HELI G Series Installation and operating instructions

FOREWORD

G series 1-3.5t lithium battery counterbalanced forklift truck is designed on the base

of G series 1-3.5t battery counterbalanced forklift truck combined with lithium battery

manage system. The truck has characters of environment friendliness, maintenance free,

long service life, high efficient, energy saving, safety and it is suitable for low

temperature. These trucks are all suited for handling and stacking packed goods in

stations, ports, goods yards and warehouses and used widely in food processing, light and

textile, mining industries and other factories, with some of attachments fitted, the trucks

can be applied more and more.

These trucks feature a wide-visible hoisting system, full powered steering unit,

continuously variable speed adjuster, overhead guard with opened port and high quality

motor, battery, MOSFET controller and LED display with large screen so they have a lot

of advantages such as good performance, easy operation, wide visibility of operator,

flexible steering, reliable braking, powerful and smooth power, low noise, no

contamination to environment and beautiful contour.

This manual states the trucks’specifications, operation, maintenance, service, main

assemblies’constructions and working principles so as to help operators to use the trucks

correctly and attain the highest functions. It is necessary to read over the manual before

they operate the trucks or service personnel serve these trucks.

The rules and notices in the manual should be abided seriously by all of relative

personnel to enable these trucks in optimized working state for long period and bring the

highest efficiency.

This manual content might not correspond with the actual condition because of the

improving of our products. Our products are subject to improvements and changes

without notice.

CONTENTS

Ι. Safety Rules for Operation and Daily Maintenance of Forklift Truck ............................ 1

Ⅱ. Main Specifications of Forklift Truck........................................................................... 6

Ⅲ. Construction, Principle, Adjustment and Maintenance of Forklift Trucks................. 14

1. Transmission System ............................................................................................ 14

2. Brake System ........................................................................................................ 19

3. Steering System..................................................................................................... 34

4. Electric System ..................................................................................................... 41

5 Hydraulic System................................................................................................. 100

6. Lifting System..................................................................................................... 121

1

Ι. Safety Rules for Operation and Daily Maintenance of Forklift Truck

It is important that driver and manager for forklift trucks remember the principle of

the “first safety” and ensure the safety operation as the description in 《OPERATION

AND SERVICE MANUAL》&《OPERATION MANUAL》.

1.Delivery of Forklift Truck

It must be pay attention to the following items when you deliver forklift trucks with

container or trucks.

(1) Apply the parking brake.

(2) Fix the mast and the balance weight with steel wire. Wedge up all wheels.

(3) Sling points should be always at the positions specified in sling index plate when

hoisting up the forklift truck.

(4) Charge the battery to make the electricity quantity to stay between 40% and 60% and

press the emergency button.

2.Storage of Forklift Truck

(1) Apply antirust to the surface of the parts not painted. Apply lubrication oil to the lift

chain.

(2) Lower the mast to the lowest position.

(3) Apply the parking brake.

(4) Wedged up the wheels.

(5) Charge the battery to make the electricity quantity to be more than 60% and press the

emergency button.

3.Precautions Before Operation

(1) Don’t check fuel leakage and lever or instruments at the place where there is open

flame. Never fill the fuel tank with the truck running.

(2) Check the tire inflation pressure.

2

(3)Check the devices of lighting, sound and alarm: check the lights, buzzer and horn

(button on the handle included).

(4) The forward-reverse lever should be in neutral.

(5) Check all the levers and pedals.

(6) Complete the provisions before starting.

(7) Release the parking lever.

(8) Make trying operation of the mast for lifting, lowing and Fwd/Bwd tilting and the

truck for steering and braking.

4.Operation of Forklift Truck

(1) Only trained and authorized operator shall be permitted to operate the truck.

(2) Wear all the safety guards, such as shoes, helmet, clothing and gloves while operating

the truck.

Check all the control and warning devices before starting the truck. If any damages or

defects are found, operate it after repairing.

(4) At the rated loading center, either overload or overload operation is strictly prohibited.

The center of cargo should be in line with the frame center, not out of the line. The fork

should insert completely under the cargo and make the cargo placed on it evenly. Do not

raise an object with one fork end.

(5) The starting, turning, driving, braking and stopping operation of the truck should be

done smoothly. When steering on the humid or low friction road, the truck should be

decelerated.

(6) Travel with loads as low as possible and tilted backward.

(7) Be careful when traveling on a slope. When climbing grades with a slope of more

than 10%, the truck should forward travel, and when descending so grades, backward

travel. Never turning on a slope. Avoid loading and unloading operation when

3

descending.

(8) Pay attention to pedestrian, obstacle and bumpy road when driving. Pay attention to

the clearance over forklift truck.

(9) Never allow any persons to stand on the forks or the truck to carry persons.

(10) Never permit anyone to stand or walk under upraised forks.

(11) Don’t operate truck and attachment of it at any position out of the drive seat.

(12) On the high lift forklift truck, when the lift high more than 3m, it is noted that the

goods on it should not fall down or the protection measures must be taken if necessary.

(13) Tilt the mast of the high lift forklift truck as backward as possible while the truck

working. Use minimum forward tilt angle and Min. reverse tilt when loading and

unloading.

(14) Be careful and slowly driving over a dockboard or bridge-plate.

(15) Shut down the truck and don’t stay on the truck when checking fuel level.

(16) The unloaded forklift truck with attachments should be operated as a loaded truck.

(17) Don’t handle unfixed stacked goods. Be careful to bulky goods to be handled.

(18) If leaving the truck, lower the forks on the ground and let the shift lever to neutral,

shut down the engine or cut down electric supply. If parking on a slope is unavoidable,

apply the parking brake and block the wheels.

(19) Don’t adjust the control valve and relief valve at will to prevent the damage of

hydraulic system and its components because of excessive pressure passing them.

(20) Inflate a tyre according to its stated air pressure. Never over inflate a tyre.

(21) Be familiar with and pay attention to the functions of the decals on the forklift

trucks.

5. Daily Maintenance of Forklift Trucks

(1) Inspection before startup

4

a) Hydraulic oil volume: oil level should stay in the middle of oil meter scale;

b) Check piping, joints, pumps and valves for leaks or damages;

c) Check service brake:

The free travel of brake pedal should be within the range of 40mm;

The clearance between the front floor and the pedal should be bigger than 20mm;

d) Check parking brake. The unladen truck can park on the 15% grade ramp, when

the parking lever is pulled to the bottom;

e) Check instruments, lighting, switches and wiring to see if they work normally or

not.

(2) Oil used for forklift trucks

Name

Recommended

brand

Brand and temperature of using

Level per unit (L)

1-1.8t

2-2.5t

3-3.5t

Hydraulic oil

Long pan

Sticky

grade

L-HM32

wearable

hydraulic

oil

L-HV32

low temp.

wearable

hydraulic

oil

25

34

40

Temp.

of using

(℃)

≥-5

≥-20 (cold

region)

Brake fluid

Chong qing

yi ping

4604 compound brake fluid GB

12981 HZY4

0.2

Lubricating

grease

Long pan

2# L-XDCBB2 low temperature

lubrication grease (-40℃~

+120℃)

Gear oil of

heavy-laden

truck(GL-5)

Long pan

Sticky

grade

85W/90

80W/90

3.2

3.2

8

Temp.

of using

(℃)

-15~+49

-25~+49

●Apply lubricating grease NYOGEL 782G to the conductive plate which the

connecting point of the steering wheel horn switch acts on.

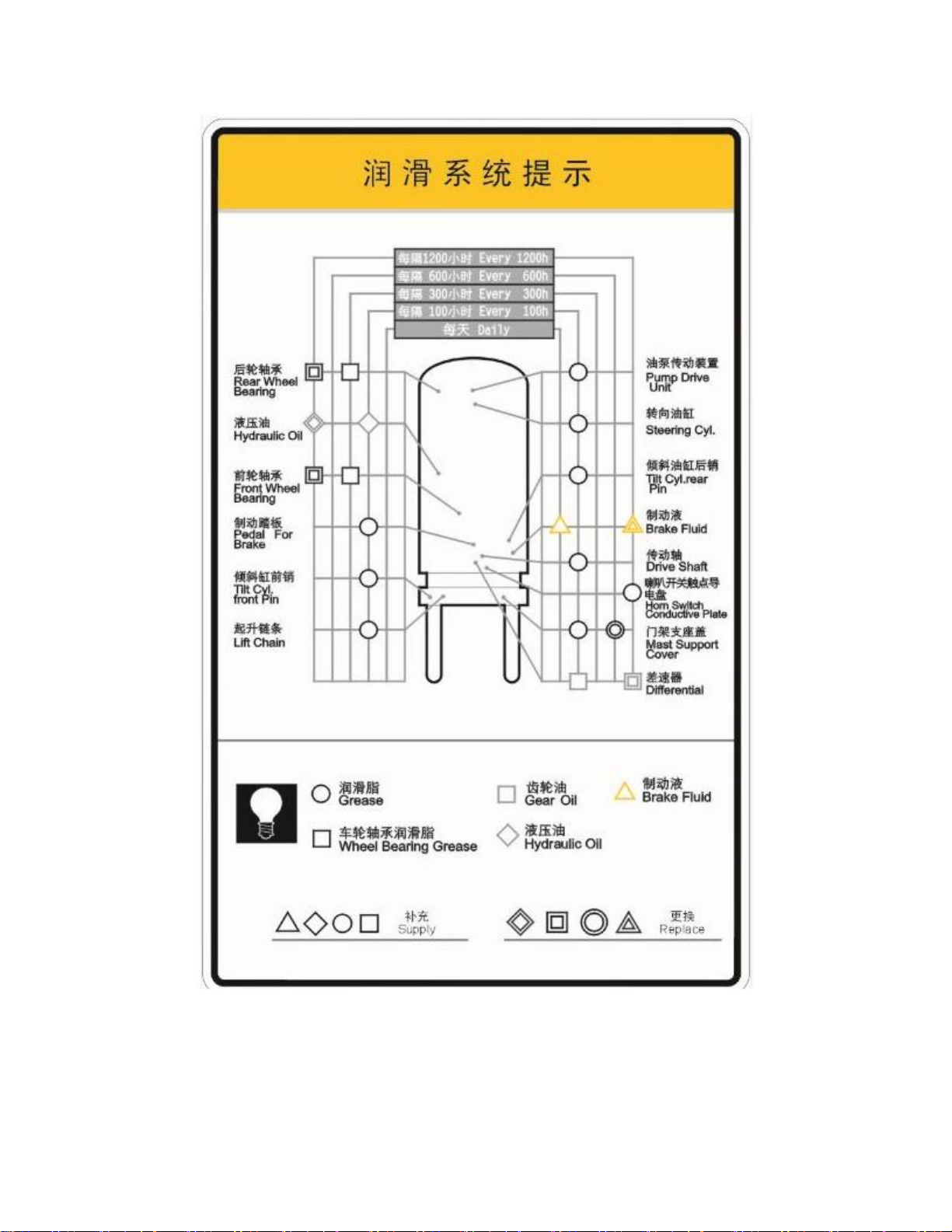

(3) The table of lubrication system

5

6

Ⅱ. Main Specifications of Forklift Truck

Enternal view of forklift trucks

7

Main Specifications(1)

Model

Unit

CPD10

CPD15

CPD18

GC1Li

/GD1Li

GC1Li

/GD1Li

GC1Li /GD1Li

Rated capacity

kg

1000

1500

1750

Load center

mm

500

Lifting height

mm

3000

Free lifting height

mm

145

Mast tilt angle (fwd/bwd)

(α/β)

°

6/8

Fork size (T×W×L4)

mm

32×100×770

35×100×920

Wheelbase L1

mm

1380

Tread (front/rear) (W3/W2)

mm

910/920

Overall length (without

forks) L’

mm

2070

Overall width W1

mm

1086

Overall height

(mast/overhead guard)

(H1/H4)

mm

1985/2130

Seat height

mm

1080

Under-clearance (H5/H6)

mm

90/80(in the middle of the

truck body)

80/75(in the middle

of the truck body)

Min. turning radius r

mm

1750

fork adjustment range

(outside) Max/min W5

mm

960/200

Travelling speed

(loaded/unloaded)

km/h

15/16

Lifting speed

(loaded/unloaded)

mm/s

DC: 290/450

270/450

280/530

AC: 410/600

400/600

380/600

Descending speed

(loaded/unloaded)

mm/s

400/500

Gradeability

(loaded/unloaded)

%

20/25

19/24

17/22

Tyre (front/rear)

6.00-9-10PR/16×6-8-10PR

6.00-9/16×6-8-10PR

Traction motor power

kW

8.2 (AC)

7.5(DC)

8.6(DC)

Pump motor power

kW

10.6 (AC)

Battery

V/Ah

48/400(standard)

48/500(optional)

Service weight (with/without

battery)

kg

2700/2350

2955/2605

3105/2755

Battery weight

kg

350

8

Main Specifications(2)

Model

Unit

CPD20

CPD25

GC1Li/GD1Li/GD3Li

GC1Li/GD1Li/GD3Li

Rated capacity

kg

2000

2500

Load center

mm

500

Lifting height

mm

3000

Free lifting height

mm

145

Mast tilt angle (fwd/bwd)

(α/β)

°

6/8

Fork size (T×W×L4)

mm

40×122×920

40×122×1070

Wheelbase L1

mm

1550

Tread (front/rear) (W3/W2)

mm

960/950

Overall length (without forks)

L’

mm

2285

2335

Overall width (front/rear) W1

mm

1185

Overall height (mast/overhead

guard) (H1/H4)

mm

1995/2150

Seat height Q

mm

1100

Under-clearance

(H5/H6)

mm

110(at mast)/115(in the middle of the truck

body)

Min. turning radius r

mm

2000

2060

fork adjustment range (outside)

Max/min W5

mm

1030/244

Travelling speed

(loaded/unloaded)

km/h

14.5/15

Lifting speed (loaded/unloaded)

mm/s

DC: 280/490

260/490

AC: 350/510

330/510

Descending speed

(loaded/unloaded)

mm/s

410/490

Gradeability (loaded/unloaded)

%

22/24

20/22

Tyre (front/rear)

23×9-10-16PR/18×7-8-14PR

Traction motor

kW

11.5 (AC)

Pump motor

kW

10.5 (DC)

15 (AC)

Battery

V/Ah

48/500

48/600(optional)

Service weight(with/without

battery)

kg

3615/3215

4035/3635

Battery weight

kg

400

500(optional)

9

Main Specifications(3)

Model

Unit

CPD30

CPD35

GC1Li/GD1Li/GD3Li

GC1Li/GD1Li/GD3Li

Rated capacity

kg

3000

3500

Load center

mm

500

Lifting height

mm

3000

Free lifting height

mm

145

150

Mast tilt angle (fwd/bwd) (α/β)

deg.

6/10

Fork size (T×W×L4)

mm

45×125×1070

50×125×1070

Wheelbase L1

mm

1685

Tread (front/rear ) W3/W2

mm

1000/950

Overall length (without forks) L’

mm

2545

2550

Overall width (front/rear) W1

mm

1238

Overall height (mast/overhead guard)

(H5/H6)

mm

2075/2215

2180/2215

Seat height

mm

1165

Under-clearance (H1/H2)

mm

135(at mast )/145(in the middle)

Min. turning radius r

mm

2240

2260

fork adjustment range (outside) Max/min

W5

mm

1060/250

Travelling speed (loaded/unloaded)

km/h

15/15.5

14.5/15

Lifting speed (loaded/unloaded)

mm/s

DC:280/460

270/440

AC:340/460

325/450

Descending speed (loaded/unloaded)

mm/s

-/500

Gradeability (loaded/unloaded)

%

17/20

15/20

Tyre ,front

28x9-15-12PR

28x9-15

Tyre, rear

18x7-8-14PR

18x7-8

Traction motor

kW

16.6 (AC)

Pump motor

kW

13 (DC)

13.5 (AC)

Battery

V/Ah

80/400(standard)

80/500, 80/600(optional)

Service weight(with/without battery)

kg

4760/4200

5330/4770

10

Main Specifications(4)

Model

Unit

CPD30

CPD35

GB3Li

GB3Li

Rated capacity

kg

3000

3500

Load center

mm

500

Lifting height

mm

3000

Free lifting height

mm

145

150

Mast tilt angle (fwd/bwd) (α/β)

deg.

6/10

Fork size (T×W×L4)

mm

45×125×1070

50×125×1070

Wheelbase L1

mm

1715

Tread (front) W3

mm

1000

Tread (rear) W2

mm

990

Overall length (without forks) L’

mm

2525

2550

Overall width W1

mm

1245

Overall height (mast/overhead guard)

(H1/H4)

mm

2075/2215

2180/2215

Seat height

mm

1165

Under-clearance (H5/H6)

mm

135(at mast)/145(in the middle)

Min. turning radius r

mm

2240

2260

Fork adjustment range (outside) Max/min

W5

mm

1060/250

Travelling speed (loaded/unloaded)

km/h

17/18

16.5/17.5

Lifting speed (loaded/unloaded)

mm/s

340/460

325/450

Descending speed (loaded/unloaded)

mm/s

-/500

Gradeability (loaded)

%

18

15

Tyre ,front

28×9-15-14PR

28x9-15

Tyre, rear

200/50-10

Traction motor

kW

16.6 (AC)

Pump motor

kW

13.5 (AC)

Battery

V/Ah

80/400(standard)

80/404、80/500、80/542、80/600(optional)

Service weight(with/without battery)

kg

4490/4030

5100/4640

11

Main Specifications(5)

Model

Unit

CPD30

CPD35

GB7Li

GB7Li

Rated capacity

kg

3000

3500

Load center

mm

500

Lifting height

mm

3000

Free lifting height

mm

145

150

Mast tilt angle (fwd/bwd) (α/β)

deg.

6/10

Fork size (T×W×L4)

mm

45×125×1070

50×125×1070

Wheelbase L1

mm

1715

Tread (front) W3

mm

1000

Tread (rear) W2

mm

990

Overall length (without forks) L’

mm

2525

2550

Overall width W1

mm

1245

Overall height (mast/overhead guard)

(H1/H4)

mm

2075/2215

2180/2215

Seat height

mm

1165

Under-clearance (H5/H6)

mm

135(at mast)/145(in the middle)

Min. turning radius r

mm

2240

2260

Fork adjustment range (outside)

Max/min W5

mm

1060/250

Travelling speed (loaded/unloaded)

km/h

17/18

16.5/17.5

Lifting speed (loaded/unloaded)

mm/s

340/460

325/450

Descending speed (loaded/unloaded)

mm/s

-/500

Gradeability (loaded)

%

18

15

Tyre ,front

28×9-15-14PR

28x9-15

Tyre, rear

200/50-10

Traction motor

kW

16.6 (AC)

Pump motor

kW

13.5 (AC)

Battery

V/Ah

80/400(standard)

80/404、80/500、80/542、80/600(optional)

Service weight(with/without battery)

kg

4490/4030

5100/4640

12

Main Specifications(6)

Model

Unit

CPD30

CPD35

GB2Li

GB2Li

Rated capacity

kg

3000

3500

Load center

mm

500

Lifting height

mm

3000

Free lifting height

mm

145

150

Mast tilt angle (fwd/bwd) (α/β)

deg.

6/10

Fork size (T×W×L4)

mm

45×125×1070

50×125×1070

Wheelbase L1

mm

1715

Tread (front) W3

mm

1000

Tread (rear) W2

990

990

Overall length (without forks) L’

mm

2525

2550

Overall width W1

mm

1245

Overall height (mast/overhead guard)

(H1/H4)

mm

2075/2215

2180/2215

Seat height

mm

1165

Under-clearance (H5/H6)

mm

135(at mast)/145(in the middle)

Min. turning radius r

mm

2240

2260

Fork adjustment range (outside)

Max/min W5

mm

1060/250

Travelling speed (loaded/unloaded)

km/h

17/18

16.5/17.5

Lifting speed (loaded/unloaded)

mm/s

340/460

325/450

Descending speed (loaded/unloaded)

mm/s

-/500

Gradeability (loaded)

%

18

15

Tyre ,front

28×9-15-14PR

28x9-15

Tyre, rear

200/50-10

Traction motor

kW

16.6 (AC)

Pump motor

kW

13.5 (AC)

Battery

V/Ah

80/400(standard)

80/404、80/500、80/542、80/600(optional)

Service weight(with/without battery)

kg

4490/4030

5100/4640

13

Main dismountable parts size and weight

Counterweight

Overhead guard

Mast (lifting height

3000mm)

Max. outline

dimension

Weig

ht

Max. outline

dimension

Weig

ht

Max. outline

dimension

Weig

ht

Model

mm

Kg

mm

Kg

mm

Kg

CPD10-GC1Li /GD1Li

300×825×10

70

500

1050×1414×1

551

72

1010×480×1 9

25

450

CPD15-GC1Li /GD1Li

300×825×10

70

720

1050×1414×1

551

72

1010×480×1 9

25

450

CPD18-GC1Li /GD1Li

300×825×10

70

770

1050×1414×1

551

72

1010×480×1 9

25

450

CPD20-GC1Li /GD1Li

370×890×11

50

790

1100×1457×1 5

15

86

1102×506×1 9

30

745

CPD25-GC1Li /GD1Li

420×920×11

50

1160

1100×1457×1 5

15

86

1102×506×1 9

30

745

CPD30-GC1Li

/GD1Li/GB3Li/GB7Li/G

B2Li

405×8 95×1 2

25

1330

1140×1578×15

73

77

1164×459×19

57

785

CPD35-GC1Li

/GD1Li/GB3Li/GB7Li/G

B2Li

465×8 95×1 2

25

1490

1140×1578×15

73

77

1164×464×19

57

815

14

Ⅲ. Construction, Principle,Adjustment and Maintenance of Forklift

Trucks

1. Transmission System

1.1 General description

The transmission system consists of differential assembly and gearbox & axle

assembly. With direct connection of the drive gear and the drive motor, the travel speed of

the truck can be changed with the speed of the motor, and the travel direction can be

changed with the rotation direction of the motor.

1.2 Differential assembly

The differential is respectively installed on the main housing of the reducer casing

and spindle head assembly of the axle housing through bearings on both ends. The

differential housing of 1-2.5t truck is of integral type. The differential of 3-3.5t truck is of

right and left split type. The differentials include two half-shaft gears and two planet

gears. (See Fig. 1-1)

Fig. 1-1 Differential assembly

15

1. Differential house 2. Planetary gear 3. Half axle gear 4. One-line axle

5. Half axle gear adjusting gasket 6. Duplex stopping locking plate 7. Bearing

8. Bolt 9. Pin 10. Gear ring

Figure 1-2 differential assembly (3-3.5t)

1.3 Gearbox & axle assembly

The gearbox & axle assembly mainly consists of the housing, differential, half shaft,

wheel hubs, brake and the wheels. It is installed in the front of the frame.

The housing of 1-2.5t truck is a fission cast. The housing of 3-3.5t truck is of wholly

casted structure. The tyre with the rim is fixed to the hub with bolts and nuts. The power

is transmitted to the half-shafts through the differential and drives the front wheels

through the hubs. Each hub is fixed on the housing with two tapered roll bearings, so that

the half-shafts bear only the torque transmitted to the hubs. In the inside of the hub are oil

seals to prevent water and dust from entering or oil leakage. (See Fig. 1-2)

The tyre, rim and the pressure of the front wheel are followed. (See Table 1-1)

Table 1-1

16

Truck model

1t,1.5t,

1.8t

2t,2.5t

3t

3.5t

Tyre size

6.0-9-10PR

6.0-9

23×9-10-16PR

28×9-15-14PR

28×9-15

Rim size

4.00E

6.50F-10

7.00-15

Tyre pressure

860kPa

Solid tyre

1030kPa

830kPa

Solid tyre

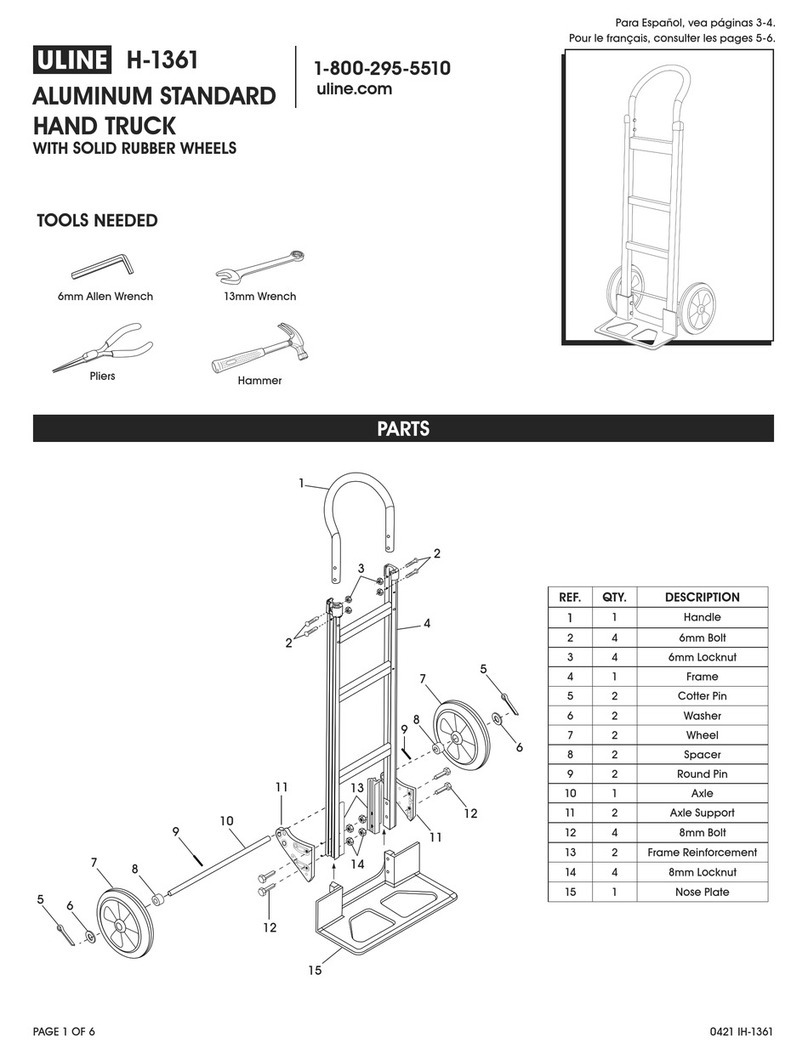

Fig. 1-3 Gearbox & axle assembly

(1) Differential assembly (2) Main housing of the reducer casing (3) Spindle head

assembly of the axle housing Ⅰ(4) Connecting plate (5) Brake assembly (R) (6)

Brake drum hub assembly (7) Half-shaft Ⅰ(8) Oil seal AE2483E0 (9) Bolt

(10) Washer 20 (11) O-ring seal 90×5.3 (12) Nut M30×1.5 (13) Washer 30

(14) Bearing 32208 (15) Dual gear Ⅱ(16) Bearing 6010/C3 (17) Washer 12

(18) Bolt M12×40 (19) Oil seal AE2791A0 (20) Pinion (21) Bearing 6208

(22) Dual gearⅠ(23) Bearing 6206 (24) BoltM20×1.5×55 (25) Bearing 32915

(26) Half-shaft Ⅱ(27) Spindle head assembly of the axle housing Ⅱ(28) Washer

75 (29) Nut M75×2 (30) Cone nut (31) Bolt M18×1.5 (32) Brake assembly (L)

Note: the bolts (9)(18)(24) should be applied with GY-340 adhesive; the o-ring

shown in (11) used on 1-1.8t truck is 75×5.3 and other trucks are 75×5.3.

17

Fig. 1-4 Gearbox & axle assembly(1-1.8t,2t,2.5t)

Figure 1-5 reducer and differential (3-3.5t)

This manual suits for next models

5

Table of contents

Other HELI Truck manuals

HELI

HELI CQDH13 User manual

HELI

HELI CPD15 Installation and operating instructions

HELI

HELI green Series User manual

HELI

HELI CBD35-530 User manual

HELI

HELI CBD15J-Li2 Series User manual

HELI

HELI G3 Series Installation and operating instructions

HELI

HELI gieen Series Installation and operating instructions