Contents

Operating and Maintenance Instructions

JumboPicker-Flex Jungheinrich

www.schmalz.com

1Safety Instructions...............................................................................................6

1.1 Classification of safety instructions ...................................................................................6

1.2 Warnings ...........................................................................................................................7

1.3 Mandatory symbols ...........................................................................................................7

1.4 Regulations in these instructions.......................................................................................8

1.5 Fundamental safety instructions........................................................................................8

1.6 Intended use......................................................................................................................9

1.7 Obligations of the Manufacturer of the Finished Unit......................................................10

1.8 Requirements and Instructions for Installation, Maintenance and Operating Staff.........10

1.9 Requirements for the Location of Use.............................................................................11

1.10 Danger Zone Definition ...................................................................................................12

1.11 Emissions........................................................................................................................14

1.12 Personal protective equipment........................................................................................14

2Product Description...........................................................................................15

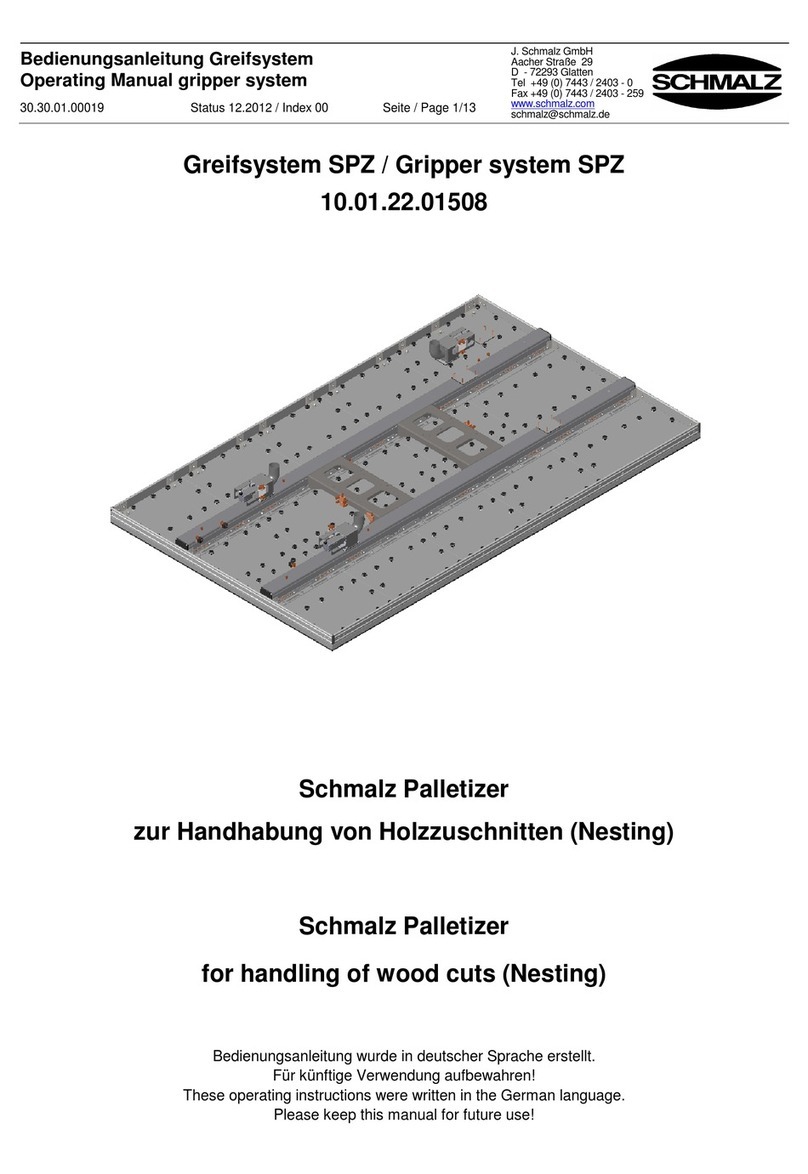

2.1 Components of the vacuum tube lifter JumboPicker-Flex ..............................................15

2.2 Description of Operation..................................................................................................15

2.3 Controls...........................................................................................................................16

2.3.1 Button Assembly..............................................................................................................16

2.3.2 Tube lifter operator handle..............................................................................................16

2.4 Lift tube............................................................................................................................16

2.5 Rotary Union....................................................................................................................16

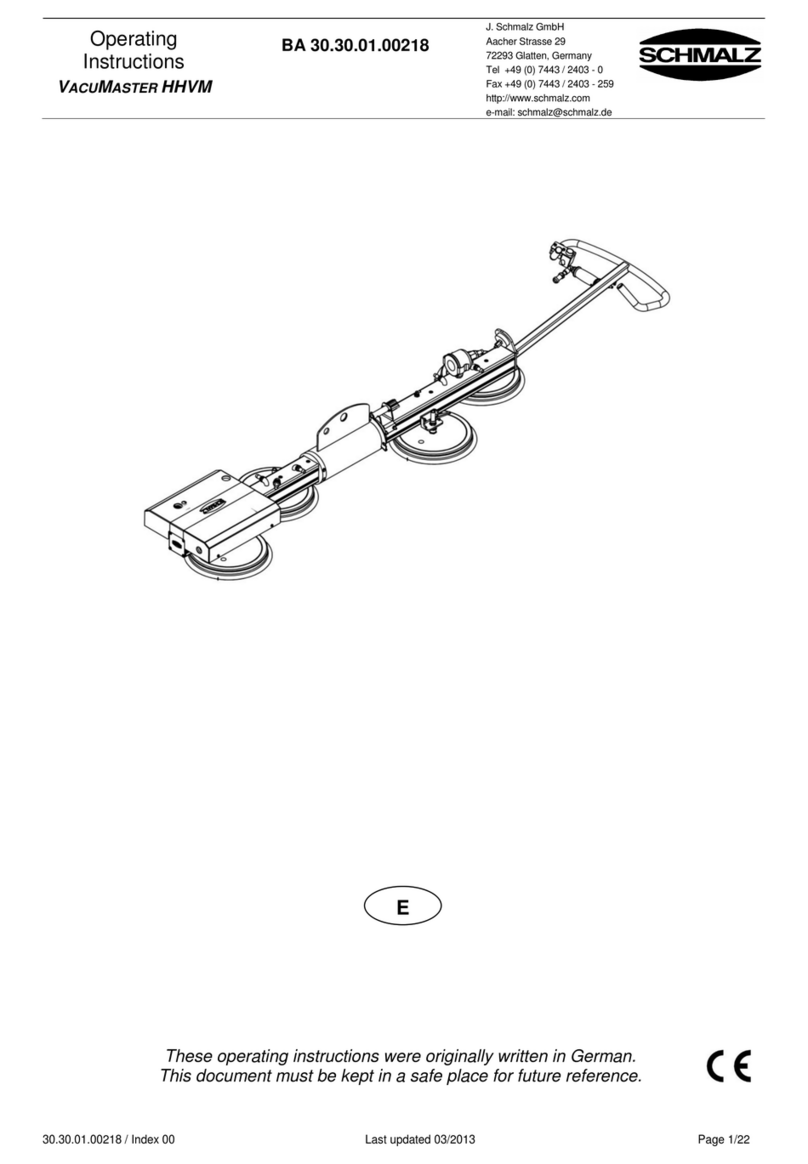

2.6 Load suspension devices / suction cups.........................................................................17

2.7 Vacuum Generation ........................................................................................................17

2.7.1 Vacuum Generator..........................................................................................................17

2.7.2 Dust Filter (STF)..............................................................................................................17

2.8 Safety Features...............................................................................................................17

2.8.1 Vacuum Limiting Valve....................................................................................................17

2.8.2 Sensors ...........................................................................................................................17

2.8.3 Non-return valve..............................................................................................................18

2.9 Type Plate .......................................................................................................................19

2.10 Optional Accessories.......................................................................................................19

2.10.1 Warning Light ..................................................................................................................19

2.10.2 Scissor arm brake ...........................................................................................................19

3Technical Data..................................................................................................20

3.1 JumboPicker-Flex............................................................................................................20

3.2 Dimensions......................................................................................................................21

4Delivery, Packaging and Transport...................................................................22

4.1 Delivery............................................................................................................................22

4.1.1 Items Included in Delivery ...............................................................................................22

4.1.2 Check for Completeness.................................................................................................22

4.1.3 Report damage................................................................................................................22

4.2 Packaging........................................................................................................................22

4.3 Handling the System .......................................................................................................24

4.4 Transporting the Finished Unit ........................................................................................24