HELGI COBRA Instructions for use

Helgi Europe

Via Artigiani 29/31 29020 Vigolzone (PC) Italy

education@helgi-solutions.com | business@helgi-solutions.com

www.helgi-solutions.com

1

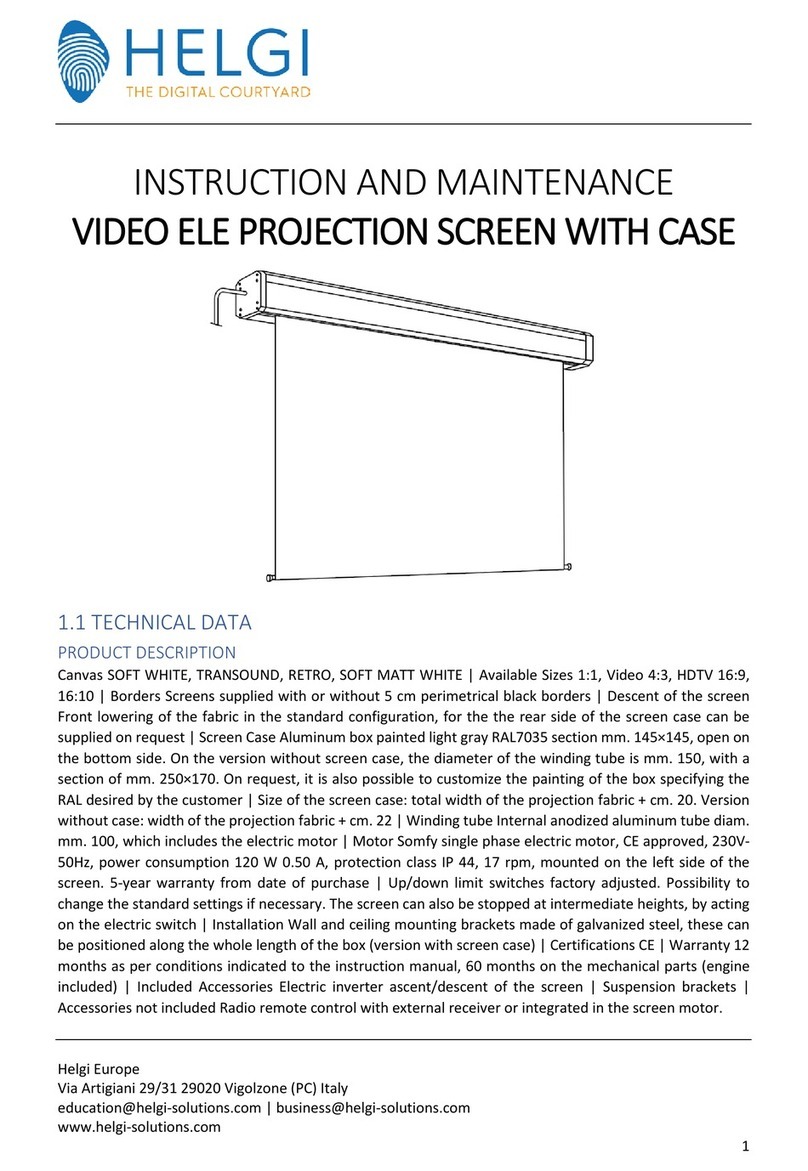

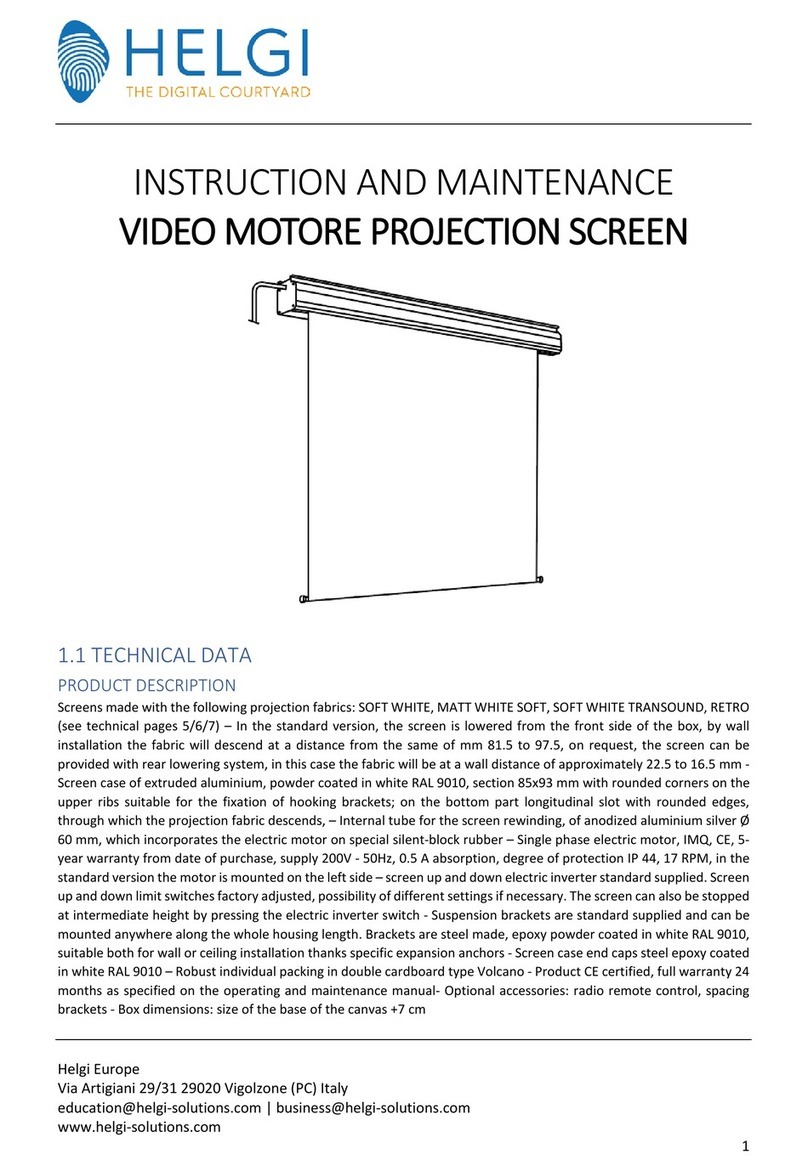

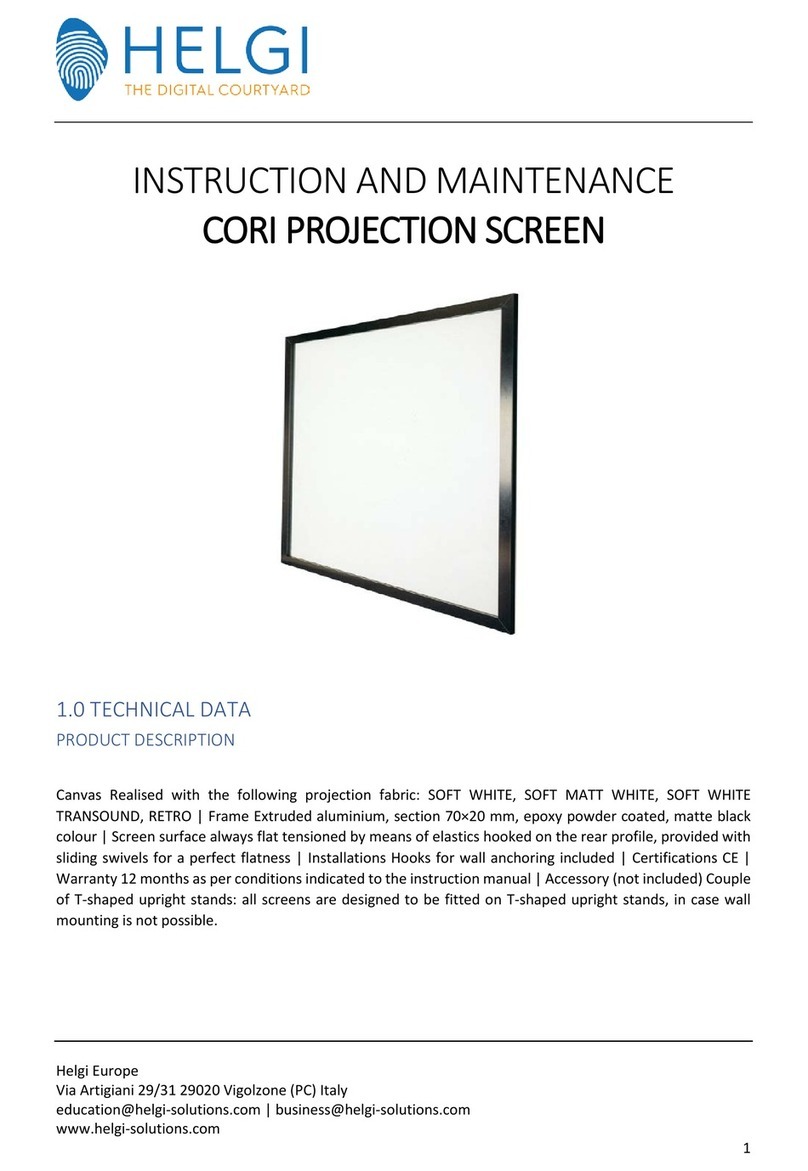

INSTRUCTION AND MAINTENANCE

COBRA PROJECTION SCREEN

1.0 TECHNICAL DATA

PRODUCT DESCRIPTION

Innovative motorized screen with upwards unrolling system, self standing, suitable for attics installation and

rooms with skewed ceiling; buildings of historical and architectural relevance and anywhere it’s impossible

to drill holes in the wall or ceiling; theatres, cinemas and stages; yachts and boats; renting or service

equipment.

Canvas SOFT MATT WHITE | Ratio Video 4:3, HDTV 16:9 | Borders Projection screen with or without 5 cm

perimetrical black borders and variable bottom black drop depending on the projection format | Motor

Opening of the projection screen by robust alluminium lifting arms and gas pistons, while the closure is

controlled by a silent and powerful electric motor | Installation COBRA screen is a self standing structure.

Supply with adjustable feet suitable to adapt to not perfectly even floors; it can be fixed to the floor with

suitable dowels. Depending on the installation it is possible to create suitable mounting structures or it can

be embedded in to the floor | Certifications CE | Warranty 12 months as per conditions indicated to the

instruction manual, 60 months on the mechanical parts (engine included) | Accessory (not included) Radio

remote control or radio remote receiver integrated in the electric motor and transmitter

Helgi Europe

Via Artigiani 29/31 29020 Vigolzone (PC) Italy

education@helgi-solutions.com | business@helgi-solutions.com

www.helgi-solutions.com

2

1.1 SCREEN DESCRIPTION

1.2 GENERAL CHARACTERISTICS

This screen has been built in compliance with the dispositions of the following E.E.C. directives: low voltage

E.E.C. Directive 73-23, electro-magnetic compatibility E.E.C. Directive 89-336. All employed projection fabrics

are fire-proof certified. The fire-proof degree and relative classification class vary according to the type of

projection fabric used. This screen has been studied by technicians with a great experience in this field and

it is built according to the high quality standards that identify our products. If the machine is used following

the instructions of this handbook, you will gain the maximum efficiency and a longer life. As a consequence

we beg you to read these pages very carefully and to always follow the remarks and the advices indicated.

Safety regulations for the maintenance

Follow the maintenance regulations that are in this booklet. Do not make any repair with the machine in

motion. Use original spare parts..

Adopted safety criteria:

The standard electrical cables are contained in a single case of self extinguishing plastic materials. Thermal

electric device in case of overheating of the electric motor. Emergency red button on the screen base.

1.3 GENERAL SAFETY REGULATIONS

Read the following instructions carefully before using the machine or doing the maintenance. The

instructions of this booklet do not substitute but complete the obligations towards the safety and accident

regulations in force.

1.3.1 Before:

Read the instructions concerning the preparation of the machine. Check all the protections of the machine

and substitute the damaged parts immediately with the original spare parts. Read the handbook for use and

maintenance.

1.3.2 During:

Pay attention to the electrical parts and when the screen is in movement.

1.3.3 After:

Clear the main switch

Helgi Europe

Via Artigiani 29/31 29020 Vigolzone (PC) Italy

education@helgi-solutions.com | business@helgi-solutions.com

www.helgi-solutions.com

3

2.0 WARRANTY

The company guarantee the functioning of the machine for a period of twelve months as for the mechanical

parts, and of 5 years as for the electric motor, beginning from the date of delivery indicated on the bill of

transport. The warranty is limited to the substitution of the damaged parts or defect related to the building

of the machine and in any case does not provide for the replacement of the product. The warranty in not

valid for defects that are caused by natural use or by the purchaser's carelessness, not for the parts that are

subject to a rapid wear and tear for the material or the kind of the use, nor for the parts with which the

machine is fitted out. The eventual damages or defects have to be communicated within eight days form the

receipt of the screen, on the contrary the warranty will not be valid. After approving the damage, the

company replace the damaged parts, if the purchaser has not tampered with them in order to try to repair

them and if he has complied with the contractual duties. Any other indemnity is not admitted. In case of

parts that are installed after the purchase, see the above-mentioned indications for the warranty. The

spedition, transport and manpower costs are charged to the purchaser. Any damage that may be caused

from the transport must be immediately communicated to the forwarder, on the contrary the warranty will

not be valid.

3.0 IDENTIFYING THE MACHINE

Matriculation number, weight, construction year, power supply and consumption as written on the labels

applied on every screen. For any communication with the constructor always mention the matriculation

number of the machine that is present on the main label.

3.1 Use admitted of the machine

The machine has been conceived only to be used as a screen for projections. Any other use is not admitted.

3.2 Regulations for the use

The machine is to be used in a covered place at a temperature of 15-40°C, it must be kept dry with a relative

humidity of 30-40% without condensate.

Helgi Europe

Via Artigiani 29/31 29020 Vigolzone (PC) Italy

education@helgi-solutions.com | business@helgi-solutions.com

www.helgi-solutions.com

4

4.0 WHAT YOU HAVE TO DO AND WHAT YOU HAVE TO AVOID

4.1 Always

•follow the indications and the instructions in the handbook and check the integrity of the machine

parts

•follow the indications and the instructions showed on the machine; the warning labels have to be

clearly readable

•prove the functionally of the command key

4.2 Never

•change, tear off the adjustment of the safety system and / or tamper with the machine

•do any temporary repairing or any not-complying-with-the-instructions attempt to repair

•make the machine perform any operations for which it has not been conceived

•cover, tamper with, tear off even if partially the labels that are on the machine

5.0 INSTALLING AND USING THE SCREEN

•Remove the straps only when installation is completed.

•Screen should always been operated from the front and not from rear.

•Pay attention that hands are not placed in mechanism while the screen is being opened or retracted.

•In case of emergency push the red button on the left side of the screen to stop it.

•Be sure that the screen is installed on a perfectly horizontal surface.

•Be sure that any obstacle is present while the screen is opening and closing.

•Before connecting the screen to the main switch check that the main switch supply correspond to

the voltage of the screen.

•Connect the screen to an earthed power point.

•The screen can be supplied with electric switch or with radio remote transmitter, both with three

buttons for open, stop and close the screen. Push the “up” button to open the screen, push the

“stop” button to stop the screen at any position, push the “down” button to close it.

•Never modify the setted up and down limit switches.

Helgi Europe

Via Artigiani 29/31 29020 Vigolzone (PC) Italy

education@helgi-solutions.com | business@helgi-solutions.com

www.helgi-solutions.com

5

5.0 MAINTENANCE OF THE SCREEN

The screen do not need any particular maintenance: it need only normal maintenance. Mechanical parts:

free from dust using a colourless soft clean cloth, and, if it is the case, a not aggressive detergent. Projection

surface: use a soft, clean, wet cloth, eventually combining neutral detergents. Since the fabric could be

charged with static electricity after cleaning due to the rubbing with the cloth, it is advised to apply an anti-

static liquid on the fabric with a clean cloth, to prevent dust from being attracted again. Avoid to pass with

detergents on the black borders.

5.1 USE OF THE SCREEN AFTER A LONG STORAGE TIME

5.1.1 Check the storage conditions of the screen:

•if it has been protected in a proper way

•if it has been covered in the right way

•if it has been stocked in a humid or saline or dusty place

5.1.2 Essential checks:

•the condition of the screen: if it has been attacked from humidity or water, if the paint is intact, if

the screen is without dust

•if the main parts are intact

•the state of efficiency of the electrical parts

•the start-up should be made following the instructions of this booklet

5.1 DISPOSAL

It is inevitable when the screen should be damaged and irrecoverable.

5.1.1 Preliminary operations

•disconnect the power supply

•remove the cables and the electric motor

•remove all the plastic parts

5.1.2 Subdivision of the materials

•Divide the plastic, rubber and other parts form the aluminium ones. Plastic and rubber parts should

be disposed as special waste and follow the antipollution laws of the Country.

Table of contents

Other HELGI Projection Screen manuals

Popular Projection Screen manuals by other brands

DirectConnect

DirectConnect Reel View DC84FS16x9 user guide

Kindermann

Kindermann Cineroll Electric Mounting instruction

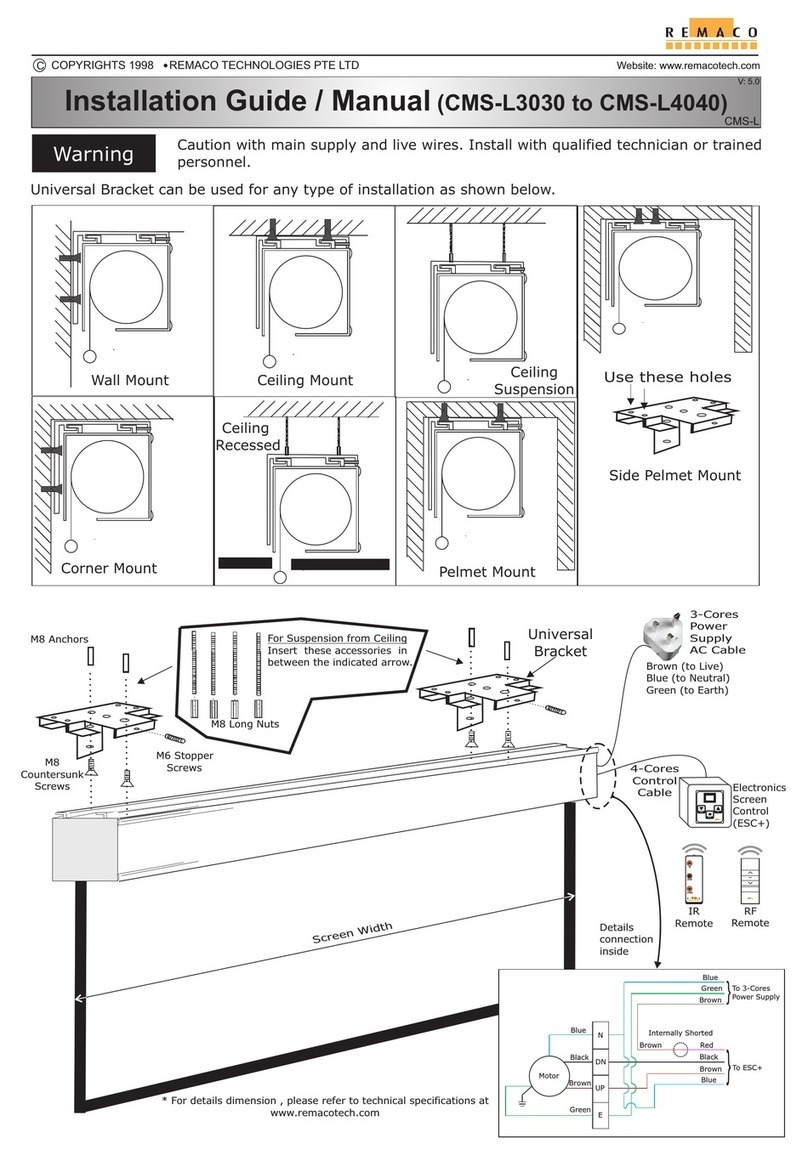

Remaco

Remaco CMS-L3030 Installation guide & manual

Da-Lite

Da-Lite Polacoat Flex Plex Instruction book

ORION Images

ORION Images R4K Series Installation and user guide

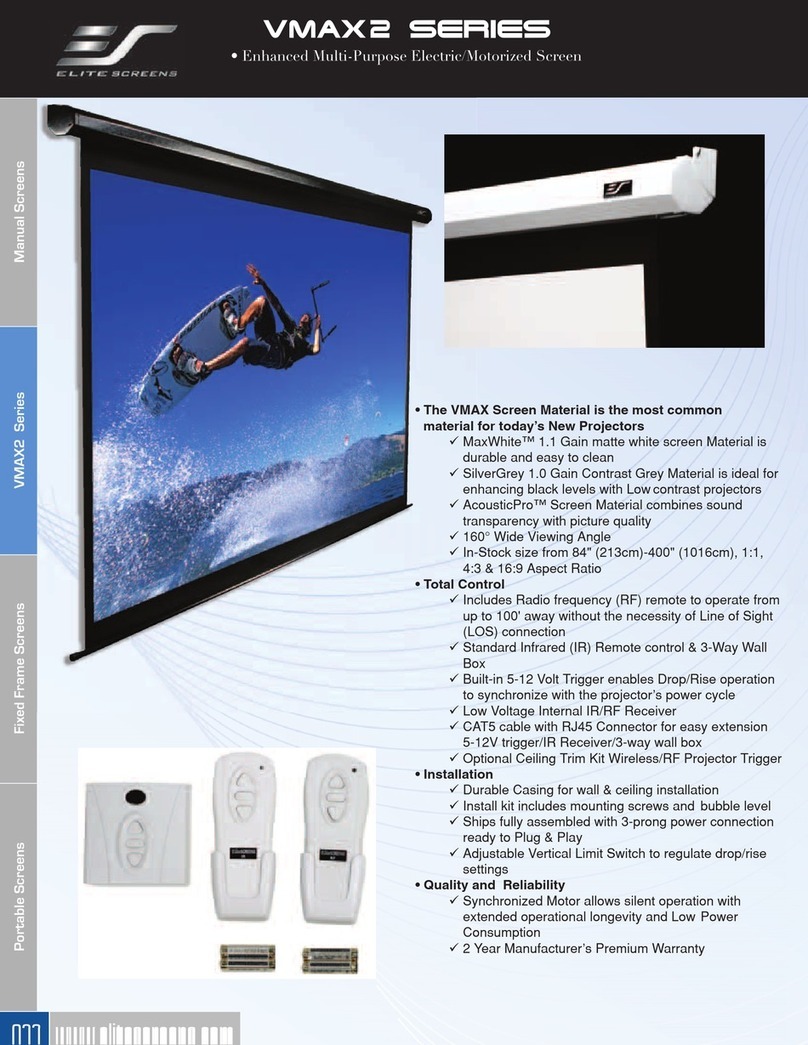

Elite Screens

Elite Screens SILVERMAX106H2 brochure

Da-Lite

Da-Lite TENSIONED LARGE ADVANTAGE ELECTROL Instruction book

Bei automation

Bei automation Laminar XL installation instructions

Da-Lite

Da-Lite PROFESSIONAL ELECTROL Instruction book

Da-Lite

Da-Lite Tensioned Cosmopolitan electrol Instruction book

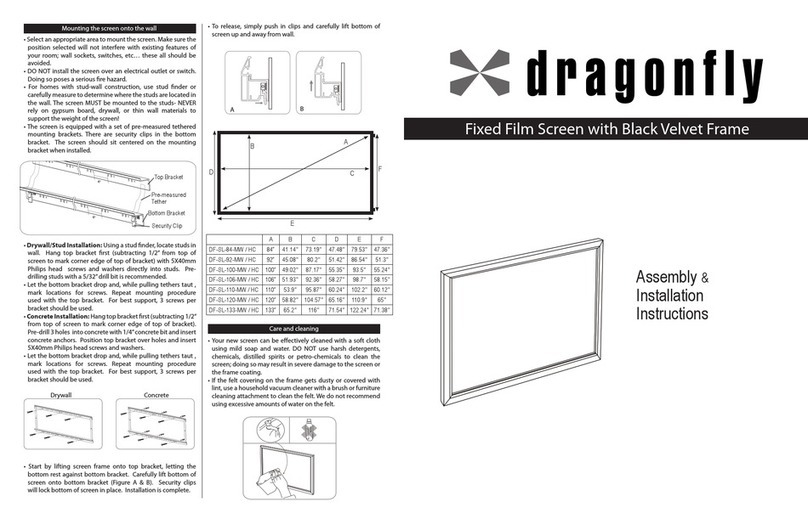

Dragonfly

Dragonfly DF-SL-84-MW/HC installation instructions

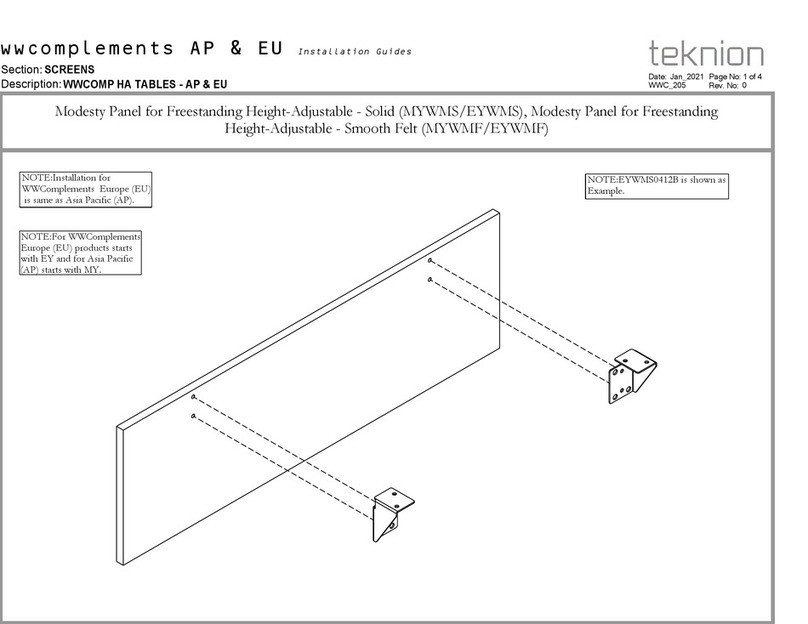

Teknion

Teknion MYWMS Installation guides