Heinzmann PRIAMOS I Series User manual

Heinzmann GmbH & Co. KG

Engine & Turbine Controls

Am Haselbach 1

D-79677 Schönau (Schwarzwald)

Germany

Phone +49 7673 8208-0

Fax +49 7673 8208-188

www.heinzmann.com

V.A.T. No.: DE145551926

HEINZMANN®

Digital Electronic Speed Governors

Basic Systems

PRIAMOS I

DC 16.1-03

DC 30.1-03

DC 40.1-03

Copyright 2006 by Heinzmann GmbH & Co KG. All rights reserved. This document may not be reproduced or handed on to third parties.

Manual DG 93 101-e / 04-06

PRIAMOS I

Priamos I

for engines up to approx. 4000 kW

Basic SystemDG 161 - 03

D :

Digital

DG :

Digital Governor (Basic System)

DC :

Digital Control Unit

StG : Actuator (Stellgerät)

SW : Setpoint Potentiometer (Sollwertpot.)

IA : Pickup (Impulsaufnehmer)

Control Unit DC 161 - 03

Actuator StG 16 - 01

Setpoint Pot. SW ...

Pickup IA ...

Basic SystemDG 301 - 03

Control Unit DC 301 - 03

Actuator StG 30 - 01

Setpoint Pot. SW ...

Pickup IA ...

Basic SystemDG 401 - 03

Control Unit DC 401 - 03

Actuator StG 40 - 01

Setpoint Pot. SW ...

Pickup IA ...

Read this entire manual and all other publications appertaining to the

work to be performed before installing, operating or servicing your

equipment.

Practice all plant and safety instructions and precautions.

Failure to follow instructions may result in personal injury and/or

damage to property.

HEINZMANN will refuse all liability for injury or damage which

results from not following instructions

Please note before commissioning the installation:

Before starting to install any equipment, the installation must have been

switched dead!

Be sure to use cable shieldings and power supply connections meeting

the requirements of the European Directive concerning EMI.

Check the functionality of the existing protection and monitoring

systems.

To prevent damages to the equipment and personal injuries, it is

imperative that the following monitoring and protection systems

have been installed:

Overspeed protection acting independently of the speed governor

Overtemperature protection

HEINZMANN will refuse all liability for damage which results from

missing or insufficiently working overspeed protection

Generator installation will in addition require:

Overcurrent protection

Protection against faulty synchronization due to excessive frequency,

voltage or phase differences

Reverse power protection

Overspeeding can be caused by:

Failure of the voltage supply

Failure of the actuator, the control unit or of any accessory device

Sluggish and blocking linkage

Warning

Danger

Danger

Danger!

High

Voltage

Danger

Electronically controlled injection (MVC) will in addition require

to observe the following:

With Common Rail systems a separate mechanical flow limiter must

be provided for each injector pipe.

With Pump-Pipe-Nozzle (PPN) and Pump Nozzle (PNE) systems fuel

release may be enabled only by the movement of control piston of the

solenoid valve. This is to inhibit fuel from being delivered to the

injection nozzle in case of seizure of the control piston.

The examples, data and any other information in this manual are

intended exclusively as instruction aids and should not be used in any

particular application without independent testing and verification by

the person making the application.

Independent testing and verification are especially important in any

application in which malfunction might result in personal injury or

damage to property.

HEINZMANN make no warranties, express or implied, that the

examples, data, or other information in this volume are free of error,

that they are consistent with industry standards, or that they will meet

the requirements for any particular application.

HEINZMANN expressly disclaim the implied warranties of

merchantability and of fitness for any particular purpose, even if

HEINZMANN have been advised of a particular purpose and even if a

particular purpose is indicated in the manual.

HEINZMANN also disclaim all liability for direct, indirect, incidental

or consequential damages that result from any use of the examples,

data, or other information contained in this manual.

HEINZMANN make no warranties for the conception and engineering

of the technical installation as a whole. This is the responsibility of the

user and of his planning staff and specialists. It is also their

responsibility to verify whether the performance features of our devices

will meet the intended purposes. The user is also responsible for correct

commissioning of the total installation.

Warning

Warning

Danger

Contents

PRIAMOS I

Contents

Page

1 Safety Instructions and Related Symbols............................................................................ 1

1.1 Basic Safety Measures for Normal Operation................................................................. 2

1.2 Basic Safety Measures for Servicing and Maintenance .................................................. 2

1.3 Before Putting an Installation into Service after Maintenance and Repair Works.......... 3

2 General Remarks................................................................................................................... 4

3 Mode of Operation................................................................................................................ 7

4 Block Diagram of the Digital Governor DG 16.1 - 03 up to DG 40.1 - 03........................ 8

5 Sensors.................................................................................................................................... 9

5.1 Overview ......................................................................................................................... 9

5.2 Magnetic Pickup IA ...................................................................................................... 10

5.2.1 Technical Datas...................................................................................................... 10

5.2.2 Installation ............................................................................................................. 10

5.2.3 Tooth Profile.......................................................................................................... 11

5.2.4 Clearance for IA 02 - 76 up to IA 13 - 102............................................................ 11

5.2.5 Clearance for IA 22 - 76 and IA 23 - 102.............................................................. 11

5.2.6 Mounting Measurements ....................................................................................... 12

5.2.7 Redundant Speed Signal........................................................................................ 12

5.3 Cooling Medium Temperature Sensor TS 01 - 28 - PT 1000 ....................................... 13

5.4 Pressure Sensors............................................................................................................ 14

5.4.1 Oil Pressure Sensor................................................................................................ 14

5.4.2 Boost Pressure Sensors.......................................................................................... 15

5.4.2.1 Boost Pressure Sensor with Plug ................................................................... 15

5.4.2.2 Boost Pressure Sensor with Housing and Terminal Strip.............................. 16

6 Speed Setpoint Adjusters.................................................................................................... 17

6.1 Setpoint Potentiometer SW 01 - 1 - b (1 turn)............................................................... 17

6.2 Setpoint Potentiometer SW 02 - 10 - b (10- turn)......................................................... 17

6.3 Setpoint Value Adjustment by Current Signal.............................................................. 18

6.4 Digital Presetting of Setpoint Values ............................................................................ 18

6.5 Setpoint Value Adjustment by Pedal............................................................................. 18

6.6 Pneumatic Setpoint Adjusters........................................................................................ 18

7 Control Unit DC 16.1 - 03 up to DC 40.1 - 03................................................................... 19

7.1 Specification.................................................................................................................. 19

7.2 Measurements................................................................................................................ 20

Contents

PRIAMOS I

8 Actuators.............................................................................................................................. 21

8.1 Design and Mode of Operation ..................................................................................... 21

8.2 Installation..................................................................................................................... 22

8.3 Specification.................................................................................................................. 23

8.4 Measurements................................................................................................................ 25

9 Regulating Linkage............................................................................................................. 26

9.1 Length of Lever Arm..................................................................................................... 26

9.2 Order Specification for Lever Arm ............................................................................... 26

9.3 Connecting Linkage....................................................................................................... 26

9.4 Linkage Adjustment for Diesel Engines........................................................................ 27

9.5 Linkage Adjustment for Carburettor Engines ............................................................... 28

10 Electric Connection........................................................................................................... 29

10.1 Connection of Shielding.............................................................................................. 29

10.2 Connection of Power Supply....................................................................................... 30

10.3 Example of Connection for Generator Set with digital Accessories........................... 32

10.4 Example of Connection for Generator Set with analogue Accessories....................... 33

10.5 Example of Connection for Vehicle Operation........................................................... 34

10.6 Example of Connection for Locomotive Operation with 16 Notches......................... 35

10.7 Example of Connection for Locomotive Operation with Speed Setpoint via Current

Signal................................................................................................................................... 36

10.8 Example of Connection for Marine Operation with Master/Slave.............................. 37

10.9 Example of Connection for Marine Operation in single Operation............................ 38

11 Harness............................................................................................................................... 39

11.1 Cable Lenghts.............................................................................................................. 39

11.2 Plug Designations........................................................................................................ 40

12 Programming Possibilities................................................................................................ 41

12.1 Programming by the Manufacturer ............................................................................. 41

12.2 Programming with the Hand- Held Programmer 2 ..................................................... 41

12.3 Programming by PC .................................................................................................... 41

12.4 Programming with User Masks................................................................................... 41

12.5 Transferring Data Sets................................................................................................. 41

12.6 Assembly Line End Programming .............................................................................. 42

13 Starting the Engine - Brief Instructions.......................................................................... 43

14 Ordering Specifications .................................................................................................... 44

14.1 General ........................................................................................................................ 44

14.2 Cable Length ............................................................................................................... 44

15 Figure List.......................................................................................................................... 47

1 Safety Instructions and Related Symbols

PRIAMOS I 1

1Safety Instructions and Related Symbols

This publication offers wherever necessary practical safety instructions to indicate inevitable

residual risks when operating the engine. These residual risks imply dangers to

persons

product and engine

environment.

The symbols used in this publication are in the first place intended to direct your attention to

the safety instructions!

This symbol is to indicate that there may exist dangers to the engine, to the

material and to the environment.

This symbol is to indicate that there may exist dangers to persons. (Danger

to life, personal injury))

This symbol is to indicate that there exist particular danger due to

electrical high tension. (Mortal danger).

This symbol does not refer to any safety instructions but offers important notes for

better understanding the functions that are being discussed. They should by all

means be observed and practiced. The respective text is printed in italics.

The primary issue of these safety instructions is to prevent personal injuries!

Whenever some safety instruction is preceded by a warning triangle labelled “Danger” this is

to indicate that it is not possible to definitely exclude the presence of danger to persons,

engine, material and/or environment.

If, however, some safety instruction is preceded by the warning triangle labelled “Caution”

this will indicate that danger of life or personal injury is not involved.

The symbols used in the text do not supersede the safety instructions. So please do not

skip the respective texts but read them thoroughly!

Note

Warning

Dan

g

er

Danger!

High

V

olta

g

e

1 Safety Instructions and Related Symbols

2PRIAMOS I

In this publication the Table of Contents is preceded by diverse instructions that

among other things serve to ensure safety of operation. It is absolutely imperative

that these hints be read and understood before commissioning or servicing the

installation.

1.1 Basic Safety Measures for Normal Operation

•The installation may be operated only by authorized persons who have been duly

trained and who are fully acquainted with the operating instructions so that they are

capable of working in accordance with them.

•Before turning the installation on please verify and make sure that

- only authorized persons are present within the working range of the engine;

- nobody will be in danger of suffering injuries by starting the engine.

•Before starting the engine always check the installation for visible damages and make

sure it is not put into operation unless it is in perfect condition. On detecting any faults

please inform your superior immediately!

•Before starting the engine remove any unnecessary material and/or objects from the

working range of the installation/engine.

•Before starting the engine check and make sure that all safety devices are working

properly!

1.2 Basic Safety Measures for Servicing and Maintenance

•Before performing any maintenance or repair work make sure the working area of the

engine has been closed to unauthorized persons. Put on a sign warning that

maintenance or repair work is being done.

•Before performing any maintenance or repair work switch off the master switch of the

power supply and secure it by a padlock! The key must be kept by the person

performing the maintenance and repair works.

•Before performing any maintenance and repair work make sure that all parts of engine

to be touched have cooled down to ambient temperature and are dead!

•Refasten loose connections!

•Replace at once any damaged lines and/or cables!

•Keep the cabinet always closed. Access should be permitted only to authorized

persons having a key or tools.

1 Safety Instructions and Related Symbols

PRIAMOS I 3

•Never use a water hose to clean cabinets or other casings of electric equipment!

1.3 Before Putting an Installation into Service after Maintenance and Repair

Works

•Check on all slackened screw connections to have been tightened again!

•Make sure the control linkage has been reattached and all cables have been

reconnected.

•Make sure all safety devices of the installation are in perfect order and are working

properly!

2 General Remarks

PRIAMOS I

4

2General Remarks

HEINZMANN digital governors with control units DC 16.1-03 up to DC 40.01-03 constitute

speed governors offering a wide range of functions.

In addition to speed regulation, the following functions are available:

a) Starting Fuel Flow Adjustment

When setting starting fuel flow, starting minimum fuel flow or starting maximum fuel flow

are available as alternatives. If nesessary, both als can be depent on temperature. Furthermore,

variable starting fuel flow can be provided, by which starting fuel flow is increased

automatically during start-up.

b) Speed Ramp

For applications in which speed is not supposed to respond as fast as possible to changes of

setpoint values (e.g., locomotive operation), a speed ramp is available which according to

requirements may be programmed separately for increasing or decreasing speed.

c) Fixed Fuel Limitation

For the stop-position and the maximum fuelling position "electric catches" can be provided.

This will prevent the governor's thrust from affecting the terminal stops of the injection pump,

etc.

d) Speed Dependent Fuel Limitation

For variable speed governors, there is provided an option of programming speed dependent

limit curves. Thus, for any speed, torque can be reduced as is permissible for the engine or

desired by the user.

e) Boost Pressure Dependent Fuel Limitation

For turbocharged engines, fuelling can be reduced to achieve smokeless operation in case of

missing boost pressure (e.g., starting or load change). The respective limit curves can be

programmed accordingly.

f) Idling and Maximum Speed Control

For vehicle application, the governor can be made to operate as an idling and maximum speed

controller. In addition, one fixed intermediate speed is available, e.g., for an application

combining driving and stationary mode (e.g., generator at power take-off). If necessary, a

2 General Remarks

PRIAMOS I 5

5

change-over switching of the droop can be provided, i.e., during stationary operation also

droop zero is possible

g) Temperature Dependent Idling Speed

For low temperatures, the engine can be run at some higher idling speed. With the engine

warming up, idling speed is reduced to its normal value.

h) Oil Pressure Monitoring

For the purpose of oil pressure monitoring, speed/pressure dependent limit curves can be

provided. If oil pressure is too low, an alarm is given; if oil pressure continues to drop, the

engine is shut down.

i) Load Regulation System

For diesel-electric locomotive operation, a load regulation system can be provided, by which

generator output is regulated in dependence on speed resp. load.

j) Anti Stick Slip Device

For locomotive operation, an anti stick slip device can be provided.

k) Accessories

Accessories such as synchronizing units, load measuring units, disturbance variable

compensation units can be connected via a CAN-Bus within the control unit. The CAN-Bus

may also be used to implement load distribution by equal fuelling (e.g., two engines on one

gear).

l) Output Signals

For speed and actuator travel, proportional signals are available in the range of

4–20 mA. They can be used for purposes of display or for further processing (e.g., switches).

m) Operating Data Storage

On request, operating data storage can be provided, by which in cases of disturbances and

failures the causes may be traced back even at some later time.

Furthermore, if errors occur at the sensors or within the control system, an alarm is given.

2 General Remarks

PRIAMOS I

6

When selecting and determining the functions, it has to be ascertained whether

the hardware equipment suffices with respect to the total range of functions.

Note

3 Mode of Operation

PRIAMOS I 7

3Mode of Operation

The actual speed of the engine is read by a pulse pickup from a cog wheel, preferably from

the starter gear. The microprocessor (CPU) of the control unit compares the actual speed with

the preset value. If differences are stated, the new actuator signal is calculated by the CPU and

transmitted to the actuator via the output stage. Feedback from the actuator indicates the

current position of the output shaft thus allowing optimum signal adjustment by the CPU.

As the governor comprises an I-fraction and as for any load level the speed is permanently

compared with a fixed preset value, speed can be kept constant also in steady state, i.e., droop

is zero.

For applications requiring droop, the speed related to the respective fuelling is calculated by

the CPU and entered as correction of the setpoint value.

During standstill, a particular circuit ensures that only the current of the control unit is

received by the governor, but no current flows to the actuator motor.

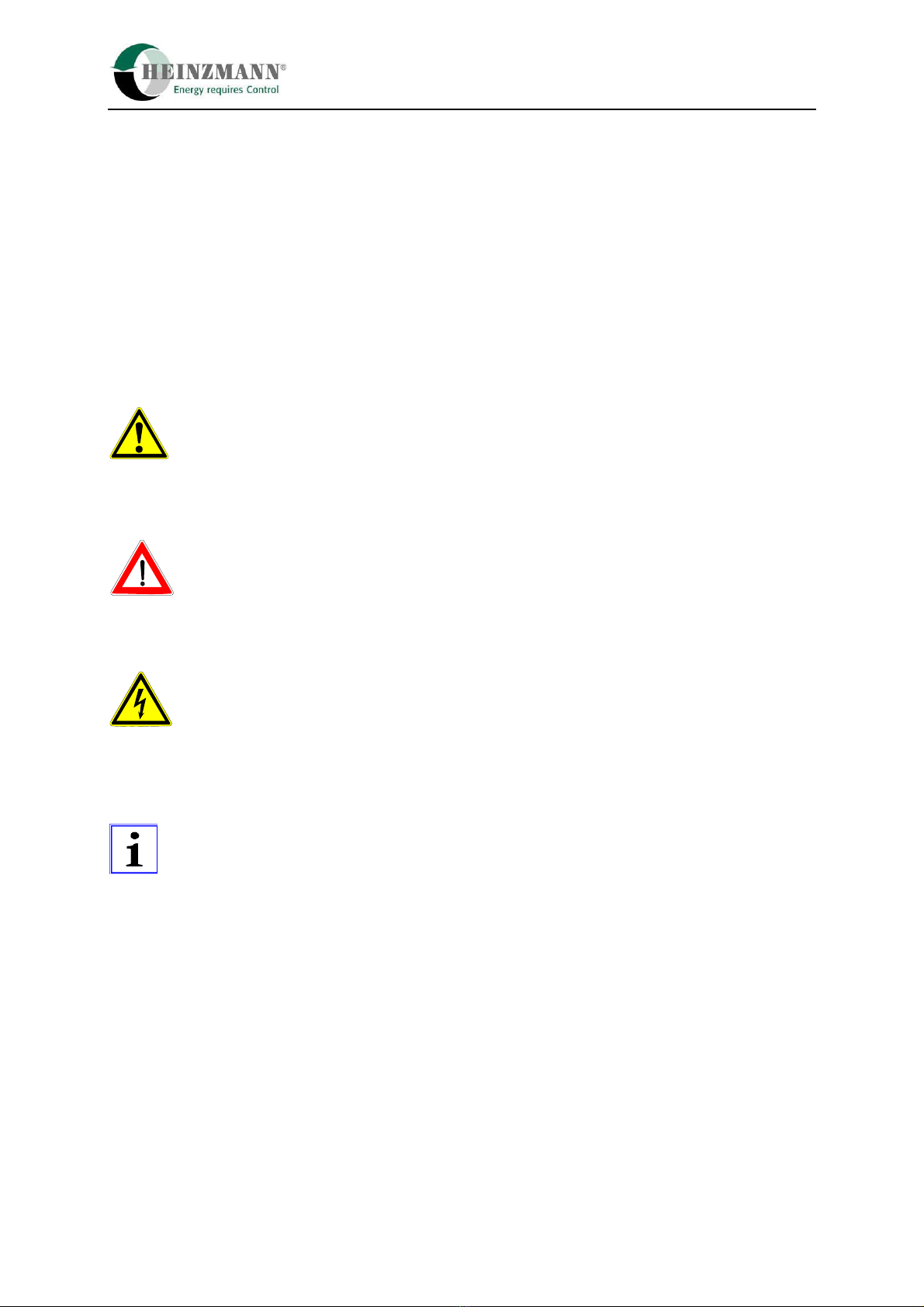

4 Block Diagram of the Digital Governor DG 16.1 - 03 up to DG 40.1 - 03

8PRIAMOS I

4Block Diagram of the Digital Governor DG 16.1 - 03 up to DG 40.1 - 03

Memory

Mikroprocessor

Power CAN - Bus

Interface

Control Unit

DC 641 03 /

DC 901 - 03

Magnetic pickup

Redundant Engine Speed Signal

Setpoint Values

Temperature Sensor

Engine Stop

Oil Pressure Sensor

Digital Inputs

Actuator

StG 64 - 03 /

StG 90 - 03

Engine Speed

Actuator Travel

Alarm

Programming Attachment

Diagnostics

Digital Application Units

e.g. Synchronizer, Load

Measuring Unit

Additional

Processor

Converter

Converter

Converter

Boost Pressure

Sensor

Amplifier

Feedback

Drive

Figure 1: Blockdiagram DG 16.1 - 03 up to DG 40.1 - 03

5 Sensors

PRIAMOS I 9

5Sensors

5.1 Overview

Sensor Speed

Coolant

Temperature Oil Pressure Boost Pressure

HZM Designation IA .. TS 01-28-PT1000 DSO 01-6

DSO 01-10

DSO 01-16

DSL/G 0..-2

DSL/G 0..-5

DSL/G 0..-10

Connection SV 6-IA-2K

2 pole

SV 6-IA-2K

2 pole

DIN 43650 A

2 Line System

DIN 43650 A

2 Line System

Measuring Procedure inductive, active PT1000, passive active active

Measuring Range 50...6.000 Hz -50...+150°C 0...6 bar

0...10 bar

0...2 bar

0...5 bar

0...10 bar

Supply Voltage

Range passive 10...34 V DC 12...36 V DC

Output Signal Range 0...10 V AC ca. 700...1500 Ohm 4...20 mA 4...20 mA

Operating

Temperature Range -55...+120°C -50...+150°C -25...+125°C -40...+100°C

In order to ensure maximum flexibility with regard to the sensors, the minimum/ maximum

current values and the measuring ranges of the pressure and temperature sensors have been

provided programmable.

5 Sensors

10 PRIAMOS I

5.2 Magnetic Pickup IA ...

5.2.1 Technical Datas

Operating principle inductive sensor

Distance from sensing gear standard 0.5 to 0.8 mm

with IA 22.. and IA 23.. 2.5 to 3 mm

Output 0 V .. 10 V AC

Signal form Sine (depending on tooth shape)

Resistance approx. 52 Ohm, with IA 22.. and IA 23..

approx. 130 Ohm

Temperature range -55°C up to +125°C

Protection grade IP 55

Vibration < 10g, 10 .. 100 Hz

Shock < 50g, 11 ms half sine wave

Corresponding plug SV 6 - IA - 2K (EDV- No.: 010-02-170-00)

5.2.2 Installation

The installation of the pickup has to be arranged in such a way as to obtain a frequency

as high as possible. Normally, the HEINZMANN digital governors DG 16.1 - 03 up to

DG 40.1 - 03 are designed for a maximum frequency of 6.000 Hz. The frequency (by

Hz) is calculated according to the formula:

f

(Hz) =

z = number of teeth on the pickup wheel

Example:

n = 500

z = 80

f = = 666.67 Hz

It should be taken care that the speed can be measured by the pulse pickup without any

bias. For best results therefore, the speed pickup should take the engine speed from the

crankshaft. A suitable position for this is, e.g., the starter gear (but not the injection

pump wheel).

The pickup gear must consist of magnetic material (e.g., steel, cast iron).

This manual suits for next models

3

Table of contents

Other Heinzmann Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

MBW

MBW R442 Operator's safety and service manual

MÄDLER

MÄDLER Accuride DZ 5417 Installation guides

KTR-Group

KTR-Group CLAMPEX 620 Operating & assembly instructions

Morgana

Morgana AutoCreaser Pro 50 Service manual

Pepperl+Fuchs

Pepperl+Fuchs KCD2-SLD-Ex1.1045 instruction manual

ABB

ABB HT562800 Operation manual

Mitsubishi Electric

Mitsubishi Electric NZ2GFCF-D62PD2 user manual

HSB

HSB Gamma 90-ZSSD Original Assembly and Maintenance Instructions

ABB

ABB XAC25744 Operation manual

M2I

M2I CTOP2 Series user manual

Renishaw

Renishaw RLP40 quick start guide

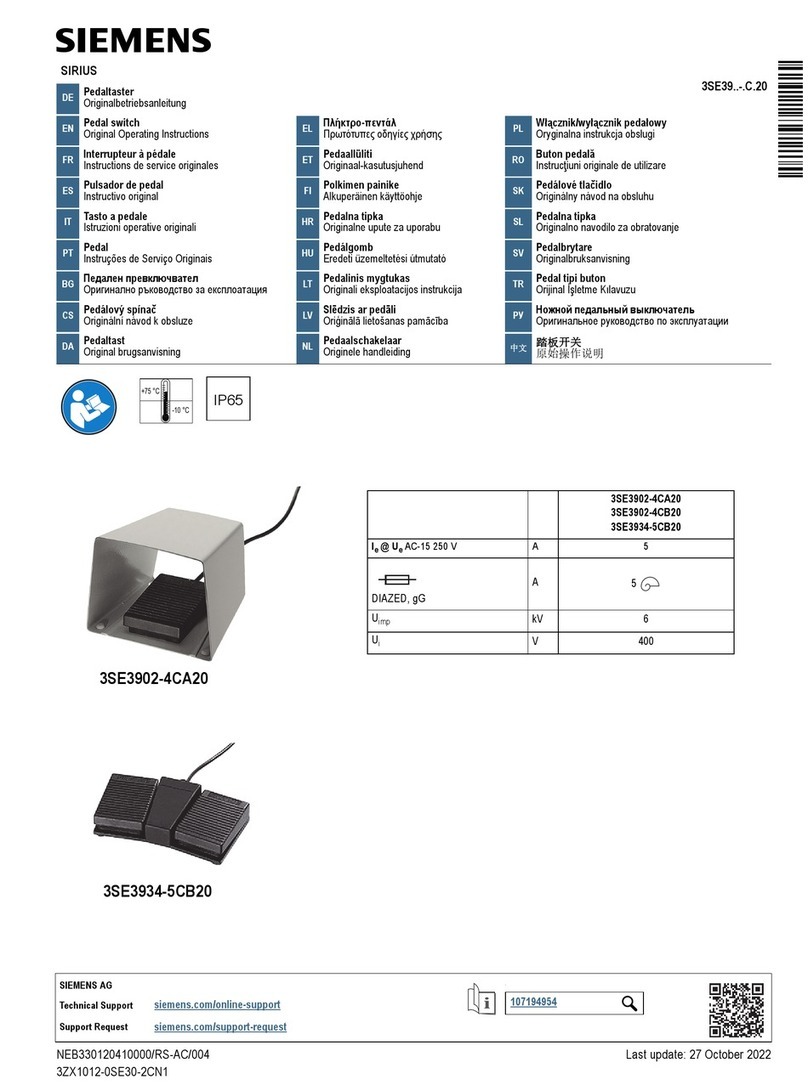

Siemens

Siemens SIRIUS 3SE39 C 20 Series Original operating instructions