Heinz Walz ULM-500 User manual

ULM-500

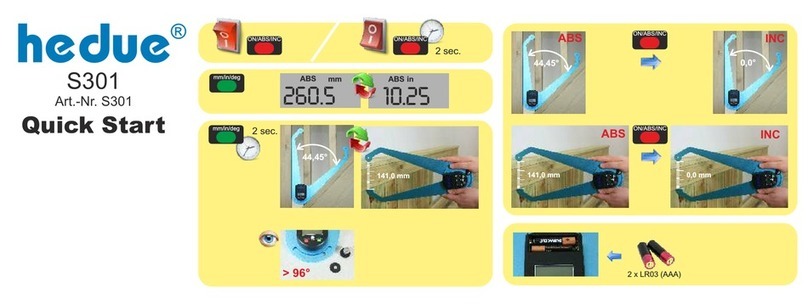

ENTER CALIBRATION FACTOR

SAVE

OK ESC

4x

finish with:

ESC

3x

finish with:

enter Main Menu

MENU

MENU

MENU

MENU

MENU

chose

Display

chose

Sensors

chose

Calibration

chose

PAR

Sensors

chose

Connector

mark

connected

sensor with:

MENU

ESC MENU

adjustment with:

also chose unit

SAVE

OK ESC

4x

finish with:

SAVE

OK ESCESC

4x

finish with:

ESC

3x

finish with:

ESCESC

3x

finish with:

enter Main Menu

MENU

MENU

MENU

MENU

MENU

chose

Display

chose

Sensors

chose

Calibration

chose

PAR

Sensors

chose

Connector

mark

connected

sensor with:

MENU

ESC MENU

adjustment with:

also chose unit

enter Main Menu

MENUMENU

MENUMENU

MENUMENU

MENUMENU

MENUMENU

chose

Display

chose

Display

chose

Display

chose

Sensors

chose

Sensors

chose

Sensors

chose

Calibration

chose

PAR

Sensors

chose

PAR

Sensors

chose

Connector

chose

Connector

mark

connected

sensor with:

MENU

mark

connected

sensor with:

MENUMENUMENUMENU

ESC MENU

adjustment with:

also chose unit

ESC MENUESCESC MENUMENU

adjustment with:

also chose unit

CONTENTS

1Safety Instructions .......................................................................1

2Assembling the ULM-500............................................................2

2.1 The Keypad...............................................................................5

3Input of Calibration Values.........................................................6

3.1 Order of measuring windows....................................................8

3.1.1 The PAR Window............................................................... 9

3.1.2 The Leaf-Clip Window.......................................................9

3.1.3 The Air Sensor Window ................................................... 10

3.1.4 The Chart Window............................................................ 10

3.2 Before the Measurement.........................................................12

3.2.1 Changing Calibration Factors........................................... 14

3.2.2 Measure Settings...............................................................15

3.2.3 Device Settings.................................................................18

3.2.4 Applications...................................................................... 19

3.2.5 User Applications ............................................................. 21

3.2.6 Info.................................................................................... 22

3.2.7 Memory............................................................................. 22

4Connection to the Computer.....................................................23

5Operating the ULM-500 via WinControl-3............................. 24

5.1 The Initial Tab / Chart Tab .....................................................24

5.1.1 Main Menu Bar - Box (1) ................................................. 25

5.1.2 Data Management and Graph Design - Box (2) ...............26

5.1.3 Sidebar - Box (3)............................................................... 28

5.1.4 Online Values - Box (4)....................................................30

5.1.5 Triggered Data - Box (5)...................................................30

5.1.6 Store Data Point - Box (6) ................................................30

CONTENTS

5.1.7 Protocols - Box (7)............................................................30

5.1.8 Graph, Data and Fluorometer Settings Tabs - Box (8)..... 31

5.1.9 Axis Control - Box (9)...................................................... 31

5.1.10 Ordinate Selection and Text Field - Box (10)...................32

5.1.11 Chart - Selecting Data.......................................................33

5.2 The Report Tab ....................................................................... 34

5.2.1 Data Management and Graph Design - Box (2) ...............35

5.2.2 The Report Data Field – Box (11) .................................... 37

5.3 The Memory Tab ....................................................................37

5.3.1 Box (12) – Memory Operations........................................ 38

5.4 The Settings Tab ..................................................................... 39

5.4.1 Chosen Instrument and Reset button - Box (12)............... 39

5.4.2 Instrument Settings - Box (13).......................................... 40

5.4.3 Instrument Information - Box (14) ...................................42

5.4.4 System Settings – Box (15)...............................................43

6Technical Specifications*........................................................... 45

7Warranty Conditions.................................................................47

SAFETY INSTRUCTIONS

1

1Safety Instructions

Instructions. Read all the safety instructions and operating

instructions thoroughly before using the device for the first time. Keep

these safety instructions and operating instructions somewhere safe in

case you need to refer to them again in the future.

Safety warnings. Pay heed to safety warnings on the device and in

the operating instructions. Follow the instructions for operation and use

of the device in every respect.

Temperature. Do not install the device near any heat sources such

as radiators, hot-air dryers, ovens, etc. Do not place naked flame

sources, such as lighted candles or Bunsen burners, on or near the

device.

Moisture. Keep this device out of the rain and away from moisture.

Do not expose the apparatus to dripping or splashing and do not place

any object filled with liquid, such as drinking vessels, beakers or test

tubes, on or close to the device. Never use the device near water, for

example near a sink.

Solid objects. Take great care to ensure that no sharp objects

penetrate inside the device through openings of the casing.

Service. Do not open the casing. There are no user serviceable parts

inside. Refer all servicing to qualified service personnel. Servicing is

required when the apparatus has been damaged in any way, e.g., by

exposure to wet conditions, excessive heat, or has been dropped.

Power source. Connect the device only to the 5 Volt power source

of a USB socket of a computer using the USB cable supplied with the

device. Run the USB cable so that no one can step on it and nothing can

rest on or against it.

Device not in use. If you are not going to use the device for some

time, remove the plug from the socket and remover the batteries..

Cleaning. Clean only with dry cloth.

THE ULM-500 INSTRUMENT

2Assembling the ULM-500

The ULM-500 can be connected with sensors via BNC standard

connectors (Bayonet Neill-Concelman, PAR #1 and #2) shown in the

image below:

Fig. 1 configuration of ULM-500 sensor connectors

After connecting new sensors to the ULM-500 please do not forget

to check the calibration factors needed! (Chapter 2)

Two further optional accessories used mainly on Monitoring-PAMs,

the leaf-clip holder (e.g. MONITORING-LC JUNIOR-B or MINI-

PAM-LC 2030-B) and the Air-Sensor (Humidity and Temperature – not

available yet) can be connected via the panel plugs 1 and 2 (located in-

between the BNC connectors). Insert batteries like indicated in figure 2.

Open the battery compartment by pushing the release of the back cover.

2

THE ULM-500 INSTRUMENT

Insert four AAA batteries (1.5 V) with the correct and polarity

(marked in the compartment).

Fig. 2 Polarity of the batteries

Close the battery compartment completely again before using.

NiCd or NiMH cells are also possible but can not be charged when

inserted. Under extreme low temperature (0°C) 1.5V Li-cells are

recommended. When placing the ULM-500 into storage for a longer

time, please make sure that no batteries are inserted.

3

THE ULM-500 INSTRUMENT

Fig. 3 Connecting sensors to the ULM-500 (here: BNC to PAR #1)

To connect a male BNC plug to PAR #1 or #2 push and carefully

right-turn the connector as shown in Fig. 3 The connectors used for the

panel plugs 1 and 2 need to be screwed to get good contact with the

accessory sensors.

4

THE ULM-500 INSTRUMENT

5

2.1 The Keypad

The ULM-500 keypad offers six buttons which from which have

more than one function.

ON/OFF switches the instrument on or off when held for more than

3 seconds. Additionally the display illumination can be switched on

with this button by pressing it shortly while the ULM-500 is already

switched on. Illumination will switch off automatically after 40 seconds

to save battery power.

SAVE freezes the display during a measurement and stores the

recent data (HOLD is shown in the lower left display corner). A new

line in the report is produced.

ESC is normally used to navigate back to the previous menu item

when it is pressed once shortly. When being deeper in the settings menu

ESC can be held for some seconds to go completely back to the starting

window.

MENU is used to enter the menu for changing settings. The key is

also used as an “enter” button to confirm settings. The arrow indicates

that it moves forward in a menu or on a screen.

UP/DOWN buttons are used for the navigation inside a menu. They

control the cursor position (which is displayed on the screen as inverted

field).

MENU AND OPERATION

6

3Input of Calibration Values

After having connected all necessary sensors to the ULM-500 the

instrument needs Calibration factors before the first accurate

measurement can start. Only leaf-clips that like the JUNIOR-B, 2030-B

or 2060-M do not need calibration factors. Nevertheless they might

need to be calibrated from time to time as it is necessary for all sensors.

Touch the “ON” key and the instrument will wake up with a short

beep and show the start screen - similar to the screen shown below.

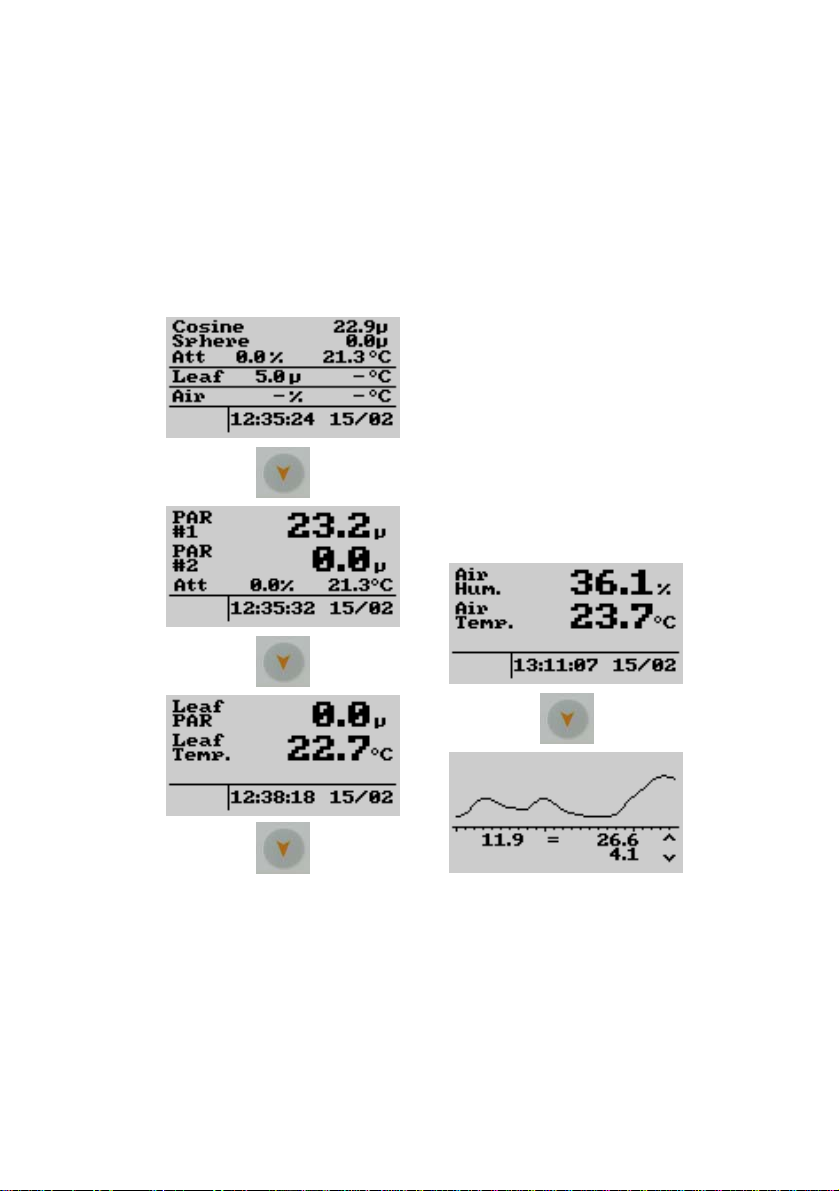

Fig. 4 Starting screen with two PAR sensors and a leaf clip connected.

Line 1 and 2 show the chosen sensors connected via BNC. 3 is the

perceptual difference between these sensors. 4 and 5 are sensors

connected via the panel plugs. 6 is the recent time and date in the

instrument

The first two lines of the start-screen show the values measured

with the sensors connected to PAR #1 and PAR #2 (second line).

The “µ” is used instead of the PAR unit µmol/m-2s-1 (via

WinControl-3 the shown unit can be exchanged against a W (for Wm-2)

in case a pyranometer for the measurement of the solar irradiance is

connected to the ULM-500).

In the third line “Att” is the attenuation index as perceptual loss of

PAR intensity between sensors connected via PAR #1 and PAR #2. The

third line also shows the internal temperature of the ULM-500 (this

MENU AND OPERATION

7

value may differ from the ambient temperature when the ULM-500 is

operated in sunlight).

The parameter “Air” in the fifth line of the start screen refers to a

humidity sensor that will be available in the near future. The first value

shown is the relative humidity calculated from the temperature sensor

built in this “air” sensor and the absolute humidity measured (this

sensor is connected via panel plug 2 – Fig 1).

In the last line the recent time and date used in the instrument is

indicated (these values can be set via the ULM-500 or automatically via

WinControl-3 software when the ULM-500 is connected).

When switching the instrument on for the first time, there is only a

standard set of calibration values for typical PAR sensors stored. The

sensor names can be defined via WinControl-3 software (chapter 4) and

also the most important calibration factors can be entered via

WinControl-3 but also the ULM-500 directly (in this case the sensor

names can not be changed).

.The ULM-500 will remember the last screen used, when it is

switched on the next time.

There are four more screens available in

the ULM-500, each focuses on a different

set of parameters, accessories or sensors.

By using the “up” or “down” button one

can switch from one screen to another beginning with the normal

starting screen. After switching off the ULM-500 it will automatically

show up with the last measuring window used after switching it on

again..

MENU AND OPERATION

8

3.1 Order of measuring windows.

In the image below the order of measuring windows is shown when

the “down” arrow button is used. Scrolling through these windows is

also possible by using the “up” arrow button to navigate in the opposite

direction.

1

2

3

4

5

From here the instrument can be switched off at any time by

pressing the “off” button for three seconds (pressing this button once

shortly will activate the display illumination for 5 mins). From this

measure mode, the menu can be entered by pressing “MENU” on the

keypad of the ULM-500.

MENU AND OPERATION

9

3.1.1 The PAR Window

The PAR window displays values

coming from sensors connected via the

BNC connectors to PAR #1 and #2 (see

also Fig. 1). In this case it is of great

importance that the calibration factors for

the sensors are set correctly (please also read chapter 3.2 and 3.2.1). The

parameter “Att” in the third line stands for the attenuation index that is

calculated as perceptual difference between the both sensors connected

to PAR #1 and #2. At the end of the line, the internal temperature of the

instrument is shown. Please note that this temperature may differ from

the ambient temperature when the ULM-500 is operated e.g. in sunlight.

Below date and time stored in the instrument are shown (can be

synchronized with the system time of a computer via WinControl-3

software – chapter 5).

3.1.2 The Leaf-Clip Window

In case the 2030-B leaf-clip holder or

the sensor set 2060-M shall be used for

light and temperature measurement with

the ULM-500, an optional adapter cable

(2030-B/ULM) is necessary. 2030-B and

2060-M carry a thermocouple and a light sensor and are normally used

together with the MINI-PAM, PAM-2500 or JUNIOR-PAM. These two

parameters are shown in bigger letters in the leaf-clip screen.

Additionally also the date and time is displayed.

MENU AND OPERATION

10

3.1.3 The Air Sensor Window

The “Air” sensor is not yet available.

3.1.4 The Chart Window

In the chart window the recent changes

of the incident radiation can be observed

(PAR #1 channel). Maximum, minimum

and average values (left) are shown in

addition to the graphic. This screen is also

used for the triggered measurement (chapter 3.2.2). The timeline

displayed can be switched from 1.2 to 2.4 seconds in the measure

settings “chart” in chapter 3.2.2.

Fig. 5 Typical shape of light flashes from different light sources. The

right saturating pulse has been recorded from a Diving-PAM which

is using a halogen lamp; the left curve is derived from a PAM-2500

working with fast red LEDs. The curves are shown normalized to

fit them into the chart screen. The measured amplitude is displayed

as value below the chart.

When the trigger has been activated the chart runs as long as the trigger

level is not yet reached. In case the ULM-500 registers a fast increase of

MENU AND OPERATION

11

the radiation the graphic will stop so that the shape of the flash and its

values can be evaluated on the display.

Also without having the trigger activated the chart can be stopped.

Pressing “SAVE” freezes the chart. The chart window now displays the

message “HOLD” in the lower left corner. The chart can be released

again by pressing “ESC” and the trigger is still activated again (if it has

been activated before).

The graphic is not saved; a continuous record of the radiation can be

achieved when the ULM-500 is used together with the WinControl-3

software. In this case the recording time is not limited.

MENU AND OPERATION

12

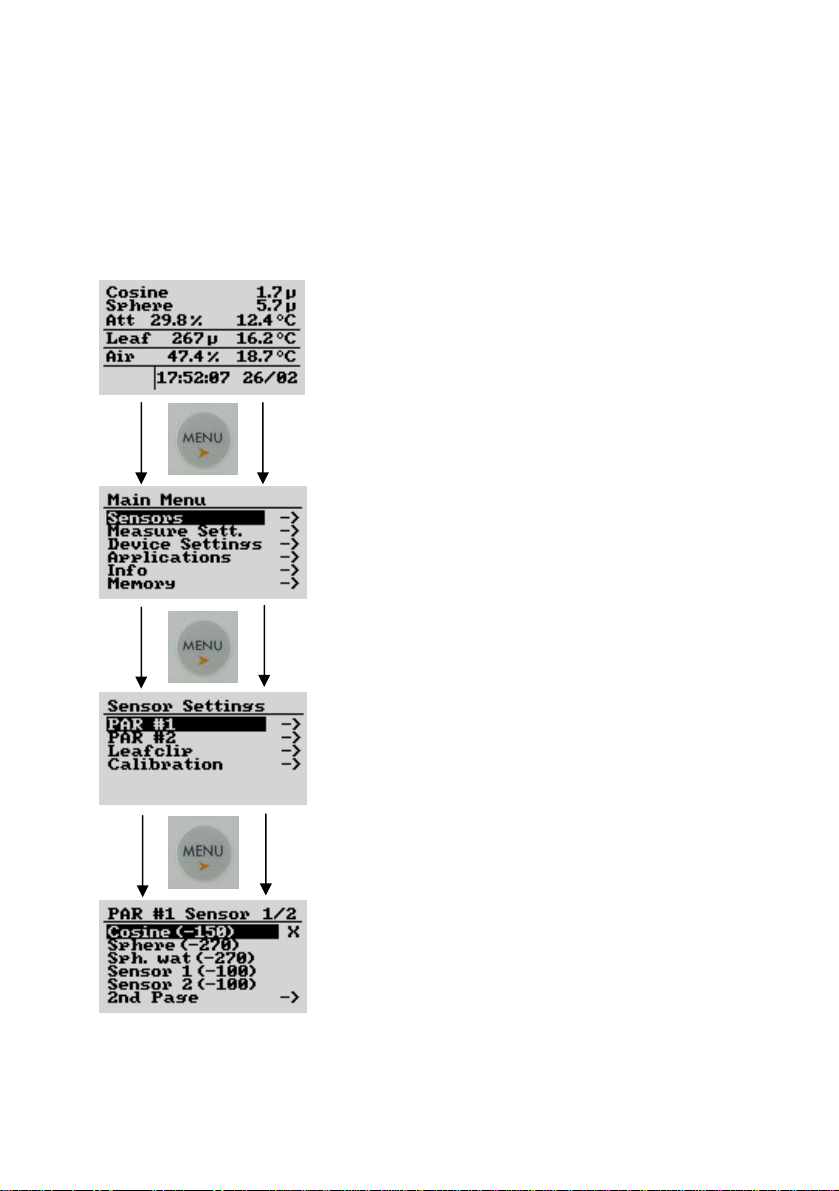

3.2 Before the Measurement

Please always check the calibration values for the chosen sensors

before the measurement

Checking the sensor settings for the PAR

channels is really easy – starting e.g. with #1

from any of the parameter screens pressing

“Menu” will switch one level deeper into the

calibration settings. To make the navigation

easier, the ULM-500 remembers the position

in the menu that you chose last time and

displays it inverted. Moving the active field is

done by using the “up” and “down” arrow

buttons.

With the “ESC” key the display jumps one

step back in the menu. Going completely back

to the start screen is possible by pressing the

“ESC” button for 3 seconds from any position

in the menu.

At the end of the navigation a window

with the stored sensor types/names and

settings appear (lowest image). In the case

shown, the setting for the PAR channel #1 is

shown.

The “X” at the end of a line marks the

sensor chosen for channel #1 is named

“Cosine” in this case its calibration factor is -

150 (shown as rounded value - can be edited

in the “PAR Calib.” window described below)

MENU AND OPERATION

13

If another sensor (already stored) shall be chosen, the cursor

(inverted field) can be moved up or down and entered by pressing

“MENU” once again. Also a second page with five more sensors can be

chosen (2nd Page).

Under “Leafclip” also the optional leaf-clip holder connected to the

ULM-500 can be defined. In the case of a MINI-PAM or PAM-2500

leaf clip holder (2030-B) or the sensor set 2060-M an additional adapter

cable is necessary (2030-B/ULM) and the setting has to be “MINI-

PAM LC”. When a leaf clip from a JUNIOR-PAM shall be connected

(JUNIOR-B), “MONITORING LC” has to be chosen to get correct

measurements. This can also be done via the WinControl-3 software

(chapter 5.4).

MENU AND OPERATION

3.2.1 Changing Calibration Factors

Connecting a new or different

radiation sensor normally needs a

change of calibration factors prior to

the measurement.

Please use the “up” and “down”

arrow buttons, “Menu” and “ESC” as

described in the chapter 3.1.1 to

navigate in the ULM-500 menu.

Going completely back to the start

screen is possible by pressing the

“ESC” button for 3 seconds.

In the “PAR Calib.” window the

calibration factors for each radiation

sensors can be edited (this can also be

a pyranometer). Just move the

inverted field (cursor) to the desired

line (“up” and “down”), afterwards

press “MENU” to enter the

calibration factor digits. The value

can be changed digit by digit - “up” and “down” increase or

decrease the digit. “MENU” moves the cursor to the next digit of

the calibration factor. Pressing “ESC” for 3 seconds moves to the

very start of the settings menu and confirms the changed settings.

The ULM-500 stores up to 10 calibration factors shown on

two pages in the menu. While the factors themselves can be edited

directly in the ULM-500, it is not possible to change the sensor

names in the field without using a computer. This can only be

done with the help of the WinControl-3 software that has been

14

Table of contents

Other Heinz Walz Measuring Instrument manuals