Contents

Page

Contents

Page

Technical 1

Description

1.1

1.1.1

1.1.2

1.2

1

2.1

1.2.2

1.2.3

12.4

1.3

1.3.1

External

Functions T30

Pin

Layout

X41

(00)

(25-pole D-Submlniature Socket) T30

External Zero

Reset

T30

Storage

(Pulse.

Contact)

T31

Zero Crossover Signal

T31

EMERGENCY

STOP

Signal

T31

Linear and Angle Encoders

132

Layout of Encoder

Flange

Sockets

Xl

X4

T32

Connection of

Probe

Systems T33

Pin

Layout

Xl

0(15·pole O-Subminiature Socket) _

135

Specifications

136

Dimensions T38

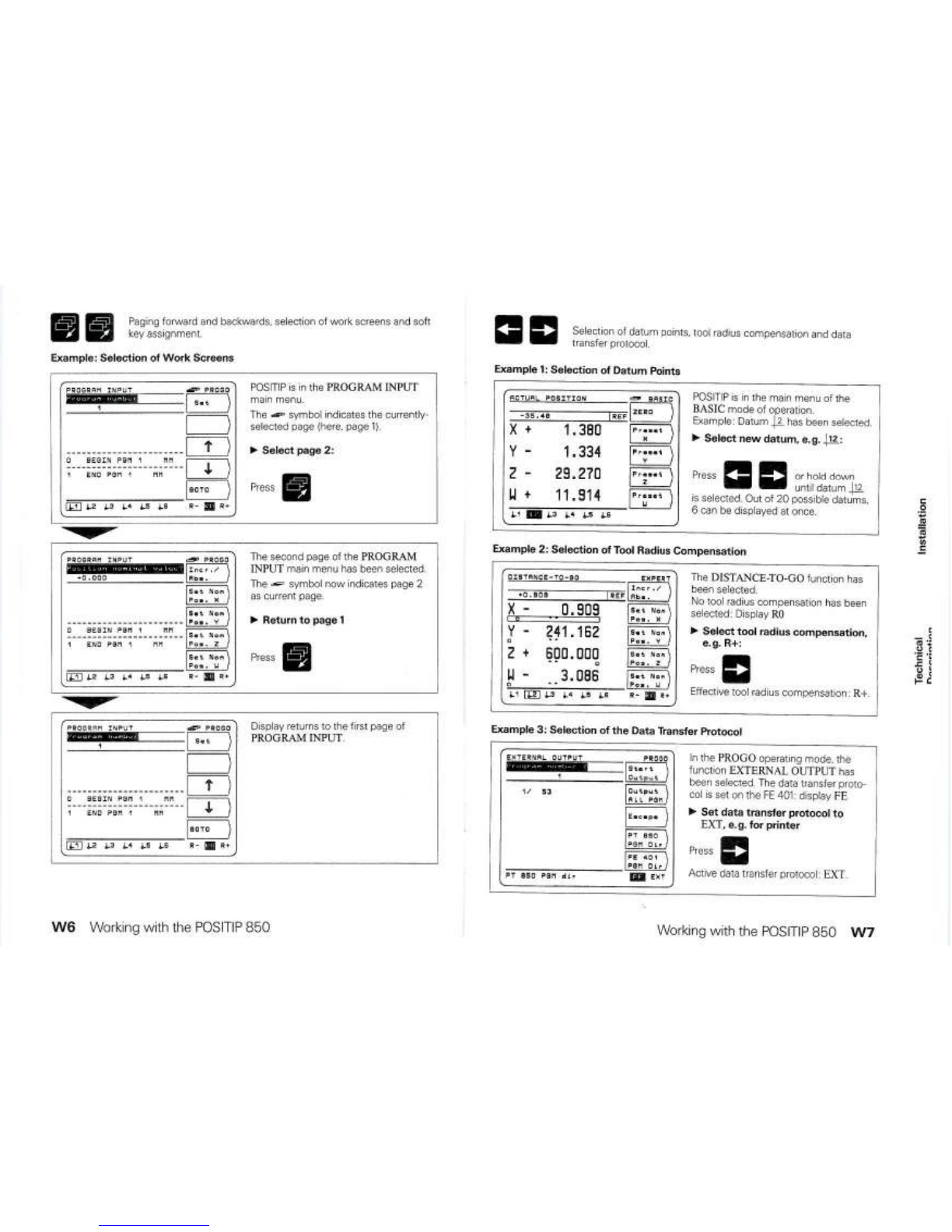

4

4.1

4.2

4.3

4.4

4.5

5

5.1

6

6.1

7

8

______________

G1

1.3.2

1.3.3

1 4

1.4 1

1.4.2

2

2.1

22

2.3

2.4

2.5

3

31

3,1.1

312

3.1.3

3.2

3.3

General

Information

Working

with

the

POSITIP

850

For

Milling

W1

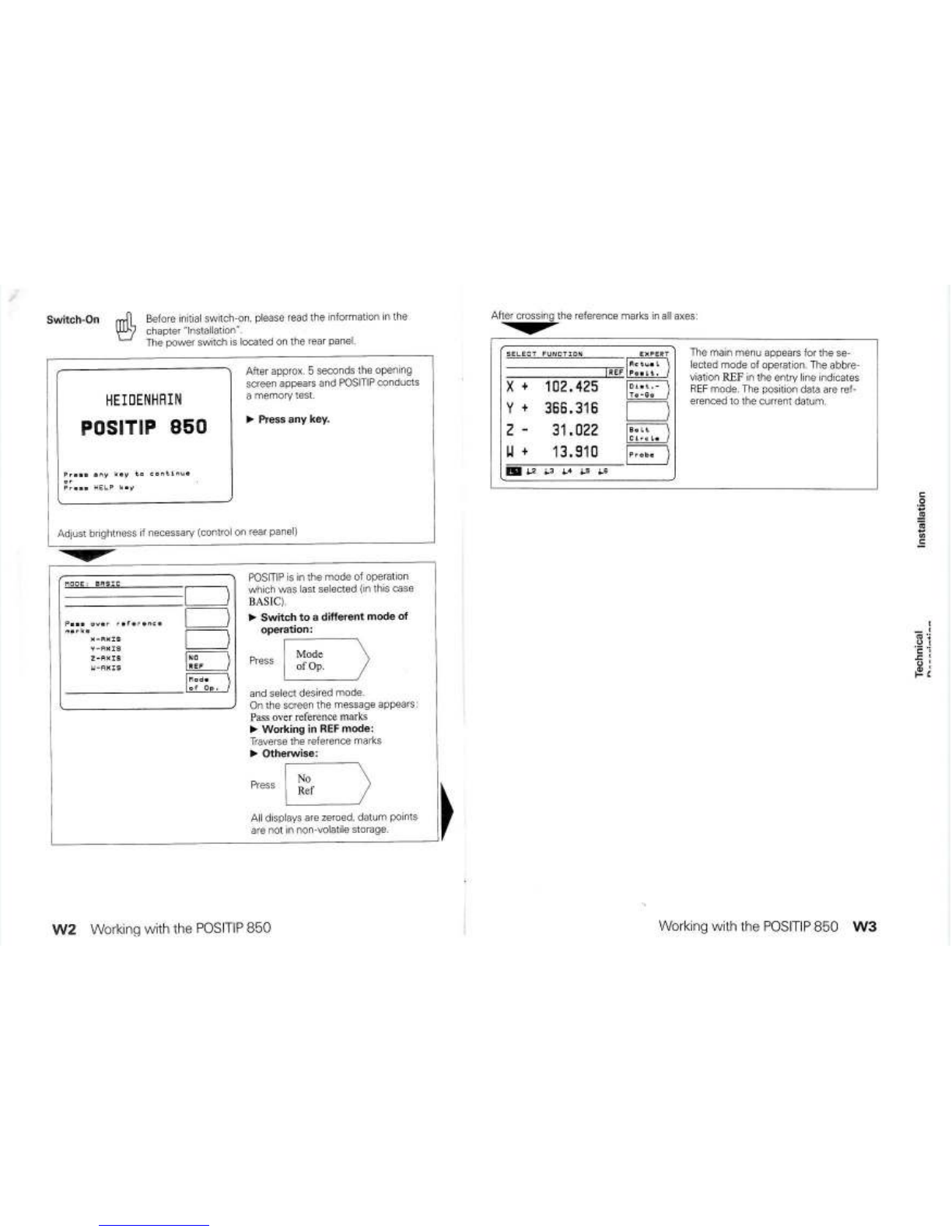

Installation 1Connections and Controls

(Rear

of Umt)

11

2Mounting the

POSITIP

850

12

3Connecting

Une8r

and

Angle

eョ」ッ、B・セGセウ]]]]ZGR

4Connecting

the

KT

110

Edge Finder

セ

13

5Power

cッョョ・」エゥッョセZセセセZ]]]]]]]iS

6

SWItch-On

and Function Check

]3

7Optlmizing the Parameters

14

Parameters

T1

User Parameters

T1

Olanging User Parameters

T2

Overview of User Parameters

T4

Operating Parameters

T5

AcceSSing

the Operating Parameters T5

Configunng the User Parameters T7

Presenrng the User Parameters

T9

Overview

of

Operating

Parameters

T10

Tables

T14

Display Step, Stgnal Period and Subdivision

Factor

for

linear Encoders

-c-::-:-:c-:c---::---

T14

Display

Step.

lme

Count and Subdivision Factor

lor

Angle

eョ」ッ、・セウセセセセセセセセセセセセtQT

Distance-Coded Reference Marks T15

Parameter Description T16

User Parameters T16

Operating Parameters P

T17

RS·232-C/V.24

Data

Interface

T21

DefinItion of the RS-232-C/V.24 Interface

T21

Pin

LaYOut/Signal

Description

T21

Connection of External

UnIlS

(Wiring) T22

Data

Transfer

Rate

(Baud

Rate)

T23

Data

Format T23

Data

Transfer T24

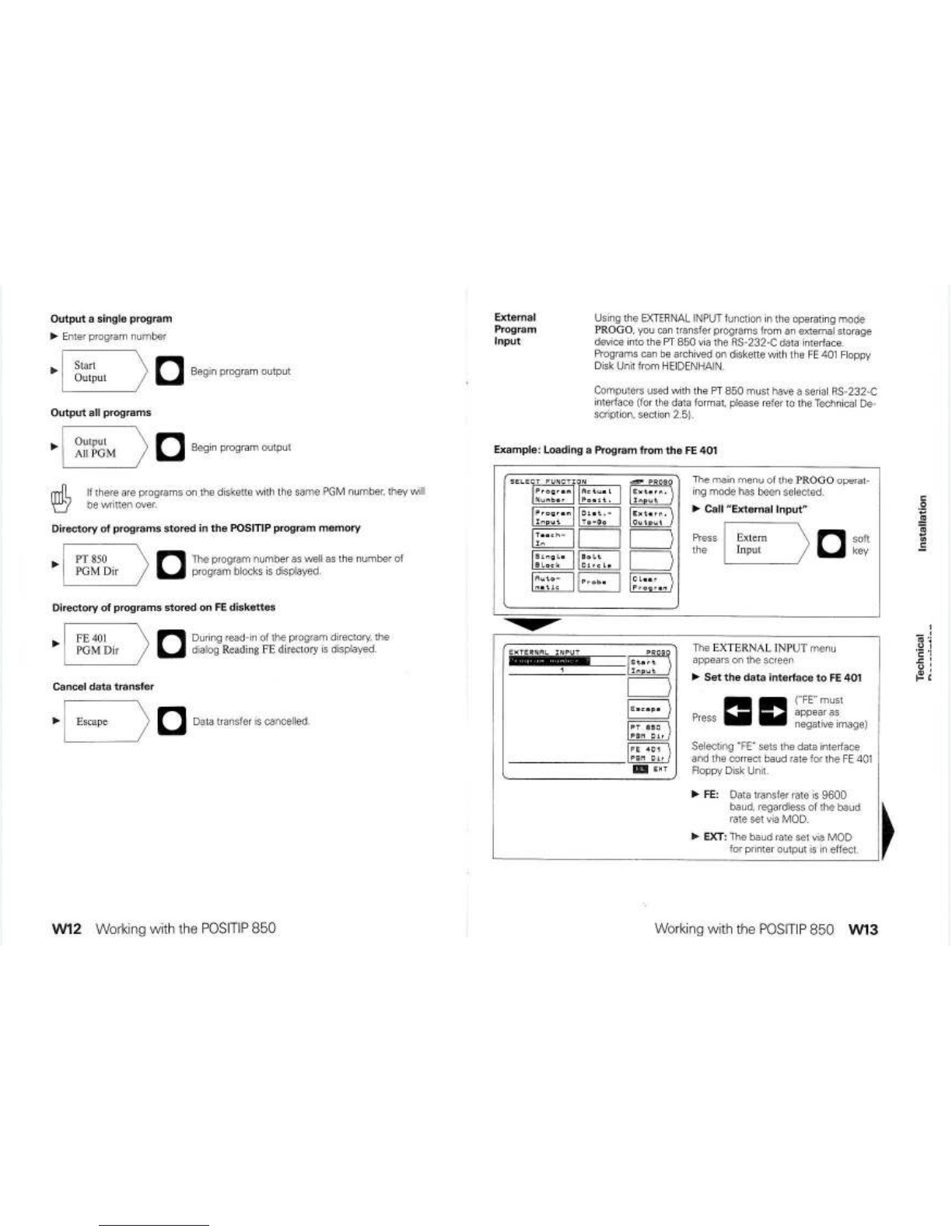

Measured Value Output T25

Storage

Via

RS

232-C Interface T25

Storage

Via

External

Functions T26

Sequence of Character Output T27

External Input/Output of Programs T29

Input/Output of Operating Parameters T29

G2

General

Information

General

Information

G3