HELI green Series User manual

S274-3:2020

1.6-1.8t

Electric Narrow Aisle

Reach Truck

OPERATOR’S

MANUAL

FOREWORD

This manual provides the proper operation to operator, service man and

administrative person of the reach truck. Read this manual carefully before operation

to exert the capacity and enhance efficiency of reach truck.

The manual is based on truck with standard equipments, other kinds of truck is

explained only in different parts.

If you have any questions during using, please contact with HELI specified sale

point for service.

This manual content might not correspond with the actual truck because of the

improving of our products and using method.

Dangers during operation, inspection and maintenance can not be predetermined

and monitor by us in user actual operation.

For the operation, inspection and service not listed in the manual, please take

into consideration by yourself for safety reason.

Symbols are corresponding meanings used in the manual and truck plates are

followed:

Symbol

Meaning

DANGER

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury. You must observe this instruction.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury. You must observe this instruction.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, could

result in minor or moderate injury. You must observe this instruction.

NOTE

Indicates a statement of directly or indirectly related to the safety of

personal and maintain of the truck.

CONTENTS

I. About use method…………………………………………………………………1

1. Main use of reach truck……………………………………………………..1

2. Working plan and environment………………………………………………2

3. Travelling road……………………………………………………………….6

4. Selecting driver………………………………………………………………6

5. Truck and load………………………………………………………………..8

6. Inspection…………………………………………………………………….10

7. Transporting…………………………………………………………………11

8. What vehicle the reach truck is……………………………………………..11

9. Driving…………………………………………………………………….. .15

10.Lifting………………………………………………………………………22

11. Parking…………………………………………………………………….27

12. Inspection and repair………………………………………………………28

13. Plates………………………………………………………………………32

II. Operating device…………………………………………………………………39

1.Name of parts………….…………………………………………………39

2.Operating device and using method…………..………………………………40

III. Operation of the truck…………………………………………………………..48

1. Notes on new truck usage…………………………………………………48

2. Relationship between load and stability of truck ………………………….48

3. Load center and load chart………………………………………………….49

4. Truck stability………………………………………………………………49

5. Transporting of the truck…………………………………………………….50

6. Note on get onto or get out of the lorry…………………………………….50

7. Operation of the truck………………………………………………………51

8. Battery usage……………………………………………………………….54

9. Loading and unloading………………………………………………………57

10. Vehicle storing……………………………………………………………….60

IV. Inspection………………………………………………………………………..62

1. Inspection prior to operate……………………………………………………62

2. Periodic inspection…………………………………………………………65

1

I. About use method

1. Main use of reach truck

The main use of reach truck is handle and stack the loads that on the pallets.

It is prohibited to use it in prohibitive applications.

The prohibitive applications refer to travel with human riding on, lift human up,

tow other vehicles and so on. The truck can not be used in the prohibitive

applications.

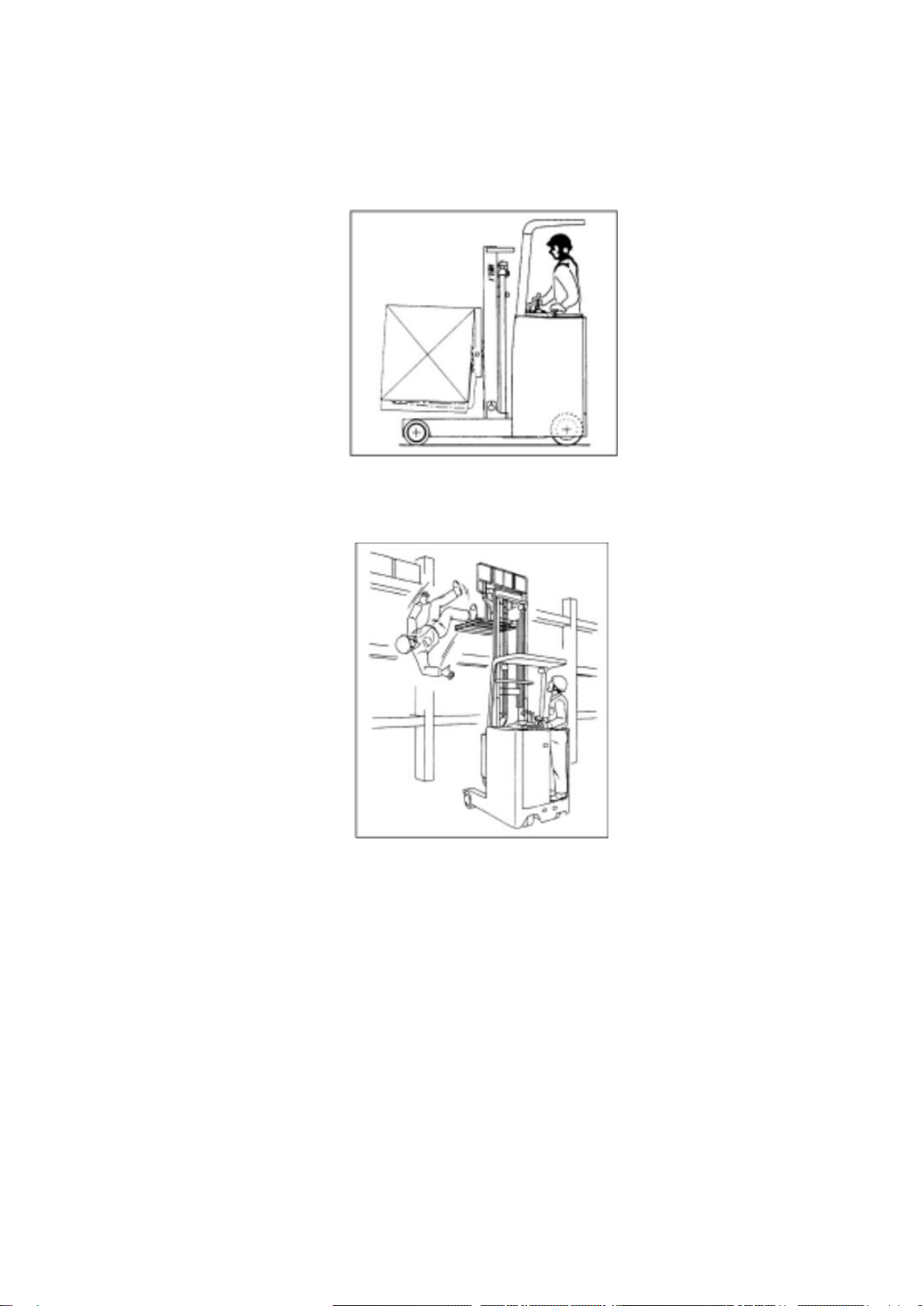

Examples of prohibitive applications:

Lift with people standing on fork or pallet

Stand on the fork to press the goods

Hoist the goods with steel wire hang on the forks directly

Tow other trucks

2

Push the loads or other trucks with forks

Open or close the doors of other trucks with forks

2. Working plan and environment

(1) Set down working plan and discuss the plan well

You must decide the travel route and the method of working before start and

discuss the safe problem well.

(2) Regulate limit speed

You must regulate limit speed in working environment and set striking plate in

order to show clearly.

(3) Avoid dropping

Set protector on sideways or platform’s edges in order to avoid reach truck

dropping.

3

(4) Point out travel area of reach truck and clean up the load

Point out travel area of reach truck and clean up the road in the travel area in

order to avoid obstacle.

(5) Prohibit passerby to come into working area

Prohibit passerby to come into working area and prohibit the guider of the truck

to contact with reach truck.

(6) Prohibit the reach truck without license to come into working area

Prohibit the reach truck without license to come into working area and set a clear

sign.

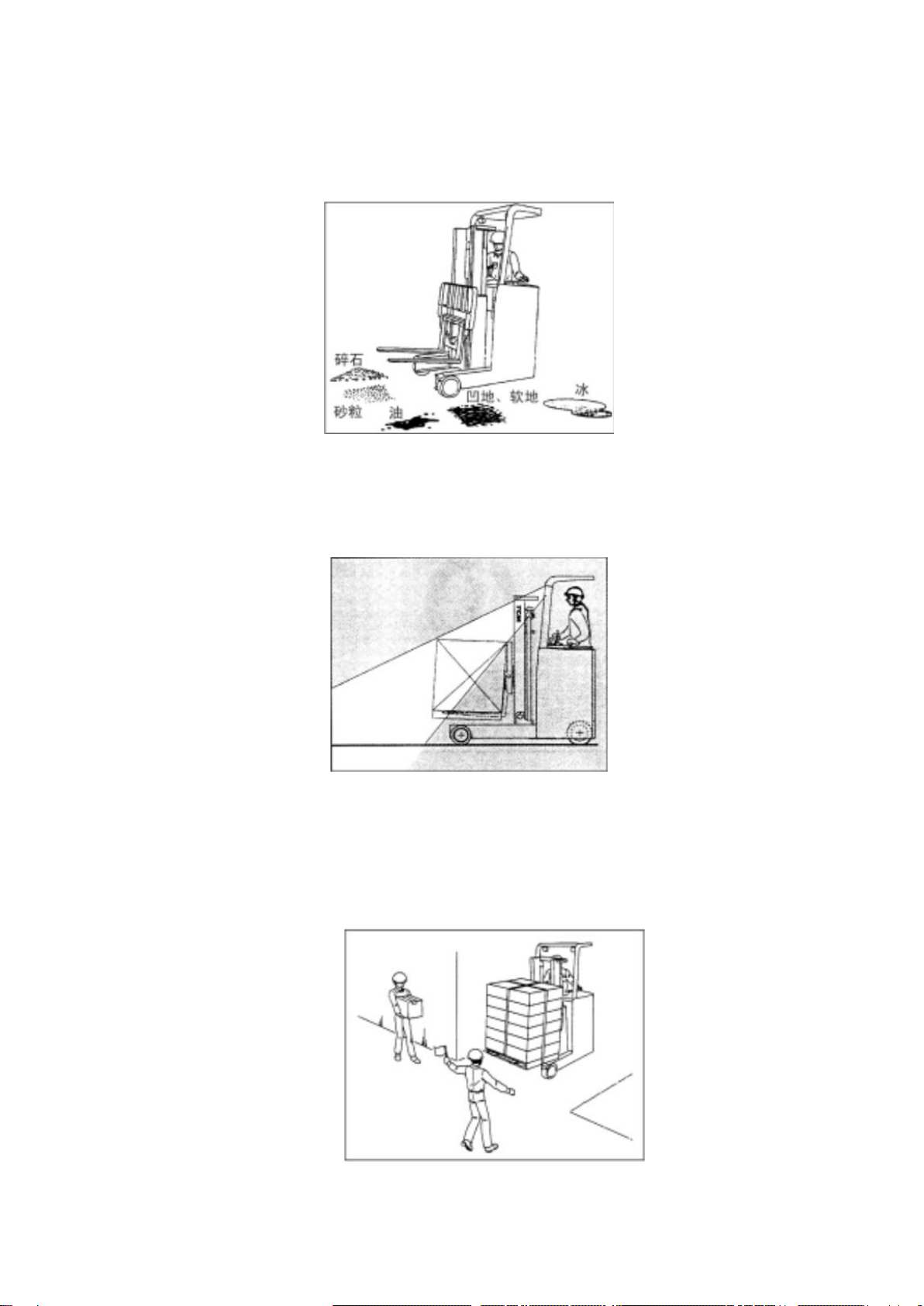

(7) Keep good condition of road surface and wipe off oil and grease

4

Clean up working area, keep good condition of road surface and wipe off oil

and grease on the road.

(8) Lighting for operation area is needed for safety working

It is difficult to find passerby and obstacle on dark way and it is very dangerous.

Keep brightness and full of full of sunshine on way and working area.

(9) Arrange a guider when working in narrow area

Arrange a guider when working in narrow area or working with other works and

other truck. Do working according to the guider’s lead.

5

(10) Affirm contact method in emergent condition

Affirm contact method in emergent condition in order to deal with fire, accident

and other unpredictable things properly.

(11) Set and affirm fire extinguisher

Set fire extinguisher to avoid fire hazard, accident and other unpredictable thing.

Use the fire extinguisher according to its operating rules.

(12) Safety precautions in danger

Set a clear sign in dangerous place in order to

alarm the truck to keep away from assisted

(13) As a motor vehicle, the truck should only be used

in the following condition:

a) Temperature: -25℃ to 40℃

b) Relative humidity:≤90%

c) Altitude: ≤1200m

(14) The stability of the truck will be affected by the

6

power and direction of the wind outside, so do no work in strong wind to make sure

people and truck safety.

3. Travelling road

(1) Prohibit travel on public road

Reach truck is the special vehicle for indoor use.

It is different to go through ramp and rough road for its small and compact

structure. Reach truck will upset if go through ramp and rough road. In other hands, it

will block the travel of other vehicle and person’s pas for its low speed. If the wheel is

out of round or the status of the road surface is not good, it will raise the running

noise.

Prohibit travel on public road. Only use indoor.

4. Selecting driver

(1) Wear safety clothes

Please wear proper safety clothes when driving. Improper clothes may be caught

by operating levers or pedal which may cause truck mis-moving.

Be sure to wear safety helmet and safety shoes.

Please wear other necessary protective clothes according to working area

condition

(2) Safety education on goods stacking

7

Goods stacking is for storage, it is not to put goods on platform, but stack goods

together.

If goods are not stacked accurately, goods will collapse and it will threaten driver

and other people.

It is necessary to make safety education for the people carrying out stacking

operation.

(3) It is essential to make safety periodic education for experienced driver

Periodic education every five-year. Structure of vehicle will change and rule

of law will change for technique renovation.

Make safety education when operation method and equipment using method

have important change.

Because the fast development of truck structure, application of microcomputer

and automatic devices and changes of law, it is necessary to receive the courses from

expert.

(4) Do not let someone operate the reach truck when he is tired or have poor health.

Do not let someone operate the reach truck when he is tired or have poor health

because accidents may be caused by absent minded.

8

5. Truck and load

(1) Do not use the reach truck when its overhead guard is dismantled.

(2) Modifications shall not be carried out by user at will.

Modifications on truck or attachments that affect performance, safe construct and

strength shall not be performed.

For example, modifications that enhance the weight of counterbalance shall not

be performed without the written approval of our company.

(3) Decal must be put on obvious position

You must paste new plate when it damaged or lost.

Check the plate in periodic checking.

(4) Do not over trust overhead guard

The overhead guard is used to protect the driver when goods are falling from the

top of head. But it does not mean it can withstand the impact of all falling goods.

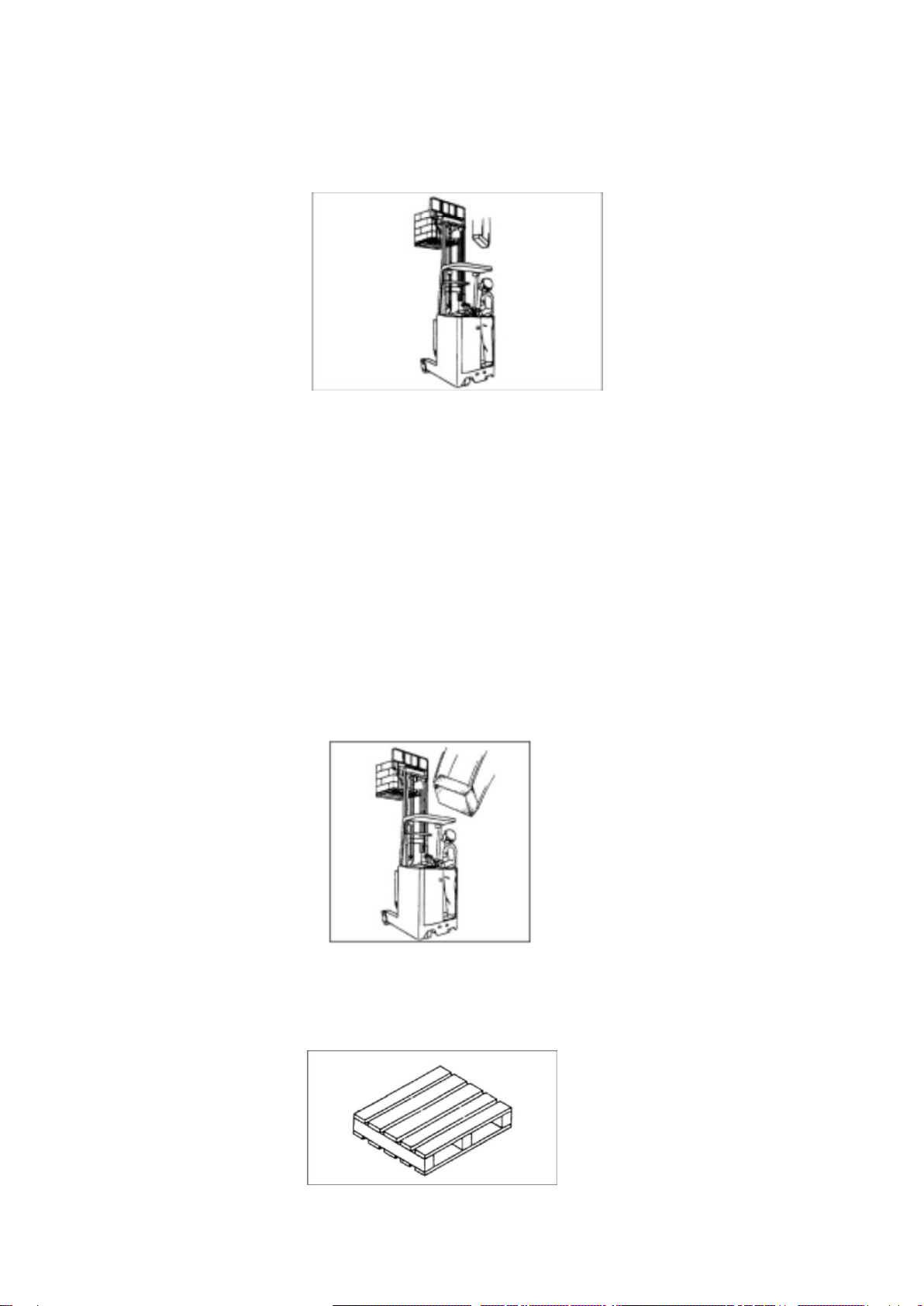

(5) Using a hard pallet

9

The pallet must endure the weight of load. Worn-out pallet must be repaired in

time.

(6) Make sure to load and unload the goods in stable and safe condition.

Avoid off-center loads or falling loads. Make sure to load and unload the goods

in stable and safe condition.

(7) Be careful of the capacity of ground

The reach truck is heavy. 80%-90%of reach truck weight is center on front wheel

when the reach truck is loaded. You must investigate the ground of warehouse, and

enhance the quality of ground if necessary.

6. Inspection

(1) When operation, have a good habit of inspection.

10

Operator should inspect the truck before operation and if there is any fault, report

to administrative person.

(2) Inspect regularly and make a record.

Inspect monthly and annual, repair it immediately if there is any fault. the

inspection should be carry out by professionals because special technique and

equipments are needed. The record of inspection must be saved three years.

(3) Change the important parts regularly.

Name of safety parts

Term

1

Pipe for lifting system

1~2

2

Chain s of lifting

2~4

The items listed above must be replaced for a fixed period because they are very

important for safety.

(4) It is strictly prohibited to operate fault truck.

Before driving you should check truck carefully. If there is any fault, hang a

warning plate on the truck and then remove the key and report to the administrative

person.

(5) Assign a guider for truck maintenance and attachments working

Assign a guider and do according to his command.

The truck body and parts are heavy and some place have high pressure. Be care

when repair.

11

7. Transporting

Load and unload the goods on flat and solid surface. Besides, take care of

connecting plate length, width and strength and make sure it is reliable and safe. In

rainy days, use anti-slip connecting plate or stop working.

When handling goods from or to the truck, it is very safe to use the truck

assembled with jack and winch.

8. What vehicle the reach truck is

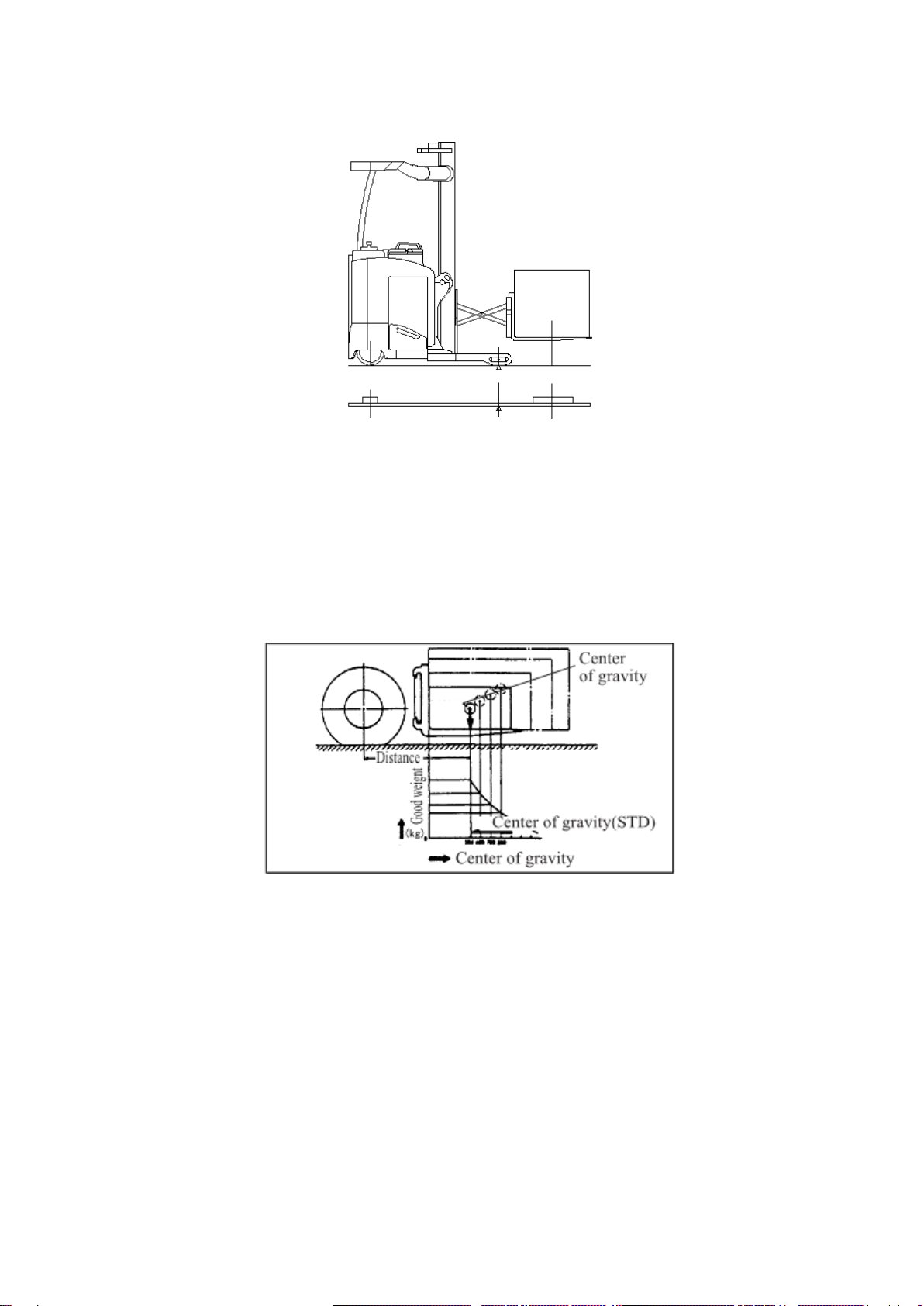

(1) Keep the balance of the truck

The reach truck is equipped with the fork in the lifting system that can move

forward and backward. The supporting point of the reach truck is its front wheels

which balance the truck’s center of gravity with the goods’. For this reason, the center

of gravity of the truck together with the goods’are important for truck safety.

The stability of the truck will be improved a lot when the fork is drawn back.

12

Load wheel supporting point load weight

(2) Be sure the center of the goods’gravity

The goods can be boxlike, board like, stick and all other kinds of shape.

To estimate the stability, it is important to well-known the center of gravity of all

kinds of the goods shape.

(3) The variety of the center of its gravity

The combine barycenter of the truck itself and the loading determined the truck’s

stability. While unloading, the combine barycenter is the truck’s center gravity itself.

While loading goods, the barycenter combined the truck’s barycenter with the loading

goods. The barycenter changed while the mast tilt forward or backward or lift the fork

arm. Tor this reason it changed the combine barycenter also. In addition, the truck’s

barycenter depend on the following facts.

13

The size, the weight and the form if the loading

The height of the loading

The tilt angle of the wheel

The material of the wheel

The acceleration, deceleration and the rolling radius of the truck

The road status and the gradient of the road

The type of the attachment

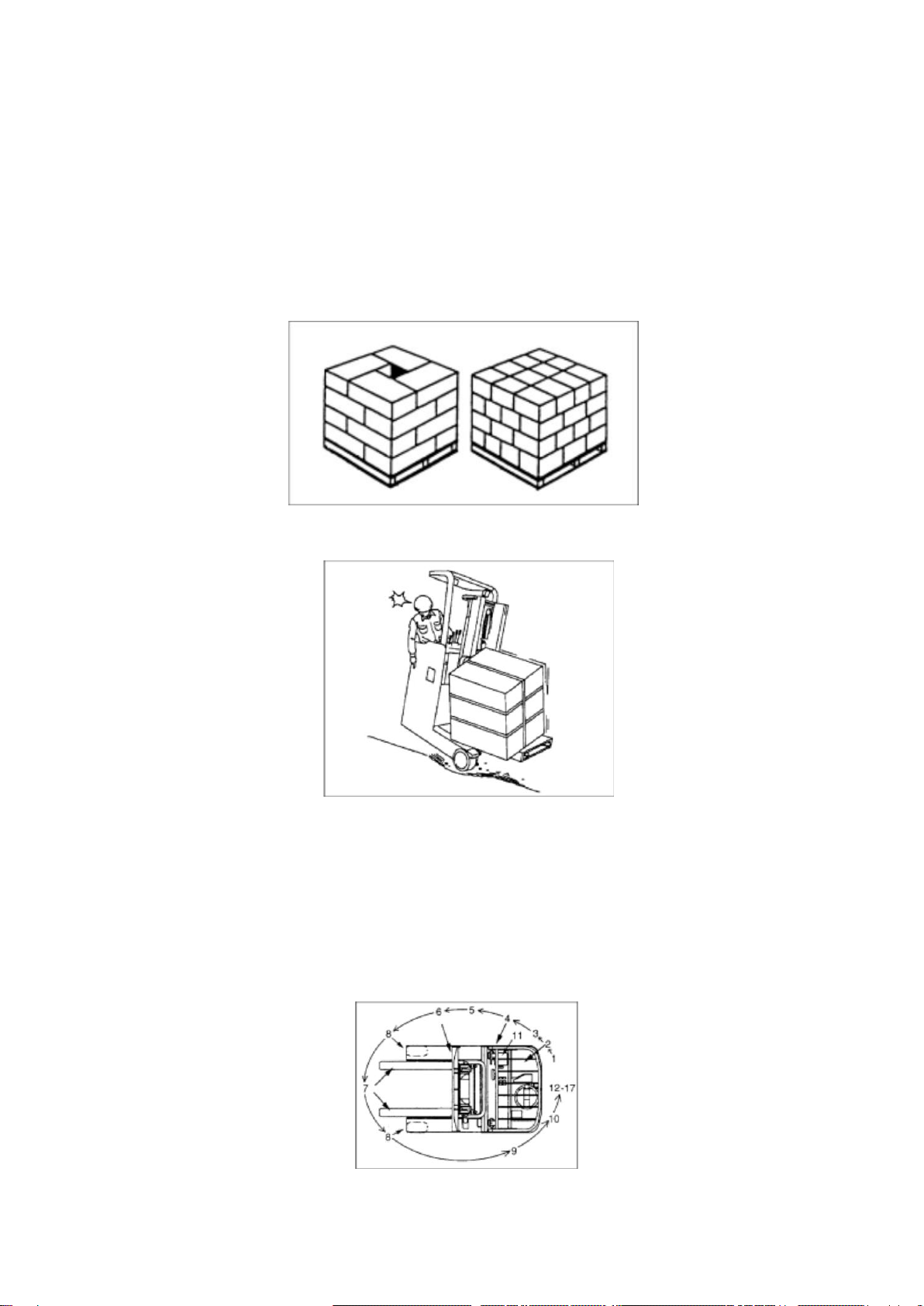

To level off the truck, the combined center-of-gravity shall be located in the

interior of triangle composed by the ground contacting points of left front wheel, right

front wheel and drive wheel. If the combined center-of-gravity exceeds the position of

front wheel and tipping forward with the front wheel as supporting point will be

resulted. If the combined center-of-gravity exceeds the right or left side, tipping

towards left or right side will be resulted.

14

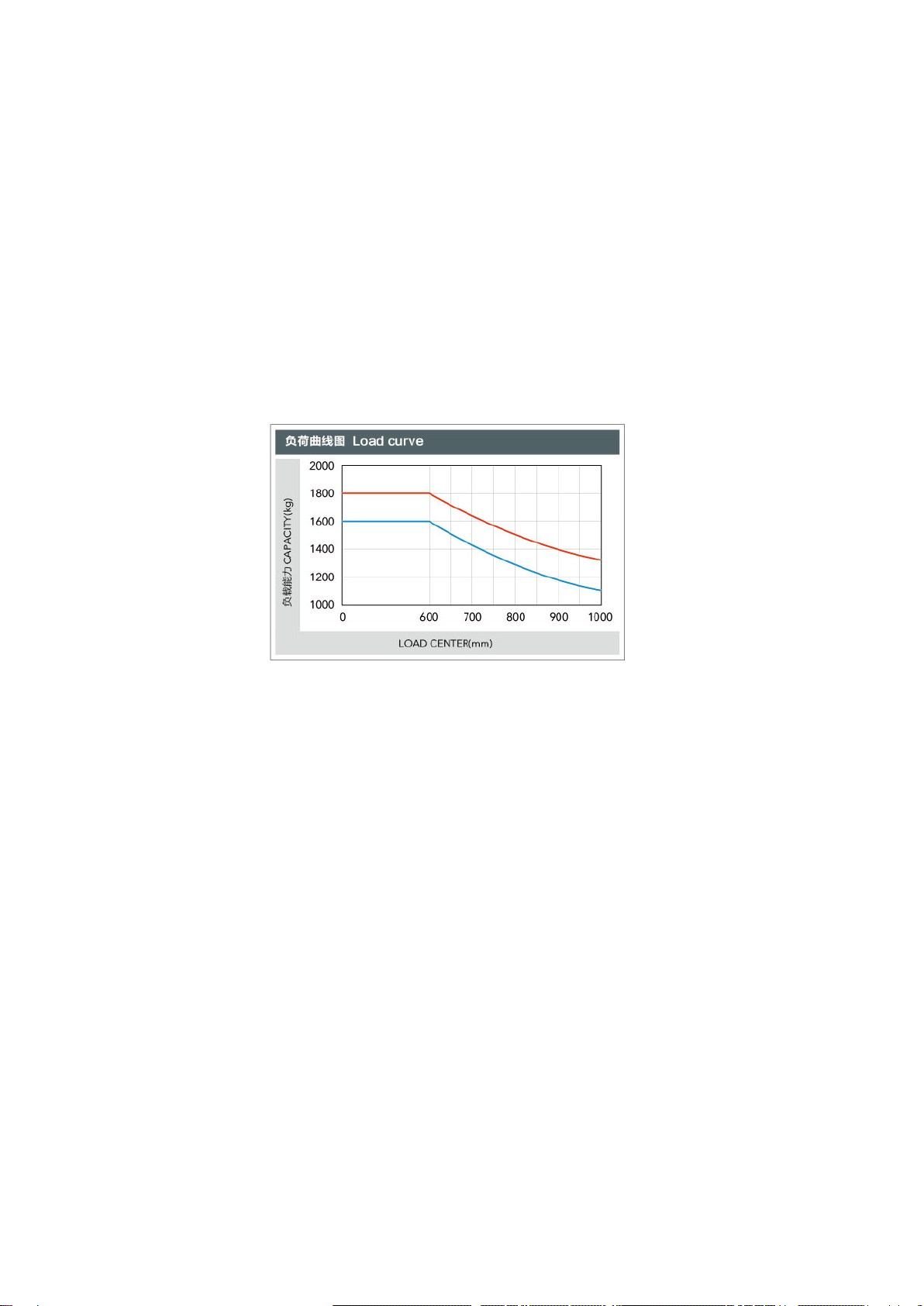

(4) The max loading weight (the loading weight and its center)

The horizontal distance from the center of gravity of the loading to the bottom of

the fork arm (in front of the load backrest) called the load center distance. The

maximum weight that can load in the just load center called the maximum loading

capacity.

The capacity chart showing the relationship of the maximum loading capacity to

the load center distance. It paste in the truck as a plate. The load center moves forward

to the fork arm as well as the combine weight and the load capacity decrease too.

load curve

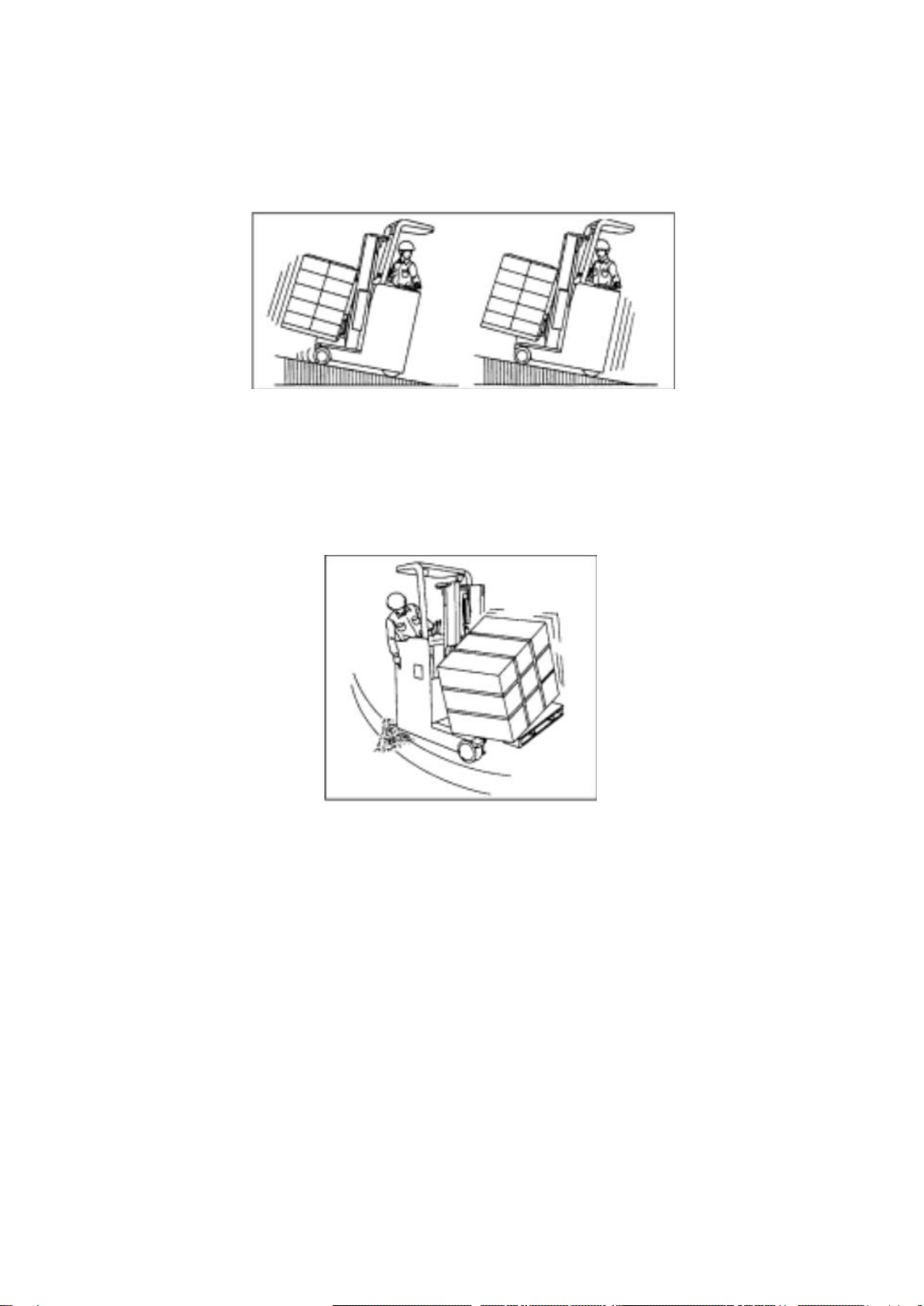

(5) Acceleration, deceleration and the rolling radius of the truck

A quiescent object will be keeping its state if out of outside force. And it is

applicable to the moving object also. This is called inertia.

The inertia is of the same direction when the truck moving forward. The inertia

will increase with the increasing of speed. While braking, the inertia will make the

truck overturn to the forward. It is dangerous while braking emergently for it will

largen the overturn force. in addition, when rolling the truck, the rolling center’s

centrifugal force acts. The truck makes the truck overturn to the outside, especially the

stably area around the truck. So you should decelerate the truck while rolling

overturn.

When the loading is lifted, the combine barycenter will rise too. It is dangerous

to overturn to the forward or sideward.

15

9. Driving

(1) Read this manual before driving

Prior to operation, read this carefully to ensure safety and efficient material

handling by proper driving and maintenance,

This manual should be kept by operator and read it carefully.

(2) Attention before the start

When you start the truck, please obey the following rules:

Check if all operating levers position are in neutral position

Make sure foot is away from braking pedal

Begin operation after ensuing the safety around

WARNING

Operate the truck on designated operating position.

Prohibition of reach lever operating when your body is between the

mast and chassis or this will lead to a dangerous condition unexpectedly.

Operate the mast on the designated operating position.

(3) Change the direction after the truck is stopped.

Sharp direction changing is very dangerous.

(4) Do not drive or make a turn with forks lifted up.

When travelling with lifted forks, this could cause an unstable condition and a

turn over of the truck.

(5) Lower the center of gravity

Tilt the mast backward and keep the fork about 20cm above the ground when

16

travelling in order to lower the center of gravity.

(6) It is prohibited to lift or tilt sharply when loaded.

Do not lift or tilt the mast sharply when it is loaded. If so, the truck may have a

danger of overturn.

(7) Rude operation such as sudden start, sudden stop, sudden steering and so on are

prohibited.

Rude operation such as sudden start, sudden stop, sudden steering and so on are

prohibited. when steering, please slow down. The truck will have a danger of overturn

when making a sharp steering without load because the rear of the truck is very heavy.

(8) Driving on a slope

Do not make a turn and travel horizontally on a slope or truck may have a

danger of overturn.

Take care of the road height when there is a sharp slope so as to avoid fork

or pallet contacting with ground.

When traveling on a slope without load, travel backward when go up the

slope and travel forward when down a slope.

When traveling on a slope with load, travel forward when go up the slope

and travel backward when down a slope.

17

When down a slope, make full use of brake system.

When travelling on a slope, do not make engine power off.

(9) Do not drive into a weak road shoulder.

Do not drive into a weak road shoulder because it has a danger of collapse.

Keep a safe distance with the road shoulder in narrow road so as to avoid truck

falling.

(10) when operating in a container

It is prohibited to travel on the platform edge because it has a danger of

falling down which may even cause death.

Check the connecting plate capacity and its safety. It is prohibited to use

improper connecting plate.

Apply the hand brake of the lorry and wedge the four wheels to prevent it

from slipping.

Lift the truck with jack to prevent the truck from sinking when the reach

truck travels in because of heavy load.

Table of contents

Other HELI Truck manuals

HELI

HELI CBD15J-Li2 Series User manual

HELI

HELI G3 Series Installation and operating instructions

HELI

HELI CBD35-530 User manual

HELI

HELI gieen Series Installation and operating instructions

HELI

HELI G Series Installation and operating instructions

HELI

HELI CPD15 Installation and operating instructions

HELI

HELI CQDH13 User manual

Popular Truck manuals by other brands

Sealey

Sealey Premier CST989HD quick start guide

freightliner

freightliner Run Smart ECASCADIA PE116DC 2022 Maintenance manual

EINHELL

EINHELL TC-PT 2500 S Original operating instructions

Sealey

Sealey Power Products HPT1000 instructions

Peterbilt

Peterbilt 348 2017 Operator's manual

Scheppach

Scheppach DP5000 Translation from the original instruction manual