SPIETH MSW Series User manual

Document

ma-mswk-en1817

Page 1 of 7

Assembly Instructions

MSW from M20 to M70

The Assembly Instrcutions are also available for download at www.spieth-me.de. In case of any questions, please

contact Spieth-Maschinenelemente GmbH & Co. KG directly.

Legal:

Spieth-Maschinenelemente GmbH & Co. KG, Alleenstraße 41, D - 73730 Esslingen

Phone +49 711 930730 0 - Fax +49 711 930730 7

E-Mail: info@Spieth me.de - Web: www.spieth-me.de

KG: Esslingen HQ, Stuttgart county court, company register sect. A 210689

PhG: Spieth-Beteiligungs-GmbH, Esslingen HQ, Stuttgart county court, company register sect. A 210636

Managing director: Dipl.-Ing. Alexander Hund

©Spieth

Proprietary

notice

ISO 16016

Previous document: ma-mswk-en1604

See

www.spieth-me.de/english/service-download/catalogue-instructions/

Successive document: N/A

Created: 27 Apr 2018/Fd

For any questions, requests or suggestions, please contact

info@spieth-me.de

Checked: 27 Apr 2018/Ax

Original version of assembly instructions

Für

Baureihen

Bauteile

Spieth locknuts

(precision locknuts)

MSW until M70

MSW 20.28 MSW 20.40 MSW 25.28

MSW 25.40 MSW 30.28 MSW 30.44

MSW 35.28 MSW 35.44 MSW 40.28

MSW 40.44 MSW 45.28 MSW 45.44

MSW 50.32 MSW 50.46 MSW 55.46

MSW 60.46 MSW 65.46 MSW 70.46

Document

ma-mswk-en1817

Page 2 of 7

Assembly Instructions

MSW from M20 to M70

©Spieth

Proprietary

notice

ISO 16016

Previous document: ma-mswk-en1604

See

www.spieth-me.de/english/service-download/catalogue-instructions/

Successive document: N/A

Created: 27 Apr 2018/Fd

For any questions, requests or suggestions, please contact

info@spieth-me.de

Checked: 27 Apr 2018/Ax

Assembly instructions for Spieth Locknuts

Table of Contents

Assembly instructions for Spieth Locknuts...................................................................................................................2

Table of Contents .....................................................................................................................................................2

1 Information about Spieth Locknuts......................................................................................................................3

1.1 General information .....................................................................................................................................3

1.2 Safety notices ...............................................................................................................................................3

2 Description of Spieth Locknuts.............................................................................................................................4

2.1 Structure.......................................................................................................................................................4

3 Assembling Spieth Locknuts .................................................................................................................................4

3.1 Preparing for assembly.................................................................................................................................4

3.2 Ambience/Environment ...............................................................................................................................5

3.3 Assembly process .........................................................................................................................................5

4 Disassembling Spieth Locknuts.............................................................................................................................7

5 Maintenance and servicing of Spieth clamping sleeves.......................................................................................7

Document

ma-mswk-en1817

Page 3 of 7

Assembly Instructions

MSW from M20 to M70

©Spieth

Proprietary

notice

ISO 16016

Previous document: ma-mswk-en1604

See

www.spieth-me.de/english/service-download/catalogue-instructions/

Successive document: N/A

Created: 27 Apr 2018/Fd

For any questions, requests or suggestions, please contact

info@spieth-me.de

Checked: 27 Apr 2018/Ax

1Information about Spieth Locknuts

1.1 General information

Spieth locknuts are precision parts and require careful handling. Follow the information in these assembly

instructions and the operating instructions. Failing to comply with them may significantly impact functionality and

service life.

To apply the locking force, use only original Spieth clamping screws. Do not actuate the clamping screws until the

locknut thread has been fully screwed onto the spindle thread. Otherwise, damage such as ductile deformation

may occur on the locknut and render it unusable. Spieth-Maschinenelemente GmbH & Co. KG assumes no liability

for damage from improper handling, incorrect installation, or unauthorised structural changes.

1.2 Safety notices

Spieth locknuts are intended for use on threaded spindles. Please follow all relevant safety notices.

Caution!

Any work carried out with or on the locknut needs to follow the "safety first" guideline!

During operation, keep your hands away from the working area of the locknut!

Prior to any assembly work, switch off all machine drives!

Secure the machine against accidental power-up!

Prior to commissioning the machine, install all safety devices!

Only expert personnel are allowed to perform assembly work on Spieth locknuts. Using Spieth locknuts is only

admissible according to specifications. Spieth-Maschinenelemente GmbH & Co. KG assumes no liability for

violations of the operating instructions or safety notices. This also applies to incorrectly interpreting or circulating

these notices and to incorrect assembly or maintenance.

The locknuts described here are state of the art at the time these assembly instructions are printed. Subject to

changes based on evolved technologies. For international deliveries, follow the safety regulations applicable in

the target country.

Document

ma-mswk-en1817

Page 4 of 7

Assembly Instructions

MSW from M20 to M70

©Spieth

Proprietary

notice

ISO 16016

Previous document: ma-mswk-en1604

See

www.spieth-me.de/english/service-download/catalogue-instructions/

Successive document: N/A

Created: 27 Apr 2018/Fd

For any questions, requests or suggestions, please contact

info@spieth-me.de

Checked: 27 Apr 2018/Ax

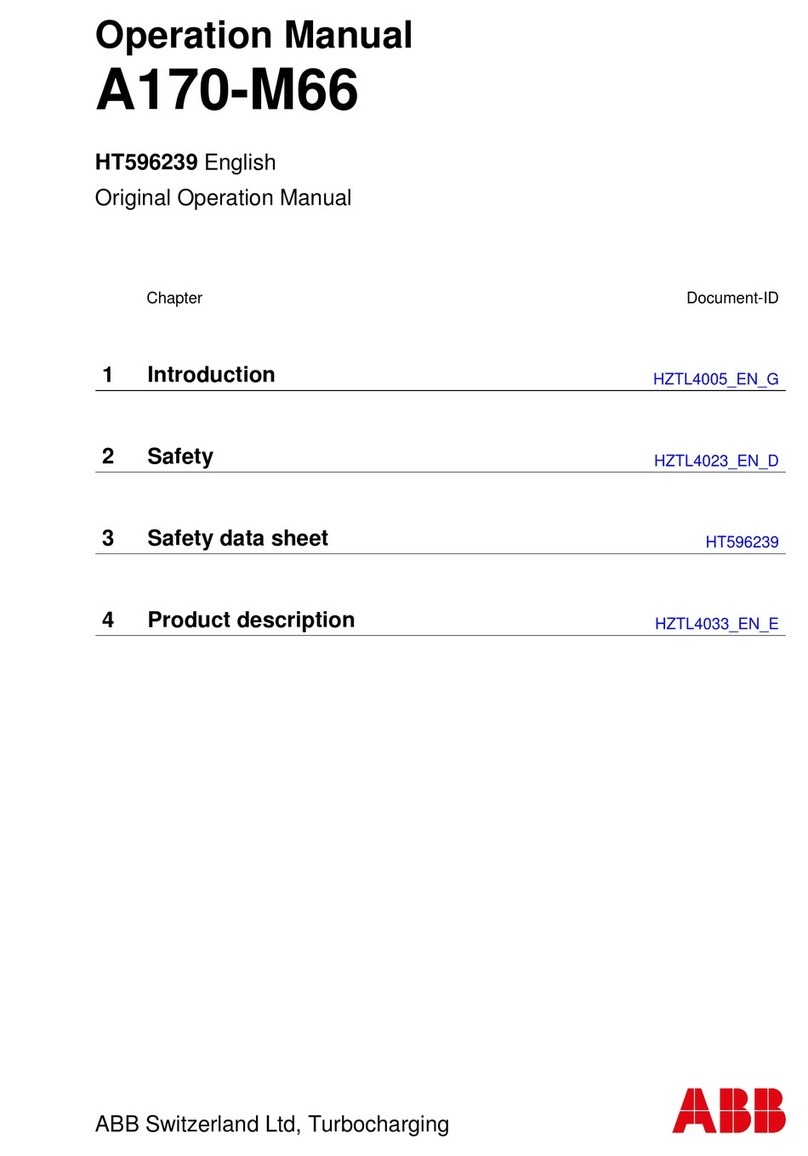

2Description of Spieth Locknuts

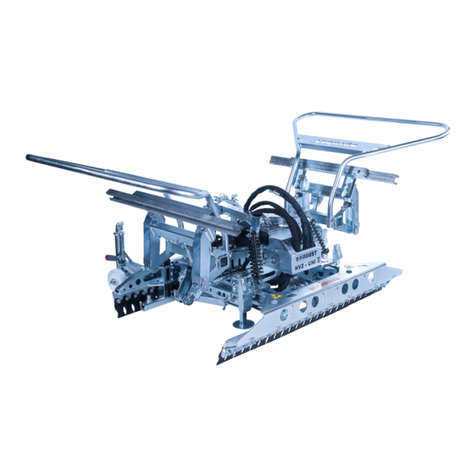

2.1 Structure

Spieth locknut bodies

Fig 1: Schematic representation similar to

Spieth MSW series locknuts

Spieth clamping screws

Grooves for hook spanner DIN 1810 - A

Identifying features (for original Spieth locknuts)

Spieth logo

Name

Batch number

Locking torque MSfor clamping screws

The Spieth MSW series locknuts are assemblies consisting of locknut bodies and clamping screws. The thread

inside the locknut body is interrupted by a groove, separating the locknut body into a load and a locking part. A

diaphragm connects load and locking part.

3Assembling Spieth Locknuts

3.1 Preparing for assembly

Remove Spieth locknuts from their packaging right before assembly. As hand perspiration can cause corrosion,

ensure to keep your hands dry and clean and/or to always wear protective gloves for assembly.

Please note:

For environmental reasons, please comply with applicable statutory regulations and guidelines when

disposing of packaging materials.

In case of damage to packaging components, check the locknuts for damage and remove any contamination.

The preservative used is compatible with all conventional machine oils. If in doubt, check the preservative's

compatibility.

For an optimum mode of action of Spieth locknuts, remove the thin wax-like film of preservative from the contact

surfaces using a lint-free cloth. Directly afterwards, use machine oil without friction-reducing additives to lightly

oil the component and protect it from corrosion.

Document

ma-mswk-en1817

Page 5 of 7

Assembly Instructions

MSW from M20 to M70

©Spieth

Proprietary

notice

ISO 16016

Previous document: ma-mswk-en1604

See

www.spieth-me.de/english/service-download/catalogue-instructions/

Successive document: N/A

Created: 27 Apr 2018/Fd

For any questions, requests or suggestions, please contact

info@spieth-me.de

Checked: 27 Apr 2018/Ax

3.2 Ambience/Environment

During assembly, ensure that...

the assembly location is clean and free from dust,

the components have no contact with corrosive media,

foreign bodies such as sand, sawdust, fluff, etc. are kept away from the component,

metal filings (in particular from machining tools such as files, etc.) are kept away from the component.

Caution!

Contamination can significantly impact the functionality and service life of Spieth locknuts.

For best results, use a suitable, enclosed space for assembly and proceed swiftly. If this is not possible, make sure

to protect the components from ambient contamination and from damage.

3.3 Assembly process

Essentially, assembly is a 4-step process:

1. Screwing

2. Aligning

3. Tightening

4. Locking

For an optimum mode of action of Spieth locknuts, perform all four assembly steps in the specified order.

Caution!

To apply the locking force, use only original Spieth clamping screws. Do not actuate the clamping

screws until the nut thread has been fully screwed onto the spindle thread.

Otherwise, damage such as plastic deformation may occur on the locknut and render it unusable.

Use only the following assembly process for assembling Spieth MSW series locknuts:

3.3.1 Screwing:

First clean, lightly oil and then screw the locknut onto the spindle thread but avoid contact with the end face. It is

recommended to lightly oil the spindle thread, too. Since the nut thread is coordinated with the clearance of the

spindle thread, you can easily do this manually. We recommend maintaining sufficient distance to the planar

support while ensuring that the locking part of the nut body is fully screwed onto the spindle thread.

Document

ma-mswk-en1817

Page 6 of 7

Assembly Instructions

MSW from M20 to M70

©Spieth

Proprietary

notice

ISO 16016

Previous document: ma-mswk-en1604

See

www.spieth-me.de/english/service-download/catalogue-instructions/

Successive document: N/A

Created: 27 Apr 2018/Fd

For any questions, requests or suggestions, please contact

info@spieth-me.de

Checked: 27 Apr 2018/Ax

3.3.2 Aligning:

Tighten the clamping screws stepwise and crosswise. Regularly check how much play the nut has on the thread.

Repeat this process until the movement is nearly free of play. This aligns the end face of the locknut with the

spindle axis. This requires very little torque on the clamping screws (normally far less than 1 Nm); we recommend

using a manual tool (screwdriver or spanner) for sensitive tightening.

3.3.3 Tightening (1):

To reduce subsidence, first use an increased pretensioning torque MVe to tighten the locknut against the planar

support; then undo it. Depending on the load capacity of the connecting components, the increased

pretensioning torque MVe of the locknut may amount up to 1.2 to 1.5 times the calculated pretensioning torque

MV(see design guide/see note).

3.3.4 Tightening (2):

Now tighten the locknut with the calculated pretensioning torque MV(see design guide/see notice) using a

suitable tool (see design guide).

3.3.5 Locking:

Lock locknut by tightening the clamping screws stepwise and crosswise until the specified locking torque MS(see

design guide). For optimum effectiveness we recommend tightening the clamping screws in three steps (50%,

75% and 100% of the specified locking torque MS). Due to the operating principle there may be a slight localised

relief of strain of the contact on the end face but this has been factored into the calculated pretensioning torque

MV. Lock Spieth locknuts only if used with original Spieth clamping screws and if the nut thread is fully screwed

onto the spindle thread.

In case of maximum demands on spindle concentricity you can individually adjust the clamping screws to achieve

the desired result.

Please note:

Intense clamping at the thread flanks during the locking process causes a high level of axial rigidity

on the locknut. In turn, this slightly reduces the pretension. The degree of this end face strain relief

is reproducible and is easily compensated by the calculated pretensioning torque MV (see design

guide).

Following specified assembly, Spieth locknuts are ready for use immediately.

For more information on assembly, please see the relevant assembly instructions, available at www.spieth-me.de.

Document

ma-mswk-en1817

Page 7 of 7

Assembly Instructions

MSW from M20 to M70

©Spieth

Proprietary

notice

ISO 16016

Previous document: ma-mswk-en1604

See

www.spieth-me.de/english/service-download/catalogue-instructions/

Successive document: N/A

Created: 27 Apr 2018/Fd

For any questions, requests or suggestions, please contact

info@spieth-me.de

Checked: 27 Apr 2018/Ax

4Disassembling Spieth Locknuts

If handled correctly, Spieth locknuts can be reused several times. Due to the adjustments made, once a locknut

has been locked onto a spindle thread you can only reuse it on the same thread after they have been

disassembled.

Caution!

Unlock all the clamping screws stepwise and crosswise to avoid overstraining the screws. Otherwise,

the screws may fracture or the locknut or its adjoining components may be damaged.

To disassemble, proceed in reverse assembly order.

1. Unlock: Unlock by undoing the clamping screws stepwise and crosswise.

2. Undo: Undo locknut from system using suitable tools.

3. Unscrew: Unscrew locknut by hand from threaded spindle.

If used as intended the diaphragm will open the interlocked thread flanks during unlocking. This restored joint

play makes it easy to unscrew the locknut manually without damaging the threaded spindle.

Please note:

Following complete disassembly, slightly (manually) tighten the loosened clamping screws until they

are flush. In any case, avoid tightening the clamping screws without a fully covered nut thread.

To enable later reuse, clean, preserve, and store Spieth locknuts correctly. Prior to reuse, proceed as detailed in

section 3.1, "Preparing for assembly" ff.

If non-original Spieth spare parts are used, Spieth-Maschinenelemente GmbH & Co. KG assumes no liability or

warranty.

5Maintenance and servicing of Spieth clamping sleeves

Spieth clamping sleeves are low-maintenance. If used as intended, Spieth clamping sleeves provide permanently

precise pretensioning and positioning of the bearing on a spindle shaft.

We recommend periodic visual inspections of the clamping sleeves for potential damage.

Follow general safety notices when using Spieth clamping sleeves.

Caution!

Never touch actively rotating components. Take protective measures against accidental contact.

If you notice irregularities with the Spieth clamping sleeves during operation, immediately switch off the

machine's drive.

This manual suits for next models

18

Table of contents

Other SPIETH Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Spirax Sarco

Spirax Sarco TD42 Installation and maintenance instructions

HANG

HANG 102-50 Translation of the original operating instruction

KINSHOFER

KINSHOFER AUGERTORQUE SB Series Operator's manual

Nexen

Nexen AIR CHAMP MWHS user manual

Dover

Dover Destaco Ronohand RP Series Service manual

ABB

ABB HT568456 Operation manual