Heiniger ONE/G User manual

swiss made

Version/Index: ONE/G 05-21

Eintourige Schuranlage Original-Betriebsanleitung

Single Speed Shearing Plant Translation of the original instructions

Tondeuse à 1 vitesse Traduction de la notice originale

Gruppo di tosatura a una velocità Traduzione delle istruzioni originali

Esquiladora de una velocidad Traducción del manual original

Eentoerige scheeraandrijving Vertaling van de oorspronkelijke handleiding

Klippeanlæg med 1 hastighed Oversættelse af den originale brugsanvisning

Stationär klippmaskin för får, 1 hastighet Översättning av bruksanvisning i original

Enhastighets klippemaskin for sau Oversettelse av den originale brukerveiledningen

Yksinopeuksinen leikkuulaite Alkuperäisten ohjeiden käännös

Acionamento de tosquia de velocidade constante Tradução do manual original

Κουρευτική μηχανή μίας ταχύτητας Μετάφραση πρωτοτύπου οδηγιών χρήσης

de

en

fr

it

es

nl

da

sv

nb

fi

pt

gr

Table of contents

1 Safety regulations ..............................................................................3

1.1 Introduction ......................................................................................... 3

1.2 Symbols and warning notes ............................................................... 3

1.3 Stipulated usage ................................................................................. 4

1.4 Basic safety principles ....................................................................... 4

1.4.1 Power supply connections ................................................................. 4

1.4.2 Safety precautions .............................................................................. 4

1.4.3 Noise emission / personal protective equipment ............................... 5

1.4.4 Residual dangers ................................................................................ 5

1.4.5 Replacement power cable .................................................................. 6

1.4.6 Supervision of children ....................................................................... 6

1.5 Operator requirements ....................................................................... 6

2 Stipulated usage ................................................................................6

2.1 Component list .................................................................................... 6

2.1.1 Designation of individual parts ........................................................... 6

2.2 Purpose of use ................................................................................... 7

2.3 Technical data .................................................................................... 7

2.4 Equipment ........................................................................................... 8

3 Initial start-up .....................................................................................8

3.1 Important notes .................................................................................. 8

3.2 Assembling the shearing plant ........................................................... 8

3.2.1 Securing / suspending the shearing plant .......................................... 8

.. .............................................................. 9

3.3 Switching the shearing plant on / off .................................................. 9

4 Maintenance .......................................................................................9

4.1 Cleaning.............................................................................................. 9

4.2 Service................................................................................................ 9

4.3 Lubrication ........................................................................................ 10

4.3.1 Portable shearing plant .................................................................... 10

4.3.2 Flexible drive .................................................................................... 10

4.3.3 Shearing handpiece ......................................................................... 10

4.4 Storing the machine ......................................................................... 10

5 Troubleshooting and repairs ............................................................. 11

5.1 Introduction ........................................................................................11

5.2 Troubleshooting .................................................................................11

6 Environmental protection and waste disposal .................................. 12

6.1 Introduction ....................................................................................... 12

6.2 Material groups ................................................................................. 13

7 Contact address ............................................................................... 13

ONE Shearing Plant – Translation of the original instructions

2

NOTE!

Read these instructions carefully before starting operation.

1 Safety regulations

1.1 Introduction

yThis chapter describes the safety regulations that are to be

taken into consideration as a matter of course when using the

shearing plant.

yAll persons who carry out work on and with the shearing plant

must read the operating instructions.

yThe operating instructions are to be kept in a secure place that

is accessible at all times.

yAuthorised service agents may only carry out service and re-

pair work.

1.2 Symbols and warning notes

Various symbols are used in the operating instructions. These

symbols indicate possible hazards or bring to the user‘s attention

such technical information that, if not complied with, may lead to

personal injury and material damage or to uneconomic operation.

Hazard symbols

WARNING!

Denotes a possibly hazardous situation. Serious injury and even

death can result if such situations are not avoided.

CAUTION!

Denotes a possibly hazardous situation. Light or slight injury can

result if such situations are not avoided.

Information symbols

NOTE!

A note which, if not complied with, can lead to operational stopp-

ages or damage.

ONE Shearing Plant – Translation of the original instructions 3

1.3 Stipulated usage

The shearing plant’s intended purpose of use is described in

Chapter 2.2, “Purpose of use”. Use for any other purposes, par-

ticularly on people and dangerous types of animals, especially

predators, is expressly forbidden.

The shearing plant must only be used in dry areas.

The details contained in Chapter 2.3, “Technical data”, are to be

considered as legally binding limit values and characteristic data.

The safety check refers only to the portable shearing plant and

not to the mechanical shaft and the shearing handpiece.

1.4 Basic safety principles

1.4.1 Power supply connections

WARNING!

XNever plug the equipment into damaged sockets. Observe the

relevant regulations applicable in your country.

XMaintenance and cleaning work must only be carried out when

the equipment is not plugged in.

XSockets must be equipped with a circuit breaker (FI).

XIf the SUPPLY CORD is damaged, it must be replaced by the

order to avoid a hazard.

1.4.2 Safety precautions

WARNING!

XAvoid touching machinery that has come into contact with wa-

ter or other liquids.

XNever shear wet animals.

XChildren are forbidden from operating the equipment.

XLay out the power cable cleanly.

XCheck the power cable occasionally for damage.

XKeep the power cable well away from machinery & equipment

operating in close proximity.

XSwitch off the plant before pulling out the plug.

XAfter use remove the plug from its socket. The plant should

only be cleaned or the cutter replaced when the plug is remo-

ved from the power socket.

ONE Shearing Plant – Translation of the original instructions

4

XAvoid kinks or coils in the cable. Never wind the power cable

around the plant during periods of storage. This can result in

breaks and damage to the insulation.

XEnsure that animals do not stand on or walk over the cable, and

that they do not get caught up in the cable.

XKeep children away from shearing areas.

XNever use a damaged plant. Have the machine checked for

faults and repaired immediately by an authorised service agent.

XThe air intake for the ventilation holes (Diag. 2+3, pos. a) must

be kept clear. Never insert any object into the shearing plant’s

ventilation holes.

XNever shear in the vicinity of explosive objects or gases.

XNever shear with blunt or broken shearing combs and cutters.

XAvoid any contact with the moving shearing cutters.

XStore the plant in a clean, dry place to which children and an-

imals have no access.

XThis appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities,

or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the applian-

ce by a person responsible for their safety.

XChildren should be supervised to ensure that they do not play

with the equipment.

1.4.3 Noise emission / personal protective equipment

Noise emission during operation is less than 70 dB (A), as the

noise of the shearing hand-piece is also present during shea-

ring. We recommend that ear protection, safety glasses and

gloves are always worn when operating the plant.

Personal protective equipment to be provided by the operator.

1.4.4 Residual dangers

Should dangers and hazards occur during operation which are

not directly related to the shearing of animals, we request that

you inform us of this. This also applies in the event of a technical

failure that causes a hazard.

ONE Shearing Plant – Translation of the original instructions 5

1.4.5 Replacement power cable

NOTE!

If the power cable of this equipment is damaged, it must be re-

placed by the manufacturer or its after-sales service or a similarly

.

1.4.6 Supervision of children

WARNING!

Children should be supervised to ensure that they do not play

with the equipment.

1.5 Operator requirements

NOTE!

The safe use of the machine places few demands on operating

personnel. These must, however, be observed and maintained as

a matter of course.

yThe operator has experience in dealing with the animals being

shorn.

yThe operator has read and understood the operating instruc-

tions, or has been indoctrinated into the operation of the ma-

chine by a skilled person, and the risks and dangers have been

pointed out to him.

2 Stipulated usage

2.1 Component list

2.1.1 Designation of individual parts

Pos.

No.

Description Quantity Pos.

No.

Description Quantity

1Handle 120 Hexagonal nut 1

2Upper section ONE 121 Speed control

sensor ONE

1

3Reinforcement

plate ONE

222 Control unit ONE/

EVO

1

4LS-screw 623 Hexagonal nut self-

securing

2

5Motor ONE 125 PH-screw 1

ONE Shearing Plant – Translation of the original instructions

6

Pos.

No.

Description Quantity Pos.

No.

Description Quantity

7 126 Switch support 1

8Centering washer 127 Micro switch 1

9Countersunk screw 128 Socket head cap

screw Phillips

2

10 Insulating washer 129 Retaining ring for

shaft

1

11 130 Washer 1

12 PT-screw counter-

sunk

431 Spring for switch 1

13 Capacitor 132 Lever for switch 1

14 Capacitor 133 Cord black 1

15 Drive housing ONE 134 Ring spanner 1

16 LS-screw 435 Catch spring ONE/

EVO

1

17 Socket head cap

screw

737 PT-screw 1

18 Cable 138 Rating plate 1

19 Anti-kink sleeve 140 Spacer sleeve

(USA only)

1

2.2 Purpose of use

The portable shearing plant is specially designed to provide the drive for

mechanical shearing handpieces. The complete shearing unit is expressly

designed for the shearing of sheep, goats, llamas, alpacas and other mem-

bers of the Camelidae species.

2.3 Technical data

Product name: ONE

Mains voltage: see rating plate

Motor output: see rating plate

Rotary speed: see rating plate / support plate

Required fuse protection: see rating plate

Dimensions in mm (W/H/L): 243 x 317 x 209

Weight not including cable: 7.8 kg

Max. ambient temperature: 0 ° - 40 °C

Max. humidity: 10% - 90% (relative)

Noise emission (LpAm): < 70 dB(A)

We reserve the right to make technical changes and improvements without

notice.

ONE Shearing Plant – Translation of the original instructions 7

2.4 Equipment

yPortable shearing plant

yOperating instructions

yScrewdriver

yDrip feed lubricator 100 ml

yUniversal grease

Options

yFlexible drive, worm

yFlexible drive, pin

yFerrule short

yShearing handpiece, Icon, worm

yShearing handpiece, Icon, pin

yCombs and cutters for the shearing handpiece

3 Initial start-up

3.1 Important notes

WARNING!

y

power supply must match. The plant may only be connected to

an AC power supply.

yIt is a compulsory that the operator has read the safety regu-

lations.

yIn the event that the plant is operated from a generator, the

maker‘s rating plate.

3.2 Assembling the shearing plant

.

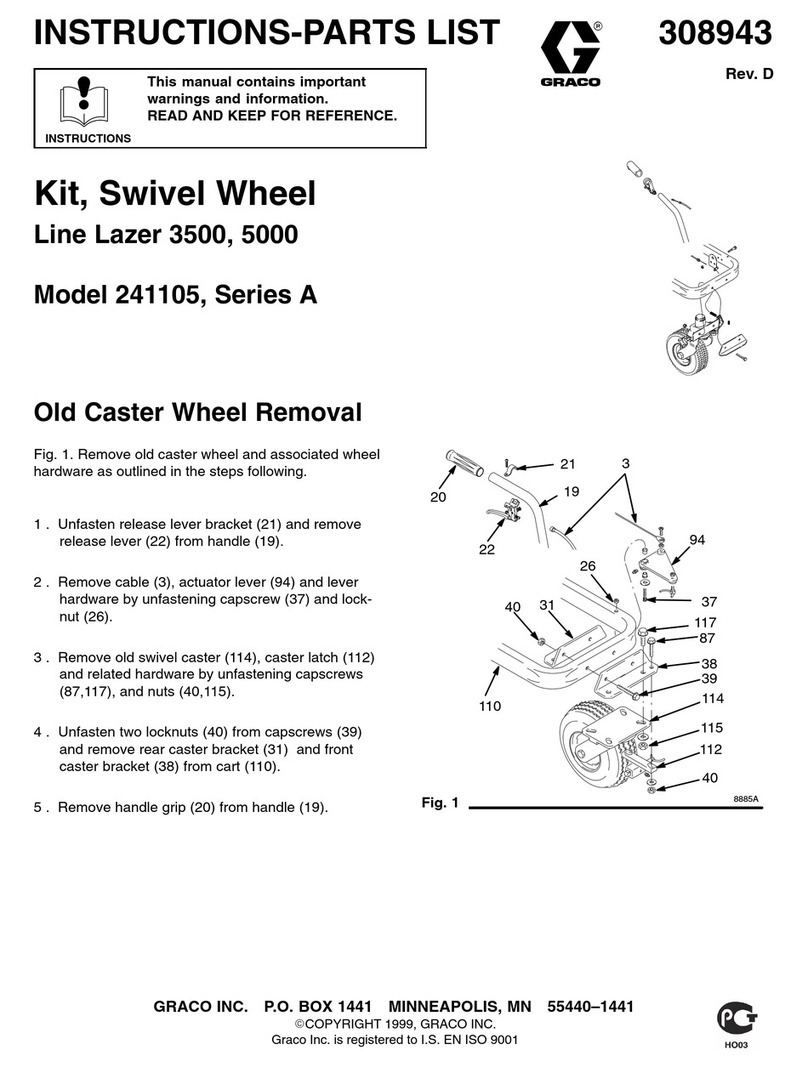

3.2.1 Securing / suspending the shearing plant

The shearing plant can be suspended by means of a strong rope or

chain. The hole provided in the handle should be used to secure the plant

(Diag. 2, pos. c).

ONE Shearing Plant – Translation of the original instructions

8

3.2.2 Assembling the exible drive

XStart up the motor (see Chapter 3.3).

X -

ally (Diag. 3, pos. b).

X

sleeve and then position this by means of slight pressure upwards until

the lock button engages in the hole (Diag. 3, pos. c).

3.3 Switching the shearing plant on / off

CAUTION!

Make sure that the ventilation holes are always clear (Diag. 2+3,

pos. a). The shears drive remains switched off after the connec-

tion to the power supply. The shearing plant is switched on and

off respectively via the cord / lever (Diag. 2, pos. b). The drive is

switched on by means of one downward pull, and is switched off

again by repeating this operation.

Should the power supply be interrupted whilst the drive is running,

for safety reasons the motor switches off automatically, which

means that the unit must be switched on again via the cord / lever

when the power supply is re-established.

4 Maintenance

4.1 Cleaning

Before commencing any maintenance work disconnect the electrical power

supply by pulling out the plug!

Remove any oil and dirt from the shearing plant by means of a dry cloth. Do

not use liquids!

4.2 Service

WARNING!

For safety reasons the portable shearing plant should be subjec-

ted to an annual inspection. It is important that the self-tensioning

belt is checked periodically, since the functionality of the patented

safety cut-out device is dependent on this.

ONE Shearing Plant – Translation of the original instructions 9

4.3 Lubrication

-

ce a lack of lubrication is the most common source of faults for unsatisfac-

tory shearing results.

4.3.1 Portable shearing plant

Requires no lubrication.

4.3.2 Flexible drive

prior to each period of operation

-

placed (Diag. 4, pos. a).

after 100 hours of operation

-

arings. The rotating shaft bore must, however, be greased at regular in-

tervals (after approximately 100 hours of operation or every 2 years). To

residue from the shaft bore. Then re-lubricate the shaft bore along its whole

length with fresh, high-quality mineral grease.

4.3.3 Shearing handpiece

See operating instructions for shearing handpiece.

4.4 Storing the machine

CAUTION!

Get into the habit of always giving the shearing plant a good clean

after use, store the unit in a dry and clean location out of the re-

ach of children.

ONE Shearing Plant – Translation of the original instructions

10

5 Troubleshooting and repairs

This product has been developed and assembled using the best individu-

al components available. It is designed to give longevity and high perfor-

mance. If spare parts are used during the life of this product, please ensure

that they are genuine Heiniger parts. Failure to use genuine Heiniger spares

may reduce the performance of this precision engineered product and will

void any warranty claim.

5.1 Introduction

WARNING!

The following troubleshooting guide will aid in determining prob-

lems and offer a solution. An authorised service point may only

carry out solutions that appears against a dark background.

An authorised service agent is to be contacted in the event of

malfunctions that are not contained in this manual.

5.2 Troubleshooting

Malfunction Cause Rectication

Motor does not run. No power. Power supply and/or fuse

faulty.

Cable faulty. Have the cable replaced.

Switch faulty. Have the switch replaced.

Motor faulty. Have the motor replaced.

Control unit faulty. Have control unit replaced.

Capacitors faulty. Have the capacitors repla-

ced.

ONE Shearing Plant – Translation of the original instructions 11

Malfunction Cause Rectication

Motor always switching

off.

Cutter blocked. Remove blockage.

Mechanical damage in

the shearing handpiece

.

For the purposes of fault

the shearing handpiece

and restart the plant. If the

fault persists, uncouple

the rigid drive downtube

shearing plant. Rectify any

damage.

If the fault still persists,

then have the shearing

plant repaired.

Reverberation sensor’s

magnet faulty.

inc. magnet, replaced.

Faulty reverberation

sensor.

Have the reverberation

sensor replaced.

Power supply too weak. Check the power supply.

Motor system does not

switch off by lock up.

Control unit faulty. Have control unit replaced.

Shearing unit is noisy or

vibrates.

Faulty motor bearing. Have the motor replaced.

Motor gets hot. Faulty motor bearing. Have the motor replaced.

Ventilation screen dirty. Clean ventilation screen.

Malfunctions in the rigid

drive and / or shearing

handpiece.

.

Shearing plant cannot

be switched off.

Switch faulty. Have the switch replaced.

6 Environmental protection and waste disposal

6.1 Introduction

The operator bears the responsibility for disposing of the machine in the

proper manner. Observe the relevant regulations applicable in your coun-

try.

ONE Shearing Plant – Translation of the original instructions

12

6.2 Material groups

Please hand this in to a service point or your local specialist electrical work-

shop when the machine is to be dismantled.

Material contained in pos. X taken from Diag. 1

Rubber 18

Polyamide PA 2/10/15/19

Polypropylene PP 33

POM 7/32

Iron/steel 3/4/5/8/9/11/12/16/17/23/25/26/28/29/30/31/34/35/37/40

Copper 18

Brass 20/27

Aluminium 16

other substances 38

Electronics 13/14/21/22/27

7 Contact address

-

horised service points, or, alternatively, refer to the nearest service point in

your area.

ONE Shearing Plant – Translation of the original instructions 13

A1

1

1

2

3

4

5

22

37

35

14

13

15

7

8

9

10

11

12

21

20

23

25

4

32

34

33

27

26

35

28

31

3029

19

38

18

16

17

40

(only USA)

A2

2 3

a

a

b

c

b

c

5

4

a

In case of claim, please return your machine with the instruction manual and the warranty card

directly to your local distributor. Please do not cut off the warranty card from the instruction

manual.

© 2021 Heiniger AG. All rights reserved.

This instruction manual may not be duplicated or distributed, neither completely nor in extracts, or

by electronic or mechanical means (including photocopying), transmitted or used for the purpose

of competition without authorisation from Heiniger AG.

Subject to change without notice.

Contact:

warranty garantie garantía

Item

Artículo

Article

Artikel

Articolo

Artico

Artikel

Artikel

Artikel

Artikkel

Tuote

Προϊόν

Serial no.

No. de serie

No. de série

Serien-

nummer

No. di serie

No. de série

Serie nr.

Serie Nr.

Serienr.

Serie nummer

Sarjanro

Αρ. σειράς

Date of

purchase

Fecha de

compra

Date d’achat

Kaufdatum

Data di vendita

Data de

compra

Datum van

aankoop

Købsdato

Köpdatum

Kjøpsdato

Ostopäivä

Ημερομηνία

αγοράς

Stamp and signature

Sello y firma

Cachet et signature

Stempel und

Unterschrift

Timbro e firma

Carimbo e assinatura

Stempel en handte-

kening

Stempel og

underskrift

Stämpel och

namnteckning

Stempel og

underskrift fra forret-

ningen

Myyjän leima ja alle-

kirjoitus

Σφραγίδα και

υπογραφή

Heiniger AG

Industrieweg 8

CH - 3360 Herzogenbuchsee

Switzerland

Tel. +41 (0)62 956 92 00

marketing(at)heiniger.com

Original-Betriebsanleitung

Translation of the original instructions

Traduction de la notice originale

Traduzione delle istruzioni originali

Traducción del manual original

Vertaling van de originele gebruikshandleiding

Oversættelse af den originale brugsanvisning

Översättning av bruksanvisning i original

Oversettelse av den originale brukerveiledningen

Alkuperäisten ohjeiden käännös

Tradução do manual original

Μετάφραση πρωτοτύπου οδηγιών χρήσης

Other manuals for ONE/G

1

This manual suits for next models

1

Table of contents

Other Heiniger Power Tools manuals

Popular Power Tools manuals by other brands

Yokota

Yokota TKA70 manual

Chicago Electric

Chicago Electric 97114 Set up and operating instructions

Ozito

Ozito PRR-1200 Operation manual

HP

HP Indigo 5000 Preventive maintenance guide

General International

General International DP2003 Setup & operation manual

Ingersoll-Rand

Ingersoll-Rand ES45T Maintenance information