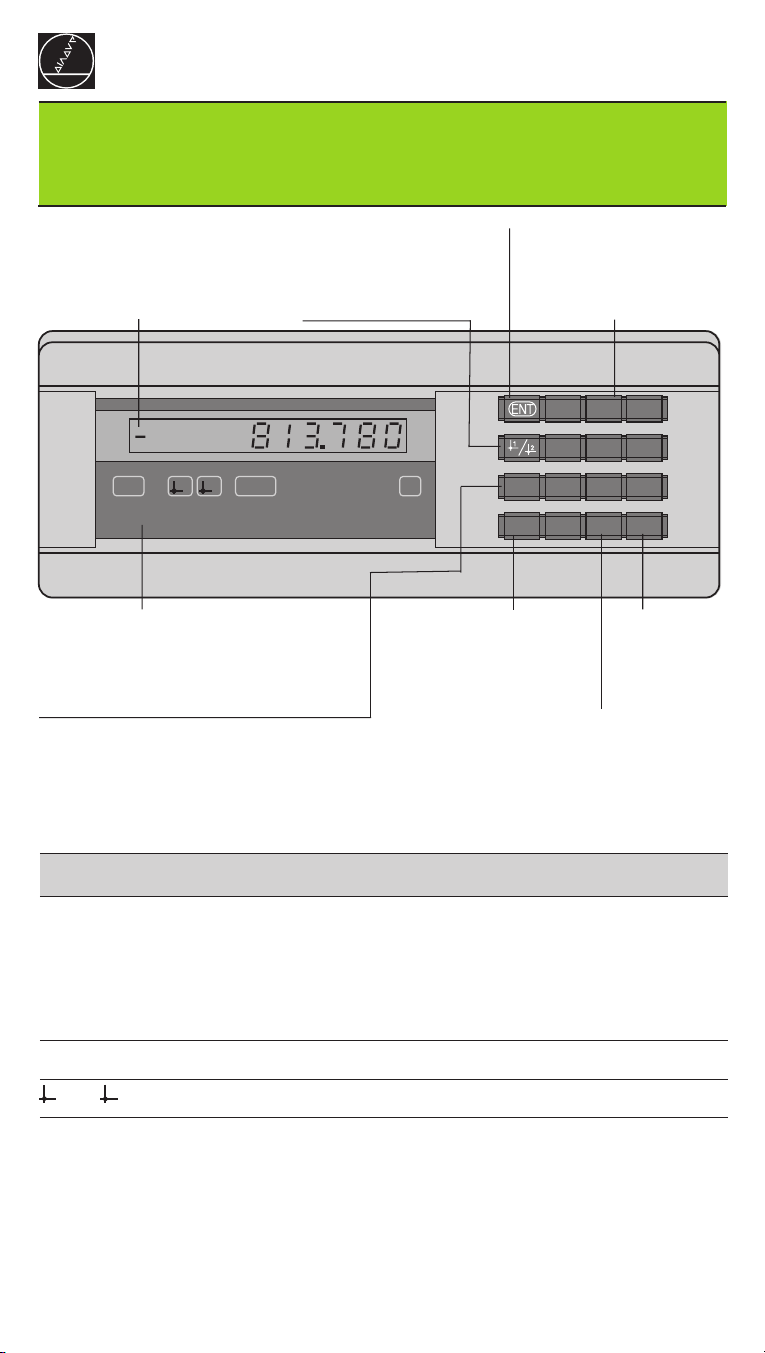

Operating Parameters

The parameters are divided into “user parameters“and “protected operating param-

eters," which can only be accessed by entering a code number.

User parameters

User parameters are operating parameters that you can change without entering the

code number: They are designated P00 to P30, P50, P51, P79, P86

Calling user parameters

To call user parameters immediately after switch-on:

➤➤

➤➤

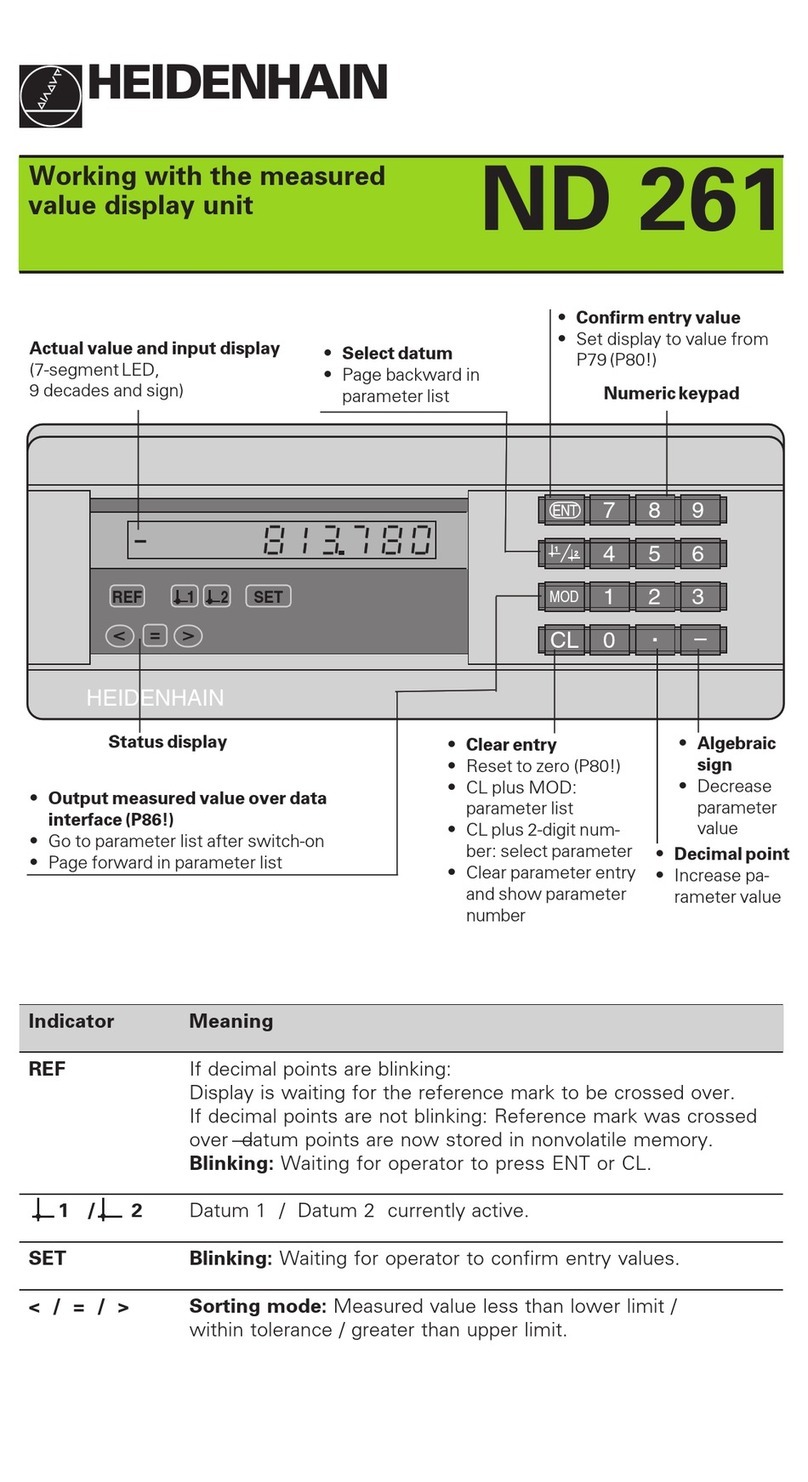

➤Press the MOD key as long as is visible in the display.

To call user parameters during operation:

➤➤

➤➤

➤Press and hold the CL key, then press MOD.

To go directly to a specific user parameter:

➤➤

➤➤

➤Press and hold the CL key, then press the first digit of the parameter number.

➤➤

➤➤

➤Release both keys and press the second digit.

Protected operating parameters

Before you can change protected operating parameters you must enter the code

number 95 148 through : They remain accessible until you switch off

the position display.

To page through the parameter list

➤➤

➤➤

➤Forward paging: Press the MOD key.

➤➤

➤➤

➤Backward paging: Press the 1 / 2 key.

By paging on, you automatically enter any change you've made in a parameter.

To change operating parameters

➤➤

➤➤

➤Increase the parameter value with the decimal point key, or

➤➤

➤➤

➤Decrease the parameter value with the minus key, or

➤➤

➤➤

➤Enter the numerical value for the operating parameter, e.g. for P41 ( SET blinks).

To correct your entries and show the parameter designation

➤➤

➤➤

➤Press the CL key.

To exit the operating parameters

➤➤

➤➤

➤Press ENT. All changes made become effective.

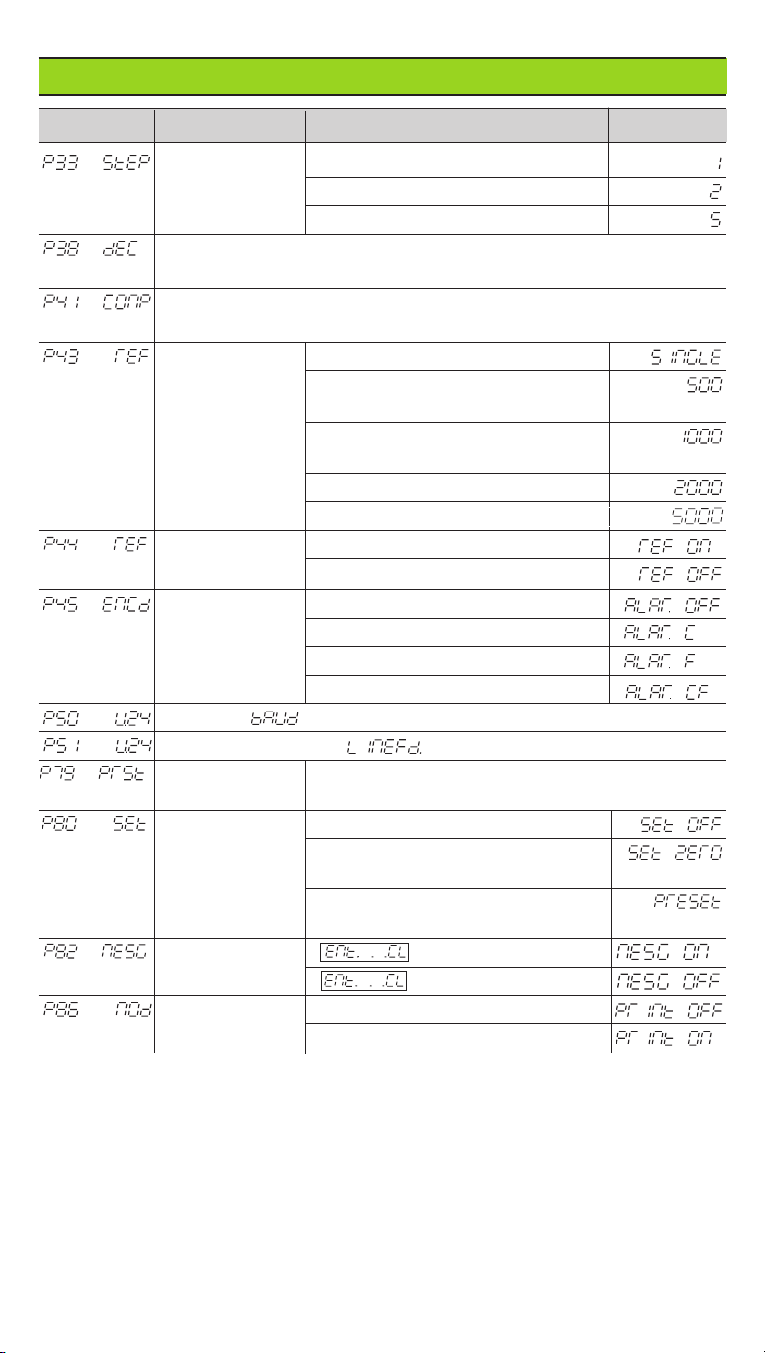

Operating Parameter List

Parameter Meaning Function / Effect Setting

Enter code number 95 148 to change a protected operating

parameter.

Unit of measure Display in millimeters

Display in inches

Counting Normal (

Positive

)

Direction

direction Inverse (

Negative

)

Subdivision of encoder signal period 400, 320, 256, 200, 160,

Subdivision

128, 100, 80, 50, 40, 20, 10, 8, 5, 4, 2, 1, 0.8, 0.5, 0.4, 0.2, 0.1