nVent.com | 10

Program a Circuit

Now it’s time to have your assistant program a circuit.

The approach is to provide guidance to the person operating the demo unit and letting them

figure out how to accomplish what you’ve asked them to do. The real power of this exercise

is in the audience seeing how little guidance is needed to actually use our system.

Suggestion:

Use keywords in your questions – when you ask someone to do a task, include a word that

they would see on the screen which would give them a clue as to what to click on to

accomplish your task.

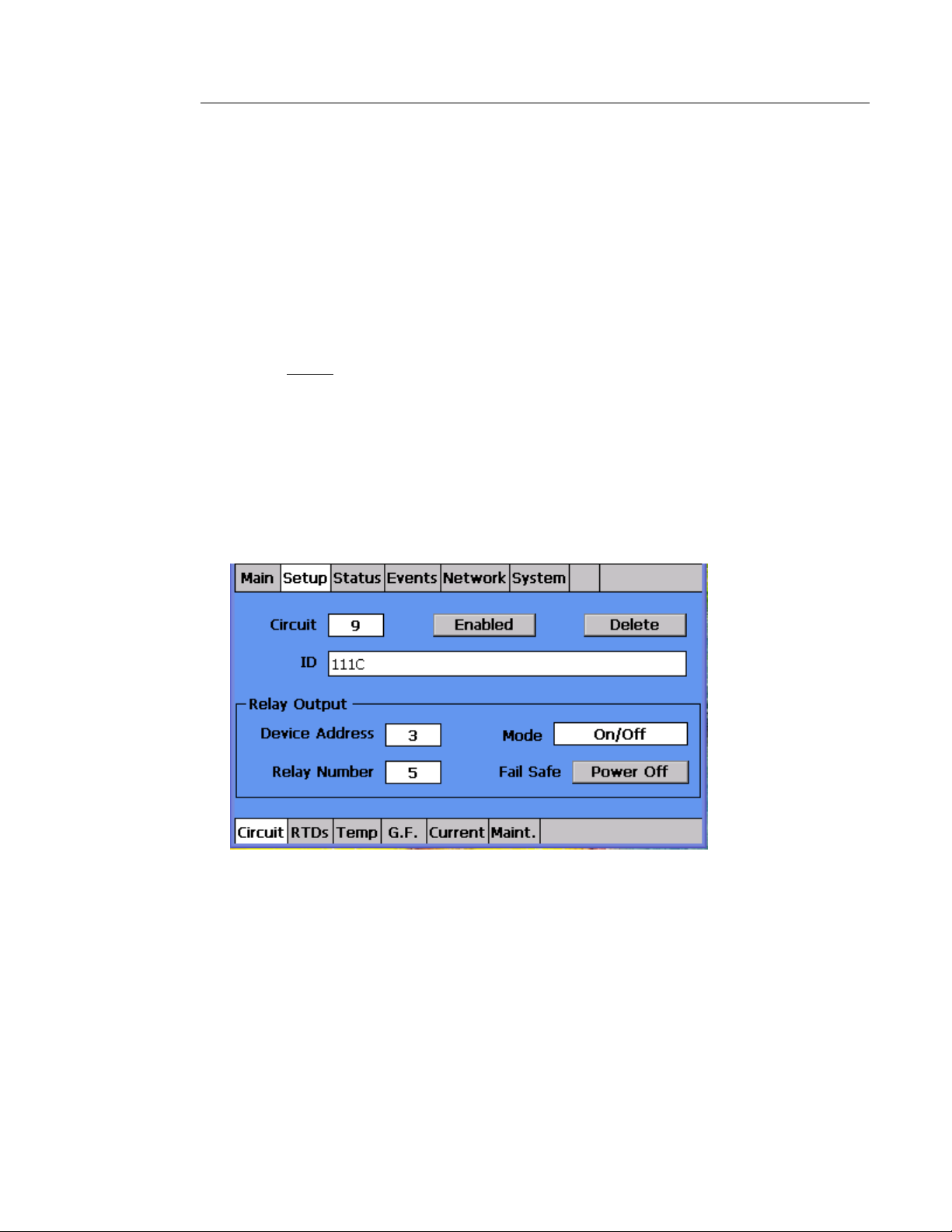

•Example: Instead of asking them to “Program a circuit”, ask them “How would you

set up a circuit? What do you think you would do?” This guides them towards

touching the Setup tab at the top of the screen.

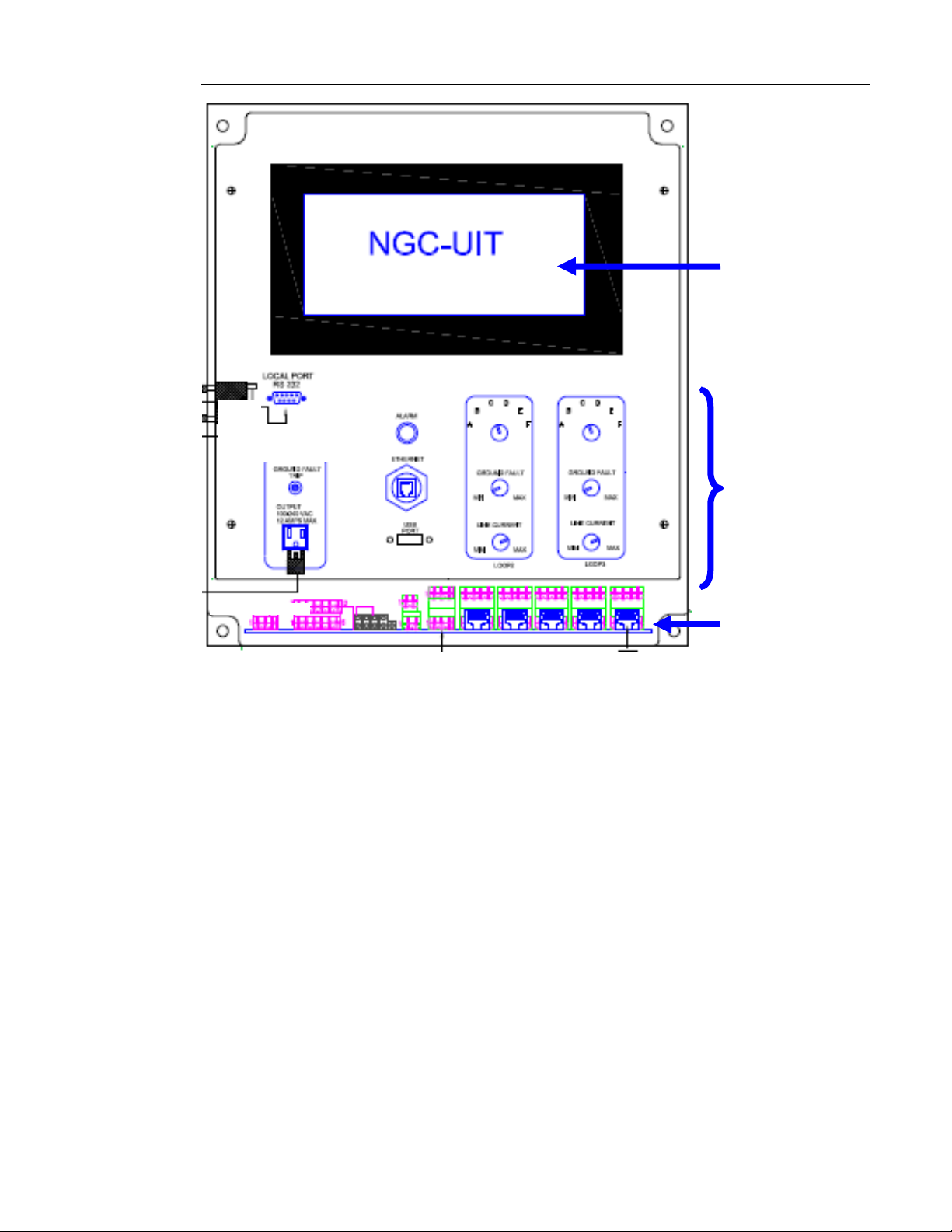

Step 1:

The demo unit should have the Main screen on display. If not, instruct the user on how to get

there.

•“Touch the Main tab”.

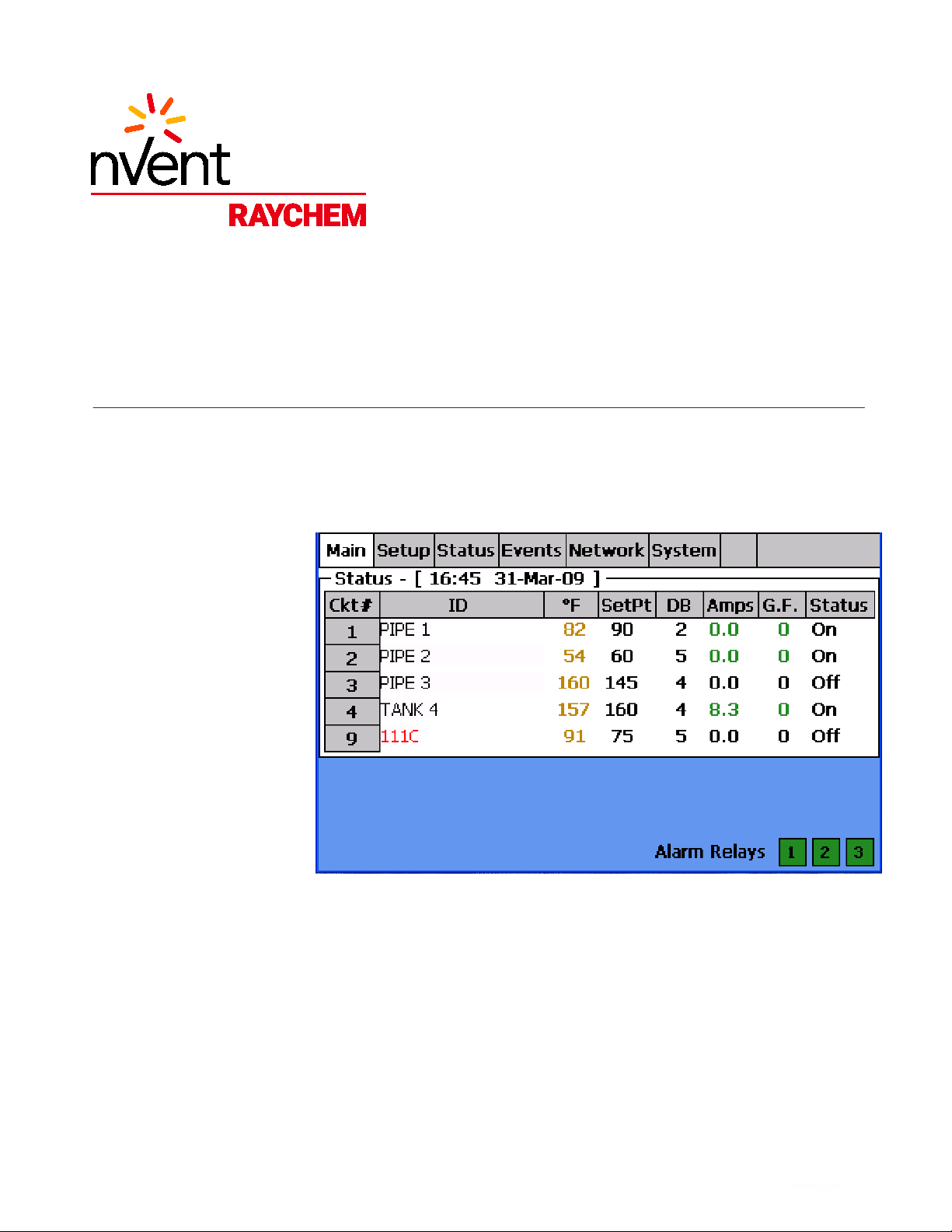

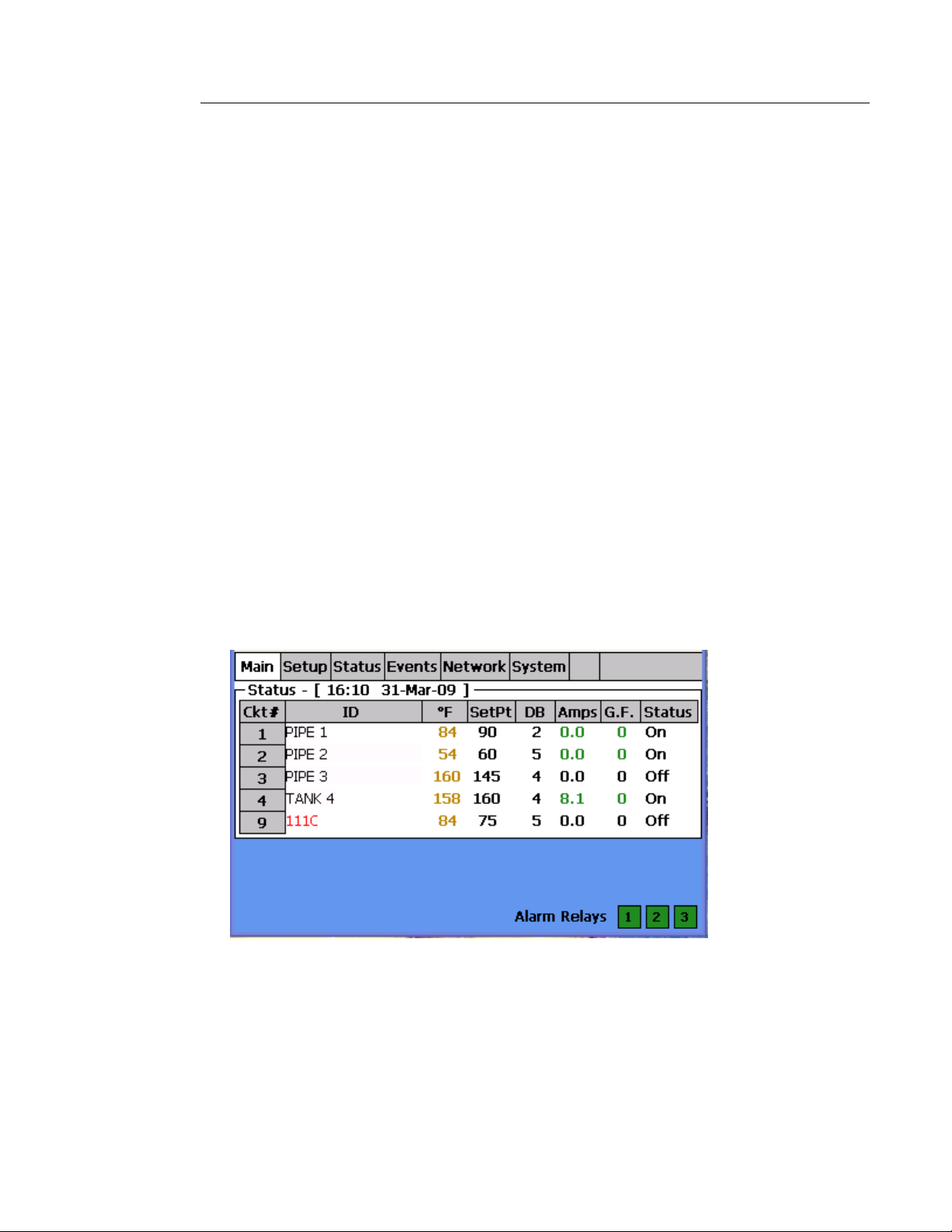

Figure 2: The Setup Screen

Preface the activity with a version of the following script:

“The NGC system User Interface Terminal is designed to be an intuitive interface to the heat-

tracing system. Its design uses plain language and is based on standard PC navigation set

up and techniques. Data is entered similar to texting on your cell phone. So if you use a

computer or a cell phone, the interface with the NGC User Interface Terminal is very similar.

OK, so let’s get started.