Instruction Manual

1. Marking

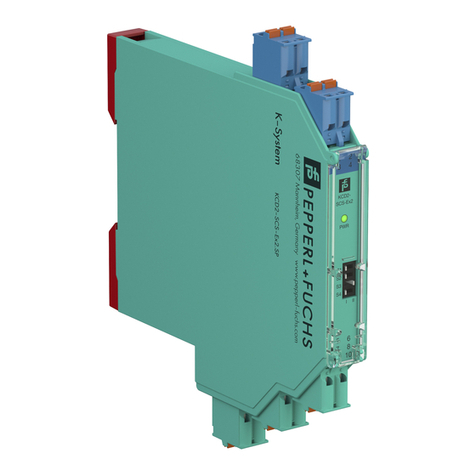

Solenoid Driver

KCD2-SLD-Ex1.1045, KCD2-SLD-Ex1.1065, KCD2-SLD-Ex1.1245

ATEX certificate: EXA 17 ATEX 0002 X

ATEX marking:

1 II 3(1)G Ex nC ec [ia Ga] IIC T4 Gc

1 II (1)D [Ex ia Da] IIIC

1 I (M1) [Ex ia Ma] I

IECEx certificate: IECEx EXA 17.0001X

IECEx marking:

Ex nC ec [ia Ga] IIC T4 Gc

[Ex ia Da] IIIC

[Ex ia Ma] I

North America Certifcates: E106378 (UL)

Class I, Division 2, Groups A-D, T4

Class I, Zone 2, Group IIC

Associated apparatus with intrinsically safe circuits for:

Class I, II, III, Division 1, Groups A-G

Class I, [AEx ia Ga] IIC, Zone 20 IIIC (US),

[Ex ia Ga] IIC, [Ex ia Da] IIIC (Canada)

Solenoid Driver

KCD0-SD3-Ex1.1045, KCD0-SD3-Ex1.1245, KCD0-SD3-Ex1.1245.SP

ATEX certificate: EXA 17 ATEX 0002 X

ATEX marking:

1 II 3(1)G Ex ec [ia Ga] IIC T4 Gc

1 II (1)D [Ex ia Da] IIIC

1 I (M1) [Ex ia Ma] I

IECEx certificate: IECEx EXA 17.0001X

IECEx marking:

Ex ec [ia Ga] IIC T4 Gc

[Ex ia Da] IIIC

[Ex ia Ma] I

North America Certifcates: E106378 (UL)

Class I, Division 2, Groups A-D, T4

Class I, Zone 2, Group IIC

Associated apparatus with intrinsically safe circuits for:

Class I, II, III, Division 1, Groups A-G

Class I, [AEx ia Ga] IIC, Zone 20 IIIC (US),

[Ex ia Ga] IIC, [Ex ia Da] IIIC (Canada)

Pepperl+Fuchs Group

Lilienthalstraße 200, 68307 Mannheim, Germany

Internet: www.pepperl-fuchs.com

2. Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation,

maintenance, and dismounting lies with the plant operator.

The personnel must be appropriately trained and qualified in order to carry

out mounting, installation, commissioning, operation, maintenance, and

dismounting of the device. The trained and qualified personnel must have

read and understood the instruction manual.

Prior to using the product make yourself familiar with it. Read the

instruction manual carefully.

3. Reference to Further Documentation

Observe laws, standards, and directives applicable to the intended use

and the operating location.

For mining applications, observe laws, standards, and directives

applicable to the operating location.

The corresponding datasheets, manuals, declarations of conformity, EU-

type examination certificates, certificates, and control drawings if

applicable supplement this document. You can find this information under

www.pepperl-fuchs.com.

For specific device information such as the year of construction,

scan the QR code on the device. As an alternative, enter the serial number

in the serial number search at www.pepperl-fuchs.com.

If you use the device in safety-related applications, observe the

requirements for functional safety. You can find these requirements in the

functional safety documentation under www.pepperl-fuchs.com.

4. Intended Use

The device is only approved for appropriate and intended use. Ignoring

these instructions will void any warranty and absolve the manufacturer

from any liability.

The device is used in control and instrumentation technology

(C&I technology) for the galvanic isolation of signals such as 20 mA and

10 V standard signals or alternatively for adapting or standardizing signals.

The device has intrinsically safe circuits that are used for operating

intrinsically safe field devices in hazardous areas.

The device supplies power to solenoids, LEDs and audible alarms located

in the explosion-hazardous area.

The device is controlled with a loop powered signal or a bus powered logic

signal.

Use the device only within the specified ambient and operating conditions.

Only use the device stationary.

The device is an associated apparatus according to IEC/EN 60079-11.

The device is an electrical apparatus for hazardous areas of Zone 2.

The device may be installed in the non-hazardous area.

If you use the device in safety-related applications, observe the

information for safety function and safe state.

5. Improper Use

Protection of the personnel and the plant is not ensured if the device is not

used according to its intended use.

If circuits with type of protection Ex i are operated with non-intrinsically

safe circuits, they must no longer be used as circuits with type of

protection Ex i.

6. Mounting and Installation

Do not mount a damaged or polluted device.

The device is designed for mounting on a 35 mm DIN mounting rail

according to EN 60715.

The device must be installed and operated only in a controlled

environment that ensures a pollution degree 2 (or better) according to

IEC/EN 60664-1.

If used in areas with higher pollution degree, the device needs to be

protected accordingly.

Do not mount the device in the dust hazardous area.

The device must be installed and operated only in an environment of

overvoltage category II (or better) according to IEC/EN 60664-1.

Supply the device with a power supply that meets the requirements for

safety extra-low voltage (SELV) or protective extra-low voltage (PELV).

Observe the installation instructions according to IEC/EN 60079-14.

If you install the device in safety-related applications, observe the

requirements for functional safety.

Requirements for Cables and Connection Lines

Use only one conductor per terminal.

Observe the permissible core cross section of the conductor.

When using stranded conductors, crimp wire end ferrules on the

conductor ends.

When installing the conductors the insulation must reach up to the

terminal.

Observe the tightening torque of the terminal screws.

Requirements for Usage as Associated Apparatus

If circuits with type of protection Ex i are operated with non-intrinsically

safe circuits, they must no longer be used as circuits with type of

protection Ex i.

Observe the respective peak values of the field device and the associated

apparatus with regard to explosion protection when connecting intrinsically

safe field devices with intrinsically safe circuits of associated apparatus

(verification of intrinsic safety). Also observe IEC/EN 60079-14 and

IEC/EN 60079-25.

Keep the separation distances between all non-intrinsically safe circuits

and intrinsically safe circuits according to IEC/EN 60079-14.

Observe the compliance of the separation distances between two

adjacent intrinsically safe circuits according to IEC/EN 60079-14.

Requirements for Equipment Protection Level Gc

The device must be installed and operated only in surrounding enclosures

that

lcomply with the requirements for surrounding enclosures according to

IEC/EN 60079-0,

lare rated with the degree of protection IP54 according to

IEC/EN 60529.

Connection or disconnection of energized non-intrinsically safe circuits is

only permitted in the absence of a potentially explosive atmosphere.

7. Operation, Maintenance, Repair

If you operate the device in safety-related applications, observe the

requirements for functional safety. In case of operating in low demand

mode, plan appropriate intervals for the proof test.

Do not use a damaged or polluted device.

DOCT-5652E / 2022-11 1 / 2