Heinz Basic Series User manual

Operating Instructions

Parallel shaft cam gear

Type :

Serial No. :

BWV_HSP_ E 2 / 16

C O N T E N T S

1. General

1.1 Validity

1.2 Safety instructions

1.3 Shipment

1.4 Transport Regulations

1.5 Weights of gear types

2. Instructions for application of the gears

2.1 Installation position

2.2 Mounting of the gear

2.3 Gear operation

3. Start up

3.1 Gear function

3.2 Oil level

3.3 Interruption operation

3.4 Important instructions

4. Maintenance Instructions

4.1 General remark

4.2 Drive

4.3 Motor brake

4.4 Gear

5. Inspection instructions

5.1 Inspection cycle

5.2 24-Hour-Service

6. Spare part installation

6.1 Remark

6.2 Parallel shaft mechanism

6.2.1 Replacing cam followers (parallel shaft cam stays built in)

6.2.2 Replacing turret (parallel shaft cam stays built in)

6.2.3 Replacing parallel shaft cam (turret stays built in)

6.2.4 Replacing mechanism completely

6.3 Tapered roller bearings

6.4 Spare part drawing

6.5 Spare and wearing parts

7. Final remark

BWV_HSP_ E 3 / 16

1 General

1.1 Validity

These operating instructions are valid for parallel shaft cam gears. They are to be read and

applied by all persons in the user’s premises who are made responsible for the installation,

operation, maintenance or repair of these gears.

For the sake of simplicity, the parallel shaft cam gears will be referred to as “the gears” within

the following instructions.

Every gear is manufactured to the state-of-the-art and according to recognized safety

regulations.

Applications other than specified or exceeding the limiting parameters, e.g. higher speeds

and/or loads or other installation positions, are considered to be contrary to agreement. The

manufacturer shall not be held responsible for any damage resulting from this. In such

cases, the risk is carried solely by the operating company.

The agreement regarding application also covers reading the operating instructions and

compliance with the inspection and maintenance stipulations. Maintenance work may only be

carried out by qualified personnel who are acquainted with the principles of the gear function.

1.2 Safety instructions

The gear corresponds to the recognized safety regulations. When employed as part of a

machine or plant, danger of injury or death for the user or a third person can result, e.g. due to

removal of the lever, gear wheel with chain or similar parts. In such cases, suitable local

protective measures should be taken by the user.

1.3 Shipment

Every gear is subjected to go through an inspection process and is properly packed. In spite of

this, we request that the gear is unpacked immediately on arrival at the installation location and

checked for transport damage.

Any complaints should be reported immediately to the transport company.

1.4 Transport regulations

Eyebolts may be screwed into the fixing holes provided. Lifting ropes or chains may only be

applied on these eyebolts. The weight of the gear should be taken from table 1.5.

BWV_HSP_ E 4 / 16

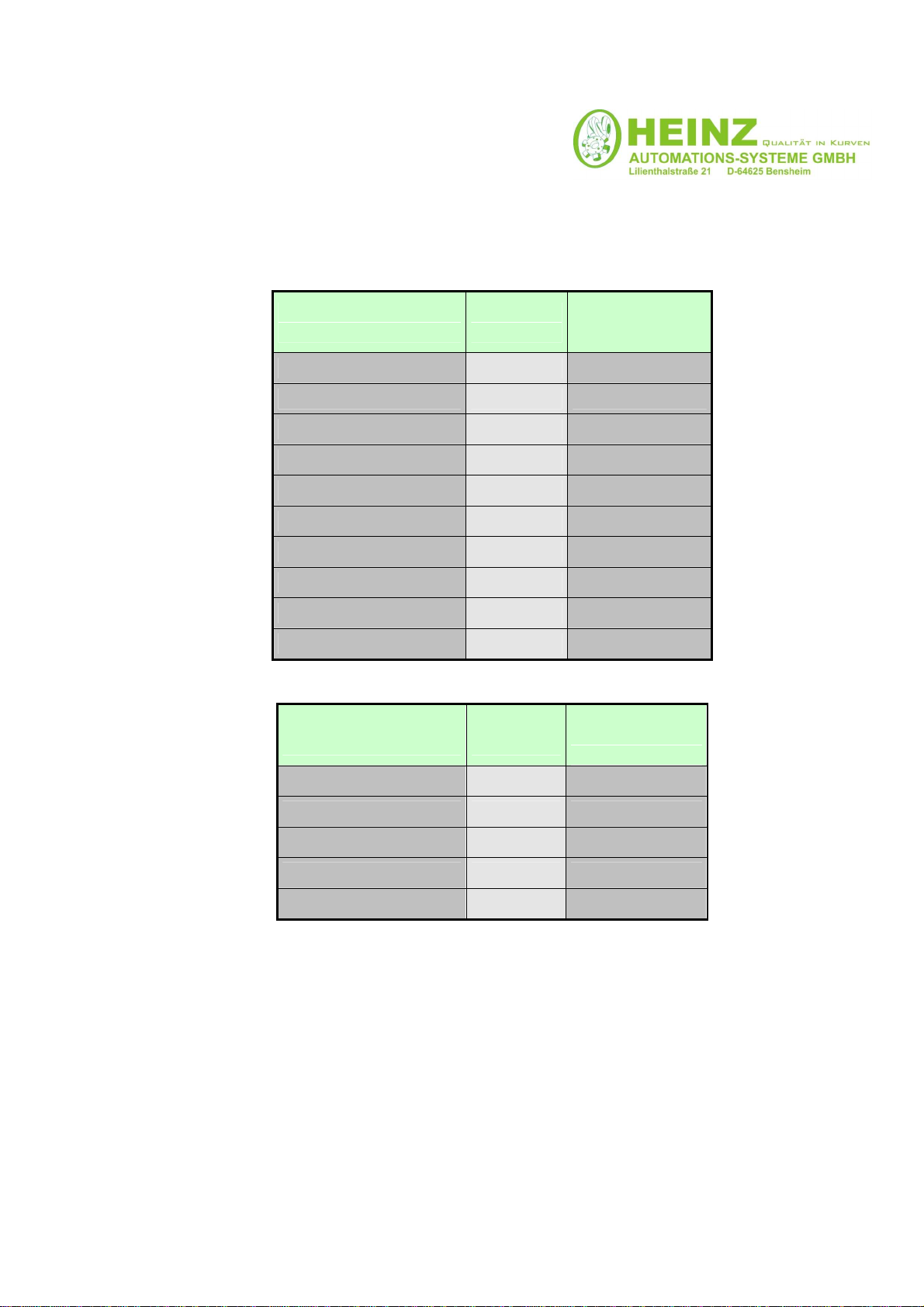

1.5 Weight of the gears

Basic series

Gear type

Housing

Weight without

motor

[kg]

HSP 40 GG 4,5

HSP 50 GG 7,5

HSP 63 GG 12,5

HSP 80 GG 25,0

HSP 100 GG 43,0

HSP 125 GG 77,0

HSP 160 GG 150

HSP 200 GG 280

HSP 250 GG 480

HSP 315 GG 680

Modified series

Gear type

Housing

Weight without

motor

[kg]

HSP 65 GG 14,5

HSP 80 X GG 27,0

HSP 80 XK GG 27,5

HSP 105 GG 48,0

HSP 130 GG 85,0

BWV_HSP_ E 5 / 16

2. Instructions for application of the gears

2.1 Installation position

Due to its universal construction, the gear can be integrated into a machine or a plant in nearly

every position required.

When placing the order, the customer can preset the installation position, the mounting position

and possibly the oil holes.

The predetermined installation position is decisive for the lubrication of the gear components

and may therefore not be subsequently altered at the plant location.

Illustration 1: Gear installation positions

2.2 Mounting the gear

Due to the principle of the functioning of the gear, the output shaft as well as the input shaft are

subjected to variable torques. The following must therefore be observed:

•The gear must be mounted on a rigid machined surface.

•The fixing bolts must be secured and, if possible, the position of the gear should be

additionally fixed by means of dowel pins.

•The connection between the gear and the driven load must be direct, free of play and

torsionally rigid. This also applies to the drive side of the gear.

2.3 Gear operation

The following should be observed with regards to gear operation:

•Elasticity and play in the driven masses can result in vibration and must therefore be

avoided.

•A possibly installed overload protection should be mounted on the output shaft.

BWV_HSP_ E 6 / 16

3. Start up

3.1 Gear function

HEINZ gears form a compact, robust unit which, through the use of accurately calculated disk

cams, enable the transformation of a constant input speed into an optimum, precise and

impact-free (intermittent) output movement.

The cam rollers fitted in the turret are guided precisely in the curve by the hardened and ground

cam path.

This cam path is formed with a variable slope and is divided into a dwell angle and index angle

area. When the cam is rotated, the precise jolt and impact-free movement of the output shaft is

produced by the cam path and the cam follower. As the cam course is constructed standard

symmetrically.

The dwell angle area has a zero slope. Through this, the cam followers result in a precise, self-

locking positioning of the output shaft without an additional locking mechanism.

When a brake motor is employed, the positioning of the output shaft is independent on the

braking accuracy of the motor as the accurate positioning is dictated by the position of cam

followers in the dwell angle area. The whole dwell angle area is available for braking (see 3.3).

3.2 Oil level

The oil level should be checked before start up. It is sufficient it the oil can be observed through

the oil level indicating glass (see also 4.3 gear)

Basic series modified series

Gear type oil volume

[ L ]

Gear type oil volume

[ L ]

Gear type oil volume

[ L ]

HSP 40 0,2 HSP 160 8,0 HSP 65 0,4

HSP 50 0,3 HSP 200 19,0 HSP 80X 1,0

HSP 63 0,5 HSP 250 29,0 HSP 80XK 1,0

HSP 80 1,0 HSP 315 36,0 HSP 105 2,0

HSP 100 2,0 HSP 130 3,5

HSP 125 4,0

BWV_HSP_ E 7 / 16

3.3 Interruption Operation

If the dwell angle area of the disk cam is insufficient for the interval of interruption required for

production, the interval can be prolonged by using a brake motor. The procedure is initiated by

an end position switch which is operated by one of the cams connected to the input shaft.

During the start up as well as during operation it has to be observed that after the braking has

occurred, the shaft key groove of the input shaft has to be positioned parallel to face 3 of the

housing and that it points towards the output shaft ( in case of double shift also a torsion of

180° is possible, cam followers should be in the middle of the dwell).

If the gear is fitted with an additional indicator, it should be observed that after braking has

occurred, the indicator is always positioned in the middle of the marking plate.

3.4 Important Instructions

With two speed drives, normal operation occurs always at the higher speed (high speed). The

lower speed (low speed) may only be used for setting up the unit or moving into the dwell angle

area after an emergency stop. During automatic operation, the gear may not be switched into

the low speed position while the unit is in the movement phase. With control systems which

only allow switching of the high speed through the low speed, this may only occur during the

dwell angle, this means during the standstill period of the output shaft or rather within the

marking plate.

Any damage which is caused by failure in complying with these instructions will result in the

rejection of any guarantee claim by the manufacturer.

BWV_HSP_ E 8 / 16

4. Maintenance Instructions

4.1. General Remark

In case of queries i.e. spare part orders, please state the type and serial number of the gear in

question.

4.2 Drive

The maintenance instructions for the gear brake motor or other drive units should be taken from

the instructions supplied by the corresponding manufacturer.

4.3

Motor brake

Due to wear of motor brake, the interruption in the dwell angle area as described in 3.3. should

be checked from time to time. The brake should be re-adjusted or renewed if necessary.

BWV_HSP_ E 9 / 16

4.4 Gear unit

4.4.1. Oil Lubrication

In Standard the gear unit is delivered with the synthetic lubricating oil “Klübersynth GHE 6 – 460”

It is lubricated for life, i.e. no oil changes are necessary at all. The oil level should be checked at regular intervals.

Sufficient oil is present if when the gear unit is stationary the oil can be seen in the sightglass

The lubrication of the cam rollers and the came is thus guaranteed

For rotating speed < 150 rpm For rotating speed > 150 rpm

Klübersynth GHE 6 - 460 Klübersynth GHE 6 - 100

Mobil Glygoyle HE 460 (ISO V6 460) Mobil Glygoyle 22 (ISO V6 150)

Shell Omala S4 WE 460 Shell Omala S4 WE 150

WARNING WARNING

Warning: Never mix different oil sorts! Only top up with the lubricant described above!

─────────────────────────────────────────────────────────────────────────

If used for the food industry, the gear unit is delivered with NSF H1 registered, conform to FDA 21 CFR § 178.3570 oil

"Klübersynth UH1 6 - 460"

It is lubricated for life, i.e. no oil changes are necessary at all. The oil level should be checked at regular intervals.

Sufficient oil is present if when the gear unit is stationary the oil can be seen in the sightglass

The lubrication of the cam rollers and the came is thus guaranteed

For rotating speed < 150 rpm For rotating speed > 150 rpm

Klübersynth UH1 6 – 460 Klübersynth UH1 6 – 150

WARNING WARNING

Warning: Never mix different oil sorts! Only top up with the lubricant described above!

─────────────────────────────────────────────────────────────────────────

4.4.2. Grease Lubrication

It is lubricated for life, i.e. no grease are necessary at all. The grease level should be checked at regular intervals.

Normal Grease Lubrication NSF H1 registered, conform to FDA 21 CFR § 178.3570

Castrol Olit 00 Cassida RLS 00

Microlube GB 00 Klübersynth UH1 14-1600

WARNING WARNING

Warning: Never mix different oil sorts! Only top up with the lubricant described above!

─────────────────────────────────────────────────────────────────────────

BWV_HSP_ E 10 / 16

5. Inspection instructions

5.1 Inspection Cycle

It is recommended to control the oil level approximately every 8000 operation hours in order to

avoid any damage of the gear by leakage of oil.

5.2 24-Hour Service

Immediate availability of important components is guaranteed through stocking of a stand-by

set (disk cams, output and cam followers) by the unit operator.

BWV_HSP_ E 11 / 16

6. Spare parts installation

6.1 Remark

Please read the following complete text carefully before the disassembly.

All construction elements have to be cleaned and to be checked if they are in perfect condition

before being installed. The list of spare parts may be helpful for the disassembly and the

installation of the individual parts.

6.2 disk cam mechanism

The mechanism is a unit consisting of two disk cam, cam followers and turret.

Due to a possible wear of the cam followers or the parallel shaft cam, it may be necessary to

replace the following parts:

•Cam followers

•Turret

•Parallel shaft cam

•Complete mechanism

6.2.1 Replacing cam followers (parallel shaft cam stays built in)

•Drain oil

•Move input shaft into dwell angle area

•Unscrew end cap of output shaft

•Lift output shaft out of parallel shaft housing

•Unscrew stud bolts off turret (are glued in) and remove cam followers

•Check shaft bore of cam followers in the turret if they are damaged and possibly

widened

•In case of defective bores: see 6.2.2

•In case of perfect condition of bores, push in new cam followers into turret

•In case of cam followers without key way, bore with core hole drill a centralisation in

every cam followers shaft. The depth of centralisation depends on the centralisation

point of the stud bolts according to DIN914 (German Industrial Standard)

•Secure cam followers with stud bolts (glue thread in)

•Check parallel shaft cam and replace by a new one if necessary (see chapter 6.2.3)

•Put output shaft with turret back into housing (observe the position of the shaft key

groove of the output shaft)

BWV_HSP_ E 12 / 16

•Apply appropriate permanently elastic sealing material upon cleaned sealing surface and

install end cap

•Move input shaft and check regular movement of mechanism

•Fill in oil

6.2.2 Replacing turret ( parallel shaft cam stays built in)

•In the case of a defective cam followers shaft bore remove (smaller) tapered roller

bearing

•Remove stud bolts off turret and disassemble turret off output shaft

•Screw tight new turret with installed cam followers again and put in new studs

•Heat tapered roller bearing slightly (max. 80°C) and push over output shaft

•Put output shaft with turret back into housing (observe position of shaft key groove of

output shaft)

•Proceed with assembly as describe in chapter 6.2.1

6.2.3 Replacing parallel shaft cam (turret stays built in)

•Drain oil

•Move input shaft into dwell angle area

•Screw off housing cover

•Release safety catch of securing steel sheets and unscrew lock nut

•Unscrew both eccentric covers

•Push inner ring of tapered roller bearing (maximum 3 mm less than width of lock nut) off

input shaft by using lock nuts

•Pull off tapered roller bearing by using an extractor

•Remove lock nut and securing steel sheets

•Drive input shaft out of parallel shaft cam without using too much power on the cam

followers

•Take old parallel shaft cam out of housing

•Put new parallel shaft cam with dwell angle area between two cam followers

•(Observe position of shaft key groove of output shaft)

•Drive input shaft into cam without using too much power on the cam followers

•Screw new securing steel sheets and new lock nuts on input shaft

•Heat tapered roller bearing (max. 80°C) and push over input shaft (replace defective

bearings by new ones)

•Screw off eccentric cover. While doing so, make sure no preloading is produced between

cam follower and cam, possibly move cam by using the lock nut or turn eccentric cover

•Check preloading of tapered roller bearing in dwell angle area, possibly by adjusting the

eccentric cover

•Adjust mechanism without backlash by turning eccentric cover and/or by moving the cam

BWV_HSP_ E 13 / 16

The height tolerance of the input shaft pivot may not exceed maximum 0,02 mm on the total

length of the pivot.

An even contact reflection of the cam follower and parallel shaft cam is absolutely required

- check with inking past! –

•Screw lock nuts tightly and secure

•Screw eccentric cover tightly

•Turn input shaft with hand and check its even running, possibly repeat adjustment

•Cover all openings

•Put pins into eccentric cover (possibly earmark pin holes on same pc-diameter with same

depth of bores, remove chips)

•Screw off eccentric cover, seal, bring into line above pin bore, tighten slightly, push pins

and screw tightly

•Install new oil seals – seal housing cover and screw tightly

•Fill in oil

6.2.4 Replacing mechanism completely

Please refer to chapter 6.2.1 to 6.2.3 for the instructions for disassembling and installation of

the turret.

6.3 Tapered roller bearing

When installing new tapered roller bearings, it has to be observed that the bearings are

adjusted free of play. If the backlash is to high or too low, this can be corrected by adjusting the

housing cover or eccentric cover. Afterwards check the correct running of the mechanism by

turning the input shaft, readjust if necessary.

BWV_HSP_ E 14 / 16

6.4 Spare part drawing

BWV_HSP_ E 15 / 16

6.5 Spare and wearing parts

1. Mechanism

1.1 Parallel shaft cam

1.2 Turret

1.3 Cam followers

2. Bearing set

2.1 Tapered roller bearing output 1

2.2 Tapered roller bearing output 2

2.3 Tapered roller bearing output

3. Sealing set

3.1 Oil seal output

3.2 Oil seal input

3.3 O-Ring output

3.4 O-Ring input

4. Input shaft

5. Output shaft

7. Final remark

All repair work requires a certain amount of experience and should therefore be carried out by

HEINZ fitters.

Address of HEINZ:

HEINZ AUTOMATIONS-SYSTEME GmbH

Lilienthalstr. 21

64625 Bensheim

Tel.: +49 (0)6251 / 1069-0

Fax: +49 (0)6251 / 1069-99

http://: www.heinz-automation.de

E-Mail: mail@heinz-automation.de

BWV_HSP_ E 16 / 16

Lilienthalstrasse 21 - D-64625 Bensheim

Telefon +49(0)6251/1069-0 - Fax +49(0)6251/1069-99

This manual suits for next models

16

Table of contents

Popular Industrial Equipment manuals by other brands

Pepperl+Fuchs

Pepperl+Fuchs PGV Series manual

ABB

ABB RELION 650 SERIES Product guide

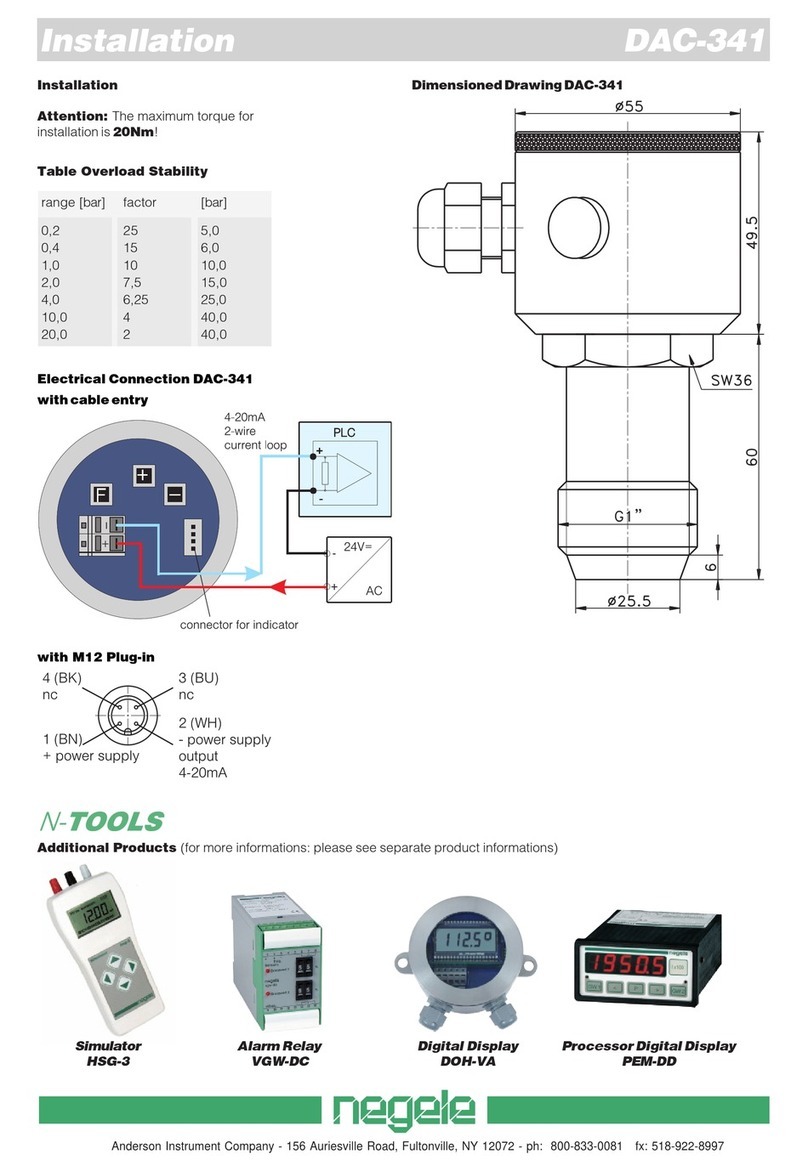

Negele

Negele DAC-341 Installation

Atlanta Attachment Company

Atlanta Attachment Company 4300 Installation, operating & service manual

permaban

permaban Alpha Joint installation guide

Siemens

Siemens TIASTAR instruction manual

Nordson

Nordson PatternJet 1065924 Customer product manual

Monosem

Monosem 7x7 NG Plus 4 Series Operator's & parts manual

ABB

ABB HT562483 Operation manual

Virutex

Virutex PEB200 operating instructions

Astronergy

Astronergy Crystalline Silicon PV installation manual

Promation Engineering

Promation Engineering P9-120N4-HR Installation & operation manual