HELI G3 Series Installation and operating instructions

Table of contents

Other HELI Truck manuals

HELI

HELI CPD15 Installation and operating instructions

HELI

HELI CBD15J-Li2 Series User manual

HELI

HELI G Series Installation and operating instructions

HELI

HELI gieen Series Installation and operating instructions

HELI

HELI green Series User manual

HELI

HELI CQDH13 User manual

HELI

HELI CBD35-530 User manual

Popular Truck manuals by other brands

HARBEN

HARBEN 4018 Operation & maintenance manual

Chevrolet

Chevrolet 30 Series 1967 Service manual

Chevrolet

Chevrolet LIGHT DUTY TRUCK 1975 Service manual

Mercedes-Benz

Mercedes-Benz Unimog 416 1976 instruction manual

Iveco

Iveco DAILY 4x4 2020 Body builder instructions

Lift-Rite

Lift-Rite LCR55 Owner's Manual, Operating Instructions Manual, and Replacement Parts Manual

Komatsu

Komatsu HD1500-5 Operation & maintenance manual

swaploader

swaploader SL-2418 Parts and operation manual

MERLO

MERLO PANORAMIC User and maintenance manual

Taylor-Dunn

Taylor-Dunn ET 1-50 Operation and maintenance manual

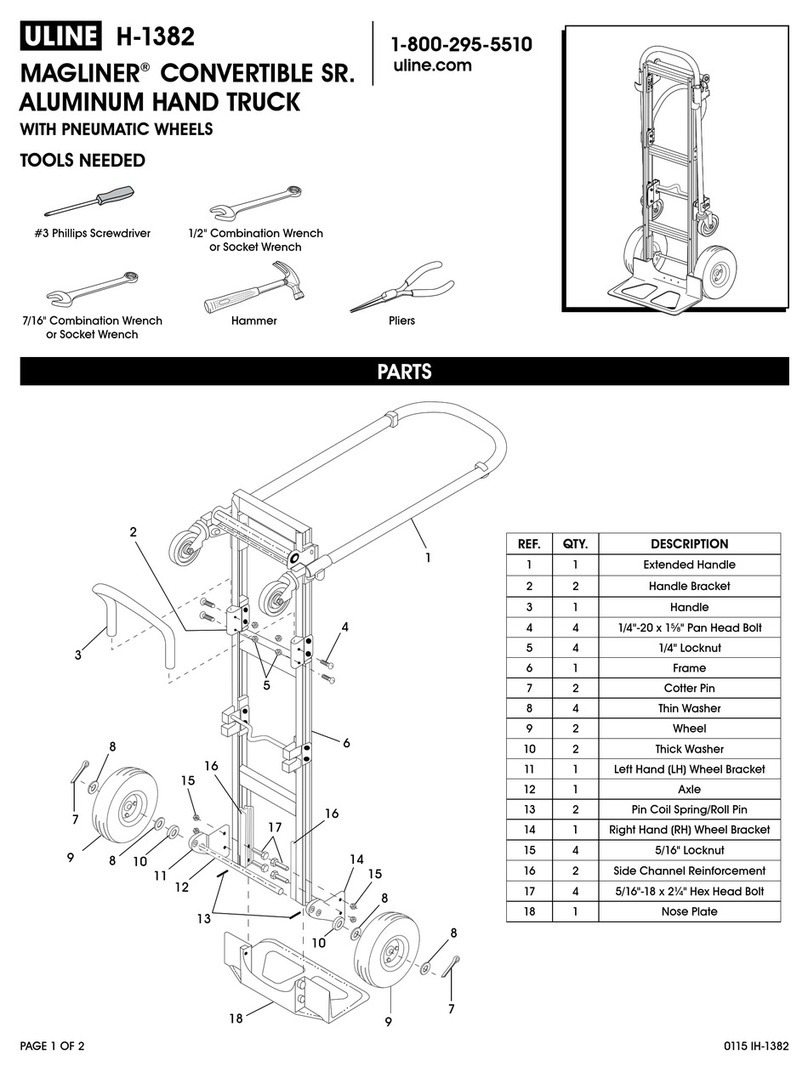

U-Line

U-Line H-9379 manual

freightliner

freightliner BUSINESS CLASS M2 Driver manual