The Specialist In Drum Handling Equipment

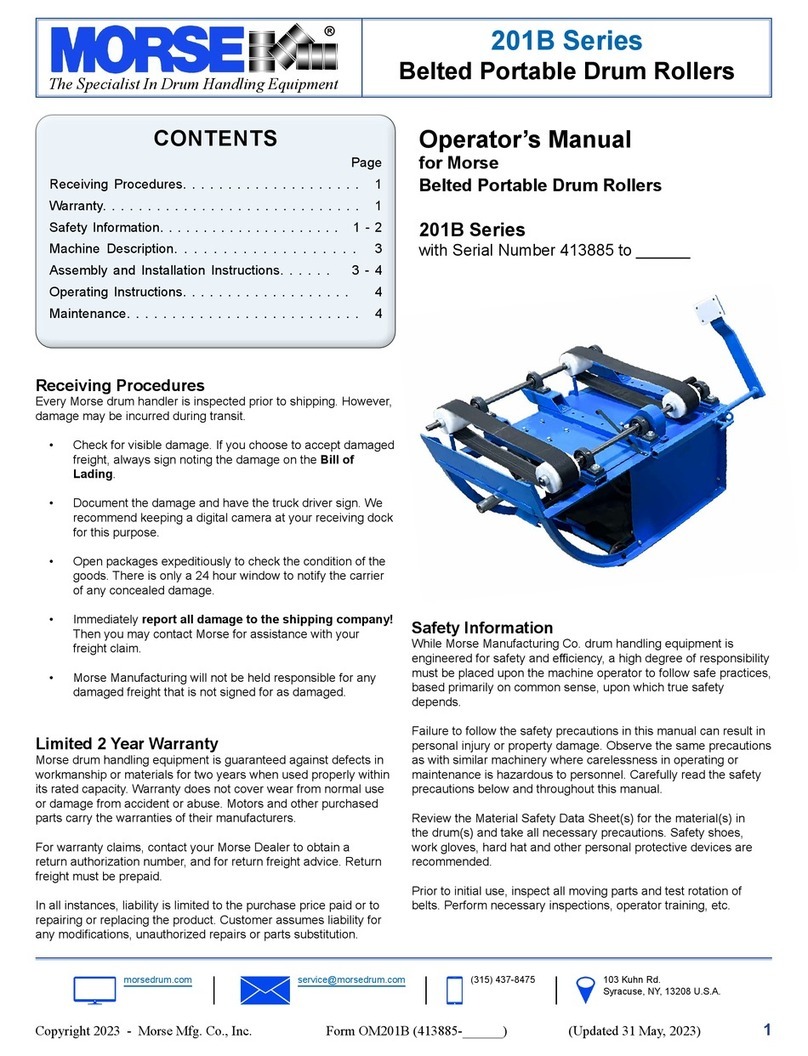

201B Series

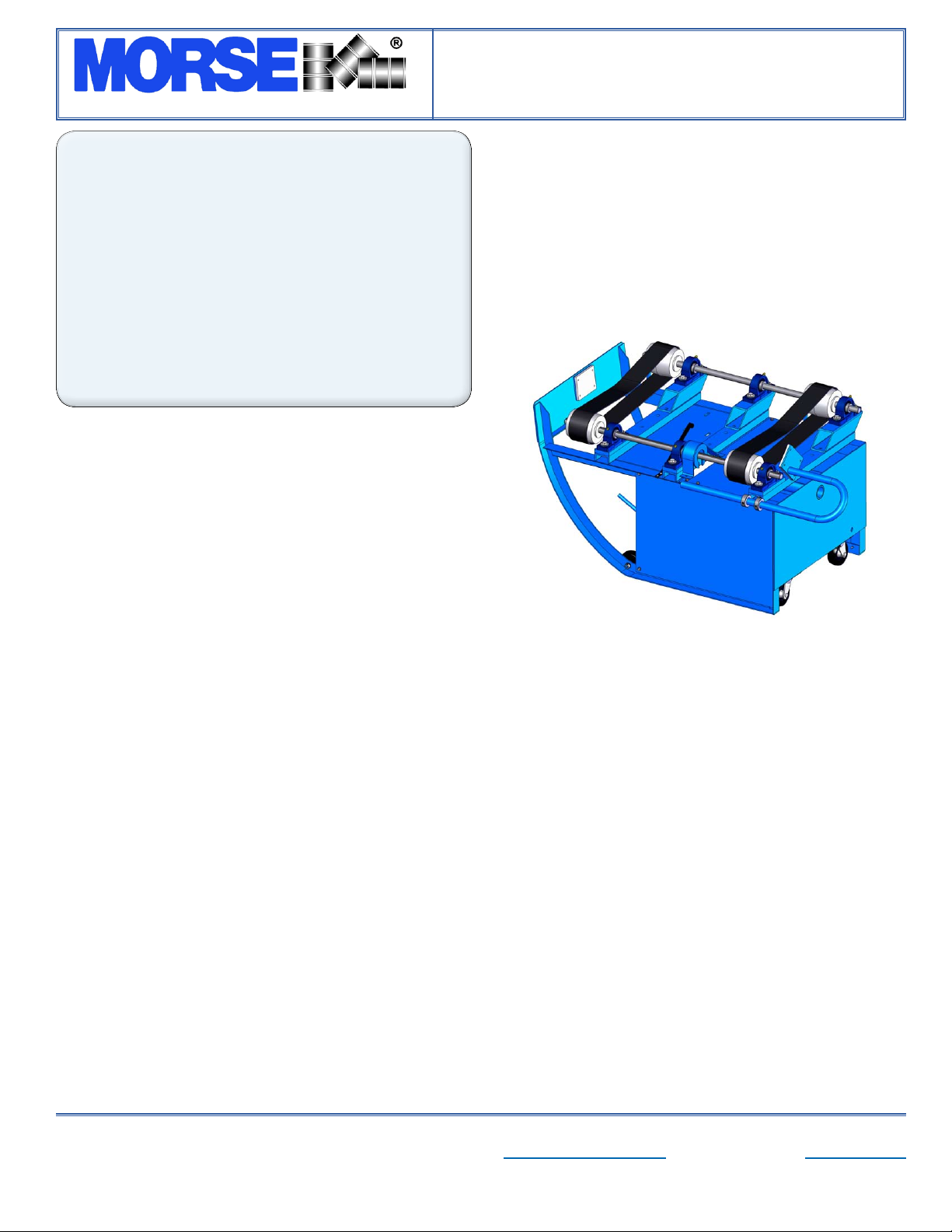

Belted Portable Drum Rollers

Operator’s Manual for Morse 201B Series Portable Drum Rollers

Serial Number 010116 to ______

morsedrum.com

Copyright 2016 - Morse Mfg. Co., Inc. Form OM201B (010116-______) (Updated December 2, 2015 2:02 PM) 3

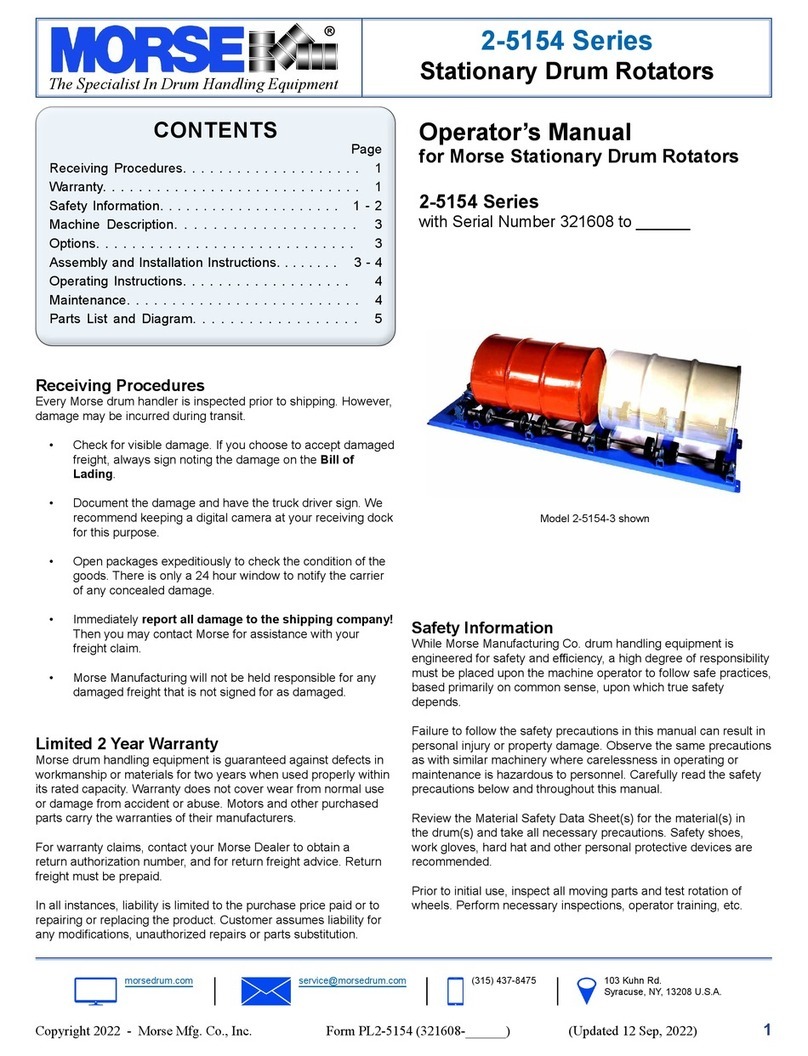

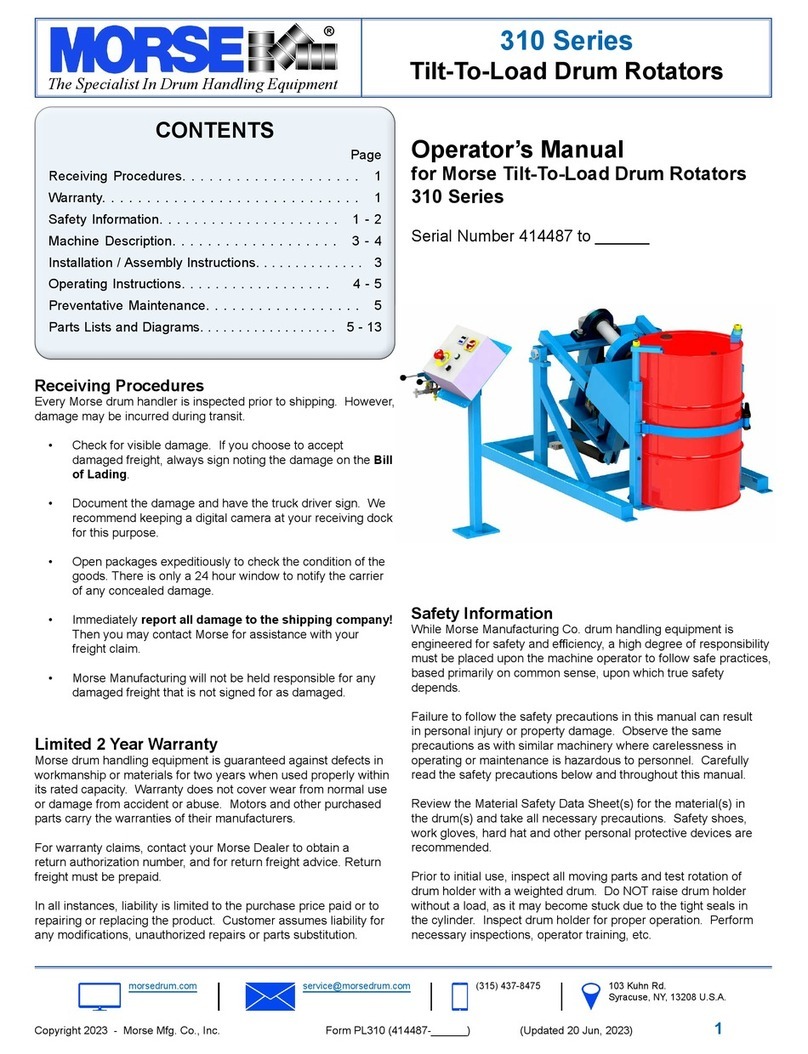

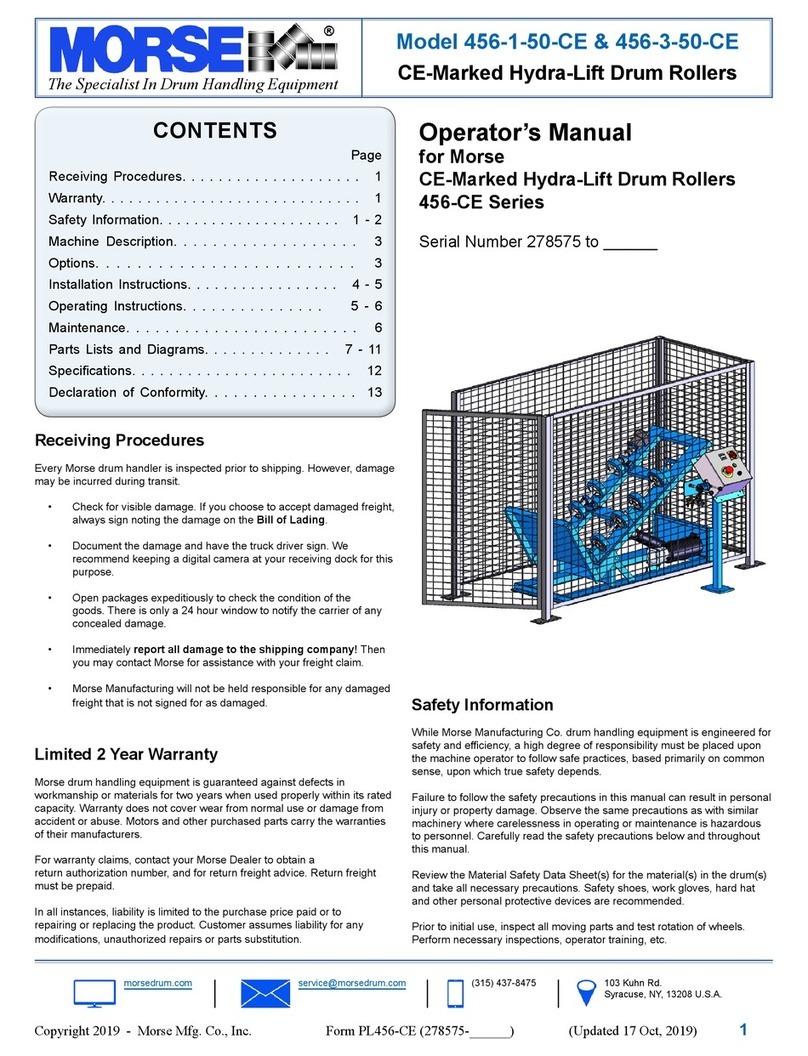

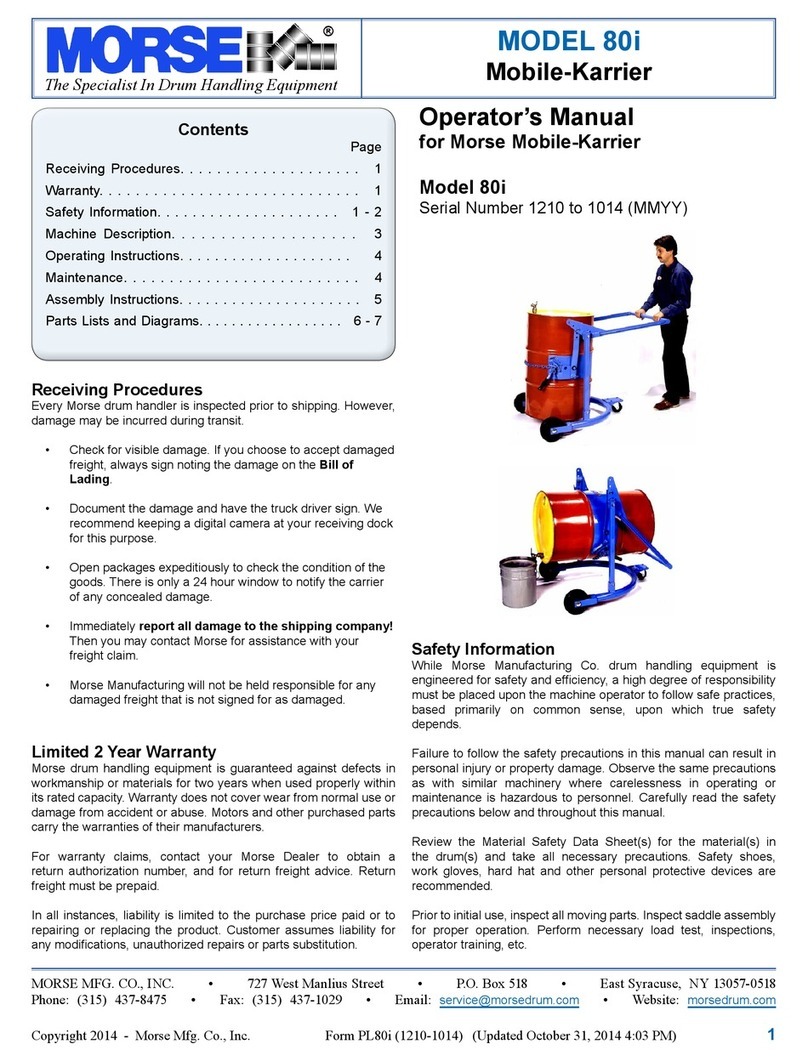

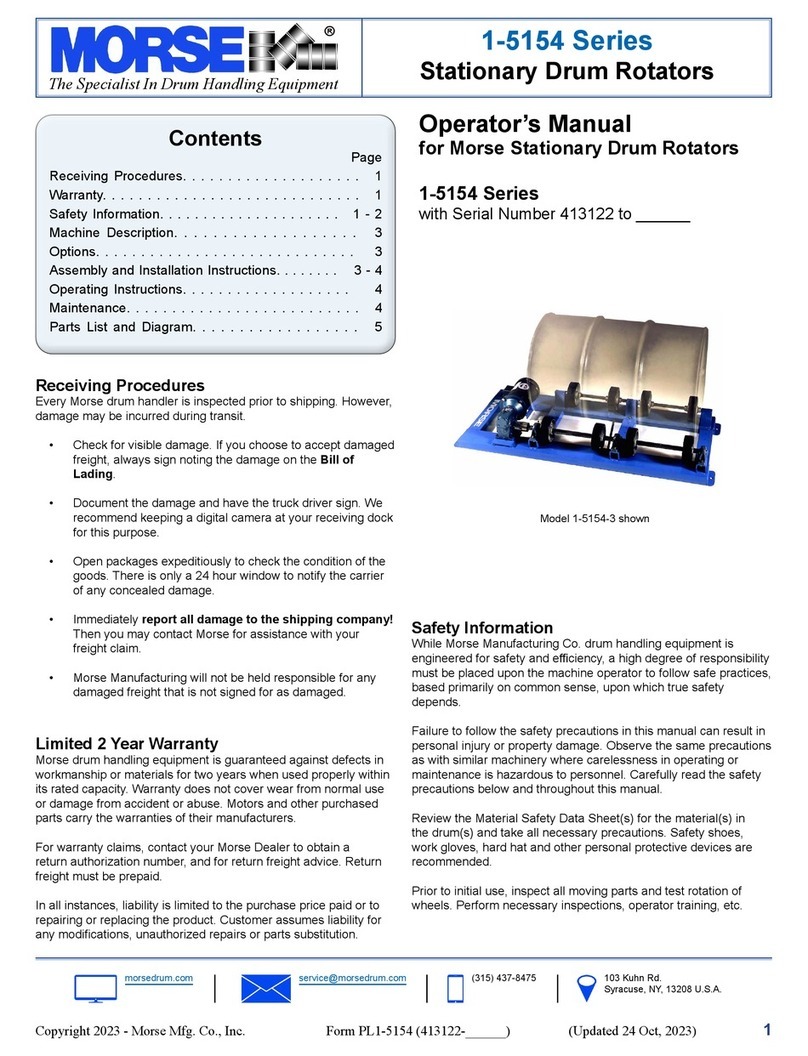

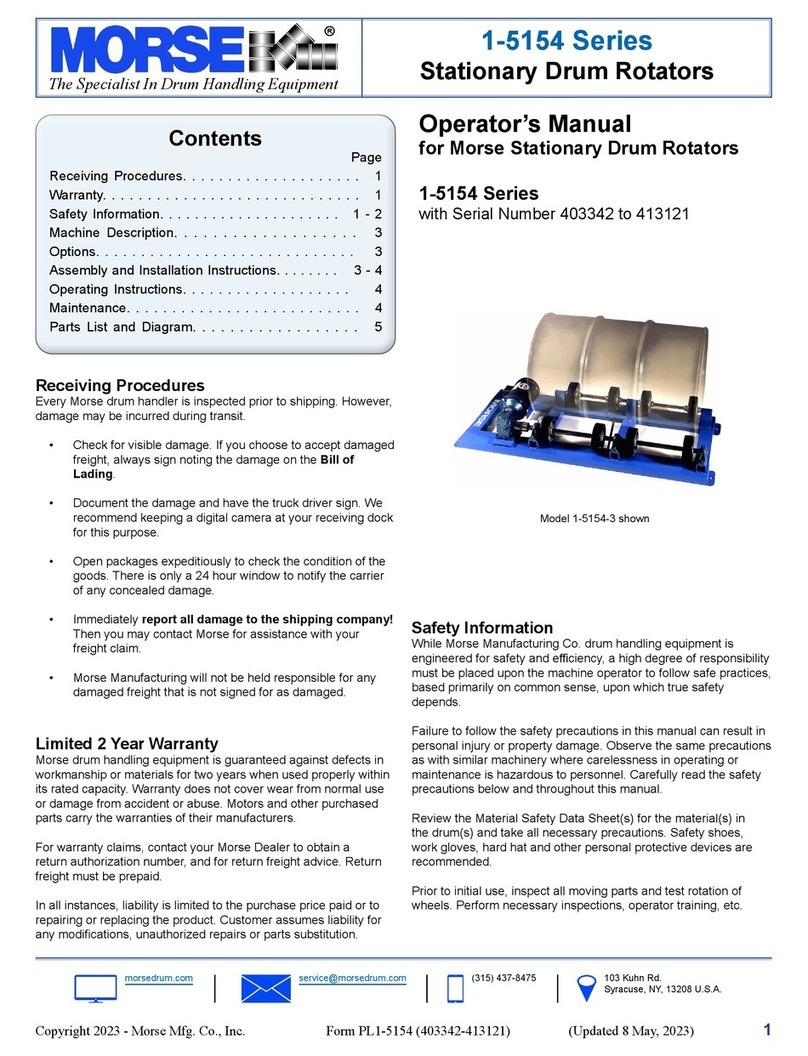

Machine Description

The201BSeriesDrumRollersaredesignedtorollaberdrum,16”to23”(41to59cm)indiameter,andupto35”(89cm)long.

Fixedspeedmodelsrolla22”(56cm)diameterberdrumat20RPM.•

The201BVSSerieshasVariableSpeedfrom15to24RPM.Thedrumrotationspeedisbasedona23”(58.4cm)diameter•

berdrumanda60Hz,1725RPMmotor.Thedrumrotationspeeddecreaseswitha50Hzmotor.

Capacity:

The maximum liquid load capacity rating is 300 Lb. (136 kg).•

Dry load capacity varies with speed of drum rotation. At 20 RPM dry load capacity is 300 Lb. (136 kg).•

ThecapacitiesofVariableSpeedmodelsare300Lb.(136kg)at15RPM,and250Lb.(113kg)at24RPM.•

WARNING - DO NOT exceed these ratings. Exceeding these ratings or handling a drum other than those mentioned above

is unsafe and could result in equipment damage, excessive wear, motor overload and shortened service life of transmission

components.

When loading, unloading, operating, or maintaining your MORSE portable drum Roller, always use care and good judgment. Maintain

securefootingandarmhold.Keephandsandlooseclothingawayfromallmovingparts.Neverallowanyonetobeneararotating

drum. Read operating instructions and review the pictures in the sales brochure before operation.

Important

Review the Material Safety Data Sheet(s) for the material(s) in the drum(s) and take all necessary precautions. Safety shoes, work1.

gloves, hard hat and other personal protective devices are recommended.

Please read all instructions thoroughly before attempting to operate your new Morse drum handler.2.

When loading, unloading, operating, or maintaining your MORSE drum Roller, always use care and good judgment. Maintain secure3.

footingandarmhold.Keephandsandlooseclothingawayfromallmovingparts.Neverallowanyonetobebelowanypartofa

raised drum handler or drum. Read operating instructions and review the pictures in the sales brochure before operation.

Morse Rollers do not comply with OSHA unless they are installed in accordance with OSHA subpart O, 1910.212 - “General4.

requirements for all machines.” Morse Rollers should be installed in accordance with OSHA requirements for enclosure and interlock,

etc. Power connections and motor controls must comply with applicable codes.

Prior to initial use, inspect all moving parts. Perform necessary inspections, operator training, etc.5.

Assembly and Installation Instructions

1. Remove cotter pin from hole in end of tipping lever. Slide lever through hole in back plate of Roller. Replace cotter pin in

hole in end of tipping lever and spread its ends.

2. Drive and idler pulleys may be adjusted for different length drums. Pulleys should remain equidistant from each end of

drum.Toadjustpulleys,loosencollarsetscrewswithprovided5/32”Allenwrench.Slidecollar/pulleyassemblytodesired

location and tighten collar set screws.

Note: Be careful not to lose key on drive pulleys.

3. Donotputintoservicewithoutpropermotorprotectionandcontrols.The½horsepower,singlephase115V60Hzunitis

supplied with a switch, cord and plug. The motor can be plugged into the wall power supply and started with the switch.

When starting the unit be careful to stand clear of the Roller as the drum will begin to rotate.

Unitsorderedwithathreephase,explosion-proofor50Hzmotorarenotsuppliedwithswitch,cord,orplug.Customer

should provide the proper controls and consult an electrician to complete the wiring.

Rollers equipped with an air motor require 40 psi, 22 scfm. Operating the air motor at higher pressures will reduce the life

of the air motor and power transmission components.