Hexagon MT-45 User manual

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 15, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

FCCC MT CNG

1

FCCC MT CNG

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 24, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

1

Diagnostic Service Manual

Freightliner Custom Chassis Corporation (FCCC) MT

CNG Fuel Systems

FCCC Model Wheelbase

MT-45 168-in

MT-55 178-in

MT-55 208-in

DSM.0008 Ver. 1.0

February 24, 2022

PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 15, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

FCCC MT CNG

2

FCCC MT CNG

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 24, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

2

Preface FCCC MT CNG

This manual is designed as asupport document for trained technicians in the maintenance and diagnostic

procedures of the compressed gas fuel system provided by Hexagon Agility®.

No attempt shall be made to fill, install, maintain, or repair this system until this manual and all referenced supporting

documentation have been read and fully understood.

Original Equipment Manufacturer (OEM) replacement parts may be obtained by contacting Freightliner Customer

Chassis Corporation (FCCC).

Fuel system warranty or non-warranty product support may be obtained by calling or emailing Hexagon Agility®

Customer Care and Technical Services (CCTS).

Please provide your name, phone number, email address, and complete vehicle information:VIN, year,

make, model, mileage, unit number vehicle owner, and current vehicle location.Aservice advisor will contact

you to arrange vehicle repair or ship apart.

Do not remove components from original packaging until necessary. Any components

that are to be reinstalled must be thoroughly cleaned, inspected, and stored in a

satisfactory manner until reinstallation.

All replacement parts must adhere to the accepted standards and ratings as specified

by Hexagon Agility®. Use of any part that is not approved by Hexagon Agility®is not

recommended and may compromise the integrity and safety of the system.

Preface FCCC MT CNG

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 15, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

FCCC MT CNG

3

FCCC MT CNG

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 24, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

3

Table of Contents FCCC MT CNG

Page

Preface 2

Acronyms 4

Safety 5

Warning and Signal Words Used in this Manual 5

Qualified Personnel 6

Safety Equipment 6

General Safety Precautions 7

Vehicle Fire Procedure 8

First Responder Guide 8

Codes and Compliances 8

Return to Service Inspection 8

Fuel System Schematic 9

Fuel System Troubleshooting and Diagnostics 11

Electrical 13

Connector Location View 13

Connector Pin-Out 15

Fuel Gauge Non-Operation 18

Crank, No-Start 36

No-Crank, No-Start 47

Engine Misfire Diagnostics 60

Fuel System Depressurization 69

Defueling 75

Filter Element Replacement 85

System Verification 95

Removal and Retightening of Tube Fittings (Appendix A. WI.0199) 96

Hexagon Agility® Customer Care and Technical Service 98

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 15, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

FCCC MT CNG

4

FCCC MT CNG

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 24, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

4

Acronyms FCCC MT CNG

AGA American Gas Association HP high-pressure

ANSI American National Standards Institute IPC instrument panel cluster

ASM assembly LP low-pressure

Bar metric unit of pressure MIL malfunction indicator light

CGA Compressed Gas Association NFPA National Fire Protection Association

CNG compressed natural gas NGV natural gas vehicle

CSA Canadian Standards Association NSC National Standards of Canada

DMM digital multimeter OEM original equipment manufacturer

DS driver side PRD pressure relief device

ECM electronic control module PS passenger side

ECU electronic control unit psi pounds per square inch

FMI failure mode identifier SPN suspect parameter number

FMM fuel management module

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 15, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

FCCC MT CNG

5

FCCC MT CNG

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 24, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

5

Safety FCCC MT CNG

Hexagon Agility® provides safety guidelines to ensure the safety of personnel servicing and / or operating

compressed natural gas (CNG) equipment. All personnel involved must adhere to the standards provided,

specialized training, along with federal, state, and municipal laws and regulations.

CNG presents unique characteristics that are distinctive from gasoline and diesel fuel. CNG when stored at ambient

temperature and 3600 psi (250 Bar) is in a gaseous state.

CNG vehicles are equipped with temperature activated pressure relief devices (PRDs) to evacuate stored fuel

safely in the event of a thermal event. PRDs trigger when cylinder(s) surroundings or internal enclosure

temperatures exceed 220°F (110°C) and use vent lines with dedicated exits to evacuate the pressurized gas. The

vent tube design allows for controlled evacuation/flaring under certain environmental conditions.

Hexagon Agility®minimizes these potential hazards through state-of-the art design and testing practices. Always

observe the procedures and recommendations of this manual.

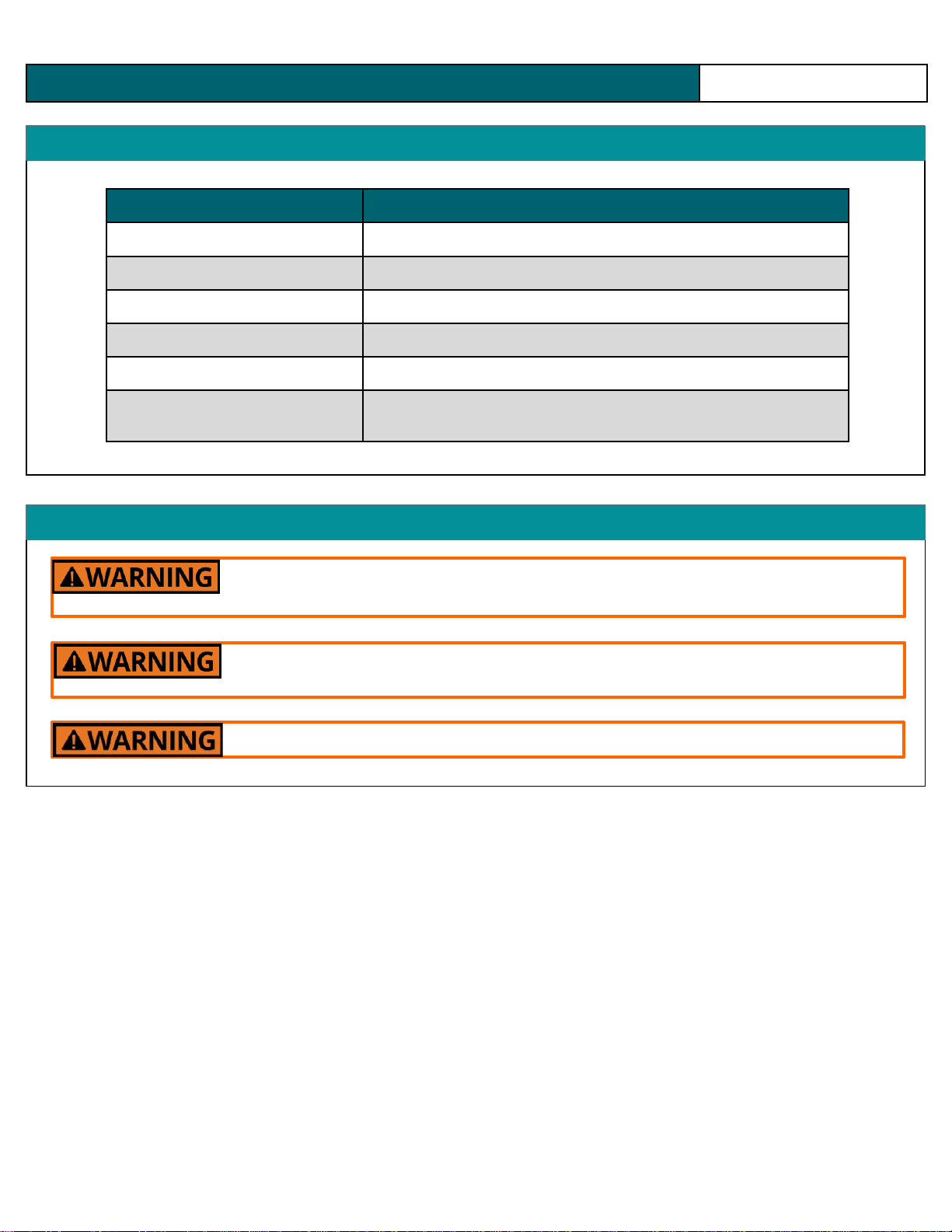

Warning and Signal Words Used in this Manual

Symbol Definition

DANGER indicates a hazardous situation which, if not avoided, will result in death

or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to physical injury, such as best

practices

or tips to help an operation or procedure go smoothly and prevent equipment

damage.

SAFETY INSTRUCTIONS indicate specific safety-related instructions or

procedures.

CRITICAL CHARACTERISTIC − Product feature directly affects:

Safety of vehicle users, people nearby and maintenance personnel, or

Regulatory compliance.

MANUFACTURING CHARACTERISTIC −

A product feature solely used to improve manufacturability or maintain process

control.

A process parameter or Step that has a significant effect on achieving a Critical

Characteristic or Significant Characteristic or maintaining material identification/

traceability.

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 15, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

FCCC MT CNG

6

FCCC MT CNG

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 24, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

6

Safety FCCC MT CNG

Qualified Personnel

Safety Equipment

Individuals involved in any aspect of CNG fuel system maintenance, emergency

response, servicing or testing must be properly trained.Individuals who are not

trained are not permitted to service, maintain, test, or inspect asystem.

Observe all recommendations below when operating or servicing aCNG fuel system.

1. CNG safety signage should be visible at all applicable locations as stipulated by federal, state, and municipal

law.

2. Natural gas rated fire extinguishers should be accessible and visible throughout all servicing and fueling areas.

Verify fire extinguishers are charged, up to date, and rated correctly.

3. In case of emergency, self-contained breathing apparatus should be on site in an easily accessible area.

4. Areas designated for CNG fueling systems must have adequate lighting that complies with NFPA code.

5. Protective eyewear and footwear should be worn by all personnel near aCNG system.

6. When locating the source of aleak only use certified leak detecting solutions such as Swagelok Snoop®or

Formula 365 (p/n 10301242)or acombustible gas detector. Any other product or solutions are unacceptable.

7. Only use tools that are in good working order with proper calibration.

8. Wear appropriate attire and PPE while servicing or maintaining any CNG system.

Due to the presence of high-pressure and flammable fuel, CNG fuels systems are a form of hazardous energy

storage.

CNG systems must be maintained and inspected exclusively by trained personnel with qualifications in accordance

with the applicable codes.

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 15, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

FCCC MT CNG

7

FCCC MT CNG

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 24, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

7

Safety FCCC MT CNG

General Safety Precautions

Observe all recommendations below when operating or servicing aCNG fuel system.

Strict compliance with proper safety and handling practices is essential when

operating aCNG fuel system.

1. Verify parking brake is engaged, wheels are chocked, and ignition switch is in OFF position.

2. Follow all maintenance procedures in the order in which they are written, do not skip steps unless with explicit

permission from Hexagon Agility®.

3. Never use an open flame as a source of illumination in proximity to a CNG system. Natural gas is both volatile

and explosive.

4. Any process or procedure that generates sparks, flames, or heated particles is never applicable in designated

CNG area.

5. If a CNG system does require a process or procedure that generates sparks, flames, or significant heat, refer

to ENP-442 for all Hot Work guidelines.

6. CNG fuel delivery systems are to be serviced in designated areas that comply will all federal, state, and

municipal laws and regulations.

7. When performing service or repairs to any portion of the fuel system, install proper lockout/tagout (LOTO)

device and observe all LOTO practices.

8. CNG servicing and fueling areas must be well ventilated as stipulated by federal, state, and municipal law.

9. Perform all maintenance and service procedures in a dust free environment.

10. Never attempt to open system components that are under pressure.

11. Never attempt to depressurize or vent a system by loosening a fitting.

12. A portable fire extinguisher rated for natural gas must be installed on the vehicle in an easily accessible

location.

13. Do not start engine if a CNG leak is detected.

14. Verify all systems are grounded before transferring CNG fuel from one vehicle to another. Transferring CNG

may cause a buildup of static electricity which could discharge and ignite the fuel.

15. Fuel system working pressure is up to 4500 psi (310.2 Bar). Hot weather fill pressures commonly reach 4100

psi (282.6 Bar).

16. Never smoke or produce an open flame near or around a CNG vehicle or a CNG dispensing/filling station.

17. Always ground vehicle prior to fueling or defueling.

18. If the vehicle will be out of service for an extended time, turn the 1/4-turn manual shut off valve to the

OFF/CLOSED” position. To consume residual CNG forward of the 1/4-turn manual shutoff valve run the

engine until it stalls.

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 15, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

FCCC MT CNG

8

FCCC MT CNG

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 24, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

8

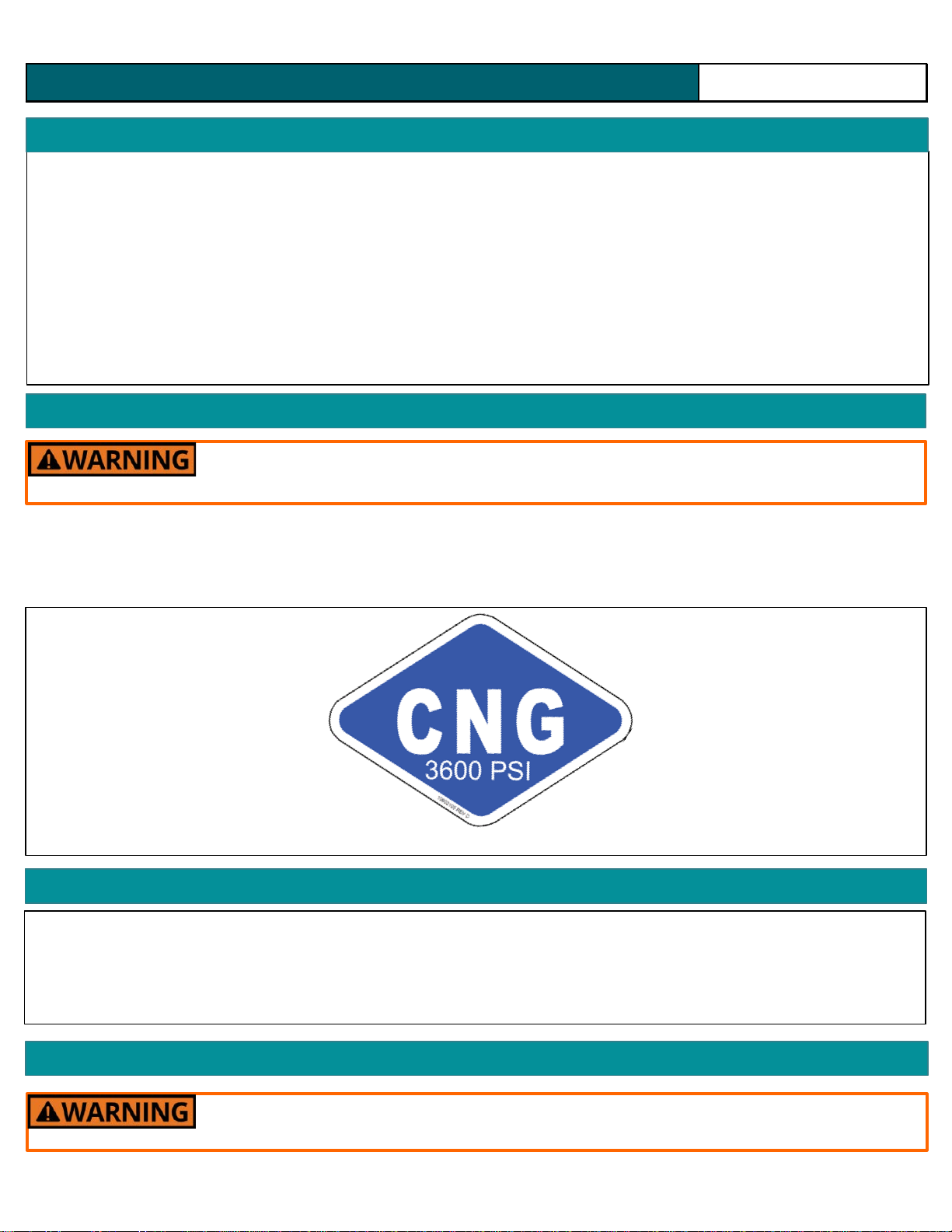

Safety FCCC MT CNG

First Responder Guide

For comprehensive emergency response procedures, refer to Hexagon Agility®

publication ENP-084,“First Responder Guide:CNG and LNG Vehicle Fuel Systems.”

Vehicles equipped with compressed natural gas must have blue reflective decals on the rear of the vehicle

identifying the fuel as CNG.

CNG blue diamond decal, Hexagon Agility®p/n 10602105

Blue diamond CNG decal cannot be installed on rear bumper per U.S. DOT mandate. Side CNG decals must be

installed adjacent to vehicle DOT number.

Codes and Compliances

For complete and detailed information concerning CNG codes and regulations please refer to the following:

USA: NFPA 52

Canada: CAN/CGA B109

North America: ANSI/AGA NGV 3.1 / CGA 12.3 and NGV 12.3-M95

In the event of aCNG fire it is imperative that the vehicle operator acts quickly and efficiently by observing the

following steps:

1. Turn off engine and set parking brake.

2. Get passengers out of vehicle as quickly as possible.

3. Evacuate the area.

4. Call 9-1-1.

5. Notify attending emergency personnel the vehicle is aCNG vehicle.

6. IF possible and only with the proper training:Extinguish fire using an appropriately rated fire extinguisher.

Vehicle Fire Procedure

Return to Service Inspection

If vehicle has been subjected to a fire or collision, the fuel storage system must be

inspected by aqualified inspector before it can be returned to service.

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 15, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

FCCC MT CNG

9

FCCC MT CNG

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 24, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

9

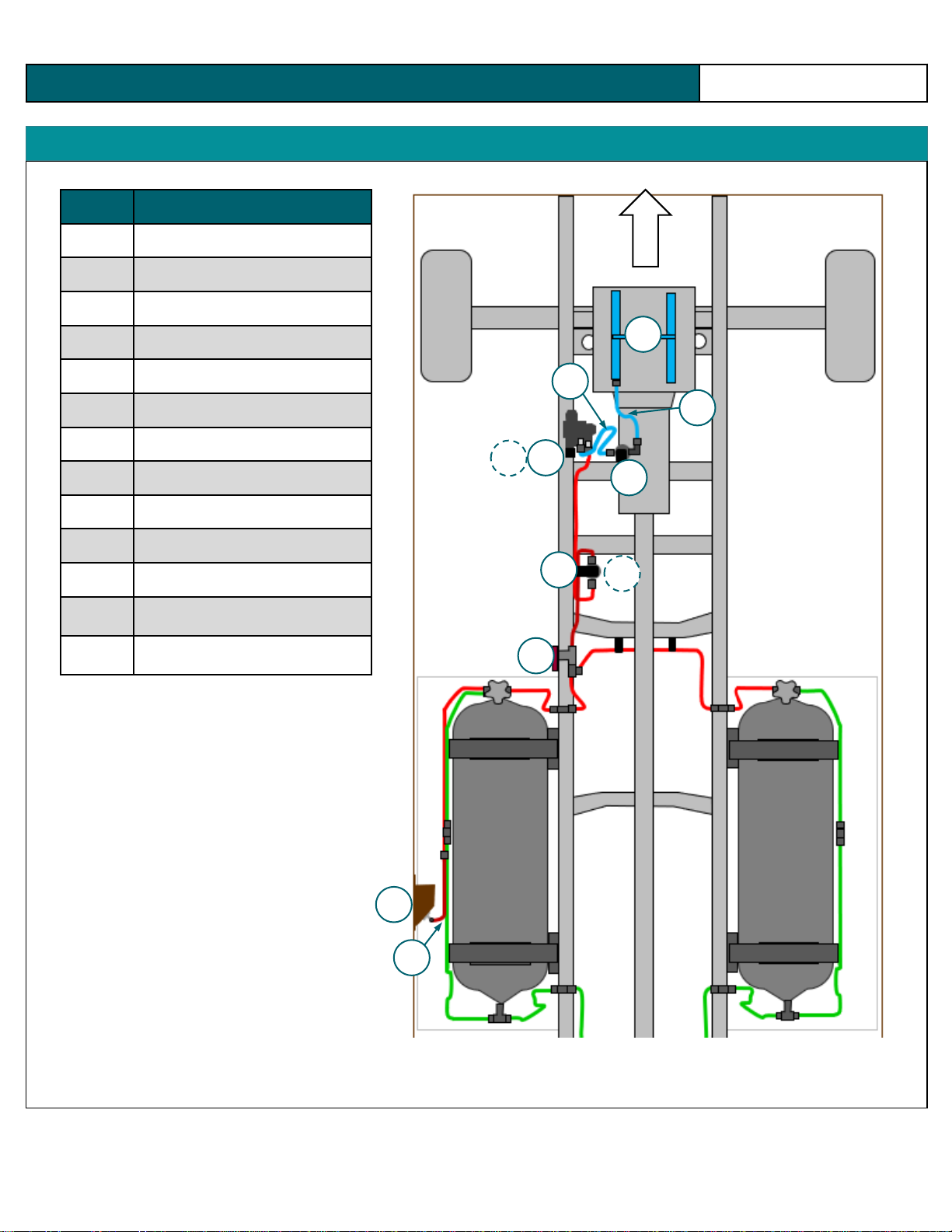

FCCC Fuel System Schematics

Item Description

1fuel fill panel

2HP flexible fuel hose

31/4-turn manual shutoff valve

4high-pressure (HP) fuel filter

5pressure regulator

6* supply solenoid valve (SSV)

7low-pressure (LP) fuel tube

8LP fuel filter

9LP flexible fuel hose

10 fuel rails and fuel injectors

11† bleed valve

▬▬ LP fuel tubes

▬▬ HP fuel tubes

*part of pressure regulator assembly

†located on HP fuel filter

11

3

4

8

79

10

1

FRONT

Fuel Delivery System Schematic

2

65

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 15, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

FCCC MT CNG

10

FCCC MT CNG

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 24, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

10

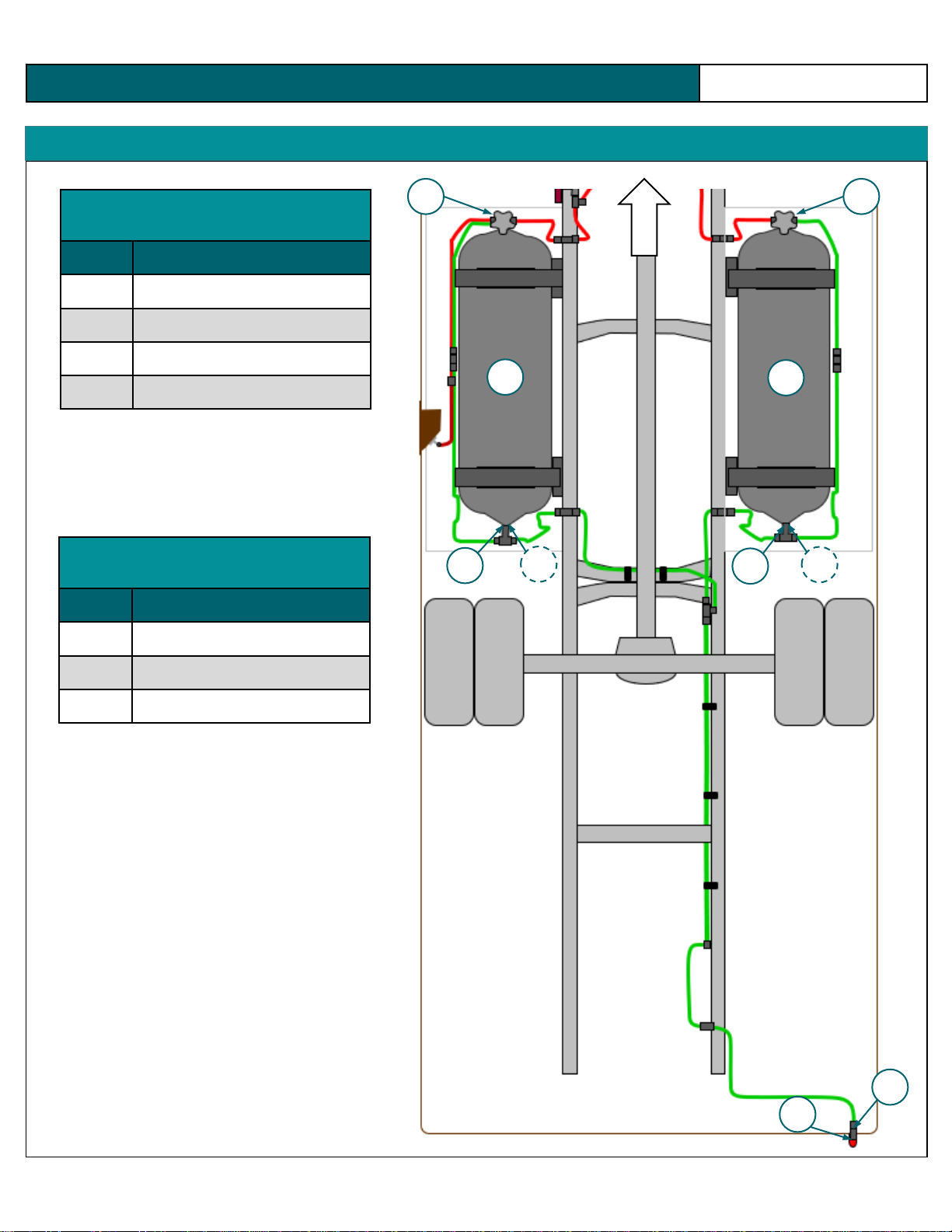

FCCC Fuel System Schematics

Fuel Storage System

Item Description

1cylinders

2cylinder manual valves

3PRDs

4* PRD adapters

*if equipped

Fuel Storage and PRD Vent System Schematics

2 2

1

1

3

FRONT

434

PRD Vent System

Item Description

APRD vent outlet (45°elbow)

B* PRD vent cap

▬▬ PRD vent tubes

*part of PRD vent outlet assembly

A

B

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 15, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

FCCC MT CNG

11

FCCC MT CNG

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 24, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

11

Fuel System Troubleshooting and Diagnostics

The following section covers avariety of potential fuel system faults and their respective solutions.The conditions

addressed in this section are unique to CNG storage systems;however, conditions concerning other onboard

systems may influence or directly cause problems with the CNG storage system.

For any faults not addressed in this manual or for warranty information please contact Hexagon Agility®Customer

Care and Technical Services:

833-4-HEX-CARE, toll-free in the U.S. and Canada

CONDITION: After disconnecting the fuel fill nozzle, CNG flows out of the fill receptacle.

Issue Solution

Fuel fill receptacle O-ring frozen due to gas

expansion

•Close cylinder manual valve(s).

•Wait for receptacle to warm to ambient temperature to check if leak

persists.

•Use a slow fill rate to avoid icing.

Damaged fuel fill receptacle O-ring •Close cylinder manual valve(s).

•Replace O-ring.

Debris in fuel fill receptacle

•Close cylinder manual valve(s).

•Inspect exterior of fuel fill receptacle for blockage or damage.

•If no debris is found, fuel fill receptacle must be removed for internal

inspection.

Damaged fuel fill receptacle –external

evidence •Close cylinder manual valve(s).

•Depressurize fuel system.

•Replace fuel fill receptacle.

NOTE: inspect fill panel check valve when performing this repair.

Damaged fuel fill receptacle –internal check

valve failure

CONDITION: With the 1/4-turn manual shutoff valve in the closed position and the vehicle continues to run

for an extended period, suspect 1/4-turn manual valve fault.

Issue Solution

Valve seat wear / debris in valve does not

allow valve to fully close

•Close cylinder manual valve(s).

•Depressurize fuel system.

•Replace 1/4-turn manual shutoff valve.

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 15, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

FCCC MT CNG

12

FCCC MT CNG

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 24, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

12

Fuel System Troubleshooting and Diagnostics

ISSUE: Poor engine performance (rough idle, lacks power, hesitation, stalls)

Issue Remedy

Low pressure side of fuel system is less than

125 psi (8.62 Bar)

•LP fuel hose restriction

•LP fuel filter clogged

•HP fuel filter clogged

•HP / LP fuel tubes kinked/bent

•pressure regulator fault

•fuel injector(s) fault

•Refer to Engine Misfire Diagnostic procedure section(s) below.

•Ignition system fault

•Induction system restriction

•Exhaust system restriction

•Mechanical engine failures

•Engine sensor fault

•Refer to OEM procedure.

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 15, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

FCCC MT CNG

13

FCCC MT CNG

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 24, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

13

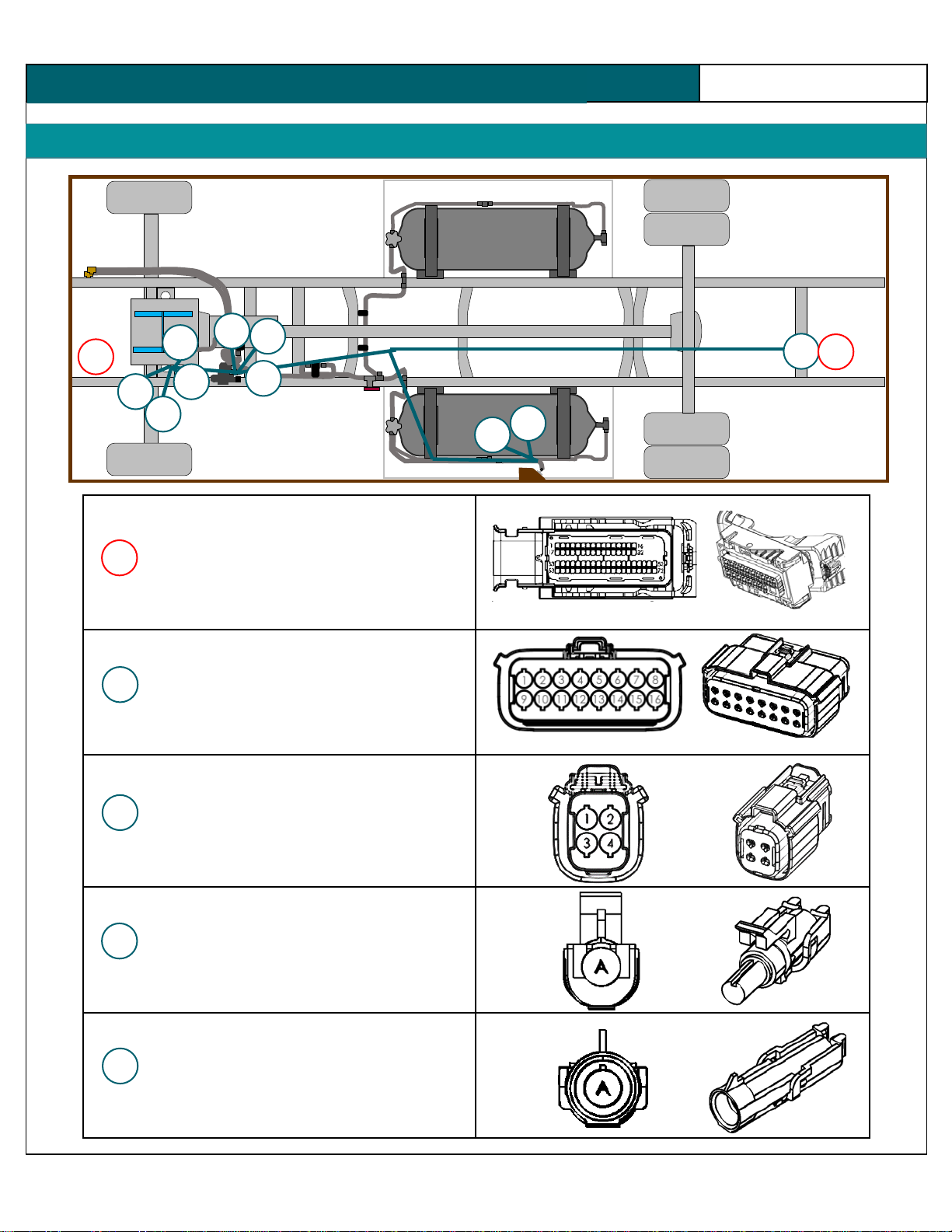

J3 OEM ECU connector located at (DS)

radiator core support. Refer to OEM

manual for pin-out.

C1 Electronic Control Module (ECM)

connector located inside at driver footwell.

C2 Electronic Control Module (ECM)

connector located inside at driver footwell.

IO31 Start Confirm connector located

behind instrument cluster.

IO30 Crank Request connector located

behind instrument cluster.

24

15

Electrical

Connector Location View

3

4

2

1

3910

11

8

5

7

612

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 15, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

FCCC MT CNG

14

FCCC MT CNG

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 24, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

14

G21 Supply Solenoid Ground located

on frame between pressure regulator and

1/4-turn manual shutoff valve.

P31 Pressure Transducer connector

located on pressure regulator.

Y41 Supply Solenoid connector located

on pressure regulator.

G20 Fill Panel Ground located on

bottom of fill panel.

D81 DAP (Drive Away Protection)

located on bottom of fill panel.

F78 Fuel System Harness Interface

located near last crossmember of

chassis.

F79 Connector OEM Fuel Send and

Return Harness

Connector Location View

6

8

7

9

11

10

Electrical

12 AD

C

B

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 15, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

FCCC MT CNG

15

FCCC MT CNG

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 24, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

15

Cavity Circuit Color Description

1409 BRN Low Reference

2604 RED 5V Reference

3 - - NA

4316 GRY Pressure Signal

1

4

2

ECM C2 connector pin-out

IO31 Start Confirm pin-out

Cavity Circuit Color Description

A313 PUR Start Relay Confirm A

Electrical

9

27

6

38

10 14 15 16

Cavity Circuit Color Description

1 - - NA

2313 PUR Start Relay Confirm

3314 BLU Start Relay Request

4 - - NA

5 - - NA

6204 PNK Supply Solenoid (B+)

7312 GRN Drive Away Protection

8204 PNK ECM Power

9408 TAN Fuel Gauge Low Reference

10 315 WHT Fuel Gauge Signal

11 - - NA

12 - - NA

13 - - NA

14 312 GRN Drive Away Protection

15 312 GRN Drive Away Protection

16 104 BLK ECM Ground

ECM C1 connector pin-out

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 15, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

FCCC MT CNG

16

FCCC MT CNG

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 24, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

16

Cavity Circuit Color Description

1409 BRN Low Reference

2316 GRY Pressure Signal

3604 RED 5V Reference

1

2

3

P31 connector pin-out

Cavity Circuit Color Description

A409 BLUE Low Reference

IO30 Crank Request

A

Electrical

Cavity Circuit Color Description

A105 BLK Supply Solenoid Ground

G21 Supply Solenoid Ground

Cavity Circuit Color Description

A104 BLK ECM Ground

G20 Fill Panel Ground

Cavity Circuit Color Description

1204 PNK Supply Solenoid B+

2105 BLK Supply Solenoid Ground

Y41 Supply Solenoid

1

2

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 15, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

FCCC MT CNG

17

FCCC MT CNG

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 24, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

17

AD

Cavity Circuit Color Description

A312 GRN Drive Away Protection

D81 DAP Drive Away Protection

Cavity Circuit Color Description

A104 BLK Supply Solenoid Ground

B315 WHT Fuel Gauge Signal

C406 TAN Fuel Gauge Low Reference

D204 PNK ECU Power

F78 Fuel System Harness Interface

A

A

D C B

Electrical

Cavity Circuit Color Description

A104 BLK Supply Solenoid Ground

B315 PK/WT Fuel Gauge Signal

C406 PK/WT Fuel Gauge Low Reference

D204 PK/WT ECU Power

F79 Connector OEM Fuel Send and Return Harness

C

B

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 15, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

FCCC MT CNG

18

FCCC MT CNG

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 24, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

18

Fuel Gauge Non-operation

Fuel Gauge Non-operation

Fuel gauge non-operation occurs when the gauge displays empty while pressure greater than 600 psi(41.3 Bar) is

indicated on the HP fuel gauge.

Possible causes include the following:

1. Power or ground insufficient at pressure transducer

2. Power or ground insufficient on connector for ECM

3. Calibration or bad OEM ECU

The following diagnostic steps are designed to systematically identify the root cause(s) of non-operation fuel gauge

condition and point to corresponding repair procedures.

Symptom Description

To confirm this condition, ignition ON. The instrument panel cluster (IPC) will

perform self-check mode.If the fuel gauge needle sweeps to full and returns to

empty, the fuel gauge non-operation condition exists.

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 15, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

FCCC MT CNG

19

FCCC MT CNG

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 24, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

19

Fuel Gauge Non-operation

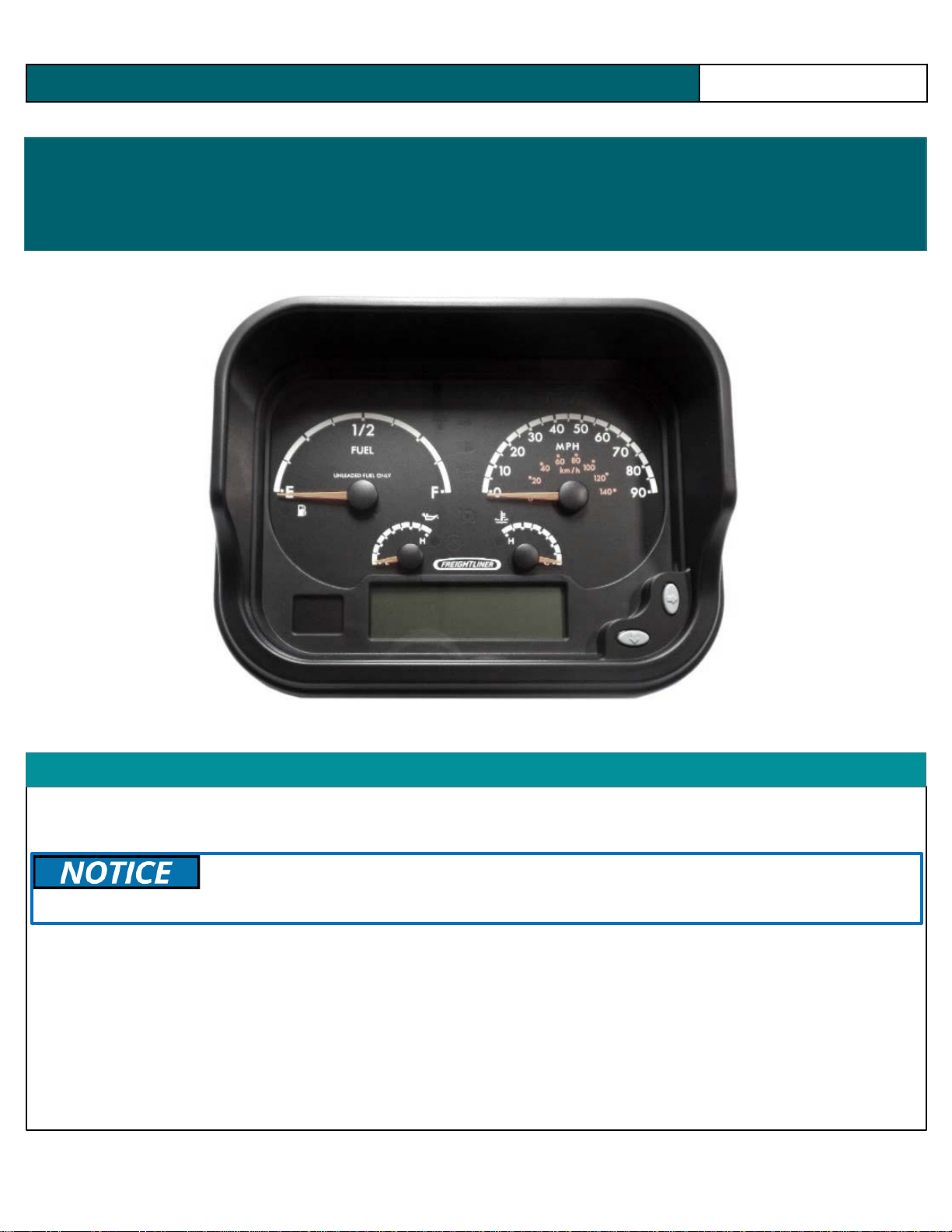

The Electronic Control Module (ECM) monitors CNG fuel system pressure using apressure transducer in the

pressure regulator.The transducer monitors cylinder pressure using a 5V signal communicated to the ECM. The

ECM uses calibration logic to transmit resistance values via the F78-F79 connector interface.The OEM ECU

transmits fuel level through the CAN network to the IPC.

Circuit / Sensor Description

SPN: 96

FMI: 2,3,4,7

FMI 2: Fuel Level Sensor “A” Circuit Intermittent

FMI 3: Fuel Level Sensor “A” Circuit High

FMI 4: Fuel Level Sensor “A” Circuit Low

FMI 7: Fuel Level Sensor “A” Circuit Range / Performance

Fault Codes

The following fault code(s) may set when vehicle ignition is left in the ON position while the driver does not engage

the starter within approximately 30 seconds.

SPN FMI Type MIL Possible Faults

96 02 B Yes

•Vehicle was left with Ignition On, Engine off for a prolonged period.

•Malfunctioning ECM.

•Intermittent poor electrical connection.

•Damaged pressure transducer.

96 03 B Yes

•Vehicle was left with Ignition On, Engine Off for a prolonged period.

•Malfunctioning ECM.

•Reference circuit shorted to power.

•Open in signal circuit.

•Damaged pressure transducer.

96 04 B Yes

•Vehicle was left with Ignition On, Engine Off for a prolonged period.

•Malfunction in the ECM.

•Short to ground in the signal circuit.

•Short to ground in the low reference circuit.

•Loose electrical connector or terminal.

•Loose electrical connector or terminal.

96 07 B Yes

•Vehicle was left with Ignition On, Engine Off for a prolonged period.

•Malfunction in the ECM.

•Intermittent or poor connection.

•Damaged pressure transducer.

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 15, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

FCCC MT CNG

20

FCCC MT CNG

DSM.0008 Ver 1.0 FCCC MT-45 / MT 55 CNG Diagnostics Service Manual

February 24, 2022 PRINTED AND DOWNLOADED COPIES ARE NOT CONTROLLED

20

Fuel Gauge Non-operation

ALWAYS use personal protective equipment (PPE) when working around

pressurized fuel systems.

Verify parking brake is engaged, wheels are chocked, and ignition switch is in

OFF position.

Tools and Supplies

General Safety Precautions

Item Purpose

safety glasses eye protection

shop rags clean fuel system components before and after repair

flashlight illuminate components

mirror observe backside of fittings while performing leak check

digital multi-meter (DMM) resistance and voltage measurements

PSI PowerLink or other

OBD-II diagnostic tool read fault codes and ECM values

Install proper lockout/tagout (LOTO) device and observe all LOTO practices.

This manual suits for next models

1

Table of contents