3

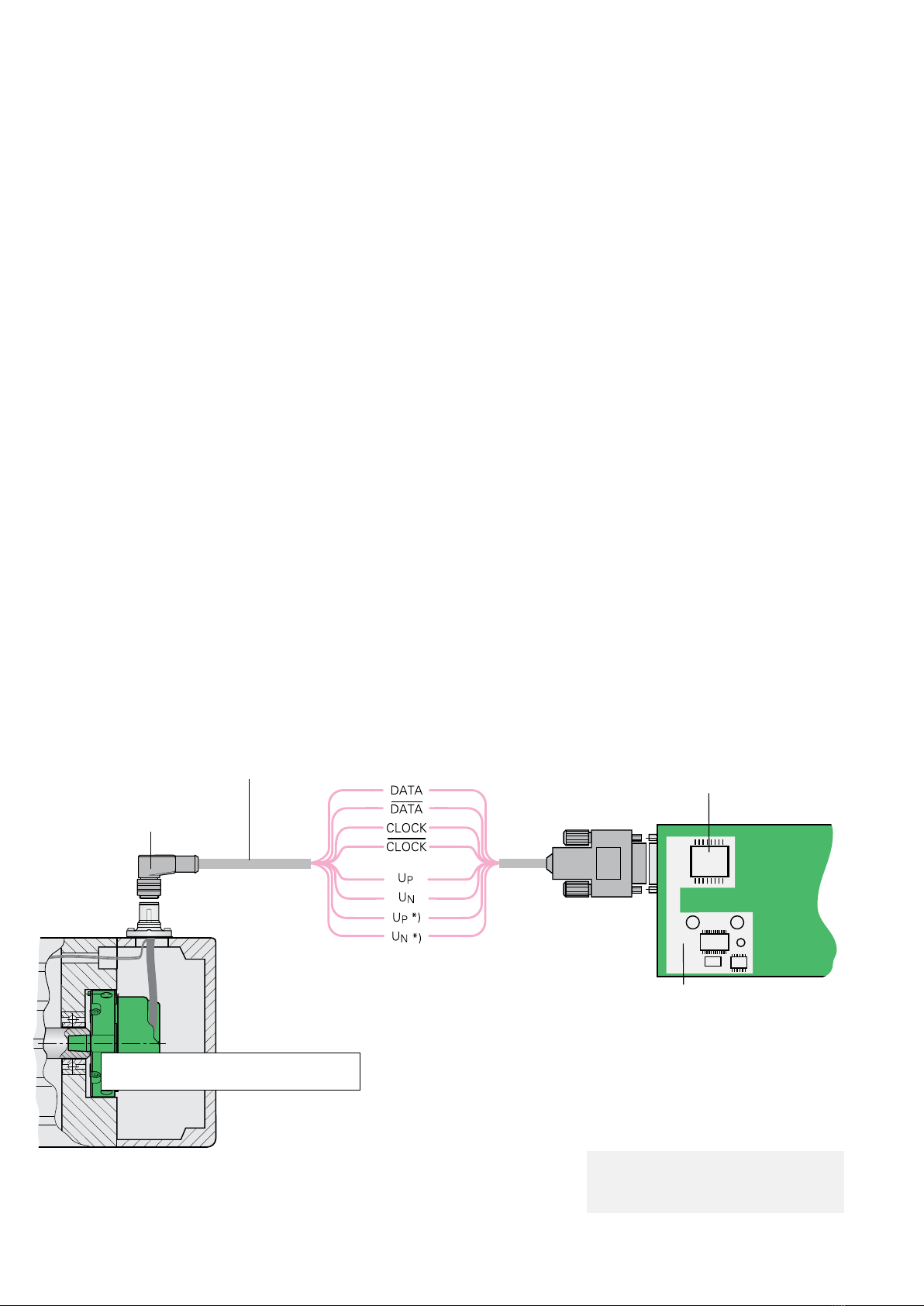

–The bidirectional interface

Interface EnDat serial bidirectional

Data transfer Position values, parameters and additional data

Data input Differential line receiver according to EIA standard RS 485 for

the signals CLOCK, CLOCK, DATA and DATA

Data output Differential line driver according to EIA standard RS 485 for

DATA and DATA signals

Position values Ascending during traverse in direction of arrow (see dimensions

of the encoders)

Incremental signals Depends on encoder

»1 VPP

, TTL, HTL (see the respective incremental signals)

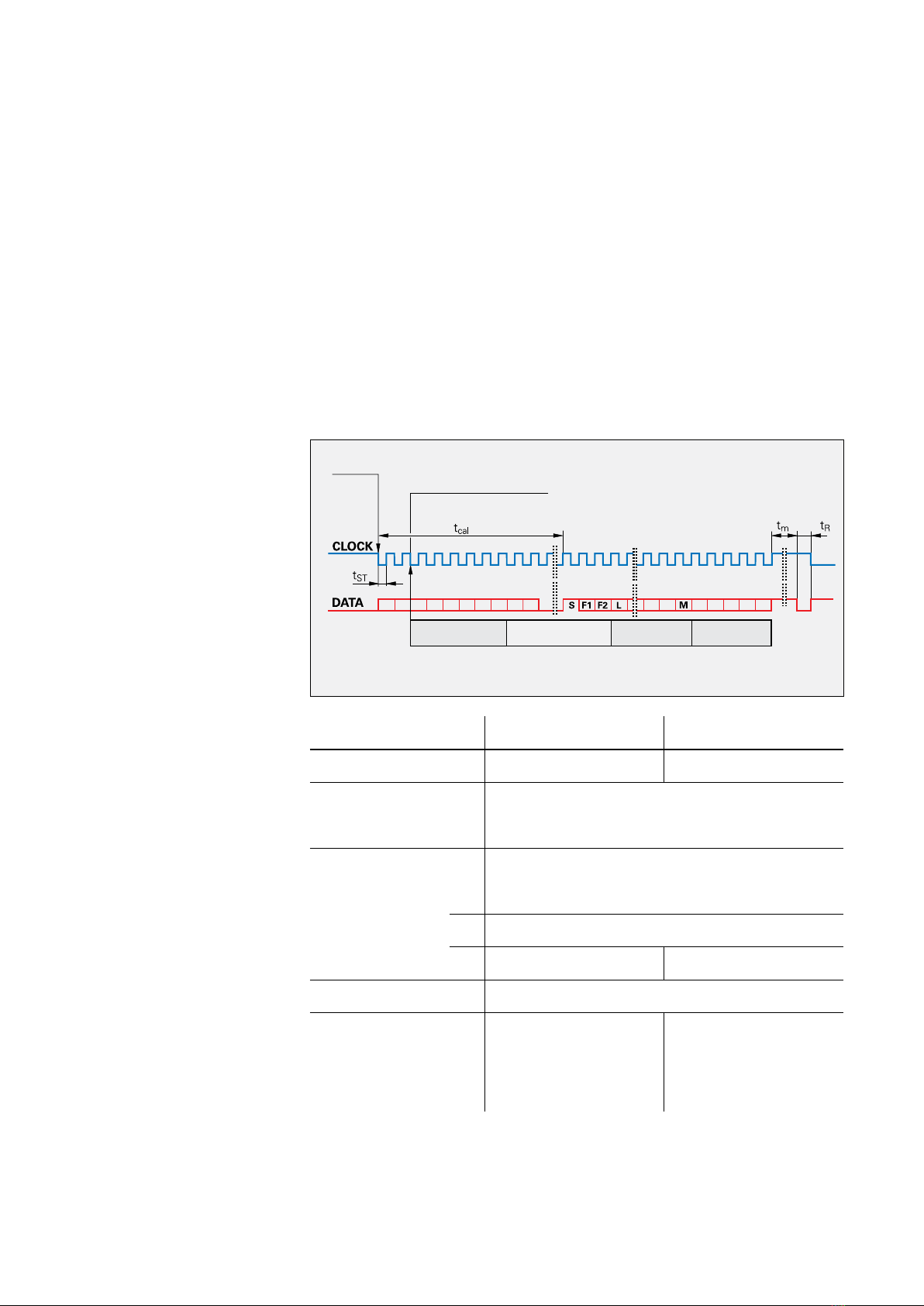

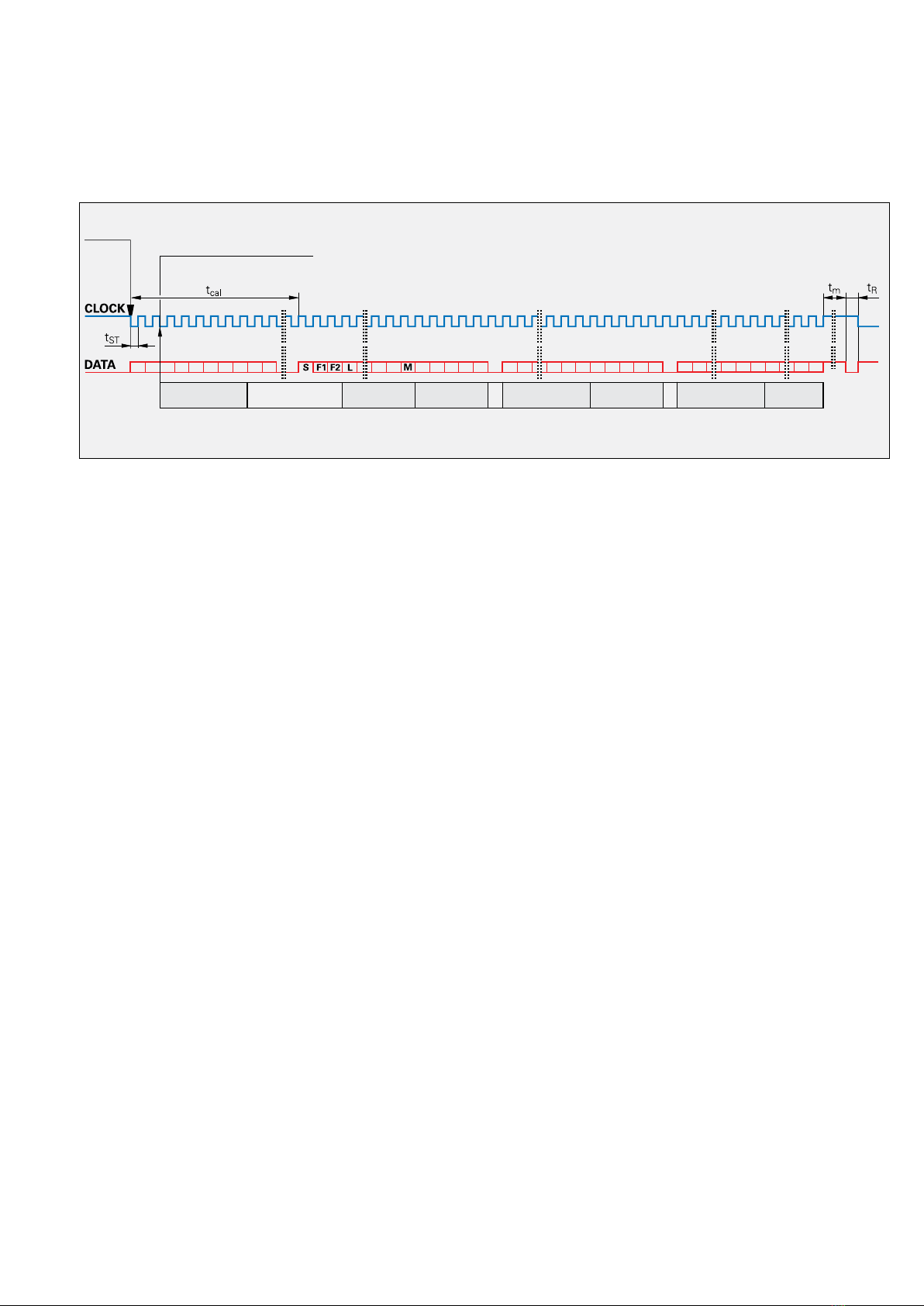

The EnDat interface is a digital,

bidirectional interface for encoders. It is

capable both of transmitting position

values as well as transmitting or updating

information stored in the encoder, or saving

new information. Thanks to the serial

transmission method, only four signal

lines are required. The data is transmitted

in synchronism with the clock signal from

the subsequent electronics. The type of

transmission (position values, parameters,

diagnostics, etc.) is selected through mode

commands that the subsequent electronics

send to the encoder. Some functions are

available only with EnDat 2.2 mode

commands.

History and compatibility

The EnDat 2.1 interface available since the

mid-90s has since been upgraded to the

EnDat 2.2 version (recommended for new

applications). EnDat 2.2 is compatible in its

communication, command set and time

conditions with version 2.1, but also offers

significant advantages. It makes it possible,

for example, to transfer additional data (e.g.

sensor values, diagnostics, etc.) with the

position value without sending a separate

request for it. This permits support of

additional encoder types (e.g. with battery

buffer, incremental encoders, etc.). The

interface protocol was expanded and the

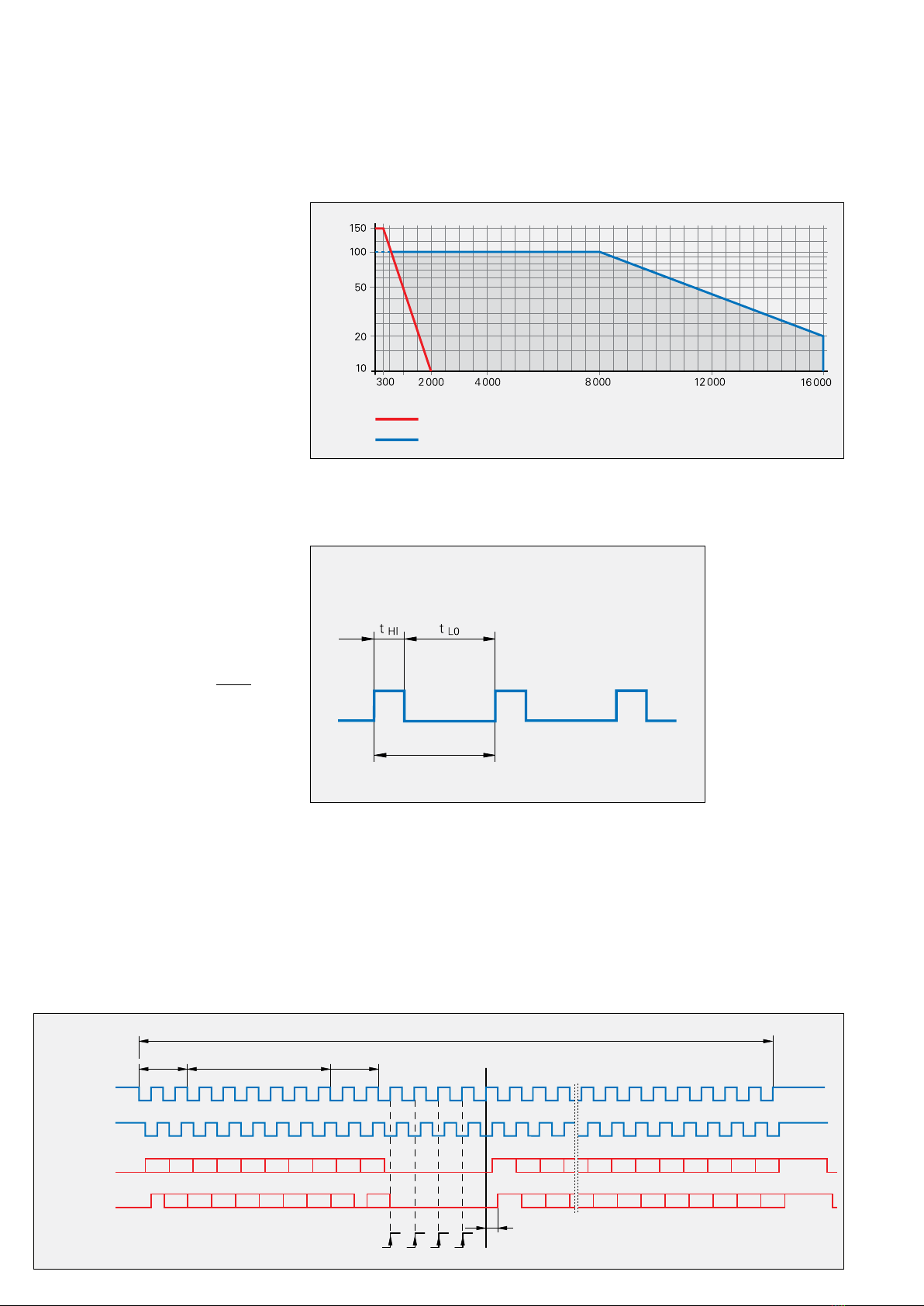

time conditions (clock frequency,

processing time, recovery time) were

optimized.

Supported encoder types

The following encoder types are currently

supported by the EnDat 2.2 interface (this

information can be read out from the

encoder’s memory area):

• Incremental linear encoder

• Absolute linear encoder

• Rotational incremental singleturn

encoder

• Rotational absolute singleturn encoder

• Multiturn rotary encoder

• Multiturn rotary encoder with battery

buffer

In some cases, parameters must be

interpreted differently for the various

encoder models (see EnDat Specifications)

or EnDat additional data must be

processed (e.g. incremental or battery-

buffered encoders).

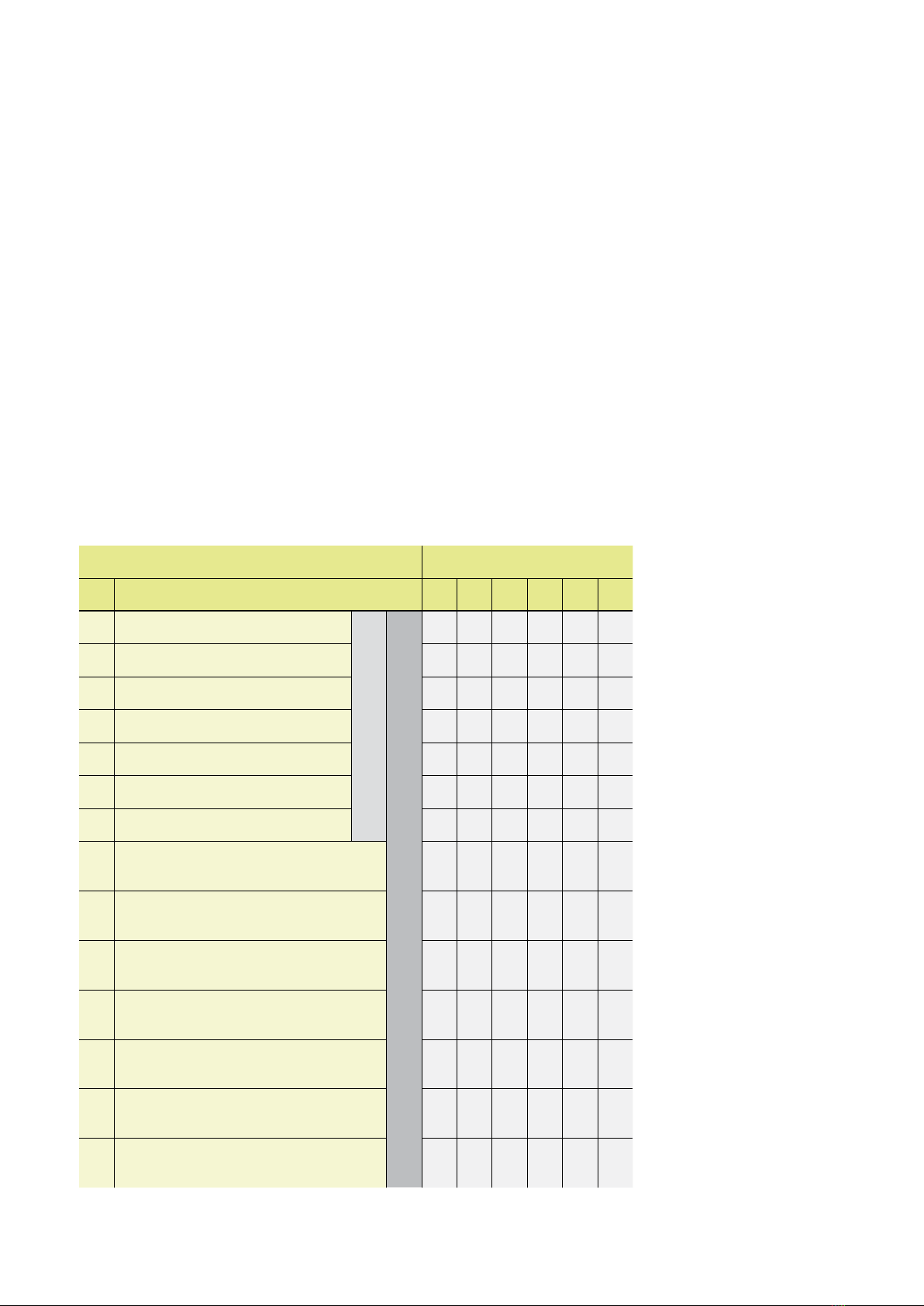

Order designations

The order designations define the central

specifications and give information about:

• Typical voltage supply range

• Command set

• Availability of incremental signals

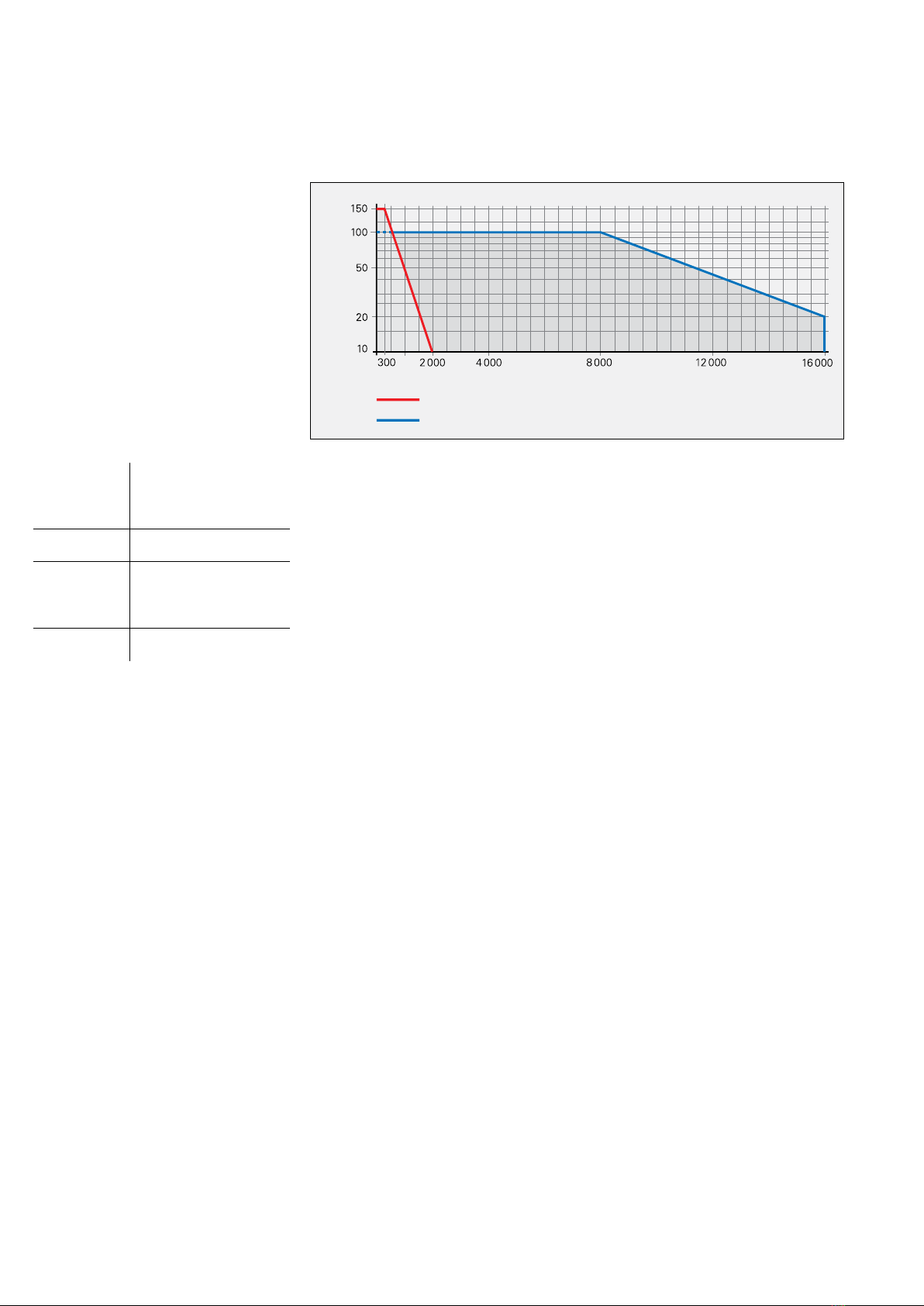

• Maximum clock frequency

The second character of the order

designation identifies the interface

generation. For encoders of the current

generation the order designation can be

read out from the encoder memory.

Incremental signals

Some encoders also provide incremental

signals. These are usually used to increase

the resolution of the position value, or to

serve a second subsequent electronics

unit. Current generations of encoders have

a high internal resolution, and therefore no

longer need to provide incremental signals.

The order designation indicates whether an

encoder outputs incremental signals:

• EnDat01 With 1 VPP incremental signals

• EnDatH With HTL incremental signals

• EnDatT With TTL incremental signals

• EnDat21 Without incremental signals

• EnDat02 With 1 VPP incremental signals

• EnDat22 Without incremental signals

Note on EnDat01/02:

The signal period is stored in the encoder

memory.

Voltage supply

The typical voltage supply of the encoders

depends on the interface:

EnDat01

EnDat21

5 V ± 0.25 V

EnDat02

EnDat22

3.6 V to 5.25 V or 14 V

EnDatH 10 V to 30 V

EnDatT 4.75 V to 30 V

Exceptions are documented in the

Specifications.

Command set

The command set describes the available

mode commands, which define the

exchange of information between the

encoder and the subsequent electronics.

The EnDat 2.2 command set includes all

EnDat 2.1 mode commands. In addition,

EnDat 2.2 permits further mode com-

mands for the selection of additional data,

and makes memory accesses possible

even in a closed control loop. When a

mode command from the EnDat 2.2

command set is transmitted to an encoder

that only supports the EnDat 2.1 command

set, an error message is generated. The

supported command set is stored in the

encoder’s memory area:

• EnDat01/21/H/T Command set 2.1

or 2.2

• EnDat02/22 Command set 2.2