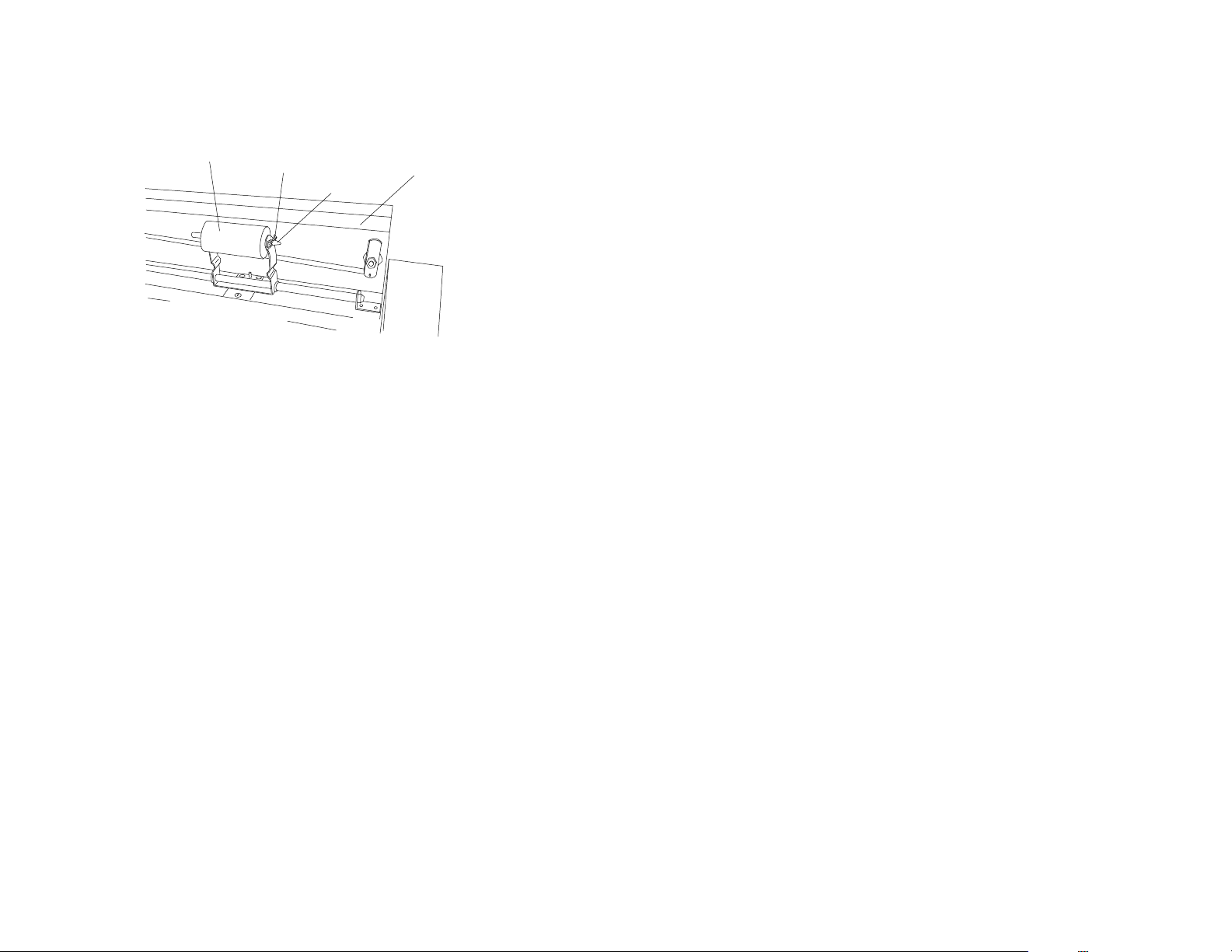

2. POSITIONING INK ROLL

The ink roll can be moved by opening the top cover and simply sliding

the ink roll assembly to the right or left as required (See Figure 10). The

ink roll must be positioned so that it inks the entire signature plate.

Figure 10

3. REPLACING INK ROLL

a. Open the top cover.

b. Put on the gloves shipped with the ink roll.

c. Pull the cotter pin out of the axle (see Figure 10).

d. Hold onto the ink roll and pull the axle out of the ink roll carriage.

e. Hold the new ink roll between the sides of the ink roll carriage and

insert the axle with the pointed end as shown in Figure 10.

f. Insert the straight side of the cotter pininto the hole in the pointed end

of the axle.

g. Push the cotter pin until the axle is secured between the two loops of

the cotter pin.

h. Close the top cover.

I. PAPER MISFEED

NOTE:Torn or damaged carrier strips can cause misfeeds or stop the machine

from operating. Check the carrier strips on the forms to make sure they will not

cause you a problem. Should a paper misfeed occur, the following stops should

be followed:

1. Stop machine by pressing the RED stop button.

2. Unlock and open cover.

3. Open tractor cover. Clear and remove checks.

4. Examine damaged carrier strips and make any necessary repairs with

scotch tape, taking care not to cover carrier strip holes.

5. Momentarily tap the START button to bring the signature plates into

proper printing position.

6. Reload checks in tractors. First check should be undamaged or

repaired.

7. Close and lock cover and remove key.

8. Repeat Step G.

Axle

Ink

Roll

Cotter

Pin

Top

Cove

r

9

SECTION 2. MODEL EDP1000 OPERATING INSTRUCTIONS

NOTE:

Model EDP1000 Operation is similar to Model EDP2000 except for the

following:

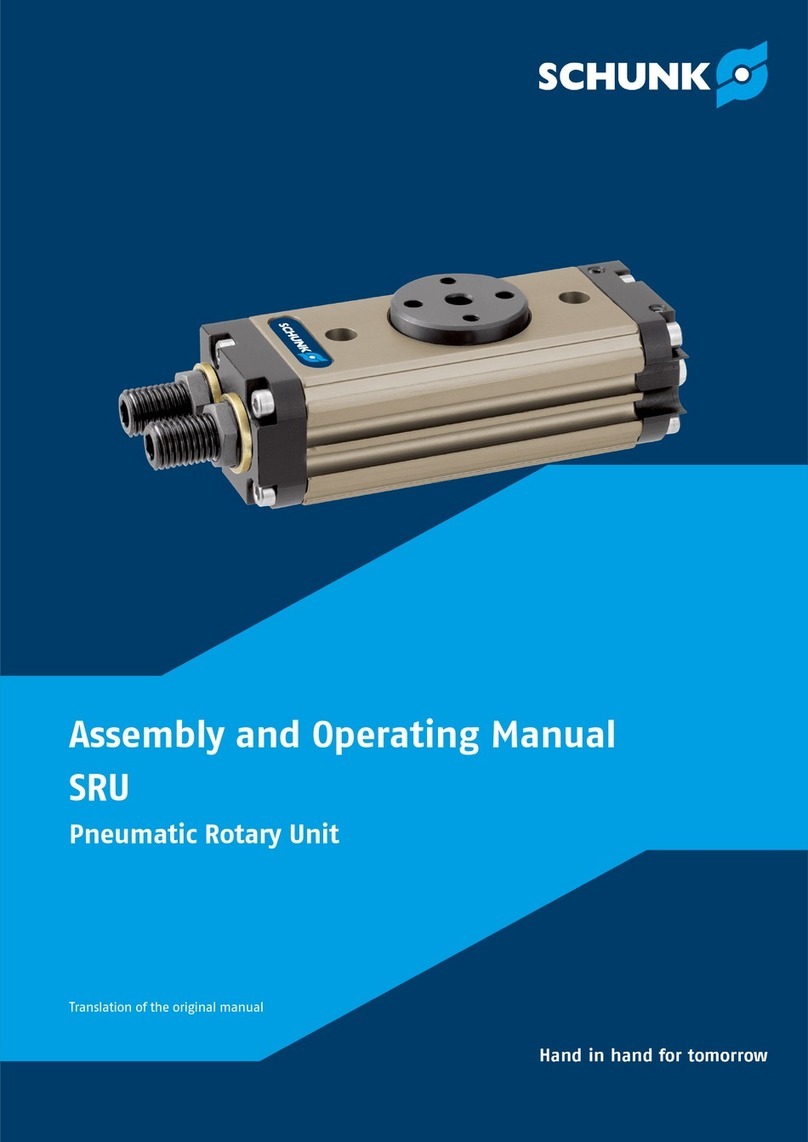

A. TO SIGN 3-1/2" FORMS YOU MUST USE TWO (2) SIGNATURE PLATES

POSITION A AND B.

Figure 11

POSITION A - TOP

POSITION B - BOTTOM

PLATEN

1. Switch ON/OFF switch to ON.

2. Unlock and open the top cover.

3. Load one signature plate into POSITION A. (See Figure 11).

4. Touch the green button momentarily to jog unit. The other signature

plate can now be loaded into POSITION B. (See Figure 11).

5. Loading paper is the same as the MODEL EDP2000 . See Page 4, Step

D. After forms are loaded procedd to Page 11, Step C.

10

B. TO SIGN 7" FORMS WITH A TOP OR BOTTOM VOUCHER (Refer to

Figure 12), ONLY ONE SIGNATURE PLATE IS NEEDED.

Figure 12

VOUCHER DIAGRAM

1. Switch ON/OFF switch to ON.

2. Unlock and open the top cover.

3. TOP VOUCHER. Load one signature plate into POSITION A (TOP).

Refer to Figure 11.

or

4. BOTTOM VOUCHER. Touch the green button momentarily to jog the

unit. The signature plate should now be in the bottom position. Load one

signature plate into POSITION B (BOTTOM). Refer to Figure 11.

NOTE:

Only one signature plate is used for 7" forms.

CURRENTLY THE UNIT WILL SIGN 7" TOP VOUCHER FORMS OR BOTTOM

VOUCHER FORMS - DEPENDING ON WHETHER THE SIGNATURE PLATE

WAS LOADED INTO POSITION A OR B.

BOTTOM VOUCHER

CHECK

CHECK

TOP VOUCHER

or

11

C. PROCEDURE FOR SIGNING FORMS

1. Reset the counter to zero by pressing the reset button on the counter.

2. Push the green button to sign forms.

3. The unit will stop after the last form is signed.

WHEN THE RUN IS DONE, MAKE SURE THAT THE SIGNATURE PLATE IS IN

THEPROPERPOSITIONFORTOPVOUCHERORBOTTOMVOUCHERFORMS.

(7" ONLY)

3-1/2" FORMS, THE COUNTER COUNTS ALL FORMS THAT ARE SIGNED.

7"FORMS,DIVIDETHE NUMBER ON THE COUNTER BY 2 TO GET THE ACTUAL

COUNT OF FORMS SIGNED.

12

MODELS EDP1000/EDP2000

TROUBLESHOOTING

SYMPTOM CAUSE

Machine will not run 1. Checks not loaded into tractors properly.

continuously. 2. Tractor switch (right tractor) not fully depressed.

3. Cover is not locked and key removed.

Machine will not 1. ON/OFF key not in ON position.

operate. 2. Check wall plug.

3. Check fuse (rear of machine). Replace with 2 AMP fuse.

4. Model EDP1000. Check Power Switch - not ON.

Signature not 1. Refer to Step C.

properly positioned

on check.

Reset counter 1. Firmly press in on center of reset bar.

not clearing.

Your Key Number____________ ON_______ CHECK_______COVER _______

OFF SIZE

Machine Serial Number ______________________________________________

This manual suits for next models

2

Table of contents