Section 28M‐A20‐200‐20C

030‐101670 Rev. C

1205ICRC 7

Consult the power supply practice for more details on the power

supply. Dress wires per company practice and secure wires with

cables ties to the tie‐down provided on the mounting (after test

ing).

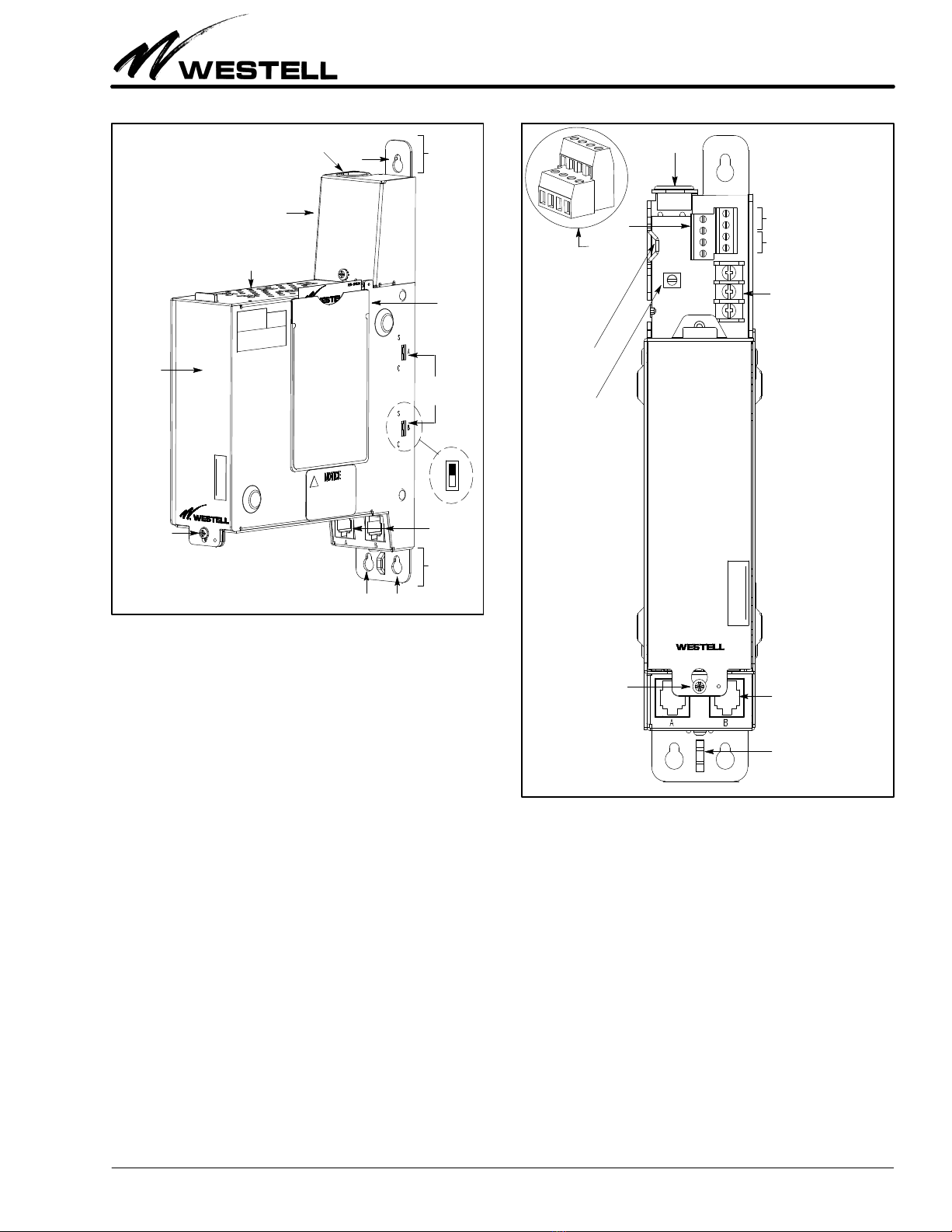

3.4.3 Facility/Network Interface Connections

Facility connections are made to two screw‐type, 4‐position con

nectors (Paragraph 2.2.2) in the Facility wiring compartment at

the top of the 28MA202. The specific type of connector varies

with the specific model ordered (see Table 1 and Figure 3). Pin

designations are shown in Figure 6, the wiring diagram. Route

wires through the grommet at the top of the 28MA202, dress and

secure wires to the connector per company practice, and secure

the wires to the cable tie‐down on the 28MA202 with the cable

ties provided, when complete (after testing).

3.4.4 Customer Interface Connections

Customer interface connections are made to one or both

RJ48C/S jacks at the bottom of the 28MA202. The specific type

of connector is determined by the application and the setting of

the operation mode switch(es) on the side of the 28MA202 (see

Paragraphs 2.1.3 and 2.1.4, and Figure 2). Pin designations are

shown in Figure 6, the wiring diagram. After testing, cables may

be secured to the 28MA202 at the cable tie‐down with the cable

ties provided.

3.4.5 Module Installation

Both 200 MECHANICSand 400‐type plug‐in modules can be

inserted into the 28MA202 after the mounting installation is

complete. The modules make electrical connection when

installed and properly seated in the card‐edge connector of the

28MA202. Before installing any module, set any option

switch(es) to the desired position(s). Align the module with the

mounting card guides above and below the unit and insert as far

as it will go into the slot connector.

‐ CAUTION ‐

Use care when installing and removing modules ‐ do not force

a module into place. If a module resists insertion, remove it

and check for obstructions in or near the connectors and

mounting slots and gently re‐insert the module.

4. TESTING & TROUBLESHOOTING

4.1 Testing

This equipment should not be field repaired. If the equipment

is suspected of being faulty, replace it with another unit, op

tioned identically, and retest. If the replacement unit appears to

operate correctly, the original unit may be faulty and should be

returned to Westell for repair or replacement (Paragraph 6.2).

4.2 Troubleshooting

If trouble is encountered, verify all installer connections to the

or mounting and check that the CO power fuse is not blown. Also

verify all module connections, option switch settings, the mount

ing's side switch settings, and verify the modules are making a

positive connection with the shelf connector. If trouble persists,

replace the suspect unit and repeat procedures outlined. These

procedures are not designed to effect repairs or modifications.

Any tests beyond those outlined herein, or repairs made beyond

replacing a faulty unit, are not recommended and may void the

warranty.

5. CUSTOMER & TECHNICAL SERVICES

5.1 Customer Service & Technical Assistance

If technical or customer assistance is required, contact Westell

by calling or using one of the following options:

Voice: (800) 377‐8766

For additional information about Westell, visit the Westell

World Wide Web site at http://www.Westell.com.

5.2 Part Numbers

This equipment is identified by a product number

(C90‐28MA202X), which consists of three parts: the issue letter

of the equipment (C), the assembly type (90), and the specific

model number (28MA202X). Each time a change is made to the

product which changes the form, fit, or function of the product,

the issue letter is incremented or advanced by one. Be sure to in

dicate the issue level as well as the model number when making

inquiries about the equipment.

6. WARRANTY & REPAIRS

6.1 Warranty

Westell warrants this product to be free of defects at the time of

shipment. Westell also warrants this product to be fully func

tional for the time period specified by the terms and conditions

governing the sale of the product. Any attempt to repair or

modify the equipment by anyone other than an authorized Wes

tell representative will void the warranty.

6.2 Repair and Return

Westell will repair or replace any defective Westell equipment

without cost during the warranty period if the unit is defective

for any reason other than abuse, improper use, or improper

installation. To return defective equipment, first request a Re

turn Material Authorization (RMA) number from Westell by

calling or using one of the options shown below. Once an RMA

number is obtained, return the defective unit (freight prepaid),

along with a brief problem description, to the address we will

provide to you when you contact us.

Voice: (630) 375‐4457

Replacements will be shipped in the fastest manner consistent

with the urgency of the situation. Westell will continue to repair

or replace faulty equipment beyond the warranty period for a

nominal charge. Contact Westell for details.