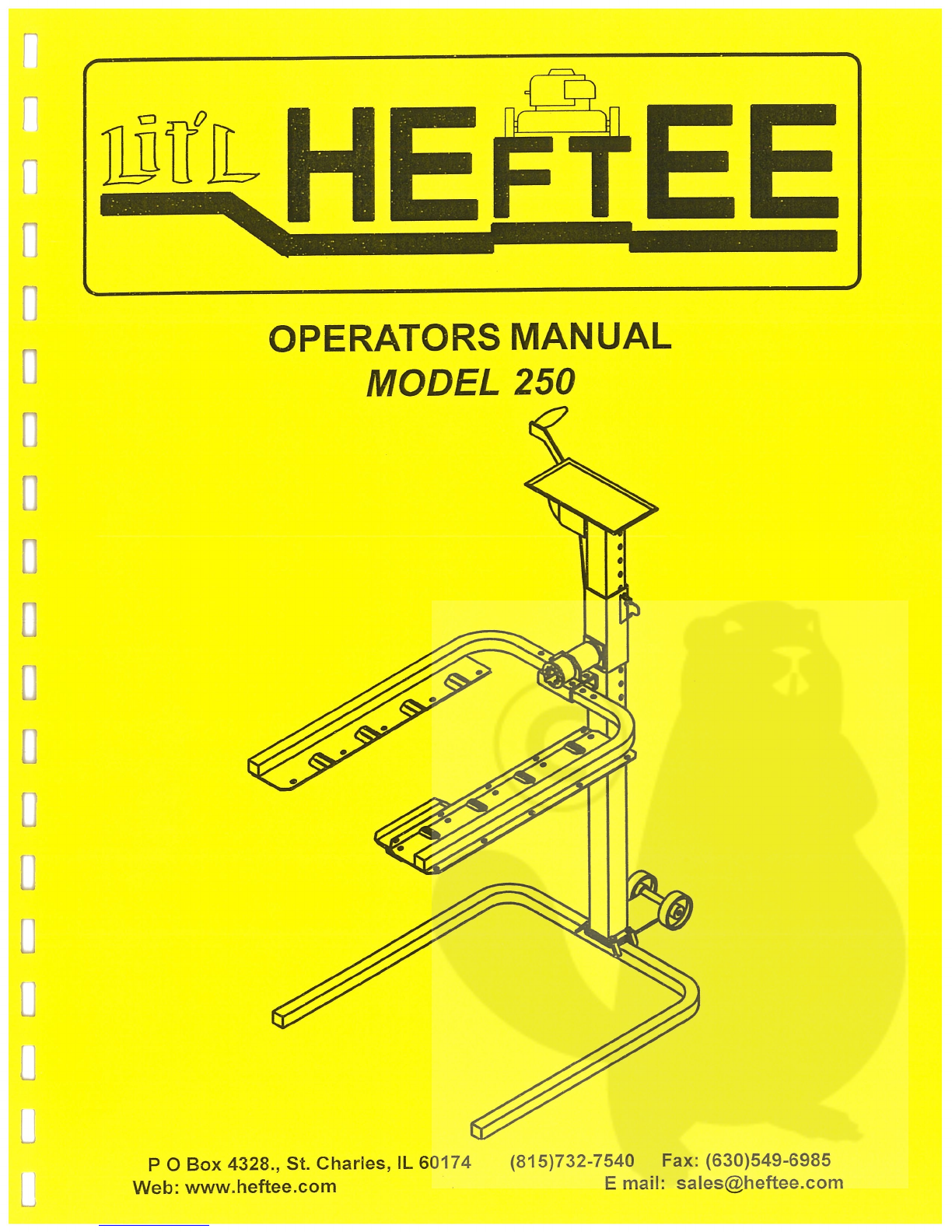

Heftee 250 User manual

OPERATORS

MANUAL

ODEL

250

P

0

Box

4328.,

St.

Charles,

IL

60174

[j

Web:

www.heftee.com

(815)732-7540

Fax:

(630)549-6985

E

mail:

1

TABLE

OF

CONTENTS

SAFETY

CERTIFICATJON:

This service

lift

does

~

come

within

the

scope

of

any

safety

standard

requirements.

However,

It

does

meet

all

of

the known

~pplicable

requirements

of

standards

relative

to

safety

and

that

are

underthe

control

of

the

manufacturer. Winch

conforms

to

ASAE

S361

.3.

FF-M50

-

1(10/99)

Serial

Number

Date

05/94

Description

250#

—

HL250

SPECIFICATION

3

CHECKLISTS

4

GENERAL

INFORMATION

4

SAFETYINFORMATION

5-7

SAFETYDECALS

ASSEMBLYINSTRUCTIONS

8-9

OPERATINGINSTRUCTIONS

io-ii

INDEXTOPARTS

12-13

SERVICE

JNSTRUCTIONS

14

WINCHINSTRUCTIONS

F-1&F-2

SERVICE

BRACKETS

&

HL200

KIT

MANUAL

In

Back

WARRANTY

Inside

Back

Cover

HL-1

SPECIFICATIONS

Lit1~.

HEFTEE

RATEDLIFTCAPACITY

250#

91

Kg

OVERALLWIDTH

maximum:

37”

86

cm

OVERALL

HEIGHT(MANUALWINCH)

6111

55CM

DEPTH

-

FRONT

TO

BACK (APPROX)

48”

122CM

TREADWIDTHTOOUTSIDEQFWHEELS

maximum:

34”

86cm

TREAD

WIDTHTO

INSIDEOFWHEELS

minimum:

13”

33

cm

LIFT FRAME

WIDTH

ADJUSTABLE

BY

PINS

maximum:

37”

86

cm

LIFT

FRAME

WIDTH ADJUSTABLE

BYPINS miminum:

20”

51

cm

LIFT

FRAME

FORK

LENGTH

39”

86CM

LIFT

HEIGHTTO

BOTTOM

OFWHEELS

maximum:

49”

125

cm

TREAD

LENGTH

(BETWEEN

AXLECENTER

LINE)

maximum:

30”

76

cm

LIFTCABLE:

1!8”AIRCRAFT

32cm

DROP

SAFETY

CONTROL

SAFETY

LOCK:

each

1

Y2”

down

to

21”

height

2

TRANSPORT

WHEELS

-

USABLE

WHEN

UNIT

IS

TIPPED BACK 4”

10

cm

dia

SHIPPINGWEIGHT(BASIC

MACHINE)

155#

64

Kg

SHIPPINGBOXSIZE

1

BOX

53Y2X32X5Y2”

135X81

X

14cm

LOADTESTEDAT~

1000

Ibs

364Kg

INSTALLATION:

NONE

REQUIRED

FOR

STANDARD FLOOR

MODEL.

USES

SUPPORT

LEGS.

WINCHRATIO(EFFECTIVE)

.

APPROX.

1:10

WINCH

ACTION:

10

TURNS

TO

FULL

UP

(APPROXIMATELY).

WINCH

TYPE:

AUTOMATIC

BRAKE—HANDLE STOPS

WHEN

RELEASED,

EITHER

UPOR

DOWN.

NO

CHANGE

REQUIRED.JUSTCRANKUP,C’RANKDOWN.MEETSASAESAFETySTANDARDFORSAFETyWINCH

ASAE

S361,3

SAFETY

FOR PORTABLE

AGRICULTURAL

AUGER

CONVEYING

EQUIPMENT

WHICH

INCLUDESWINCH

REQUIREMENTS:

Patent

Pend

Ing

-

Subject

to

charige

without

notice.

FF-M50

-2

(Rev.

12/97;

3/04)

HL

-

3

Lît’L

HEFTEE

A

NEW

GENERATION

IN

SERWCE

SAFETY

AND

CONVENIENCE.

CHECK

LISTS

PRE-USE

CHECK

LIST

GENERAL

CHECK

LIST

BEFORE

EACH

USE

lnspect

the

Lit’L

HEF

TEEthoroughly

after

assembly

to

be

certain

that

it

is

set

up

properly. The following

~

Measure

and

be

sure

wheels

of

machine

are

checklist

is

a

reminder

of

points

to

inspect.

Check

centered

in

wheel cups before raising.

off

each

item

as

it

is

found

satisfactory

or

after

proper adjustment

is

made.

L1

On

heavy

loads,

be

sure

weight

is

centered

on

EJCheck

all

boits

to

make sure

that they

are

tight.

lift

as

much

as

practical.

NOTE:

See

assembly

instructions.

LJAlways

tie

machine

to

an

arm

on

EACH

side

LII

8e

sure

safety

lock

operates freely

and

snaps

before performing

any

work, rotating,

raising,

etc.

into

place

and

hooks

and

locks properly.

8e

sure

rotational

safety

lock

swings

into

lock

Check

all

bolts

to

make sure

that

they

are tight.

position

freely.

r::i

Be

sure winch cable

is

wrapped

evenly

and

secured

to

the

lift lug.

Also

be

sure

the

cable

is

free

of

kinks or

frayed

areas.

GENERAL

INFORMATION

The

purpose

ofthis

manual

is

to

assistthe

operator

in

MAl

NTE

NANCE

maintaining

and

operating

the

Lift

HEFTEE.

Read

it

carefully.

It

furnishes

information

and

instructions

Keep tie

downs

and

safety

locks

in

good

condition

that

will

help

you

achieve

years

of

dependable

and and

working

properly.

safe

performance.

These

operating

and

maintenance

instructions

have

been

compiled

from extensive

expe

rience

and

engineering

data.

The

illustrations

and

data used

in

this manual

were

current

at

the

time

of

printing.

But

due

to

possible

in-

line

production

changes

your

lift

may

vary slightly

in

detail.

HEFTEE

Industries

LLC

reserves

the

right

to

re-design

and

change

the

lift as

may

be

necessary

without

notification.

FF-M50

-4

(3/99)

HL-

4

TO

THE

OWNER:

Read

this

manual before

using

your

Lit’L

HEFTEE.

The

information

presented

will

prepare

you

to do

a

better,

safer

job.

Keep this

manual

handy

for

ready reference

and

training

of

future

users.

The

Lit’L

HEFTEE

you

have purchased

has

been

carefully

engineered

and

manufactured

to

provide

dependable

and

satisfactory

use.

Like

all

mechanical

products,

t

will

require

cleaning

and

upkeep.

Service

the

Lift

HEFTEE

as

specified. Observe

all

safety

information

in

this manual

and

safety decals

on

the

Lit’L

HEFTEE.

Use

onlygenuine

HEFTEE

service

parts.

Substitute

parts

will

void

the

warranty

and

may

not

meetstandards

required

for

safe

and

satisfactory

operation.

Record

the model

and

serial

number

of

your

Lift

HEFTEE.

Model:

_______________

Serial

Number:

(Located

on

the

slider

asy

of

Lift

HEFTEE

frame)

Throughout

this

manual, the

term

IMPORTANT

is

used

to

indicate

that failure

to

observe

can

cause

damage

to

equipment.

The terms

CAUTION,

WARN

ING,

and

DANGER

are

used

in

conjunction

with

the

Safety-Alert

Symbol,

(a

triangle

with

an

exclamation

mark),

to

indicate

the

degree

of

hazard

for

items

of

personal

safety.

SAFETY

TAKE

NOTE! THIS

SAFETYALERTSYMBOL

FOUNDTHROUGHOUTTHIS

MANUAL

IS

USED

TO

CALL

YOUR

ATTENTION

TO

THE

INSTRUCTIONS

INVOLVING YOUR

PERSONAL

SAFETYAND

THE

SAFETY

OF

OTHERS.

FAILURE

TO

FOLLOWTHESE

INSTRUCTIONS

CAN

RESULT

IN

INJURY

OR

DEATH.

THIS

SYMBOL MEANS

-ATTENTION!

-BECOME

ALERT!

-YOUR

SAFETY

IS

INVOLVED!

CAUTION

lndicates

a

potentially hazardous situation

that,

if

not

avoided,

may

result

in

minor

or

moderate

injury.

It

may

also

be

used

to alert

against

unsafe

practices.

WARN

ING

Indicates

a

potentially hazardous situation

that,

1f

not

avoided,

could

result

in

death

or

serious

injury,

and

includes hazards that

are

exposed

when

guards

are

removed.

It

may

also

be

used to

alert

against

unsafe practices.

DANGER

Indicates

an

imminently hazardous situation

that,

1f

not

avoided,

will

result

in

death

or

serious

injury.

This signal

word

is

to

be

limited

to

the

most

extreme situations

typically for

machine

components

which,

for

functional

purposes, cannot

be

guarded.

5/94(REVISED

11/96)

PATENTS

PENDING

HL-5

SAFETY

INFORMATION

The

Lît’L

HEFTEE

has

been

designed with every

possible

safety

provision

known,

except

a

careful

opera

tor,

but only

you

can

assure

proper

and safe

use.

TRAINING

OPERATIONALSAFETY

~

READ

this

manual

especially

the

safety

and

operating

instructions

before

using.

CAUTION

c~’

Do

not

allow

children

to

operate

or

play

on

In

addition

to

the

design

and

the

configuration

machine

and

do

not

allow

anyone

to

operate

without

of

equipment,

Hazard

control

and

accident

pre

proper instruction.

vention

are

dependent

upon

the

awareness,

con

cern,

prudence

and

proper

training

of

personnel

Ç~’

Allow

no

one

to be

on

or

under machine

while

involveci

in

the

operation,

transport,

mainte

raising

or

lowering or

operating

the

controls.

nance

and

storage

of

equipment.

~

Always

wear

safety glasses, safety

shoes

and

proper

clothing

for

the

job.

c~’

Never

use

drugs or

alcoholic beverages

when

operating

any mechanical

equipment

especially

the

HEFTEE.

~~‘Replace

any

decals

immediately

if

damaged.

Clean

area

for

decal

with

soap

and

water.

Remove

any

dirt,

grease

or

remnants

of

old

decal.

Re-apply

pressure

sensitive

decal

in

same

location.

~

Position

machine

carefully

with

all

wheels

cen

tered

in

wheel

cups before

raising.

On

heavy

loads

keep

weight

centered

as

much

as

feasible

and

close

in

to

mast.

cZ

Do

not

try

to

lift

over

250#

on

HL250.

1f

it

will not

easily

raise

the

bad,

it

is

too

heavy.

Do

not

try

to

lift

full

bad

on

end

of

arms.

Read

and

observe

all

safety

decals

on

the

Lift

HEFTEE.

ç~

Never

albow

anyone

on

the

equipment

or

under

equipment

when

raising,

bowering,

or

in

any

way

operating

control.

~

Always

bower

lift

onto

safety

locks

before

at

tempting

any

work

and

bower

to

fboor

before leaving.

c~’Tie

machine

securely

to

the

lift

arms

or

wheel

cups

on

both

sides before

attempting

any

repairs.

Use

straps

provided.

ç~’

Do

not

run

machine

engine

while

on

lift.

Discon

nect

spark

plug

wire before doing

any

service

work.

FF-M50-6

HL-6

SAFETY

INFORMATION

REMEMBER

“ONLY

YOU

CANASSUREA

SAFE OPERATOR”

DO

NOT EVER

run

engine

while

on

the

lift

be

sure

~

Take

all

possible precautions when

leaving

Lift

attachments

are

disengaged,

and

machine

is

tied

HEFTEE

unattended, lower

to

ground.

securely

to

the

arms

so

it

cannot

move.

~

Periodically

check

the

entire

Lift

HEFTEE

care

DANGER

fully

for

cracks,

bent

or

worn

parts,

proper

cable

adjustment,

loose

bolts,

etc.

Do

not

use

until

prob

Remove

spark

plug

wire

before

doing

any

ser-

lems

have

been

corrected. Retorque

bolts

periodi

vice

work.

cally.

ç~’

Keep

fire

away

from

fuel.

c~

Be

sure

cable

is

in

good

condition

with

no

kinks

ç~’

Do

not

use

as

a

man

lift.

or

frayed

areas.

c~’

Hold

the

arms

and

bad

securely when

rotating

to

CAUTIO

N

maintain

safe

control.

c~’

1f

t

is

used

for

boading

or

as

a

work

table,

etc.,

Do

not

try

to

lift

heavy

bad

on

the

END

of

just

fasten securely

to

lift

arms

to

avoid

tipping

or

sliding

one

arm

as

this

could

cause

failure of

arm

or

off.

pivot lock

and

possibly

a

falling

bad.

KEEP

LOAD

CENTERED.

ç~

Keep

all

locking

devices

in

place

and

in

good

cond

ition.

SAFETY DECALS

Replace

lmmediately

1f

Damaged

Order

By

Individual

Decal

~Â

WARNING

Â

WARNING

To

Avoid

Injury

Or

Death

To

Avoid

Injury

Or

Death

*

Lower

Loads Before

Leaving.

*

Read

Operator~s

Manual

First.

*

NOT

A

MAN

LIFT,

DO

NOT

*

DON’T

LIFT

OVER

250#.

ALLOW

ANYONE

ON

LIFT.

*

Keep

All

Locking

Devices

In

Place

and

In

Good

Condition.

*

Avoid

Spilling

Gas,

Etc.

*

Use

Only

By

Qualified

Persons,

*

Keep Feet

Away

From

Lift

Legs

NO

CHILDREN.

NOT

A

TOY.

While

Lowering.

*

Strap

Securely

With

2

Straps

*

REMOVE

SPARK

PLUG

WIRE

Before

Working

0fl

Or

Tipping.

WHILE

ON

LIFT.

*

NEVER

OPERATE

WITH

A

*

Do

Not

Use

As A

Hand

Truck.

PERSON

ON

OR

UN

DER

LIFT.

*

Keep

Load

Close

To

Column

*

Don’t

Run

Engine

While

On

Lift.

and

Centered.

*

No

Smoking

Or

Fire

Near

Fuel.

ANYTHING

USED

CARELESSLY

ANYTHING

USED

CARELESSLY

CANCAUSE

AN

ACCIDENT,

CAN

CAUSE

AN

ACCIDENT,

EVEN

A

ROCK.

EVEN

A

ROCK.

__~~

HL1

07

FF-M50-7(REV.

1/95)

HL-7

PREPARATIONS

Read

this

manual

and

refer

to

parts

list

&

drawing

on

pages

12-13.

You

have

already

opened

the

container

to

view

this

manual.

Read

this

and

safety

section.

Open

the

winch

box

and

remove

small parts inside.

Open

all

containers

and

spread

out parts

for easy

access.

WARNING

Only

qualified

assembiers

should

work

on

this.

No

children.

Be

very

careful.

Use

hard

hats

and

safetyshoes.

MAST

BASE

LEG

ASSEMBLY

Restthe

base

tubeassembly

on

thefloor.

Position

the

bottom

ofthe mast

tube onto

the

base

tube

mounting

plate

so

that

the

holes

line

up.

When

looking

into

the

mast

tube

and

standing

between

the

legs,

the

row

of

holes

in

the

side

of

the

mast

tube

must

be

on

the right

side.

Refer

to

Assembly

Drawing

on

page

13.

Insert

four

(4)3/8

x

1

boits

downward

through

the

four

(4)

attaching

holes

and

secure

with

a

flanged

nut.

Tighten

securely.

Your machine

may

be

shipped

with

the

slider

removed

from

the

mast.

1f

so

proceed

as

follows

Instali

the

slider

down

over

the

mast

tube with the

safety

lock lined

up

with

the

holes

on

the right

side.

Note:

Be

sure the

four

(4)

nylon

buttons

stay

in

their

holes

onthe

inside

and

do

not

fall

outwhile

installing.

WINCH

-

TOOL TRAY

ASSEMBLY

Mount

the

winch

ontothe

mounting

angle

using

four

(4)

3/8

xl”

boits

pos

itioned with the

heads

inward

toward

the

mast

and

theflange

nuts

inside

the

winch. Tighten

securely.

Be

sure

the

crank

handle

is

positioned

towards

the

rear

(away from

the legs).

Locate

thewinch

mounting angle

onto

thetwo

boits

0fl

top

of

the

mast

with

the

winch

mount

on

the

side

opposite

the

safety

lock holes.

Position

the

tool

tray

on

top

of

these

bolts

and

secure

with

the

Y2”

flange

lock nuts.

Tighten securely.

The

hole

in

one

corner

of

the

tool

tray

is

for mounting

a

trouble

light

if

desired

and

should

normally

be

positioned

towards

the

legs (front).

Instail

the

winch crank handle

ontothe

pivot

shaft

and

tighten the

nut

that

is

provided

securely.

1f

cable

is

not

installed:

Fasten

the cable

onto

the

winch

drum

following

the

winch

instructions

provided

with

the

winch

(repro

duced

on

pages

F1

-F2),

so

thatthe cable

runs

inside

of

and

over

the

roller tube

and

downward

next

to

the

vertical mast

tube.

Tighten

the

cable

locking

clamps

securely.

Slip the loop

of

the

cable

up

over

the

lift

lug

on

the

side

ofthe sliderand

crank

upward

to

remove

the

slack

and

pull

securely.

It

is

recommended that

the

lift lug

be

bent

ifiward

slightly,

hitting

it

with

a

hammer,

so

that

the

cable

cannot

slip

off inadvertently.

WHEEL

ASSEMBLY

The

wh~els

are

already loosely

assembied

onto

the

pivot

shaft

with

washers

and

cotter

pins.

Remove

a

cotter

pin,

wheel

and

washers

from one

end,

slide

the

assembly

through

the

pivot

tube

on

the

back

of

the

lift

afid replace

with

a

washeron

each

side

of

each

wheel,

install the

cotter

pin

afid

spread

the

ends

to

secure.

LIFT ARM

ASSEMBLY

To

assemble

the

lift

arm

moufit assembly

merely

slip

it

onto the

pivot

tube which

extends

forward

from

the

vertical

slide

tube.

Line

the

lock

lug

up

with

one

ofthe

grooves

in

the

index

plate,

raise the

lock

lug

up

and

slide

the

assembly

inward

until

the

lock

drops

down

in

one

ofthe

grooves

and

locks

in

front

of

the

index plate

to

hold

the

entire

assembly

in

position

and

prevent

from

rotation.

The

arm

mounttubes

should

be

below

the

pivot

tube

as

shown

in

the

assembly

drawing. This positions the

arms

lower

to

the

floor

and

more

nearly

centers the

bad

about

the

center

pivot

shaftfor

easier

rotation

and

better

balance.

To

rotate

the

pivot

arm

assembly merely

lift

up on

the

bock

lug and

rotate

until

it

drops

into the

desired

position

slot.

ASSEMBLY

ONSTRUCTIONS

WINCH

ASSEMBLY

FF-M50

-8

(REV. 1/95,

9/98)

HL-8

ASSEMBLY

INSTRUCTIONS

NOTE:

It

is

not

necessary

to

lubricate

the

pivot

assembly,

it

will

rotate

rather

hard with

a

heavy

bad

but

this

is

an

advantage

in

holding

it

in

position

as

one

rotates.

Lubricant

may

be

used

if

desired.

Now slide the

lift

arms

into

the

square sleeves

on

the

arm

mount

assembly.

NOTE:

8e

surethelongerliftarm

is

on

the

leftside

as

facing

the vertical mast

tube

and

the

shorter

one

is

on

the

right.

This

will put

the ends

of

the

arms

approxi

mately

even. Slide

them

into

desired

position

and

secure

with

the

%~‘

balI

lock

pins

in

the

desired

hole.

When preparing

to

lift

a

bad,

it

is

desirable

to

keep

the

lift

arms

approximately equally

spaced

from the

center

pivot

so

that

the

bad

will

be

centered.

~WARNJNG

Tie

any

bad

securely

on

both

sides

before

raising

and

remove

the

spark plug

wire

before

servicing.

DO

NOT

RUN

ENGINE

ON

LIFT.

Be

careful

of fuel,

oil

or

acid

spillage

when

rotating

and

hold

securely.

Do

not

allow

fire

cbose

to

an

eng

me.

Keep

all

safety

Iocks

in

place,

secure

and

operat

ing

properly

Lower

bad

(keeping

feet

away

from

the

lift

area)

before

leaving.

Add

on

wheel

cup.

The

wheel

cup

extension

is

a

loose

piece which

may

be

positioned

any

place along

either

side

to

accommodate

a

wheel

of

a

machine

that

has

an

odd

(not

evenly

spaced)

wheel

positioning.

This

is

particularly

notable

on

the Lawn

Boy,

in

which oase

the

wheel

cup

should

be

positioned

to

the

outer

set

of

holes

on

the right

side

to

accommodate

the

right inner

rearwheel

of

the

push

mower.

Bolt

it

in

place with

two

(2) 3/8

x

1”

bolts

and

flange

nuts.

CHECK

OUT

The

vertical

slidershould

now

slidefreely

up

and

down

the

column

using

the

winch

handle.

It

takes ten

(10)

turns

to

fully

raise or

lower.

NOTE:

It

is

necessary

to hold

the

safety

lock

away

from

the

tube

while

bowering

as

itwill

stop

in

each

hobe

as

t

bowers

past

it.

The lower

area

has

no

holes

to

ease

bowering

once the

bad

is

out

of

the

normal

work

range.

No bubrication

is

required

on

the

vertical slider

column.

The

rollers should

roll

freely

and

there

will

be

no

significant

bad

on

the

slider washers

except when

a

bad

is

offset

considerabby

to

one side.

Machine

should now

be

ready

for

use.

CAUTION

Check

to

make

sure

that

all

parts

are

installed

and

positioned

the

same

as

shown

on

the

parts

drawing.

Do

not

exceed

250#

bad

and

don’t

lift

it

all

on

one

(1)

arm.

CHECK

0FF

Check

the

machine against

the

drawings

and

com

plete

the

pre-use check

list

on

page

4.

Read

the

operating

instructions

and

check

Lit’L

HEFTEEto

be

sure

all

functions operate

properby

and

safeby.

CAUTION

Do

not

albow

anyone

on

or

under

lift

when

operating.

Use

Lit’L

HEFTEEonIy

on

a

level

firm

floor.

FF-M50

-9

(REV.

1/95,

9/98)

HL-9

CAUTION

Read

the

operator’s

manual.

Any

lifted

bad

poses

a

potential

hazard and

if

used

carelessiyor

improperly

can

cause

falling

loads

and

serious

1

nj

u

ry.

Review

the

“before operation”

check

list

to

make

sure

that everything

is in

proper

condition,

bolts

are tight,

etc.

See page

4.

Read

and

understand

all

items

in

safety

section.

Position

Lit’L

HEFTEE

for convenience

in

driving

machines

on

oroif

and

providing easy access

to

the

lift

controls.

Use

Lit~L.

HEFTEE

only

on

a

firm

level

floor.

WARMNG

Do

not

albow

children

or unqualified

operators

to

use

or

work

on

this

lift

and

do

not

use

alcohol

or

drugs

when

using

any

equipment.

Do

not

attempt

to

raise

loads

that

exceed

250# and

do

not

lift

allof

the

bad

on

the

end

of

only

one

arm.

Lower

to

fboor

before

leaving.

WARNING

Keep

all

safety

locks

in

place and

in

good

condi

tion.

Wear

safety

shoes

and

eye

protection.

Your

Lit’L

HEFTEE

should now

be

ready

to use

to

elevatea

machine.

Somegeneral principalswill

make

operation

quicker, easier,

and

safer.

As

follows:

1.

Measure

the

width

of

the

outside

of

the

machine

wheels

to

be

raised.

Then

position

thewheel

arms

so

the

wheels

of

the

lifted

machine

will

rest

in

the

center

of

the

channels. Either

lift

arm

may

be

moved

inward

or

outward

by

removing

the

spring

balI

pin.

Liftthe

end

of

the

arm

so

itslides

freely

in

its

tube

and

reposition

as

needed.

8e

sure

and

position

both

arms

so

thatthe

machine

wheels fit securely

in

the

channels

and

the

bad

is

as

near

centered

on

the

lift as

practical.

NOTE: Position

so

that

on

heavy

machines

theweight

will

be

centered

as

well

as

practical.

NOTE:

It

is

a

good

idea

to

keep

the

machine moved

in

closer

to

the

mast

as

long as

accessibility

is

not

compromised,

just

to

get

more

rigidity

and

stabibity.

2.

Now

most machines

can

just

be

pushed

directly

onto the

Lit’L

HEFTEE

and

into

the

wheel

channels.

WARNING

Do

not

operate

lift

with

anyone

on

the

machine

or

under

it.

Use

extra

caution

if

anyone

is

near.

3.

For

odd

or

uneven

wheel

tread

machines

it

may

be

necessary

to

bolt

on

the

extension

wheel

cup

as

needed.

4.

TIE

DOWN.

It

is

most

practicab

to

raise

the

machine

one

to

two

feet

for

ease

of access.

Then

tie

the

machine

securely

to

the

wheel

channels

using

the

two

nylon tie

straps

provided.

The

bestway

usually

is

to

run

one

strap length

ways

on

each

side

and

route

inboard

of

the

push

arm

mounts,

wheels,

etc.

1f

any

wheels

are

to

be

removed,

then

tie

so

that

the

strap

will

not

be

in

the

way

of

the

wheels

nor

will

t

be

released

when

the

wheel

is

removed.

This

may

require

tying

crossways

of

the deck

or

even

in

an

DX”

pattern

ifappropriate.

5.

The

machine may now

be

raised to

the

desired

working

height

and

tilted

as

required.

MOWER

SERVICE

Some

mower

decks

have

a

fixed

discharge which

extends

out

considerably

beyond

the

wheels.

In

this

case

t

will

usually

be

desirable

to

lower

the

wheels

(raise the

deck)

so

the

chute

and

deck

do

not

rest

on

the

arm

tubes.

OPERATIING

INSTRUCTIONS

Everything known

has

been

done

to

make

easy,

convenient,

and

safe

opera

tion with

a

minimum

of

strain

and

time.

No

tools

are

required

for

any

forma!

use

adjustments

or

uses,

except

to

bolt

on

the

extension wheel

cup

ifneeded.

FF-M50-

10

HL-

10

OPERATING INSTRUCTIONS

DANGER

Always

tie

down

the

machine

securely

on

both

sides

before

working

on

it.

Operate and/or

rotate

carefully

and

use

the

standard

tie downs

always.

When

rotating

be

careful

of

spilling

gasoline, oil,

battery

acid,

etc.

Do

not smoke

or

allow

fire

near

machine.

1f

oh

and/or

gas

is

to

be

drained

from

the

machine

by

rotating

or

tipping,

be

very careful

in

placing

the

containerto

avoid

spillage.

Rotating

a

heavy

machine

should

only

be

attempted

with

two

(2)

persons

to

provide

control.

Be

certain

the

tie

straps

are

tight

before

attempting

any

tipping.

WARNING

Remove

the

spark

plug

wire

from

the

engine

beforeattemptinganyservice.

AN

ENGINE

COULD

START

merely

by

pulling

a

blade around

in

the

removal

or

installation

process.

Never

attempt

to run

any

engine

while

on

the

lift.

The

opportunities

for

injury

are

SEVERE

AND

OBVIOUS.

When positioning

the

mowerfor properworking

height,

raise

to

desired

level, then

Iowerenough

sothe

safety

lock

is

engaged

in

the

hole.

Leave the

handle

in

this

position

so

that

the

winch

is

also

supporting

the

bad.

NOTE: When

operating

the

winch

KEEP

CABLE

TIGHT. Any

boose

cable

will

cross

and

twist

on

the

drum.

Then when

tightened,

it

may

have

slack areas

which,

as

the

bad

is

lowered,

will

albow

a

short

dropping

of

the

bad

as

the

slack

is

taken

up.

To

bower,

raise

the

winch

high

enough

so the

safety

lock

may

be

swung

out

of

the

tube, then,

holding the

bock

raised

with

the

left

hand,

lower

the

winch

by

cranking

It

countercbockwise with

the

right hand.

There

are

no

batches

to

reverse

or any other

action

required.

The

handbe

will

stop

wherever

released,

eithergoing

up

ordown.

CAUTION

Nevertry

to

use

the

lift

as

a

hand

truck.

1f

a

mower

must

be

moved

on

the

lift,

lower

it

down

near

the

floor

level

before

tippirig

backwards

on

thewheels.

Also, operate

carefully

so

it

does not

roll

off

sideways.

Keep

feet

away

from

the

base

tube

and

out from

under

the

lift

arms

while

lowering.

Wear

safety

shoes

and

other

protective

clothing

as

appropriate.

OTHER

USES

The Lit’L

HEFTEE

makes

a

very

convenient

lifting

platform

for

raising

a

bad

to

work

on

it.

CAUTION

Do

not

raise

or

lower

the

lift

arms

with

anyone

on

or

under

it. Use

it

for

a

work

table

only

when

the

lift

has

been

lowered

into the

safety

locks.

Always

use

a

pallet

or

other platform that

is

locked

to

the arms

and

under

them

so

that

it

cannot

tip

or

slip

off

of

the

forks.

Asimplework

platformwith

stirrupsthat

go

around

the

arms

can

make

a

real

contribution

to

safety

and

productivity

by

raising

such

things

as

engines, tooling,

or

other

hard

to

handbe

difficult

objects

to

a

level

most

convenientforworking

on

etc.

OTHER

ATTACHMENTS

The

entire

lift

arm

and

mountassembly

may

be

slid

off

of

the

vertical

slider

mereby

by

raising

the

pivot lock

in

one

of

the

grooves

and

sbiding

the

assembly

offthe

end

of

the

tube.

To

use

the

engine

mount,

chain saw,

or

string

trimmer

brackets,

just

remove

the two

(2)

lift

arms

and

insert

the

desired

service

bracket.

The

most

convenient

positions

are

shown

in

the

brackets

draw

ing.

As

can

be

seen

by the

great

extent

to

which

safety

has

been

considered

on

this

machine,

we sincerely

hope

that

no

one will

ever

be

injured

or

hurt.

We

cannot

guarantee

that,

as

anything

can

cause

harm

if

used

improperly, even

a

rock.

Any

raised

heavy object

is

a

potential

hazard

if

it

shoubd

fabb

with

someone

under

neath.

PLEASE

USE

WITH

CAUTION

AND

RESTRAINT.

CAU11ON

Before

leaving

Lft’L

HEFTEE

always

lower

it

to

the

ground to

discourage

uriauthorized

use

by

the careless, the

unqualified,

or

children.

FF-M50

11

(REV.

1/95,

4/95)

HL-

11

PARTS

LIST

FOR

Lît’L

HEFTEE

MAIN

ASSEMBLY

2....

3....

4....

5....

6....

7....

8....

9....

10

11

.

12

DR

USE

12*.

13A

14

15

16

16A...

18

19

20

21

22

23

24

1

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

2

O/L*

-

OBTAIN

LOCALLY

A/R**

-

AS

REQUIRED

HARDWARE

O/L*

8

3/8’

FLAT

WASHER

(used

on

early

machines)

10

3/8’

NC

FLANGE

HEX

LOCK

NUT

2

3/32

X 1-1/4”

COTTER

PIN

10

3/8NCXI”HEXHEADCAPSCREW

2

1/16

X

3/4”

COTTER

PIN

2

3/8X4-1/2”HEXHEADCAPSCREWG5

2

1/2”FLANGEHEXLOCKNUT

2

1/2”SAE

FLAT

WASHERS

6

3/8”FLANGENONLOCKNUT

2

3/8”

TOP LOCK NUT

FF-M50-

12

(Rev.

5/95, 6/95,

9/95.11/96,12/97,1/98,4/98,

HL-

12

9/98,

3/99,

9/99)

1

REF.

NO.

PART

#

NO.

REQ.

DESCRIPTION

1

....

HL129

HF265

4

HL147

1

HL146

1

HL165

1

HLI5O

1

HLII3

2

HL139

1

HL132

1

HL155

1

MF658

1

HLI2I

4

12*

BELOW

FOR

MODELS

AFTER

SH2693

2

+

2-HLI2I

13....

HL218

1

HL123

1

HLI2O

1

HL1I9

1

‘HL163

HL162

HL116

HL137

HL143

HL126

MF659

HL138

HL153

BASE

LEG

TUBE

ASSEMBLY

PLASTIC

END

PLUG

LONG

LEFT

LIFT

ARM

ASSEMBLY

SHORT RIGHT

LIFT

ARM

ASSEMBLY

EXTENSION

ADD-ON WHEEL

CUP

ARM

MOUNT

ASSEMBLY

14”

X

2”

BALL

SPRING

PIN

WITH

RING

SWIVEL

LOCK

LATCH

SLIDER

TUBE

ASY w/

ROLLERS

&

BUSH1NGS,

ETC.

COMPLETE

SWIVEL

LOCK

COMPRESSION

SPRING

14

X

3,4

DRILLED PIVOT

PIN

1-1/8”

OD

X

1/16

THICK

NYLN FLANGE BEARING

(SLIDER

BUTTON)

5-1-95

—

these

are

included

in

HL123

3/4”

OD

NYLON

BEARING

W/

1/8

THICK

FLANGE

(used

after

5/1/95)

1-1/8”

OD

X

2-7/8”

LONG

STEEL

ROLLER

W/BEARINGS

(changed

5/98)

SET

OF

2

ROLLERS

WITH

BEARINGS

&

NYLON

SIDE

SPACERS

WINCH

CABLE

1/8

X

62”

LONG

1

TON

SAFETY

LOCK

WINCH

WITH

HANDLE

AND

CABLE ROLLER

(NO

CABLE)

5/8

OD

X

3-5/8”

STEEL

PIPE

CABLE

ROLLER

Always order

7/16

x

3-3/4” FRAME

SPACER

SLEEVE

in

pairs

WINCH

HANDLE

TOOL

TRAY

WINCH

MOUNT

ANGLE

VERTICAL MAST TUBE

ASSEMBLY

5/16

X

1-1/4”

DRILLED

LOCK

PIN

SAFETY

LOCK

DOG

SAFETY LOCK

TORSION

SPRING

SAFETY DECAL

SAFETY DECAL

LIT’L

HEFTEE

DECAL

4”

DIA.

WHEEL

WHEELAXLE

ROD

-WELD

ON

NOW-WAS

SEPARATE

ON

PRIOR

MODELS

PATENT DECAL

DECALSET

NYLON

TIE

DOWN

STRAPS

25

....

HLIO7

26

....

HL1O8

27

....

HLII4

28

....

HL154

29

....

HL159

30

....

STI5I

31

.

...

HL168

32

....

HF235

40

(early

models)

41

Oi’L~

42

O/L*

43

O/L*

44

O/L*

45

O/L*

46

O/L*

47

O/L*

48

O/L*

49

O/L*

L1rL HEFTEE

MAIN

ASSEMBLY

FF-M50

-13

(REV.

7/94,

1/95,

5/95,

6/95,

9/95,

1/98,

4/98,

9/98,

9/99)

\49

NOT

SHOWN

~—DECAL

SET

~—TIE

DOWN

STRAPS

HL-13

SERVOCE

ONSTRUCTIONS

CAU11ON

Read

the

operator’s

manual before

trying

to

operate or

service.

Any

lifted

bad

poses

a

potential

hazardarid

if

used

carelessly

or

im

properly

can

cause

falling

loads

and

serlous

i

njury.

WARNING

Do

not

allow children or unqualified

operators

to

use

or

work

on

this

lift

and do

not

use

alcohol

or

drugs

when

using

any

equipment.

Do

not

attempt

to

raise

loads greater

than

it

will

easily

lift.

Do

not

exceed

250#.

Lower

to

floor

before

leaving.

The

Lit’L

HEFTEE

has

been

designed

to

minimize

service

as

much

as

possible.

Refer

to

parts

drawings

and

safety

pages

before

working

on

Lift

HEFTEE.

INSPECTION

Periodically

check

your

Lit’L

HEFTEE

carefully

for

loose bolts,

proper

cable

lay

and

any

sign

of

cracks,

kinks

or

frayed

areas.

Replace

if

found.

DO

NOT

USE

if

any

problems

are

found. Your

safety

depends

on

it.

LUBRICATJON

1.

The rollers

used

after

4-98

in

the

slider

are solid

steel with

bronze

busings.

These

need

to

be

removed

orjust

remove

the bolt and

squirt

grease

into

the

base.

2.

The

rollers,

referto

#1

6,

page

13,

on

which

the

cable

rods

must

be

removed

and

insert

grease

to

prevent

wear

and

drag.

3.

The

arm holder,

refer

to

#6,

page

13,

will

rotate

easily

if

grease

is

added

to

the bore.

MAINTENANCE AND

REPAIRS

Proceed

as

follows.

SLIDER

ROLLER

BEARINGS.

1f

any

portion

of

the

slidertube

comes

within

1/32

of

an

inch,

underload,

oftheverticalmasttube,

itmeansthe

rollers

or

slider washers

are

worn

or

damaged

and

should

be

replaced.

Repair

as

follows.

First,

remove

the

arm

assembly

from

the

slider

tube

pivot

shaft

by

lifting

the rotation

lock

in

one

of

the

grooves

and

just

pulling

the

assembly

off

the

pivot

shaft.

It

is

easier

to

hand

le

if

the

lift

arms

are

removed

from this

assembly

first,

but

may

be

done

eitherway.

To

replace,

unhook

the

cable

from

the

slider

tube, this

may

require bending

thetab out

slightly

as

it

may have

been

bent

in

after installation.

Remove the

tool

tray

and

winchfrom

the

top

ofthe

mast

by

removing

the

two

(2)

Y2”

nuts.

Now

slide

the

slider

tube

assembly

off

the

top

of

the

mast,

being

careful

not

to

loose the nylon

wear

buttons

or

allow them

to

drop

inside

the

tube.

Check

the

rollers

and

pivot

boltfor

clearance.

1f

loose,

floppy,

worn,

etc.,

replace these

rollers.

Merely

remove

the nut

and

slide the

bolt

out,

insert new

part.

Grease

the

roller

and

slide

the

bolt

back

in

and

tighten

the nut

securely.

Do

not

try

to

tighten

it

up

solid

against

the

rollers.

See

p.

13

for

proper

assembly,

To

replace,

the

butttons

hold

them

in

place

so

they

do

not

fall out.

You

may

use

silicone

glue

or

grease

to

help hold

in

place.

Next,

lower

the

slider

assembly

back

onto

the

vertical masttube

and

replace

the

winch

and

tool tray,

re-attach

cable,

and

lower

the

slider

tube

till

the

cable

is

tight.

CAUTION

Alwayswear

safety

shoes

and

safety

glasses

and

proper

clothing

when

doing

service

work

on

the

LîtL

HEFTEE

or

anything

else.

Lower

into

safety

locks

before

working

on

L1t7..

HEFTEE.

WARNING

Do

not

operate

lift

with

anyone

on

the

machine

or

under

it.

Use

extra

caution

if

anyone

is

near.

CAUTION

Keep

all

safety

locks

in

place

and

in

good

condi

tion.

SAFETY

LOCKS

Check

both

safety

lock

pivot

pins,

springs

and

mounts

to

be

sure

they

are

in

good

condition

and

snap

securely

into

locked

position. Repair

or

replace

as

needed.

Replace

any

decals

immediately

if

damaged.

Clean

area

for

decal

with

soap

and

water.

Re

move any

dirt,

grease

or remnants

of

old

decal.

Reapply

pressure

serisitive

decal

in

same

loca

tion.

WINCH REPAIR

See Fulton page

1-2

for

instructions

and

parts.

Order

parts

from

McCanse Engineering

using Fulton

Part

Numbers

shown.

FF-M50

-

14

(5/98)

HL-

14

BRAKE

WINCHES

~

DLBBOOA

_______________

MADE

IN

U.S.A.

DUTTON~LAINSON

____

COMPANY

SINCE

1886

451

West

2nd

St.

Hastings,

NE

68902-0729

OTEL:

402-462-4141

e

FAX:

402-460-4612

Web

Site

www.dutton-Iainson.com

i~j

DLB800A

MANUFACTURED

BY

Dwg.

No.

206306W

1/16

1

ISO

9001:

2008

Original

lnstructions

ENGLISH

IMPORTANT SAFETY INFORMATION

o

This

brake

winch

is

built

for

multi-purpose

hauling

and

lifting operations. It

is

not

to

be

used

as

a

hoist

for

lifting,

supporting

or

transporting

people,

or

for

loads

over

areas

where people

could

be

present.

•

Respect

this

winch.

High

forces

are

created when using

a

winch, creating potential

safety

hazards.

It

should

be

operated

and

maintained

in

accordance

with

instructions.

Never

allow

children

or

any

one

who

is

not

familiar

wiih

the operation

of

the

winch

to

use

it.

A

winch

accident

could

result

in

personal injury.

•

Check

winch

for

proper

operation

on

each use.

Do

not

use

if

damaged.

Seek

immediate

repairs.

• Never

exceed rated

capacity.

Excess

bad

may

cause

premature

fallure

and

could result

in

serious

personal injury.

This

winch

is

rated

on

first

layer of

cable

on

the

hub.

Using

more

layers

of cable

increases

the

bad

on

the

winch.

•

Never

apply

bad

on

winch

with

cable

fully

extended.

Keep

at

least

three

full turns

of

cable

on

the

reel. Check

cable

on

every

use. Replace

at

the

first

sign

of

kinks,

broken wires,

deformation or

any

other

damage.

•

Secure

bad

properly.

When

winching

operation

is

complete,

do

not

depend

on

winch

to

support

bad.

•

Operate

with

hand

power

only.

This

winch

should

not

be

operated

with

a

motor

of

any

kind.

1f

the

winch

cannot

be

cranked easily

with

one

hand,

it

is

probably over-loaded.

•

1f

winch

will

be

used

in

freezing,

icy

conditions,

apply

silicone spray

to

ratchet

pawl

and

spacer

items,

V,

W,

X,

or

Y.

Do

n~f

spray

other

brake

mechanism

parts.

WINCH

MOUNTING AND

CABLE

ATTACHMENT

—

For

maximum

strength

and

safe

ty,

this

winch should

be

mounted with

three

3/8

bolts

(Ml0),

washers

and

lock

washers,

Usa

Grade

8

for

1500

lb/680

kg

or

greater

capacity.

(Sea

parts

drawing).

Using

fewer

bolts

or

alternate

locations

will

result

in

damage

to

the

winch

base

and

the

winch

may

malfunction.

Attach

cable

or

rope

by

method shown

in

sketch.

OPERATING

INSTRUCTIONS

—

Wind

cable

on

winch

real

by

turning

winch

handle

in

clockwise

direc

tion.

This should

produce

a

loud,

sharp,

clicking

noise.

The

bad

will

remain

in

position

when the

han

dle

is released.

Wind

cable

off

the

winch

reel

by

turn

ing

winch

handle

counterclockwise

(no noise

will

be

produced).

The

bad

will

remain

in

position

when

the

handle

is

released,

but

for

extra

security

it

is

recom

mended

that the

handle

be

turned clockwise

until

at

east

two

clicks

are

heard.

This

will

add

extra

tightness

to the

brake

mechanism.

Always satisfy

yourself that

the

winch

is

holding the

bad

before

releasing the

winch

handle.

4~kIMP0RTANT:

Sufficient

laad

must

ho

applied

to

the

cahbe

to

overcome

internal

resistance

and

oper

ate the

brake

properly,

otherwise turning

the

crank

handle

countercbockwise

will

only

remove the

han

WINCH

MAINTENANCE

—

In

order

to

insure

maximum performance,

a

periodic

inspection

for

any necessary

preventive

maintenance

should

be

made.

Check

at east

once

annually

and

more

fre

quentby

when

the

winch

is

exposed to

an

environ

ment which

is

particularly

dirty

or

wet,

For

continued

smooth performance

and

increased

life,

occasional

ly

grease

gears,

real

shaft and

handle

threads.

An

dle

from

the

shaft

—

the

real

will

not

turn.

The

mini

mum

operating

bad

requirement

is

50

1h

(23

kg)

for

Models

DLB35OA,

DLB35OAG,

DLB800A,

DLB800AG,

DLB1200A

and

DL.B1200AG,

75

1h

(34

kg)

for

DLB1500A and

Db..B1500AG,

175

1h

(80

kg)

for

Dl..B2000AG

and OLB2500A.

Models

DLB8O5A,

DLB12O5A,

DLB15O5A

&

DLB25O5A

are

equipped

with

a

lockout

lever

for

the

purpose

of ‘freewheeling’

cable

out

when

there

is

no

bad

on

the

winch.

To

‘freewheel’

cabbe

out,

simply

turn

the

handle

countercbockwise

until

bockout lever

can

be

engaged

behind

handle

hub.

In

this

condition

cable

can

be

easily

pulled

from

the

winch drum.

A~h..

WARNING:

Never

put

winch

in

freewheel

mode

if

any

potential

for

a

bad

on

the

cabbe

exists. Engaging

the

bockout

lever

keeps

the

winch

from

stopping

in

the

event

that

a

bad

is

accidentally

applied.

occasionab

drop

of

oib

on

the

drive

shaft bearings

is

also

recommended.

1f

winch

will

be

used

in

freezing,

icy

conditions,

apply

silicone spray to

ratchet

pawl

and

spacer

items

V,

W, X

or

Y~

Note:

Do

not

oib

or

grease

brake

mechanism items

H

and

J.

Keep

winch

in

good

working

order.

Damaged

or

severely-worn

parts

create

unnecessary dangers

and

could

resubt

in

personal

injury

or

property

damage.

4~

WARN

ING

READ

INSTRUCTIONS

CAREFULLY BEFORE

ATrEMPTING

To

INSTALL,

OPERATE

OR

SERVICE

THIS WINCH.

FAILURE

TO

COMPLY

WITH

INSTRUCTIONS COULD RESULT

IN

SERJOUS

OR

FATAL INJURY. RETAIN

THESE

INSTRUCTIONS

FOR

FUTURE REFERENCE.

ASSEMBLY

—

Thread

the

handbe

onto

the

winch

drive

shaif

and

be

certain

that

a

clicking

noise

is

pro

duced when

the

handle

is

turned

cbockwise.

Install

the

spring

and bocknut

(Items

E

and

G)

on

the

end

of

the

drive

shaft

as

shown

on

parts

drawing.

These

parts

may

appear

to

serve

no

function,

but

they

pro

vide

several

important

faib-safe

features,

and

should

not

be

altered

or

removed.

NOT

FOR

THE

MOVEMENT

OF

HUMAN BEINGS

Hef

Descrlptlon

Part

No.

A

Base

404900*

A

Base

—

DLB

SSOAG

404945*

8

Bushing

204012

C

‘E”

Ring

205116

D

Drive

Shaft

306061

E

Spring

204364

F

Handle

—

7”

5703061

Handle

—9-3/8” 5703103

G

Nut

205033

H

Pressure

Plato

204362

H

Pressure

Plate

“3”

SerIes

206620

To

order

replacement

parts

contact:

Dutton-Lainson

Company

Www.dlco.com

Tel:

800-569-6577

Fax:

402-460-4612

e-mail:

DLsales@dutton-lajnson.com

DLB800A

&

DLB800AG

Winch

AE

w

AK

D

H

‘J.

L

PARTS

liST

Rot

Descrlptlon

Part

No.

AH

Lockout

Lever

(optional)

404579

AJ

Spacer

(optlonal)

406160

AK Gear

Cover

(optional)

Painted Bronze

5240346

Plated

5240361

AL

Base

404896*

Base

—

DLB

1

200AG

404897*

AM

Bushing

204009

AN

Gear

Cover—

“G”

Series

406115

J

Ratchet

Wheel

404164

ALl

(3ear

Cover

(optlonal)

Painted Bronze

Plated

5240122

5240221

1<

PressureWasher

404163

AR

SpacerWasher

205120

L

Bushing

206328

AS

Real

304754*

M

Nut

205316

AS

Real —

1-7/8” (optlonal)

304768*

N

Bolt

205332

AT

Base

404891*

P

Rope

Clamp

Kit

5243506

—

Base

—

DLB

1500AG

404892*

Q

Gear Cover

—

“G”

Series 406114

AU

Drive

Shaft

304760

S

Reel

306075*

AV

Hancile

—

9-3/8” 5703103

Real

-

DLB35OAG

306167

—

Handle

—

12”

5703111

T

Locknut

204803

AW

Bolt

204804

U

Bolt

205167

AX

Reel

Spacer 204808

V

Flat

Washer

205055

AY

Gear Cover

(optional)

W

PawI

404409

Painted Bronze

5240387

PawI

—

‘G”

Series

404190

—

Plated

5240403

X

Spacer 404166

AZ

Reel

304755*

Spacer —

‘G”

Series

404191

BA

Base

—

DLB2500A

406047*

Y

Spring

204363

Base

—

DLB

2000AG

404899*

Spring

—

‘G”

Series

204460

BB

Spacer

404434

Z

RoeI

Spacer

207183

BC

Bolt

205006

AB

Bolt 203161

BD

Flat

Washer

205139

AC

Real

Spacer

204807

85

Intermed.

Drive

Shaft

306035

AE

Reel

306062*

BF Nut

205014

AF

Base

Base

—

DLB

aOoAG

404893*

404895*

BH

Real

304756*

BJ

Drive

Hub

(Optional)

304562

BM

Handle

w/Lock

Fin

(Opt)

5703426

BN

Handle

Hub

(Optional)

304630

BP

Special

Nut

(Optional)

404970

BQ

“5”

Ring

206162

8H

Bushing

206163

88

Bolt

205335

Table of contents

Popular Lifting System manuals by other brands

Magliner

Magliner LiftPlus Lite owner's manual

Schmalz

Schmalz JumboPicker-Flex Operating and maintenance instructions

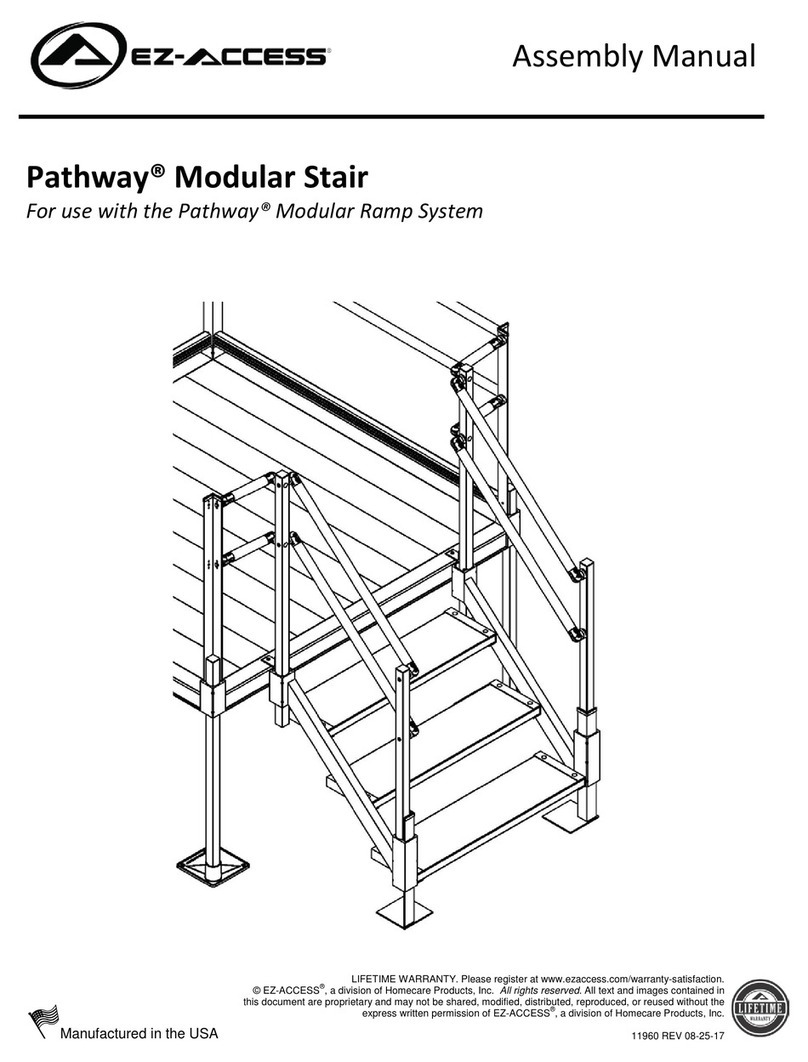

EZ-ACCESS

EZ-ACCESS Pathway MSTAIR2839 Assembly manual

jost

jost Modul B 01 01 Installation and operating instructions

Ravaglioli

Ravaglioli RAV241-RAV242 manual

ShoreDocker

ShoreDocker SD1200 Assembly and operating instructions

Beacon

Beacon BSSK-1 owner's manual

MoJack

MoJack MoJackPRO Instructions for assembly and operation

Southworth

Southworth ZLS Series owner's manual

Enhance Mobility

Enhance Mobility Hercules instructions

Granberg

Granberg Centerlift 960 installation instructions

Braun Corporation

Braun Corporation UVL Series Service manual