Heise DXD Series User manual

1

Revision 1.6.1 2/28/06 Printed in USA

DXD Series - Precision Digital

Pressure Transducer

Installation and Operating Instructions

I&M 002-10106 DXD

Revision 1.6.1 2/28/06

2

Revision 1.6.1 2/28/06 Printed in USA

3

Revision 1.6.1 2/28/06 Printed in USA

Contents

Section 1.0 Introduction .................................................................................................................................. 5

Section 2.0 Cautions ....................................................................................................................................... 5

Section 3.0 Theory of Operation .................................................................................................................... 5

Section 4.0 Unpacking .................................................................................................................................... 5

4.1 DXD Transducer(s) .............................................................................................................................. 5

4.2 Certificate of Calibration ..................................................................................................................... 6

4.3 Utility Software .................................................................................................................................... 6

4.4 Accessories (RS232 Configurations only) ........................................................................................ 6

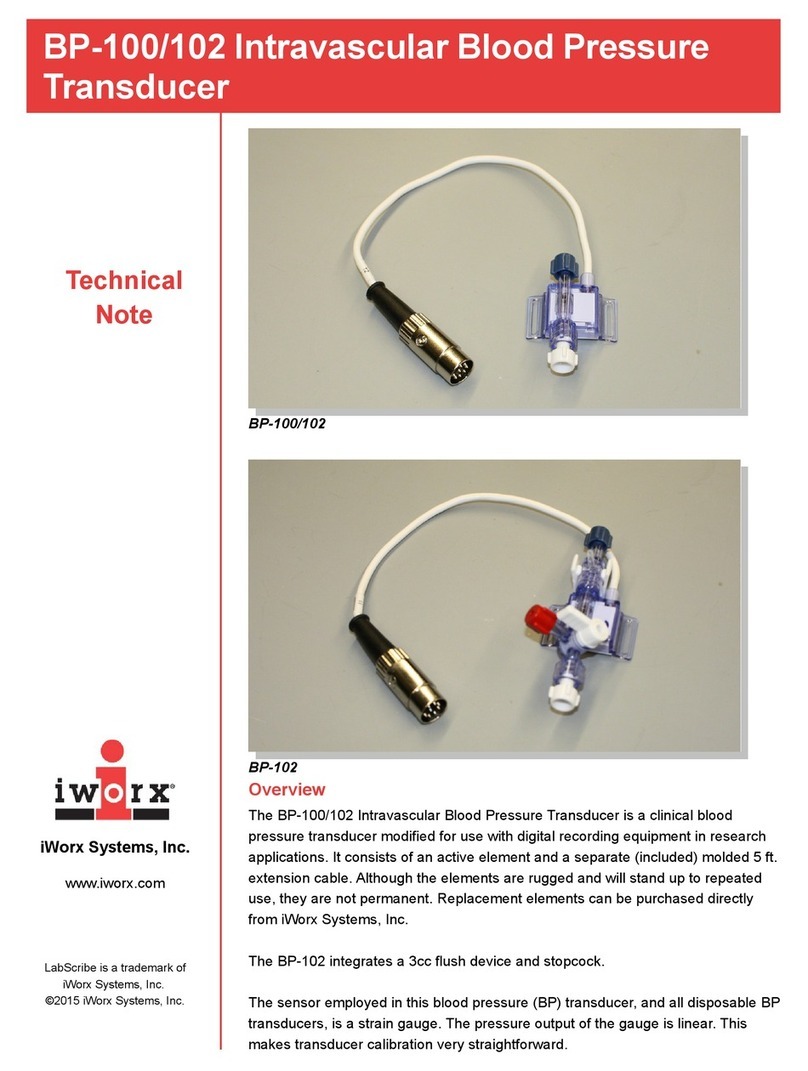

Figure 1. Modular Power Supply with RJ11/4 Connector ................................................................ 6

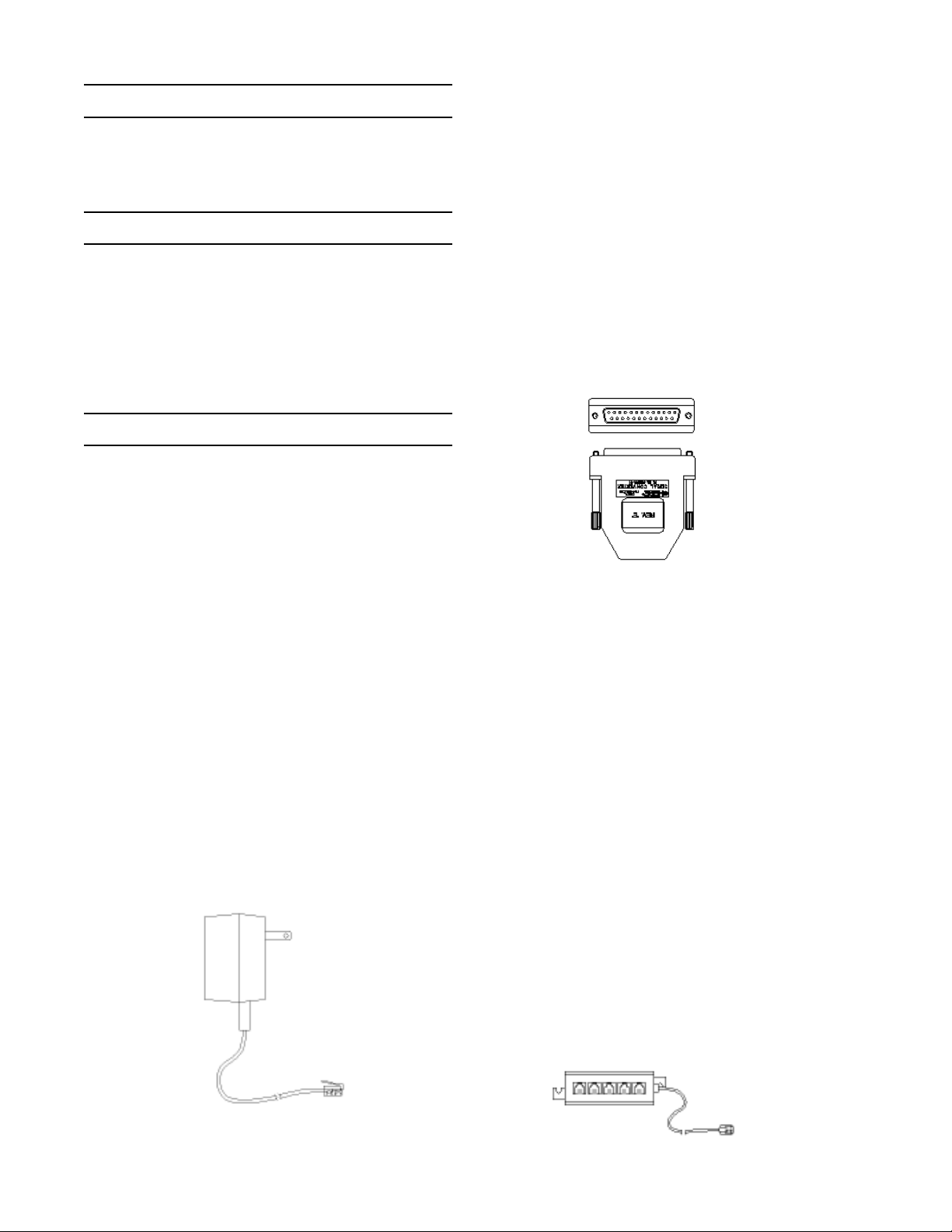

Figure 2. Serial Port Adapter Assembly ............................................................................................ 6

Section 5.0 Installation .................................................................................................................................... 7

5.1 Pressure Connections ........................................................................................................................ 7

5.2 System Wiring ..................................................................................................................................... 7

5.3 Installation Wiring for RS232 Systems with Accessory Kit .............................................................. 7

5.3.1 Pin Functions and Cable Fabrication for RS232 Compatible Systems .................................. 7

Table 1. Switchcraft EN3 Pin Assignments for RS232 Configuration. ...................................... 8

Table 2. ITT Cannon KPT03 Pin Assignments for RS232 Configuration. ................................. 8

Table 3. RJ11 Connector Functions for RS232 Systems ........................................................... 8

5.4 Wiring Installation for RS485 Systems .............................................................................................. 9

5.4.1 Pin Functions and Cable Fabrication for RS485 Compatible Systems .................................. 9

Table 4. Switchcraft EN3 Pin Assignments for RS485 Configuration ....................................... 9

Table 5. ITT Cannon - KPT03 Pin Assignments for RS485 Operation ...................................... 9

Section 6.0 Installing and Running Utility Software ................................................................................... 10

Section 7.0 Using HyperTerminal with the DXD .......................................................................................... 10

7.1 Configuring HyperTerminal .............................................................................................................. 10

7.2 Basic Communications with the DXD .............................................................................................. 10

7.2.1 Communication and Command Basics ................................................................................. 11

7.3 Launching the Previously Configured .................................................................................................

HyperTerminal Application ............................................................................................................... 11

7.4 Talking to the DXD with HyperTerminal .......................................................................................... 11

7.4.1 Determine and Set the Current Address ................................................................................ 11

7.4.2 Determine and Set Baud Rate ................................................................................................. 11

7.4.3 Determine the Pressure Type .................................................................................................. 12

7.4.4 Determine the Full Scale Pressure Range ............................................................................. 12

7.4.5 Get a Pressure Reading .......................................................................................................... 12

7.4.6 Get the Heise Label ................................................................................................................. 12

7.4.7 Get and Change the Current User Label ................................................................................ 13

7.4.8 Get and Change the Current User Tare Value ........................................................................ 13

Section 8.0 Field Calibration ......................................................................................................................... 14

8.1 Zero Adjustment ................................................................................................................................ 14

8.2 Span Adjustment ............................................................................................................................... 14

4

Revision 1.6.1 2/28/06 Printed in USA

Section 9.0 DXD Command Library .............................................................................................................. 15

9.1 Communications Settings ................................................................................................................ 15

9.2 Communications Protocol ................................................................................................................ 15

9.3 Command Library Mnemonics ......................................................................................................... 16

ERROR CODES ................................................................................................................................. 20

Section 10.0 DXD Command Summary ....................................................................................................... 21

10.1 Read Command Summary .............................................................................................................. 21

10.2 Write Command Summary ............................................................................................................. 21

10.3 Error Code Summary ...................................................................................................................... 21

Section 11.0 DXD Product Specification ...................................................................................................... 22

Appendix A- Resolution by Pressure Range .............................................................................................. 23

Appendix B - System Performace Response Time ..................................................................................... 24

Appendix C - RS485 System Schematic ...................................................................................................... 25

Index .............................................................................................................................................. 27

Appendix D - Warranty and Limitation of Liability ...................................................................................... 30

Trademark Credits

Windows is a registered trademark of the Microsoft Corporation.

Windows 95 is a registered trademark of the Microsoft Corporation.

Windows NT is a registered trademark of the Microsoft Corporation.

Visual Basic is a registered trademark of the Microsoft Corporation.

Active X is a registered trademark of the Microsoft Corporation.

Hyperterminal is a registered trademark of Microsoft Corporation

LabVIEW is a registered trademark of National Instruments.

5

Revision 1.6.1 2/28/06 Printed in USA

Section 1.0 Introduction

Congratulations on your purchase of a DXD Series

Digital Pressure Transducer. This transducer provides

unmatched performance and value. Innovative

modeling and processing firmware assures extremely

high precision over a broad temperature range as well

as extremely fast response. Please read the follow-

ing cautions and instructions carefully in order to take

full advantage of the product’s capabilities.

Section 2.0 Cautions

Pressure instruments must be selected in accordance

with industry codes and safety practices to avoid the

possibility of misuse or misapplication, which could

result in personal injury or property damage. Person-

nel responsible for selection and installation should

also be familiar with the safety recommendations of

ASME B40.1, that apply to elastic pressure elements

and their application in general and specific services.

ASME B40.1 is available from:

ASME

345 47th Street

New York, NY 10017

• Select a range so that the maximum applied

pressure will never exceed the upper range limit.

• Excessive vibration could cause loosening of

components resulting in loss of instrument

accuracy or failure to provide valid data.

• Excessive pressure pulsation could result in

fatigue failure of the pressure element.

• Operation of the instrument in an environment

where temperatures are in excess of design

ratings may result in loss of accuracy and

failure.

• Pressure boundary materials must be resistant

to the process media. Failure to assure compat-

ibility may result in pressure sensing element

deterioration or failure. Instruments used on

high-pressure gas, or potentially hazardous

service, such as oxygen should be carefully

selected in accordance with the recommenda-

tions of ASME B40.1.

• Only approved explosion proof or intrinsically

safe instruments should be used in hazardous

locations.

•Instruments used in locations where EMI/RFI

conditions exist may exhibit erroneous perfor-

mance.

• These instruments are not explosion proof or

intrinsically safe. Power levels present preclude

use in hazardous locations.

Section 3.0 Theory of Operation

The DXD transducer design employs a piezo resistive

strain gauge, a 24 bit A/D converter, microprocessor

and a 20 MHz clock. The A/D resolution is internally

reduced to 50,000 counts to optimize signal to noise

ratio. The raw data is processed with a proprietary

algorithm which employs a fourth order polynomial.

The math package fits both temperature and pres-

sure signals from the transducer using coefficients

calculated from the outputs of pressure and tempera-

ture standards during the calibration process. The

internal update rate can be set to 27.7mS or 12.6 mS.

The DXD responds to a simple ASCII command

protocol. The total transmit/ receive time for fully

corrected pressure data is 30 mS (when set to 27.7

mS) and 15 mS (when set to 12.6 mS) at 115,200

bps. There may be a slight reduction in signal stability

(1 to 3 counts) when operated at 15 mS as the

difference in signal processing time is gained at the

expense of filtering in the processor. The firmware

supports addressable, multi-drop operation. Electrical

communications are via full duplex RS232 or RS485

standards. The maximum resolution is 50,000 counts.

Section 4.0 Unpacking

Please note: When handling connectors care should

be taken to avoid electrostatic discharge to prevent

damage to the electronics. The power pins are

reverse polarity protected. Use caution if fabricating

connector and cable assemblies because the digital I/

O lines are not protected from the inadvertent appli-

cation of power. Following is a description of material

included in shipment.

4.1 DXD Transducer(s)

The DXD is available in a variety of standard pressure

ranges and types as specified at time of order

placement. It is configured for either RS232 or

RS485 operation at the factory as specified at

time of purchase. The output is not field

configurable. Please check the product label to

ensure that the pressure range and output signal type

are correct.

6

Revision 1.6.1 2/28/06 Printed in USA

4.2 Certificate of Calibration

Each DXD is provided with a report of calibration

traceable to NIST. The report is packaged with the

transducer.

4.3 Utility Software

Software is provided on three 3 1/2-inch disks or CD

rom. The Windows compatible software simplifies the

setup and installation of the DXD. It also provides

powerful data logging and pressure display capabili-

ties. It includes an “.OCX” compatible com driver

which can be utilized through Active X compliant

software.

4.4 Accessories (RS232 Configurations only)

The following accessory items are available individu-

ally or in kit form at time of order. These accessories

are designed for use with the RS232 version of the

product. The DXD with complete kit option includes

the following items:

4.41 Modular power supply. The AC Adapter

supplies 12 VDC power (500 mA) to the Serial Port

Converter and the DXD transducer(s) which are

interconnected forming a “network”. The DXD has its

own regulated power supply (internal DC to DC

converter) and is protected against spikes and supply

reversals. Each DXD consumes approximately 300

milliwatts or 15ma at 20 volts. The power supply can

be plugged in anywhere along the network, it does not

have to be near the Serial Port Converter. The

contact rating of the RJ11/4 (telephone-type) connec-

tor is 1.5 amps which provides a fast, economical,

and reliable method of interconnection.

Figure 1. Modular Power Supply with RJ11/4

Connector

4.42 Serial port converter. The Serial port converter

consists of electronics housed in a standard DB25

connector’s shell assembly. It has a standard DB25

female RS-232C socket on one end and two RJ11/4

jacks on the other. The DB25 side plugs into an RS-

232C port and the RJ11/4 jack connects to the

transducer(s). Its function is to amplify and buffer

standard RS-232C signals so that up to 99 DXD

transducers can be connected in parallel in any

configuration, Daisy Chain or Star. One converter is

required per 99 units. The converter can drive exten-

sion cables up to 1000 feet (total cable length) and

still maintain data integrity while communicating at

high speed with each transducer.

Figure 2. Serial Port Adapter Assembly

4.43 25 to 9 pin adapter. A25 pin to nine pin adapter

is provided to facilitate connecting the serial port

converter’s DB25 pin connector to a computer or

terminal serial port having a DB9 pin connector.

4.44 25 foot cable. The 25-foot cable connects the

DXD to an expander module or directly to a serial port

converter. The cable is provided with a Switchcraft or

Cannon connector on one end and an RJ11/4 (tele-

phone-type plug) on the other. Pushing the female

connector onto the male socket and then securing the

connector with the sleeve by turning the sleeve until it

locks in place makes connection to the DXD.

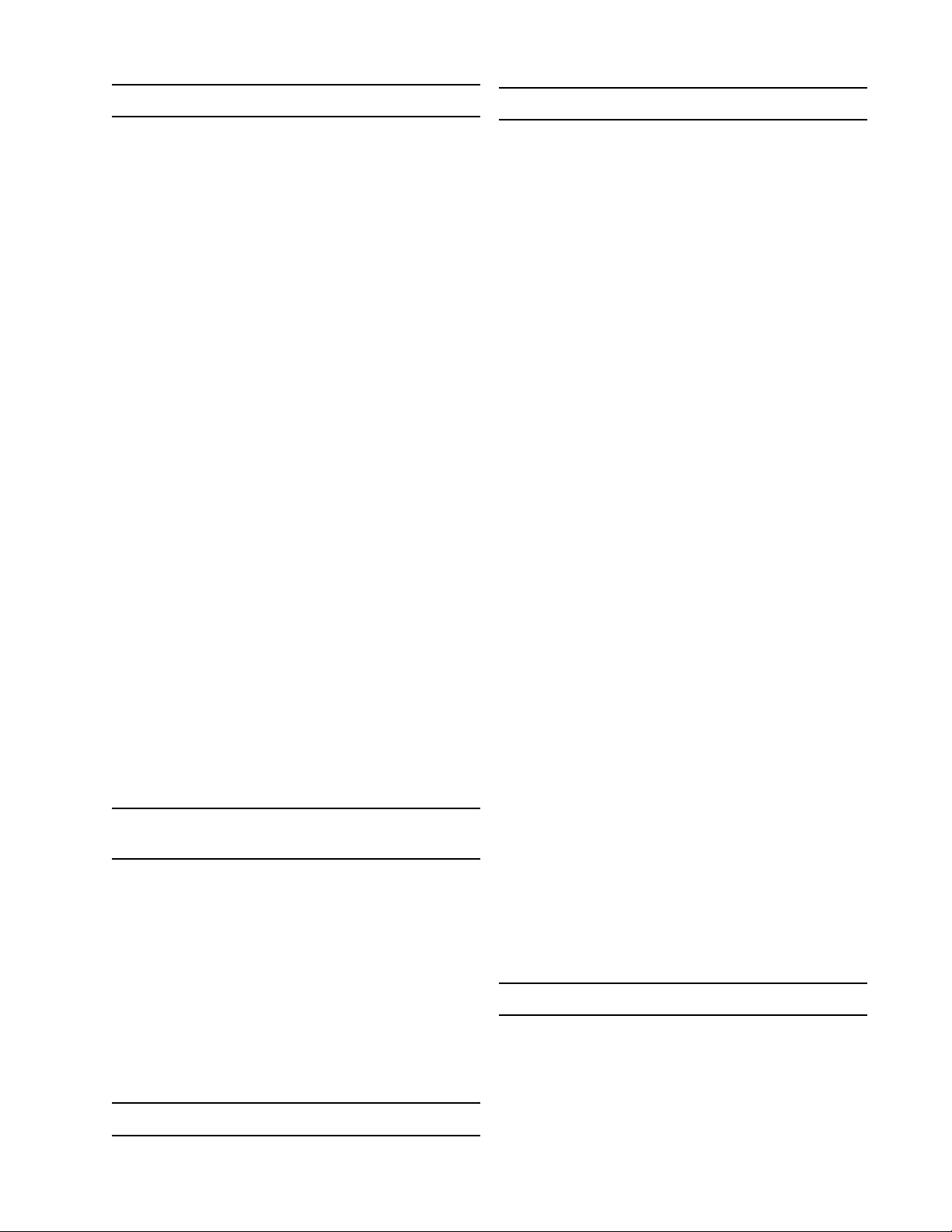

4.45 Five-port expander module. Afive-port ex-

pander module consists of a block with five female

RJ11/4 jacks and a six-inch pigtail with a male RJ11/4

connector. The DXD cable plug(s) and the modular

power supply plug are inserted into the available

jacks and the male plug on the pigtail of the five port

expander is inserted into the female jack on the serial

port converter.

Figure 3. Five-Port Expander Module

7

Revision 1.6.1 2/28/06 Printed in USA

Section 5.0 Installation

The Installation of the product has three basic steps,

which include making pressure connections, system

wiring (connecting communication and power cables

to the transducers and a PC or PLC and installing and

running software to communicate with and set up the

DXD transducer.

5.1 Pressure Connections

The standard pressure inlet fitting is a 1/4 inch NPTM

type connector unless an optional fitting was specified

at time of purchase.

IMPORTANT NOTE: The standard vented housing is

recommended for gauge pressure types with ranges

less than or equal to 500 PSI. This is because

changes in ambient temperature will increase or

decrease the pressure of the gas volume within the

housing producing an undesirable effect on the

performance of the unit. The housing is vented

through the Switchcraft or Cannon electrical connec-

tor by removal of one of the unused connector pins at

the factory (see Table 1 and 2). Asealed housing (no

connector pin removed) can be specified at time of

purchase if required. The effect is approximately

±0.027 PSI per degree Fahrenheit change in ambient

temperature.

This is not a factor on absolute pressure ranges

because the reference side of the sensor is

evacuated and sealed.

5.2 System Wiring

5.2.1 RS232 Cables. The RS232 configuration

requires four conductors for signal in, signal out,

power positive, and power negative. Prefabricated

telephone type cables with RJ11 modular connectors

and Switchcraft or ITT Cannon connectors can be

purchased from the factory as a kit for RS232 con-

figurations. Other cable and connector combinations

can be fabricated using user supplied, multiconductor

wire and connectors per the following pin function

tables. Minimum 26 AWG wire is recommended.

5.2.2 RS485 Cables.The RS485 configuration

requires six conductors two for signal in, two for

signal out, one for power positive, and one for power

negative. The user can fabricate similar telephone

type cable and modular connectors for RS485

configurations. This configuration uses eight conduc-

tor RJ45 plugs and sockets and cable such as Alpha

9314C 24 AWG. Other cables and connector combi-

nations can be fabricated using user supplied,

multiconductor wire and connectors. Minimum 26

AWG wire is recommended.

5.2.3 Cable length and transmission speed. Total

cable length, wire gage and total number of transduc-

ers connected to the system have an effect on

maximum communication speed. This is due to the

effects of cumulative resistance and capacitance on

the signals. The tables in appendix B illustrate the

relationship between cable length, number of DXD

transducers and communication speed.

5.2.4 Transducer Connectors. The DXD is available

with a standard Switchcraft EN3 electrical connector

or an optional ITT Cannon KPT03 (Bendix PTX

compatible) electrical connector. Both configurations

operate in full duplex (simultaneous send and re-

ceive) mode.

5.3 Installation Wiring for RS232 Systems with

Accessory Kit

5.3.1 Pin Functions and Cable Fabrication for

RS232 Compatible Systems

The following information is provided for reference if

you wish to fabricate your own cables. The Switch-

craft EN3 connector has eight pins. The RS232

configuration utilizes four pins with the following

assignments and functions:

8

Revision 1.6.1 2/28/06 Printed in USA

Table 1. Switchcraft EN3 Pin Assignments for

RS232 Configuration.

Table 3. RJ11 Connector Functions for RS232

Systems

Table 2. ITT Cannon KPT03 Pin Assignments for

RS232 Configuration.

DXD Definition Host Destination

Digital Output

Digital Input

9

Revision 1.6.1 2/28/06 Printed in USA

5.4 Wiring Installation for RS485 Systems

Required Equipment

RS485 card. Afull duplex RS485 card is required for

setting up an RS485 system. This type of card is

available from a wide variety of manufactures.

Factory experience is limited to National Instruments

P/N AT485/2 although any fully compliant card should

work. An RS485 system can also be connected to a

standard RS232 port using a powered RS232 to 485

adapter such as those supplied by Black Box (model

485PS).

Power supply. ADC power supply capable of

providing 12 to 24 VDC and 15mA per transducer is

required.

Wiring: According to the RS485 standard six con-

ductor, shielded, twisted pair 24 AWG is recom-

mended for interconnecting RS485 systems. How-

ever, modular telephone cable and hardware (RJ45

six conductor) can be employed depending on the

application (distance, EMI, RFI, speed). Daisy chain

interconnection is recommended with minimum drop

lengths. See RS485 schematic, appendix C.

5.4.1 Pin Functions and Cable Fabrication for

RS485 Compatible Systems

Connectors: The DXD is supplied with either

Switchcraft or Cannon (Bendix Compatible) connec-

tors as specified at time of purchase. The pin identifi-

cation and assignments are shown in Tables 4 and 5.

Table 4. Switchcraft EN3 Pin Assignments for

RS485 Configuration

Table 5. ITT Cannon - Bendix Compatible Pin

Assignments for RS485 Operation

10

Revision 1.6.1 2/28/06 Printed in USA

Section 6.0 Installing and Running Utility Soft-

ware

Computer Requirements.A Pentium class PC is

recommended to take full advantage of the high

speed capabilities of the DXD digital pressure trans-

ducer, however, any PC capable of running Windows

95 can be used.

Software. Three Disks and/or a CD rom are available

for the DXD transducer that provide a program called

DXDSetup. This optional software provides an easy

means of setting up the user configurable features of

the DXD along with data logging and display capabili-

ties. It includes an “OCX” compatible com driver

which can be utilized through Active X compliant

software. See the software supplement for details.

Section 7.0 Using Hyperterminal with the DXD

Windows 95 includes a utility terminal emulation

program called Hyperterminal. Hyperterminal can be

used to communicate with the DXD in order to setup

user preferences such as address, label, etc. and to

read pressure. The following section will guide you

through the steps required to accomplish this. This

tutorial in DXD command structure can also be used

with the Windows 3.1 Terminal.exe application or any

terminal emulation software provided you are familiar

with the setup characteristics of those programs. The

command syntax illustrated in the following section

will familiarize you with how they are implemented if

you wish to write your own software.

Basic Setup Information

Each DXD transducer is configured for address value

01 and bit rate 19,200 bits per second as shipped

from the factory. These values can be changed,

however, the following instructions assume that you

are using the DXD in the factory configuration.

Signal and Power Connections

Make all electrical and power connections as de-

scribed in Section 5.0. IMPORTANT:Be sure to

connect only one DXD until you are familiar with

its addressing conventions.

7.1 Configuring HyperTerminal

The Hyperterminal application prompts you through

the process of setting up communication parameters

that include assigning a file name and icon and

setting the com port, data format, bps (bit per sec-

ond). After this is done, you can save the configura-

tion using a name like “DXD” and simply open it by

name without need to re-configure it each time it is

used. This application will work with RS232 ports,

RS232 ports with a RS232 to RS485 adapter, or an

RS485 port.

1. Click the start button on the task bar and drag up to

Run...

2. Type hypertrm in the text box and click OK. This

will launch the Hyperterminal configuration program.

3. You will be prompted for a name so use something

easy to remember like DXD. Type the name and

select an icon. Click on the OK button.

4. The next box will prompt you for a phone number.

Pull down the Connect using: box and choose the

appropriate com port and click OK (a phone number

isn’t utilized in this type of setup).

5. Next you will be prompted for com port setup which

should be configured as follows: Bits per second:

19200, Data bits: 7, Parity: Even, Stop bits: 1, Flow

control: None.

6. Next click on the settings tab and click on ASCII

setup button.

7. Click in the check boxes labeled Send line ends

with line feeds and Echo typed characters locally.

Click OK to close this box and OK to close the next

box.

8. You have now configured HyperTerminal to com-

municate with the DXD. Open the File drop box in the

upper left hand corner of the window and select save.

This will save the com port configuration for later use.

9. Open the File drop box in the upper left hand

corner of the HyperTerminal window and select Exit.

You will be prompted by an alert message stating that

you are currently connected and asking if you want to

terminate now. Click Yes and HyperTerminal will

close.

7.2 Basic Communications with the DXD

The command library in Section 9 contains a detailed

description of all of the DXD commands, responses

and data formats. It also outlines the command

syntax required to read from or write to the DXD. The

following section describes how to use these com-

mands via HyperTerminal.

11

Revision 1.6.1 2/28/06 Printed in USA

7.2.1 Communication and Command Basics

There are some basic conventions and characteris-

tics which must be observed in order to communicate

with the DXD.

• The data format is 7 data bits, 1 stop bit, even

parity

• All commands are prefaced with the pound sign

character (#, ASCII 35) which serves as an

attention character.

• All responses are alphanumeric and include a

carriage return (CR) and line feed (LF) ASCII 13

and 10.

• The pound sign is followed by a two character

numeric address (01 through 99). Note that with

one DXD connected you can substitute a double

asterisk (*, ASCII 42) if you don’t know the

current address value.

• The DXD has two categories of commands which

are read (get data from) or write (send data to)

the DXD. All read commands are issued as

uppercase characters and corresponding write

commands are issued using lower case charac-

ters followed by the data to be written.

• The format of data used in write commands is

critical so please review the command library if

you encounter problems in the following section.

• NOTE: The [CR] in the following examples means

hit the enter key. Acarriage return (ASCII13) is

required to terminate a read or write command.

7.3 Launching the Previously Configured

HyperTerminal Application

1. Ensure that only one DXD is connected to the

computer and that power is applied.

2. Click the Start button on the task bar, select

programs, then accessories and then click on

HyperTerminal. This will open a folder on the desk top

that contains the HyperTerminal setup you created in

the preceding section. Double click the file icon to

launch HyperTerminal. When the program opens it

will be properly configured to communicate with the

DXD set to its factory defaults.

7.4 Talking to the DXD with HyperTerminal

7.4.1 Determine and Set the Current Address

The value retrieved with the AD (Address) command

is comprised of 7 alphanumeric characters (including

CR/LF) that can be modified by the user to set a

desired address value. The address value of the DXD

is user configurable and the default factory value is

01.

Note: There may be circumstances where the ad-

dress is unknown. To simplify the task of determining

the current address setting, the DXD can recognize a

“wild card” value comprised of double asterisks (**).

Substitute it in the address position of a read com-

mand. For example, #01AD can be sent as #**AD

(provided only one DXD is connected to the system).

1. To determine the DXD’s current address type the

following command:

#**AD[CR]

2. The DXD will respond with the following message:

AD=01 indicating that the address is currently

configured to the value 01.

3. To change the DXD’s address from 01 to 02 type

the following command:

#01ad02[CR]

4. To verify that the address has been changed, send

the following command:

#**AD[CR]

5. The DXD will respond with the following message:

AD=02

6. To change the DXD’s address back to 01 type the

following command:

#01ad01[CR]

7. To verify that the address has been changed, type

the following command:

#01AD[CR]

8. The DXD will respond with the following message:

AD=01

7.4.2 Determine and Set Baud Rate

The value retrieved with the BR (Baud Rate) com-

mand is comprised of 11 alphanumeric characters

(including CR/LF) which can be modified by the user

to set the desired system baud rate.

1. To read the current baud rate, type the following

12

Revision 1.6.1 2/28/06 Printed in USA

command in the HyperTerminal window:

#01BR[CR]

2. The DXD will respond with the following message:

BR= 19200

3. To change the current baud rate you first must

change the DXD’s setting then change the com port

setting for HyperTerminal. To change the DXD baud

rate from 19200 to 9600, type the following com-

mand:

#01br= 9600[CR]

4. You will be unable to communicate with the DXD

until the com port settings are changed in

HyperTerminal.

5. To do this click the File button and select Proper-

ties. Click on “Configure” then click the arrow box

next to Bits per Second then select 9600. Click OK

for the com properties box and OK for the file proper-

ties box.

6. Next click on the Call button and select Disconnect

then Connect (this activates any changes made to

HyperTerminal’s communications properties).

7. To read the revised baud rate, type the following

command:

#01BR[CR]

8. The DXD will respond with the following message:

BR= 9600

9. To change the baud rate back to 19200 type the

following command:

#01br=19200[CR]

10. Remember that you will be unable to communi-

cate with the DXD until the com port settings are

changed in HyperTerminal.

11. To do this click the File button and select Proper-

ties. Click on “Configure” then click the arrow box

next to Bits per Second then select 19200. Click OK

for the com properties box and OK for the file proper-

ties box.

12. Next click on the Call button and select Discon-

nect then Connect (this activates any changes made

to HyperTerminal’s communications properties).

13. To read the revised baud rate, type the following

command:

#01BR[CR]

14. The DXD will respond with the following message:

BR= 19200

7.4.3 Determine the Pressure Type

1. The value retrieved with the PT (Pressure Type)

command is the pressure type of the unit. It is com-

prised of 6 alpha numeric characters (including CR/

LF) and specifies the pressure type of the transducer.

It is assigned during manufacturing and can not be

changed. To read the pressure type (gauge, absolute,

vacuum, compound), type the following command:

#01PT [CR]

2. The DXD will respond by transmitting the following

message to the Hyper Terminal window.

PT=G (G for Gauge, Afor absolute, Vfor vacuum, C for

compound)

7.4.4 Determine the Full Scale Pressure Range

1. The value retrieved with the FS (Full Scale) com-

mand is the fullscale pressure range of the unit. It is

comprised of 13 alpha numeric characters (including

CR/LF) and specifies the pressure range of the

transducer. It is assigned during manufacturing and

can not be changed. To read the current FS value,

type the following command in the Hyper Terminal

window:

#01FS [CR]

2. The DXD will respond by transmitting the following

message to the Hyper Terminal window.

FS=+030.000 (Note that the decimal position is range

dependent see Appendix Afor details)

7.4.5 Get a Pressure Reading

1. To read the current pressure in PSI, type the

following command in the Hyper Terminal window:

#01PS [CR] (or #**PS[CR])

2. The DXD will respond by transmitting the following

message to the Hyper Terminal window.

PS=+000.000 (or the value of the existing pressure)

7.4.6 Get the Heise Label

1. The value retrieved with the HL (Heise Label)

command is the serial number assigned to the unit

during manufacturing and can not be changed. To

read the value stored in the HL location, type the

following command:

#01HL[CR]

13

Revision 1.6.1 2/28/06 Printed in USA

2. The DXD will respond by transmitting the following

message:

HL=000XXX (where X represents your DXD’s actual

serial number )

7.4.7 Get and Change the Current User Label

1. The value retrieved with the UL (User Label)

command is comprised of up to 16 alphanumeric

characters which can be modified by the user to form

a descriptive tag or identification name. To read the

current user label value, type the following command:

#01UL[CR]

2. The DXD will respond by transmitting the following

message:

UL=User Label Here (this is the factory default value)

3. To change the current user label to “Test Point 01”,

type the following command:

#01ulTest Point 01[CR]

7.4.8 Get and Change the Current User Tare Value

1. The value retrieved with the UT (User Tare) com-

mand is comprised of 11 alphanumeric characters

which can be modified by the user to remove or “tare

out” a pressure preload from the displayed pressure

value. To read the current user tare value, type the

following command:

#01UT[CR]

2. The DXD will respond by transmitting the following

message:

UT=+000.000 (note: This is the factory default value

and that the decimal position will depend on the full

scale range of the unit)

3. To change the current user tare to 1 PSI, type the

following command:

#01ut+001.000[CR]

14

Revision 1.6.1 2/28/06 Printed in USA

Section 8.0 Field Calibration

Calibration adjustments on the DXD are limited to

adjusting zero and span. Ahigh precision primary

standard (50 ppm or better) is required for the span

adjustment on gauge, vacuum and compound

pressure types and a precision absolute standard is

required for absolute pressure types

8.1 Zero Adjustment

1. Zero adjustment. This example will guide you

through the process of adjusting zero for a gauge,

compound or vacuum pressure type unit. Absolute

pressure types require that you connect the DXD to a

vacuum source capable of achieving 0.05 torr for

ranges from 15 to 50 PSIA or .5 torr for ranges from

60 to 500 PSIA.

2. Be sure that the DXD is at zero pressure (vented to

atmosphere for gauge, vacuum or compound pres-

sure types) or full vacuum for absolute pressure

types.

3. Send the following command: #01uz+000.000[CR].

This will reset the user zero offset value to zero.

4. Send the following command: #01PS and note the

result which will be something like PS=+000.002

5. Send the opposite sign of the PS value received in

step 4 above (-000.002) with the following command:

#01uz-000.002 [CR]

6. Confirm that the zero adjustment is complete by

sending the following command:

#01PS[CR] which should result in a display of

PS=+000.000

8.2 Span Adjustment

1. This procedure requires a primary pressure

standard of suitable accuracy. The following example

is based on a DXD with a full span rating of 30 PSI.

The value that will be adjusted is US (user span).

2. The first step is to connect the transducer to a

pressure standard and apply full span pressure (30

PSI in this example).

3. Next, retrieve the current pressure reading by

sending the following command:

#01PS[CR]

4. The result will be something like this: PS=+030.002

5. Next retrieve the current value of user span (US)

by sending the following command: #01US[CR]

6. Next calculate the new value for US by dividing the

known pressure generated with the pressure stan-

dard by the displayed value, for example, 30/

30.002=0.99993.

7. Multiply the current US value retrieved in step 5 by

0.99993 to calculate the new US value.

8. To write the new US value to the DXD, send the

following command:

#01uz+0.99993[CR]

9. Confirm that the span has been properly adjusted

by applying full span pressure and retrieving the

current pressure reading with the following command:

#01PS[CR]

10. The result should be PS=+030.000 (± 0.005% of

full span). If not, repeat steps 3 through 9 as required.

15

Revision 1.6.1 2/28/06 Printed in USA

Section 9.0 DXD Command Library

The DXD digital pressure transducer employs a simple ASCII character based protocol for communications.

ADXD UNIT cannot initiate this communication process. Ahost device, i.e. a computer, terminal or PLC

device must be used to initiate communications by querying the DXD. Multiple DXD’s on the same

communication bus are addressed sequentially so each unit must have a unique, two digit address between

01 and 99.

For applications where only one DXD is on the communications bus, wildcard characters “**” (double

astericks) can be used to address a single unit. Note: When using wildcard addressing for

communications care should be taken to ensure only one unit is being addressed. To avoid

problems that may arise from it’s use, wildcard addressing should be used primarily for testing or

troubleshooting purposes.

Commands issued to a DXD UNIT can be classified as one of two types.

1. Read Commands: These always return a value

2. Write Commands: Normally do not return a value, however, if the command issued syntax is incorrect an

error code value will be returned (see error codes section 9.3).

9.1 Communications Settings

The DXD Transducer uses the following communications settings

Bits Per Second Rates: 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200

Data Bits: 7

Stop Bits: 1

Parity: Even

Flow Control: None

9.2 Communications Protocol

9.21 Read Commands

Each read command is initiated with a pound sign (#, ASCII 35). Following the pound sign is a two character

numeric address (from 01 to99). The address is followed by a two character, upper case alpha command

mnemonic representing the command being issued. Acarriage return (ASCII 13) is used to terminate the

command.

9.22 Write Commands

Each write command is initiated with a pound sign (#, ASCII 35). Following the pound sign is a two character

numeric address (from 01 to99). The address is followed by a two character, lower case alpha command

mnemonic representing the command being issued. Following the mnemonic is the value to be written. A

carriage return (ASCII 13) is used to terminate the command. there is usually an input value to set.

Start DXD Address Command Input Value Termination

Character Mnemonic (for write only) Character

#01 through 99 2 Character Alpha Alphanumeric CR

Example 1. Read pressure command: #01PS[CR]

This command is directed to DXD UNIT address ‘01’ and a PSI pressure reading is being requested.

Example 2. Write Command: #01ulUNIT 100[CR]

This command is directed to DXD UNIT address ‘01’ and it’s User Label is being set to UNIT 100.

16

Revision 1.6.1 2/28/06 Printed in USA

9.3 Command Library Mnemonics

The same command mnemonic is used for both read and write functions. The destinction between read and

write commands is that read commands use uppercase characters and all write commands use lowercase

characters.

AD UNIT ADDRESS

Command Description: Reads or writes the DXD Unit’s address (valid address values are from 01 through

99)

Command Type :Dual (READ/WRITE) Command

Read Command Syntax: #01AD[CR]

Typical Read Command Response: The DXD transmits the address as a 7-Character string as shown below.

Char. Position 1 2 3 4 5 6 7

Response Char AD=0 1 CR LF

Write Command Syntax: #01ad03[CR]

Typical Write Command Response: None

BR BAUD RATE

Command Description: Reads or writes the DXD Unit’s Bits Per Second Rate. Valid Baud Rate values

include: 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200

Command Type :Dual (READ/WRITE) Command

Read Command Syntax: #01BR[CR]

Typical Read Command Response: The DXD transmits the Bits Per Second Rate as a 11-Character string as

shown below.

Char. Position 1 2 3 4 5 6 7 8 9 10 11

Response Char.BR=9 6 0 0 CR LF

Write Command Syntax #01br38400[CR]

Typical Write Command Response: None

ED EEPROM MEMORYMAP DUMP

Command Description: Returns the first 160 bytes of EEProm memory as decimal values. The values

returned are formatted 16 bytes per line with carriage return/line feeds appended at

ends.

Command Type: READ Command

Read Command Syntax: #01ED[CR]

Typical Read Command Response: Each line contains 65 characters including CR/LF.

005 000 000 000 000 001 000 000 000 000 000 000 000 000 003 006[CR][LF]

003 000 000 032 000 000 128 000 000 089 000 000 000 000 000 007[CR][LF]

003 000 000 064 002 000 128 000 000 089 000 000 000 000 000 007[CR][LF]

000 000 000 000 000 000 000 000 000 000 000 000 000 000 000 025[CR][LF]

000 000 000 000 000 000 000 016 000 000 000 000 000 000 000 000[CR][LF]

000 000 000 000 000 000 000 000 000 000 000 000 000 000 000 000[CR][LF]

000 000 000 000 000 000 000 000 000 000 000 000 000 000 000 000[CR][LF]

000 000 000 000 000 001 000 000 000 000 039 016 002 000 000 093[CR][LF]

000 000 000 000 000 000 000 000 000 000 000 000 000 000 000 000[CR][LF]

000 000 000 000 000 000 000 000 000 000 000 000 000 000 000 000[CR][LF]

17

Revision 1.6.1 2/28/06 Printed in USA

ER READ FROM EEPROM ADDRESS

Command Description: Returns a specified EEProm location’s value in decimal format, as a 3 digit value

ranging from 000 to 255.

Command Type: READ Only Command

Read Command Syntax: #01ER005[CR] ……Read from EE location 005

Typical Read Command Response: Displays the EEPROM location contents as a 5-character string as

shown below:

Char. Position 1 2 3 4 5

Response Char.0 0 1 CR LF

EW WRITE TO EEPROM ADDRESS

Command Description: Writes a value to the current EEProm address. The current EEProm address is set

using the ER command above. To change an EEProm address content the ER and

EW commands must be used in conjunction with each other. The ew command sets

a flag to cause the pressure and temperature coefficients to be reloaded from the

EEPROM to RAM.

Command Type: Write Only Command

Write Command Syntax: #01ew005[CR] ……Write “005”, to current EE location.

Typical Write Command Response: Echoes back the characters written as 5-character string shown below.

Char. Position 1 2 3 4 5

Response Char.0 0 5 CR LF

IMPORTANT NOTE: This command echoes back the characters written. This is the only write command that

always sends back a response. All other write commands only send back a response in cases of an error.

Valid values for writing to the EEPROM using the “EW” command are 3 character decimal values, 000

through 255.

FS FULL SCALE VALUE

Command Description: Returns the unit’s full scale pressure rating value

Command Type: READ Only Command

Read Command Syntax: #01FS[CR]

Typical Read Command Response: Outputs the Full Scale Value as a 13-character string as shown below.

Char. Position 1 2 3 4 5 6 7 8 9 10 11 12 13

Response Char.FS= + 0 1 0 0 . 0 0 CR LF

FV FIRMWARE VERSION

Command Description: Returns the unit’s current Firmware version.

Command Type: READ Only Command

Read Command Syntax #01FV[CR]

Typical Read Command Response: Outputs the Full Scale Value as a 7-character string as shown below.

Char. Position 1 2 3 4 5 6 7

Response Char.V 2 . 1 5 CR LF

18

Revision 1.6.1 2/28/06 Printed in USA

HL HEISE LABEL (SERIAL NUMBER)

Command Description: Returns the unit’s Heise Label

Command Type: READ Only Command

Read Command Syntax: #01HL[CR]

Typical Read Command Response: Outputs the Heise Label as a 11-character string as shown below

Char. Position 1 2 3 4 5 6 7 8 9 10 11

Response Char.HL=0 0 0 3 0 4 CR LF

PS PSI READING

Command Description: Returns the unit’s current pressure reading in PSI.

Command Type :READ Only Command

Read Command Syntax: #01PS[CR]

Typical Read Command Response: Outputs the PSI Reading as a 13-character string as shown below

Char. Position 1 2 3 4 5 6 7 8 9 10 11 12 13

Response Char.P S = + 0 0 0 1 . 0 2 CR LF

PT PRESSURE TYPE

Command Description: Returns the unit’s Pressure Type as a single character alpha value. Valid Pressure

Type values returned by the PT command include Afor Absolute, C for Compound,

G for Gauge, and V for Vacuum.

Command Type: READ Only Command

Read Command Syntax: #01PT[CR]

Typical Read Command Response: Outputs the Pressure Type as a 6-character string as shown below.

Char. Position 1 2 3 4 5 6

Response Char.PT=GCR LF

RC RAW COUNTS

Command Description: Returns the unit’s raw ADC values, calculated temperature feedback signal, and the

corrected pressure and corrected temperature values.

Command Type: READ Only Command

Read Command Syntax: #01RC[CR]

Typical Read Command Response: Outputs the Raw Counts as a 54-Character string as shown below.

Char. Position 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

Response Char.V P =-0 0 0 0 4 9 V I = + 0 4 4

Char. Position 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36

Response Char.1 9 2 V B = + 0 0 0 2 2 9 P = +

Char. Position 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54

Response Char.0 0 0 0 0 4 T= + 0 0 2 1 7 3 CR LF

19

Revision 1.6.1 2/28/06 Printed in USA

ST SENSOR TEMPERATURE

Command Description: Returns the unit’s current temperature reading in °C

Command Type: READ Only Command

Read Command Syntax: #01ST[CR]

Typical Read Command Response: Outputs the Sensor Temperature Reading as a 13-Character string as

shown below.

Char. Position 1 2 3 4 5 6 7 8 9 10 11 12 13

Response Char.ST= + 0 0 2 . 1 4 2 CR LF

UL USER LABEL

Command Description Reads or writes the DXD Unit’s Alpha Numeric User Label. The User Label string for

the Write command must be of a Maximum length 16 characters. Any User Label

greater than 16 characters entered to be written is ignored. If the User Label written

is less than 16 characters then trailing space (SPC), characters are appended to the

User Label written to memory and hence returned by the UL read command.

Command Type: Dual (READ/WRITE) Command

Read Command Syntax: #01UL[CR]

Typical Read Command Response: Output’s the User Label Setting as a 18-Character string as shown

below.

Char. Position 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

Response Char.DXDTra n sd u cer1CR LF

Write Command Syntax: #01ulDXD Transducer 2[CR]

Typical Write Command Response: None

US USER SPAN

Command Description: Reads or writes the DXD’s user span value. The User Span value to write to the

device has to be in exactly in the same format as shown below, i.e., a 5 decimal point

floating point value. The value is determined by applying full span pressure to the

DXD and reading the PS output. The US value is determined by dividing the known

pressure of the calibration standard by the displayed value (PS)

Command Type: Dual (READ/WRITE) Command

Read Command Syntax: #01US[CR]

Typical Read Command Response: Output’s the User Span Value as a 13-Character string as shown below.

Char. Position 1 2 3 4 5 6 7 8 9 10 11 12 13

Response Char.US= + 0 . 9 9 9 4 8 CR LF

Write Command Syntax: #01us1.00004 [CR]

Typical Write Command Response: None

UT USER TARE

Command Description: Reads or writes the DXD Unit’s User Tare Value. The value written to the device has

to be in exactly the same format as returned when the User Tare value is read. The

value to be written to Tare out the pressure reading from the Device is the inverse of

the current pressure reading from the PS command added to the current User Tare

value. For the following example, a User Tare value of +0000.12 would be written to

tare a PS reading of –0000.12 if the current User Tare value was +0000.00.

Command Type: Dual (READ/WRITE) Command

Read Command Syntax: #01UT[CR]

20

Revision 1.6.1 2/28/06 Printed in USA

Typical Read Command Response: Output’s the User Tare Value as a 13-Character string as shown below.

Char. Position 1 2 3 4 5 6 7 8 9 10 11 12 13

Response Char.UT= + 0 0 0 0 . 0 0 CR LF

Write Command Syntax: #01ut+0000.12[CR]

Typical Write Command Response: None

UZ USER ZERO

Command Description: Reads or writes the DXD’s User Zero value. The value written to the device has to be

in exactly the same format as returned when the User Zero value is read. The value

to be written to zero out the pressure reading from the device is the inverse of the

current pressure reading from the PS command added to the current User Zero

value. For the following example a User Zero value of +0000.12 would be written to

Zero a PS reading of –0000.12 if the current User Zero value was +0000.00. The

DXD can also be zeroed by first writing a value of zero to UZ then getting the PS

value and writing the inverse of the PS value to UZ.

Command Type: Dual (READ/WRITE) Command

Read Command Syntax: #01UZ[CR]

Typical Read Command Response: Output’s the User Zero Value as a 13-Character string as shown above.

Char. Position 1 2 3 4 5 6 7 8 9 10 11 12 13

Response Char.U Z = + 0 0 0 0 . 0 0 CR LF

Write Command Syntax: #01uz+0000.12[CR]

Typical Write Command Response: None

ERROR CODES

The DXD Transducer will return error codes in certain situations for example, where a user issues an

incorrect command syntax, and when measurement values are out of specifications due to sensor damage,

electrical problems, etc. The following list includes all error responses and their meanings.

Err01 ADC no response within 300 ms.

Err02 EEPROM write error. Write timeout set to 20 ms.

Err03 Incorrect numerical format for command.

Err04 Calculated pressure output over range (approximately 5% of full span).

Err05 ADC over range, could be either channel 1 or channel 2.

Err06 Bad pressure type value.

Err07 Illegal scale factor could be either channel 1 or channel 2.

Err08 ADC Reference Voltage Unstable or Not Present.

Error codes in the message string

Using error code 04 (over range)for an example, if the DXD is subjected to a pressure greater than 5% of it’s

full span rating and pressure is requested using the PS command “Err04[CR][LF] will be appended to the

data string for as long as the error condition exists as shown below. If more than one error condition occurs it

will be appended to the preceding error as shown below.

Char. Position 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Response Char.P S = + 0 0 0 1 . 0 2 CR LF Er r 0 4 CR LF

Table of contents