Heinzmann StG 40.90-09 PD User manual

Copyright 2010 by Heinzmann GmbH & Co. KG. All rights reserved.

This publication may not be reproduced by any means whatsoever or passed on to any third parties.

5369 Manual DG 10 009-e / 06-10

Heinzmann GmbH & Co. KG

Engine & Turbine Management

Am Haselbach 1

D-79677 Schönau

Germany

Phone +49 7673 8208 - 0

Fax +49 7673 8208 - 188

www.heinzmann.com

V.A.T. No.: DE145551926

HEINZMANN

Engine & Turbine Management

Digital Positioning System

StG 40.90-09 PD

Instruction manual

(original instructions)

The appropriate manuals must be thoroughly studied before

installation, initial start-up and maintenance.

All instructions pertaining to the system and safety must be followed in

full. Non-observance of the instructions may lead to injury to persons

and/or material damage.

HEINZMANN shall not be held liable for any damage caused through

non-observance of instructions.

Independent tests and inspections are of particular importance for all

applications in which a malfunction could result in injury to persons or

material damage.

All examples and data, as well as all other information in this manual

are there solely for the purpose of instruction and they may not be used

for special application without the operator running independent tests

and inspections beforehand.

HEINZMANN does not guarantee, neither expressly nor tacitly, that

the examples, data or other information in this manual is free from

error, complies with industrial standards or fulfils the requirements of

any special application.

To avoid any injury to persons and damage to systems, the following

monitoring and protective systems must be provided:

overspeed protection independent of the rpm controller

HEINZMANN shall not be held liable for any damage caused through

missing or insufficiently rated overspeed protection.

thermal overload protection

The following must also be provided for alternator systems:

Overcurrent protection

Protection against faulty synchronisation for excessively-large

frequency, voltage or phase difference

Directional contactor

The reasons for overspeeding may be:

Failure of positioning device, control unit or its auxiliary devices

Linkage sluggishness and jamming

The following must be observed before an installation:

Always disconnect the electrical mains supply before any

interventions to the system.

Only use cable screening and mains supply connections that

correspond with the European Union EMC Directive

Check the function of all installed protection and monitoring systems

Please observe the following for electronically controlled injection

(MVC):

For common rail systems each injector line must be equipped with a

separate mechanical flow-rate limiter.

For unit pump (PLD) and pump-injector unit (PDE) systems, the

fuel enable is first made possible by the solenoid valve’s control

plunger motion. This means that in the event of the control plunger

sticking, the fuel supply to the injection valve is stopped.

As soon as the positioning device receives power, it can actuate the

controller output shaft automatically at any given time. The range of

the controller shaft or control linkage must therefore be secured against

unauthorised access.

HEINZMANN expressly rejects any implied guarantee pertaining to

any marketability or suitability for a special purpose, including in the

event that HEINZMANN was notified of such a special purpose or the

manual contains a reference to such a special purpose.

HEINZMANN shall not be held liable for any indirect and direct

damage nor for any incidental and consequential damage that results

from application of any of the examples, data or miscellaneous

information as given in this manual.

HEINZMANN shall not provide any guarantee for the design and planning

of the overall technical system. This is a matter of the operator its planners

and its specialist engineers. They are also responsible for checking whether

the performances of our devices match the intended purpose. The operator is

also responsible for a correct initial start-up of the overall system.

Contents

Digital Positioning Systems

Contents

Page

1 Safety Instructions and Related Symbols ........................................................................... 1

1.1 Safety Measures for Positioning Devices........................................................................ 2

1.2 Safety Measures under Normal Operation ...................................................................... 3

1.3 Safety Measures for Maintenance and Servicing ............................................................ 3

2 Application and Function ..................................................................................................... 4

2.1 Proper and intended use................................................................................................... 4

2.2 Function description ........................................................................................................ 4

2.3 Functional Block Diagram .............................................................................................. 6

3 Specifications of Positioning System StG 40.90-09 PD ...................................................... 7

3.1 Design and Mode of Operation ....................................................................................... 7

3.2 Electrical Specification.................................................................................................... 8

3.3 Actuator Specification ..................................................................................................... 9

3.4 Dimensions .................................................................................................................... 10

4 Installation and Regulating Linkage ................................................................................. 11

4.1 Installation ..................................................................................................................... 11

4.2 Regulating Linkage ....................................................................................................... 11

4.2.1 Length of Lever Arm ............................................................................................. 11

4.2.2 Connecting Linkage............................................................................................... 11

4.2.3 Linkage Adjustment for Diesel Engines................................................................ 12

4.2.4 Linkage Adjustment for Carburettor Engines........................................................ 13

5 Electrical Connection.......................................................................................................... 14

5.1 Pin Assignment.............................................................................................................. 14

5.2 Connection of Power Supply......................................................................................... 14

6 Figure List............................................................................................................................ 16

7 Download of Manuals ......................................................................................................... 17

8 Declaration of Incorporation ............................................................................................. 18

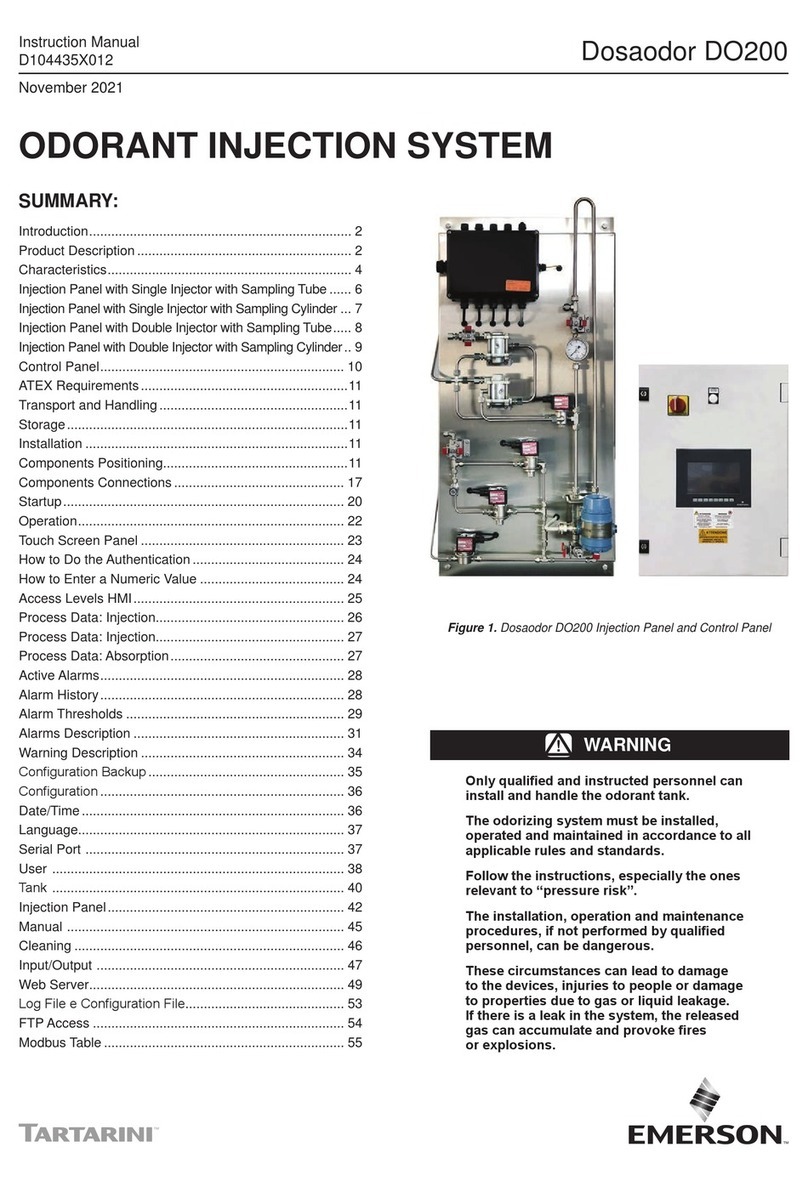

1 Safety Instructions and Related Symbols

1Safety Instructions and Related Symbols

This publication offers practical safety instructions to indicate the unavoidable residual risks

involved when operating the machine. These residual risks involve hazards to

- Personnel

- Product and machine

- The environment

The primary aim of the safety instructions is to prevent personal injury!

The signal words used in this publication are specifically designed to direct your attention to

possible damage extent!

DANGER indicates a hazardous situation the consequence of which could

be fatal or severe injuries if it is not prevented.

WARNING indicates a hazardous situation which could lead to fatal

injury or severe injuries if it is not prevented.

CAUTION indicates a hazardous situation which could lead to minor

injuries if it is not prevented.

NOTICE indicates possible material damage.

Safety instructions are not only denoted by a signal word but also by

hazard warning triangles. Red hazard warning triangles indicate

immediate danger to life. Yellow hazard warning triangles indicate a

possible risk to life and limb. Hazard warning triangles can contain

different symbols to illustrate the danger. However, the symbol used is no

substitute for the actual text of the safety instructions. The text must

therefore always be read in full!

1 Safety Instructions and Related Symbols

In this publication the Table of Contents is preceded by diverse instructions that

among other things serve to ensure safety of operation. It is absolutely imperative that

these hints be read and understood before commissioning or servicing the installation.

1.1 Safety Measures for Positioning Devices

This machine has been designed for reliable utilisation in accordance with the application,

conditions and specifications as described in these instructions. Everyone who works on

this machine must have read these instructions and the information. The employer or safety

officer bear responsibility for ensuring that these instructions are known and adhered to.

High weight of positioning device

Risk of crushing or bone injuries caused by device falling down

Wear safety shoes when transporting the device

Mechanical protection devices against falling down

Use suitable hoisting gear

Device gets hot

Risk of burn injuries

Always allow positioning device to cool down first before working on it

Wear suitable protective clothing

Risk of damage to positioning device through improper use!

Installation, maintenance and operation to be conducted by skilled

personnel only.

Never use a high-pressure cleaner for cleaning the device

1 Safety Instructions and Related Symbols

1.2 Safety Measures under Normal Operation

The system may be operated by qualified and authorised personnel only,

who are both familiar with the operating instructions and who can carry

them out!

Before switching on the system, check and ensure that:

only authorised personnel are in the machine’s operating range

no-one can be injured by the machine starting up

Before each start of the motor:

Always check the system for visible damage and ensure it is not put into

operation unless it is in perfect condition! Always notify the responsible

department immediately about any defects

Check and ensure that all safety devices are in proper working condition

Remove all material and objectives surplus to requirements from the operating

range of the system or motor

1.3 Safety Measures for Maintenance and Servicing

Before starting maintenance or repair work:

Block off access to the machine’s working area for unauthorised persons!

Put up an information board that indicates that such work is underway

Switch off main switch for mains supply and secure with a padlock! The key

to the padlock must be held by the person carrying out the maintenance or

repair work

Ensure that all parts that are capable of being touched have cooled down to

ambient temperature and have been isolated from the mains

Re-fasten loose connections

Replace any damaged lines or cables immediately

Keep the switch cabinet closed at all times! Access is solely for authorised

persons with key/tools

Never use a water spray or high-pressure cleaners on switch cabinets and

other electrical equipment enclosures for cleaning purposes! Risk of short

circuit and corrosion to positioning device

2 Application and Function

2Application and Function

2.1 Proper and intended use

The positioning devices StG 40.90-09 PD is to be used solely for control applications on

machines. It is intended for use in an industrial environment. When operated outdoors,

additional protective measures against weather are also required.

Signals are exchanged electrically. Because transmission may be interfered with by external

circumstances or influences, the user must provide additional safety devices to match the application

case.

In individual cases, the following must be coordinated with the manufacturer HEINZMANN:

Each use which deviates from the above mentioned

Modifications to the device

Use in extreme, ambient conditions that deviate from the specification

(dust, temperature, wetness)

Use under powerful electrical or electromagnetic fields

Use in aggressive atmospheres or vapours

Use in potentially explosive areas

A written opinion from the manufacturer must always be procured in the event of any

obscurities, queries or missing statement.

2.2 Function description

Positioning devices StG 40.90-09 PD is an electrical positioner with a rotating output shaft. It

can be used for a wide range of control applications or in conbination with superior control

systems for control purposes of any kind.

It is actuated by an external, electrical position set point signal, and thereby automatically

regulates the mechanical position of its output shaft. The position set point can be transmitted

to it as a current, voltage or PWM signal, depending on preattunement.. For operation the

device requires a power supply. The use of these positioners, in contrast to where positioning

2 Application and Function

devices are regulated directly by controllers, can be a practical option when more stringent

requirements are placed on control accuracy.

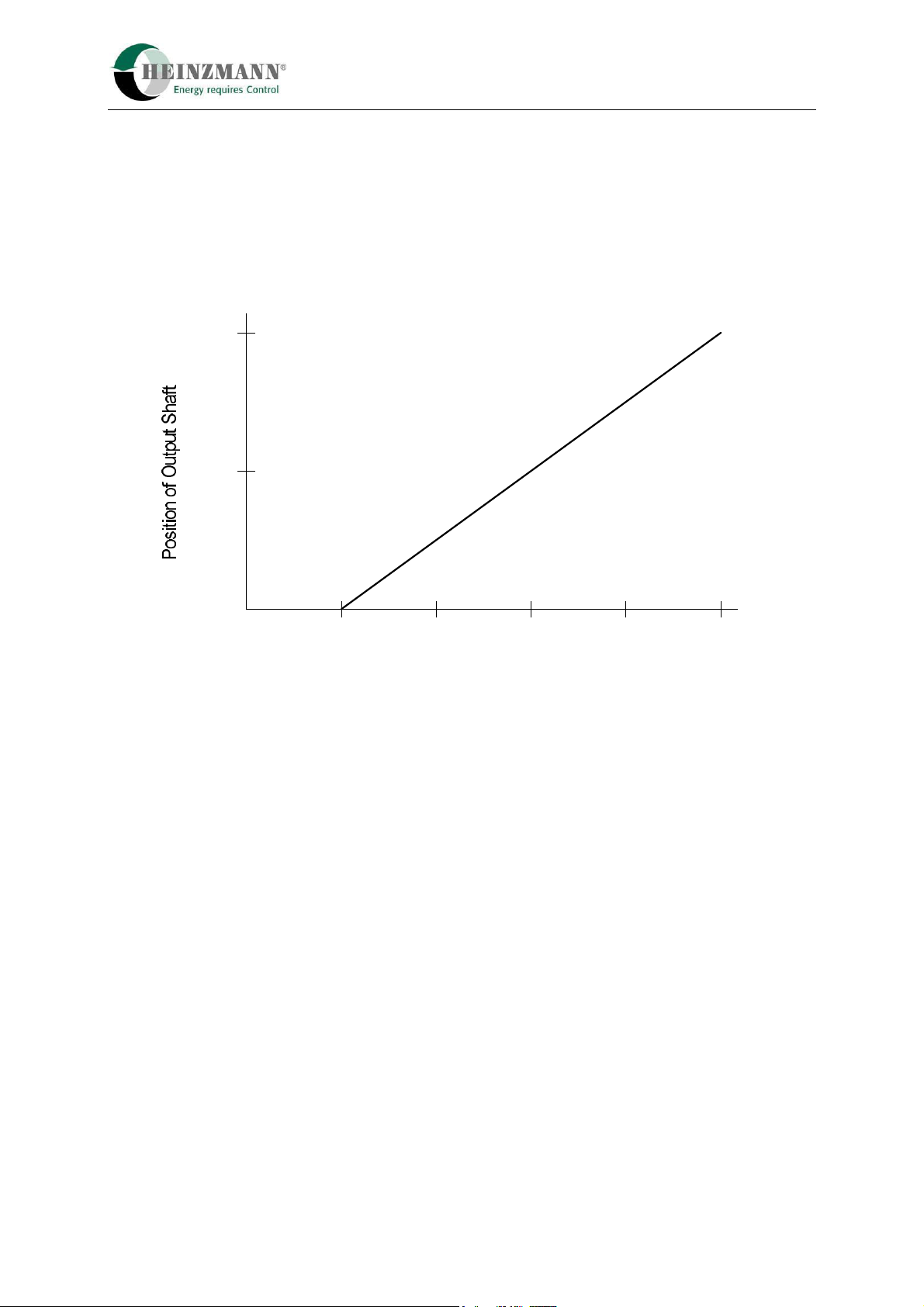

In positioners, there is a proportional correlation between the position of the actuator output

shaft and a command input signal. The following curve shows this relation for the

4 – 20 mA input signal exemplary.

4 8 12 16 20 m

A

50 %

100 %

0

Input Signal

Figure 1: Example for relation between current input signal and position

The input signal, i.e. the position setpoint for the actuator output shaft is sent to an

actual/setpoint comparator receiving the actual value from the actuator feedback. Subsequent

signal processing for position control is performed by a microcontrol.

The position control circuit incorporates a 4-quadrant amplifier which allows to drive the

actuator electrically in either direction. This ensures optimum utilization of the actuator's

rotational force. Together with very low current consumption in steady state operation heat

build-up in the actuator also is reduced.

The feedback signal, i.e. the output shaft position signal, is available as an electrical signal. It

can be used as well for further processing as for indicating actuator position.

Due to the programable microcontrol a lot of functions and capabilities of the positioning

devices StG 40.90-09 PD can be determined by parameterization. This offers various options

for the systems setting up and its configuration.

For instance linear output characteristic, range, type and sense of input and output etc. can be

adapted to users requirements.

2 Application and Function

2.3 Functional Block Diagram

Figure 2: Functional block diagram

3 Specifications of Positioning System StG 40.90-09 PD

3Specifications of Positioning System StG 40.90-09 PD

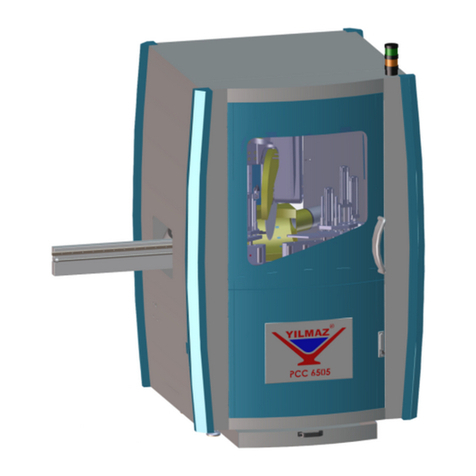

3.1 Design and Mode of Operation

Torque is generated by a DC disc armature motor and transmitted to the governor

output shaft by way of a gearbox.

A feedback cam is mounted on the governor output shaft which is scanned contactlessly

by a probe, thus providing the precise position of the output shaft as electrical signal.

If the actuator strikes against a stop, as may be caused by engine overload or cylinder

failure, the current limitation will take effect after approx. 20 seconds; by this the

current to the actuator is reduced to a value that cannot harm the motor.

Figure 3: Principle of StG 40.90-09 PD

Altogether, this type of positioner offers following advantages:

- High regulating power working in either direction.

- Extremely low current consumption during steady state and relatively low current

consumption on changes of load.

- Indifference to slow voltage changes of power supply; abrupt voltage changes,

however, will cause governor disturbances.

Positioning

control system

DC disc motor

Feedback cam Feedback probe

Gearbox

3 Specifications of Positioning System StG 40.90-09 PD

3.2 Electrical Specification

nom. supply voltage 24 V DC

max. voltage 33 V DC

min. voltage 16 V DC

maximum ripple voltage at max. actuator current 10 % at 100 Hz

acceptable voltage drop at max. actuator current max. 10 % at control unit

fuse protection 10 A (external, by user)

current consumption approx. 300 mA,

additionally current of actuator

steady state variation ±0.25 %.

storage temperature -40°C to +105°C.

operating ambient temperature -25°C to +90°C.

humidity up to 98 %

Input “command”

proportional input

alternatively :

current signal 4 ... 20 mA 350 input resistance

voltage signal 0 … 5 V 100 kinput resistance

0 … 10 V 20 kinput resistance

PWM 50 … 500 Hz 100 kinput resistance (pull up optional)

Output “actual position”

proportional output

alternatively

current signal 4 ... 20 mA max. 220 burden resistance

PWM 50 … 500 Hz lowside switch, 4,7 kpullup

U

rest < 1 V at Imax

I

max = 0.3 A

3 Specifications of Positioning System StG 40.90-09 PD

3.3 Actuator Specification

StG 40.90-09 PD

Effective rotation at the output shaft 90°

Max. torque at the governor output shaft approx. 40 Nm

Torque in steady state condition approx. 15.7 Nm

Response time 0-100 % without load < 280 ms

Current consumption

maximum current

safe current in steady state condition

approx. 7 A

max. 2.3 A

Storage temperature -40 … +105°C

Ambiente temperature in operation -20 … +90°C

Humidity up to 98 %

Protection grade IP 65

Weight approx. 25 kg

3 Specifications of Positioning System StG 40.90-09 PD

3.4 Dimensions

Figure 4: Dimensional drawing StG 40.90-09 PD

4 Regulating Linkage

Digital Positioning Systems 11

4Installation and Regulating Linkage

4.1 Installation

The positioner must be firmly mounted on the engine using a support with stiffened

brackets. Vibrating arrangements as may be caused by weak bracket material or missing

stiffenings must be avoided by all means as this will increase vibrations and lead to faster

wear of positioner and linkage.

4.2 Regulating Linkage

4.2.1 Length of Lever Arm

The length “L” of the lever arm is determined in such a way that approx. 90 % of the

governor output shaft adjustment angle can be used. Based on this, “L” for governors with

90° adjustment angle is calculated as:

with "a" being the travel distance of the injection pump or the carburettor.

Figure 5: Length of Lever Arm

4.2.2 Connecting Linkage

The connecting linkage from the governor to the injection pump or the carburettor should

be length-adjustable and have a (pressure or tension) elastic link. If the actuators torque is

less than 10 Nm, the elastic link is not needed. If possible, joint rod heads in accordance

with DIN 648 should be used as connecting links. The linkage must operate easily and

without clearance.

In case of friction or backlash in the linkage connecting actuator and injection pump resp.

throttle valve no optimal control is possible.

L ~ 0.75 · a

4 Regulating Linkage

4.2.3 Linkage Adjustment for Diesel Engines

The length of the connecting linkage is adjusted in such a way that with the governor in

stop position the injection pump is set to 0 - 2 fuel marks. (Travel of the injection pump

control rack is limited by the governor.)

Figure 6: Example of linkage for diesel engines

The resistance of the pressure elastic link is overcome when the control rack has reached

the full load stop and the speed continues to decrease (overload). Furthermore, the elastic

link is overcome when stopping via the emergency switch.

Full load position

Stop

Elastic link

Idle position

4 Regulating Linkage

4.2.4 Linkage Adjustment for Carburettor Engines

For carburettor or gas engines, the length of the connecting linkage is adjusted in such a

way that with the governor in full load position the throttle valve is completely open. In

idling speed position, the elastic link must be slightly overcome. This allows adjustment of

the idle screw without changing the governor adjustment.

Figure 7: Example of linkage for gas engines

If carburettor or injektion pump are to the left of the governor as opposed to their position

on the drawings, then the direction of motion of the elastic link must also be reversed.

Positioner

Throttle

valve

Stop screw

for idle speed

Idle position

Full load position

Elastic link

5 Electrical Connection

5Electrical Connection

5.1 Pin Assignment

A Power supply (+) 24 VDC

B Setpoint (+) 4 … 20 mA

C Setpoint (-) 0 VDC

D Power supply (-) 0 VDC

E Position value (+) 4 … 20 mA

F Position value (-) 0 VDC

G n.c.

Figure 8: Pin assignment of StG 40.90-09 PD

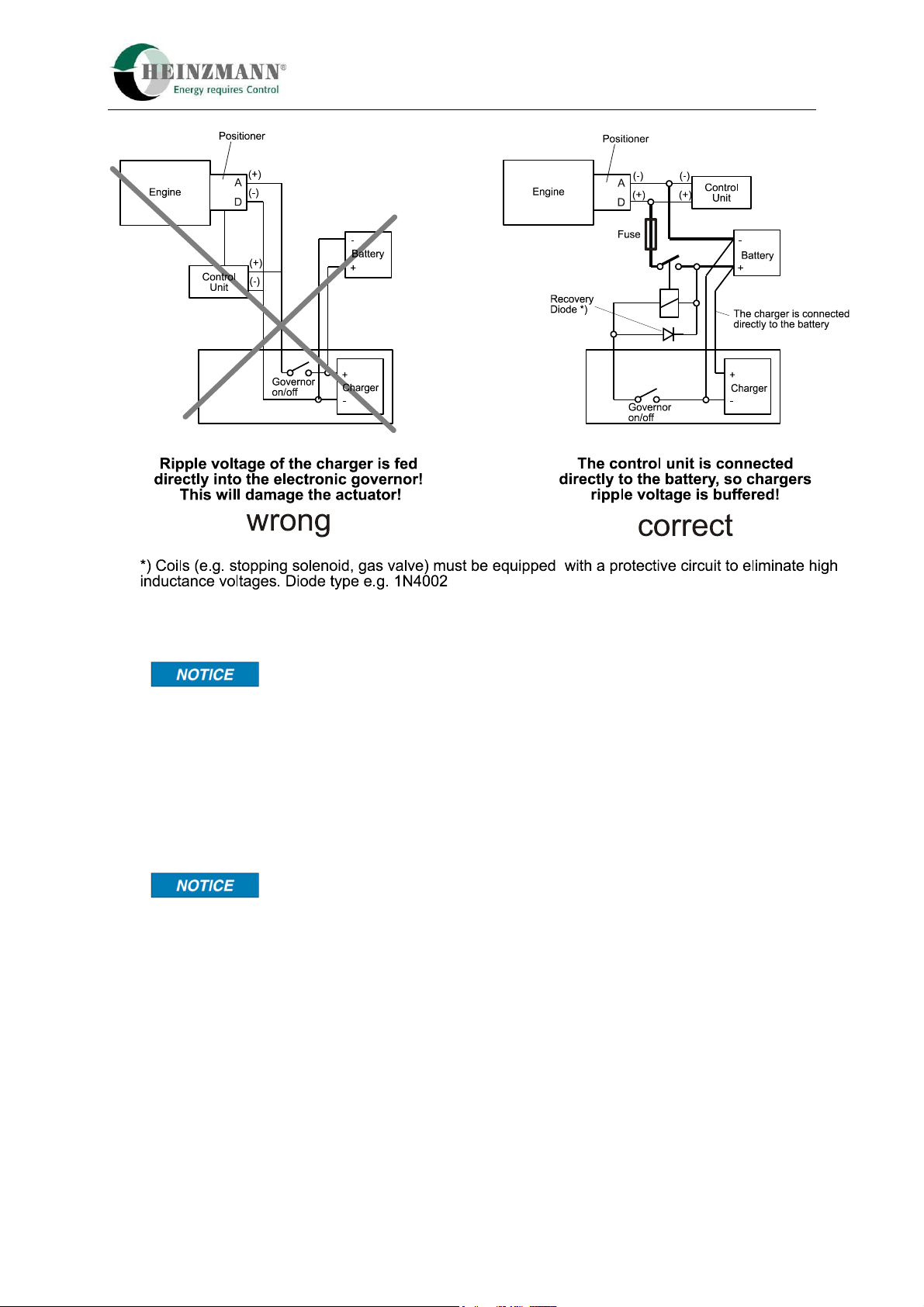

5.2 Connection of Power Supply

Inappropriate choice of power supply or insufficient battery capacitance or incorrect

connection of the power supply line or too small cable sizes of the feed line and the motor

line of the positioner are bound have an adverse effect upon the performance of the speed

governor. In steady state operation, this will cause a heavy increase of current consumption

and unnecessary vibration of the positioner drive. The high current consumption will in its

turn lead to overheating of the actuator or the position control unit, and the vibration will

result in premature wear of the gear and bearing parts or of the linkage.

In altogether, the lifetime of the control system is distinctly

reduced by the errors described above..

The following figure shows both a wrong and a correct cabling:

5 Electrical Connection

Figure 9: Correct Connection of Power Supply

If there are battery chargers with rapid charge mode installed in

the plant, the rapid charge mode should no be used during

operation.

If there is no battery provided, it is absolutely necessary that a three phase power supply or a

stabilized single phase power supply with at least 24 V DC, 10 Amps output power be used

as a power source.

The cable sizes and cable lengths described in the wiring

diagrams must not be exceeded!.

When power supply, battery and cabling have been correctly dimensioned, then on starting

the engine or with the positioner operating at maximum current consumption (approx.

6.4 A), a drop of the supply voltage directly at the control unit of approx. 2 Volts

maximum only will be admissible.

6 Figure List

6Figure List

Figure 1: Example for relation between current input signal and position................................ 5

Figure 2: Functional block diagram ........................................................................................... 6

Figure 3: Principle of StG 40.90-09 PD..................................................................................... 7

Figure 4: Dimensional drawing StG 40.90-09 PD ................................................................... 10

Figure 5: Length of Lever Arm................................................................................................ 11

Figure 6: Example of linkage for diesel engines...................................................................... 12

Figure 7: Example of linkage for gas engines.......................................................................... 13

Figure 8: Pin assignment of StG 40.90-09 PD......................................................................... 14

Figure 9: Correct Connection of Power Supply....................................................................... 15

Table of contents

Other Heinzmann Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

RenewAire

RenewAire HE Series Installation, operation and maintenance manual

STI

STI EZ-Path 33 Series Installation sheet

Dorner

Dorner 3200 Series Installation, maintenance & parts manual

SKYLUX

SKYLUX Polyprofil Mounting instructions

Trumpf

Trumpf PFO 33 Operator's manual

Viessmann

Viessmann 4519 Operation manual